All issues of organizing autonomous heat supply and preparation of hot water are solved by purchasing one boiler capable of serving both systems. Not knowing the principle of operation of a double-circuit gas heating boiler, it would be illogical not only to make a purchase, but also to operate the unit. Do you agree?

We will tell you about the operation of the heater, consider all its strengths and weaknesses. By understanding the basic operation of the equipment, you can easily enjoy all its advantages. And if necessary, it will be possible to identify failures in work in time, understand and eliminate the causes of their origin.

The content of the article:

-

Boiler device for servicing two circuits

- Types of gas burners for double-circuit boilers

- Varieties of heat exchangers for gas units

- Boiler automation or control unit

- Principle of operation and specificity

- Scheme of the operation of a double-circuit boiler

- Types of execution of gas boilers for two circuits

- Advantages and disadvantages of double-circuit devices

- Conclusions and useful video on the topic

Boiler device for servicing two circuits

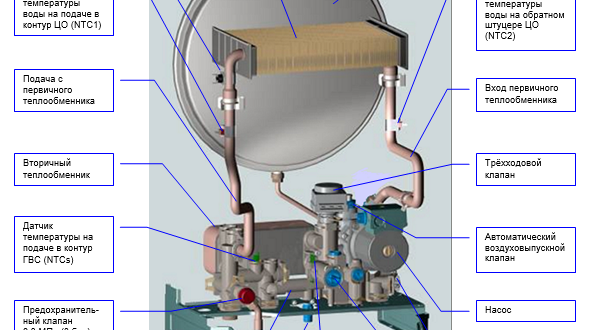

A double-circuit gas heat generator differs from a single-circuit analogue in that instead of one heat exchanger, it has two, they are called in technical terminology primary and secondary.

The first, i.e. primary heat exchanger, located directly in the combustion zone of the flame. Its task is to heat the coolant for the functioning of the heating network. The secondary heat exchanger is responsible for the operation of the DHW.

Stable operation of the heater is possible with the coordinated work of all its components. Information about the main functional units will help you understand the principle of operation of the equipment

The design of any two-circuit unit includes the following standard elements:

- Combustion chamber with burner block;

- Heat exchangers;

- Equipment control and protection devices.

To understand the features of the device of gas boilers of a double-circuit variety, we will dwell in detail on each of its structural elements.

Types of gas burners for double-circuit boilers

The gas boiler burner is responsible for generating enough heat for the heating and hot water supply circuit to function. Thermal energy is obtained by burning fuel. The burner is placed in a combustion chamber, into which, in addition to gas, air is injected. It is needed for the combustion process.

Depending on the operating conditions, the burners can be classified into the following types:

- Single stage burner. A unit with such a burner can operate in only two modes - "Stop" and "Start". Such boilers, despite their low efficiency and reduced service life, are popular due to their simplicity of design and low cost.

- Double deck burner. A heater with such a burner can operate at full and half power. Its advantages are noticeable in the warm season, when there is no need to operate the device at full power to heat not too cold water.

- Modulating burner. An intelligent boiler system with a similar burner allows for setting and adjusting the power. Such a boiler is characterized by a high service life and efficiency, but at the same time it costs an order of magnitude higher than units with single-level and two-level burners.

The burners are divided into open and closed designs. When the burner is open, the air required for fuel combustion comes directly from the room where the boiler is located. A chimney is required for the removal of combustion products, which must provide sufficient natural draft.

As a rule, atmospheric heating units are equipped with a conventional metal pipe, turbine - by a coaxial chimney. Depending on the technical conditions of the room, the smoke channel is placed vertically or built at an angle. Corner options are brought out through the wall to the street or connected to a public chimney.

A gas burner is the main element of a double-circuit gas boiler, it is responsible for burning fuel and obtaining heat energy in the required amount

Turbine boilers are equipped with closed combustion chambers, into which air cannot spontaneously enter. They are safer and more reliable to operate, but more expensive and more difficult to work with. Boilers with closed burners, in addition to the chimney, need a channel through which the oxygen required for combustion is supplied to the chamber.

Therefore, they equip turbine boilers coaxial pipes, because in addition to removing smoke, they also draw in fresh air flow from the street. It happens that for normal operation two coaxial chimneys are connected to a closed combustion chamber. In addition, the entire structure is supplemented with an air supply pipe.

All such models of boilers are equipped with fans that ensure the movement of smoke, multi-level protection systems, and automation. For the operation of the listed devices and systems, electricity is needed. Their disadvantage is considered to be volatility, which increases operating costs.

Varieties of heat exchangers for gas units

If fuel is burned with the help of a burner in order to obtain heat, then the heat exchanger ensures that this heat is obtained for further transfer to water. As already mentioned, primary and secondary heat exchangers are present in the double-circuit design.

The primary heat exchanger is located directly above the burner and is a serpentine finned tube. Under the action of the flame, the water in the heat exchanger heats up and moves through the three-way valve further into the distribution heating system.

The secondary heat exchanger is a system of corrugated plates, which are assembled into a single block with two pairs of holes. Each pair of holes has its own function.

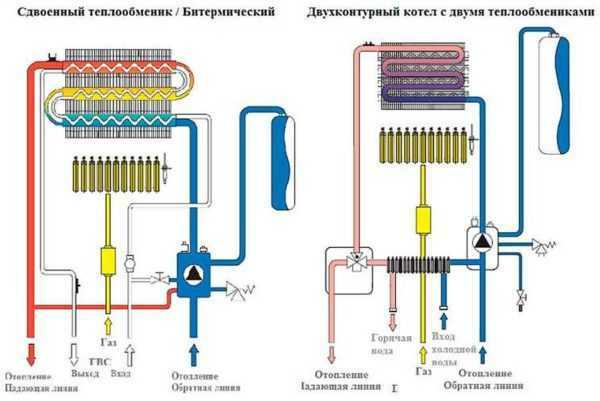

Water from the water supply flows through one of the pairs, and the coolant flows through the second, entering the heating circuit. A similar system of plate and tubular heat exchangers is referred to as double.

The primary and secondary heat exchangers are combined into one system, the correct operation of which is ensured by a special three-way valve

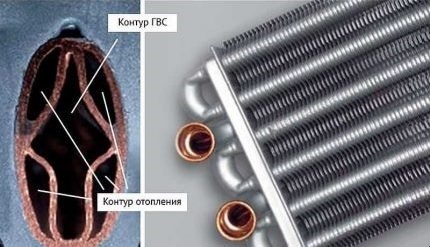

There are heating devices in which a bithermal heat exchanger of a complex configuration is used instead of a dual system. Such a heat exchanger is made of copper; it is a pair of tubes located one inside the other. The coolant moves along the outer tube, and water flows along the inner tube to ensure the operation of hot water supply.

The bithermal heat exchanger of the heat carrier and water heater is characterized by a complex configuration, when a tube of one circuit is placed in a tube of another circuit

Boilers with a bithermal heat exchanger are more difficult to operate, since both heat exchangers are presented as a single unit, which makes it difficult to descale it. But such heating devices are in demand, as they are characterized by small overall dimensions and high water heating rate.

Boiler automation or control unit

The boiler automation is responsible for safe and stable operation. It monitors the temperature of the water in the hot water components, maintains the temperature of the coolant in the heat supply lines. Gas boiler automation prevents the heater from operating in hazardous situations.

The unit interrupts operation or does not turn on in such cases:

- Reduced pressure in the gas system;

- Lack of traction;

- Absence or critical overheating of the coolant.

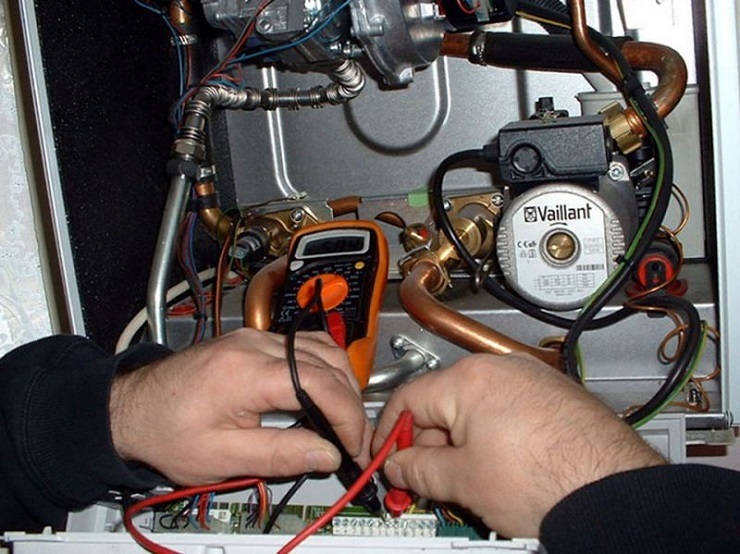

The control unit that controls the operation of protection and process automation devices is represented by a set of switches, microcircuits or their combination. In addition to ensuring safety and temperature control, it monitors the operation of the circulation pump and fan.

Modern gas boilers are distinguished by the presence of intelligent control, in the software of which there are various modes of operation.

Principle of operation and specificity

Many owners of gas equipment do not even think about how a double-circuit gas boiler really works. They mistakenly believe that the heating of the water and the heating circuit occurs at the same time. In fact, everything does not look so rosy.

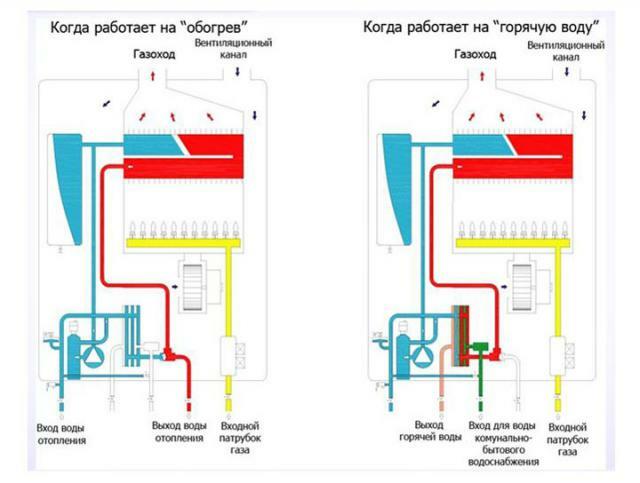

A double-circuit gas boiler cannot simultaneously operate in two modes, ensuring the operation of heating and hot water supply systems. This is confirmed by the presence of a three-way valve in its device

In normal mode, the boiler constantly works only to heat the coolant circulating in the system. In this case, the frequency of switching on and the intensity of combustion of the flame are monitored by a temperature sensor. Simultaneously with the burner, the start-up is also carried out. circulation pumpif the operation of the heating system is not based on the natural circulation of the heat carrier.

The space in the lower part of the wall-mounted boiler is intended for gas supply, cold water connection, as well as outlets of the DHW system and heating circuit

In fact, when the temperature of the coolant reaches a predetermined value, the sensor sends a signal to reduce the activity of the burner. Until the temperature drops to the set value, the boiler will be in passive mode. Then again a command is sent from the automatic sensor to activate the fuel supply valve.

Scheme of the operation of a double-circuit boiler

The presence of a DHW system slightly complicates the operation of a double-circuit gas boiler. Heated by a burner coolantmoving along the heat exchanger, it provides heating of the plate heat exchanger, through which water flows from the water supply.

Structural diagram of a double-circuit gas boiler with both bithermic and two conventional heat exchangers. In the first option, there is no need to use two heat exchangers

Simultaneous use of a two-circuit model in heating and hot water supply mode is impossible. When the hot water supply tap is activated, a three-way thermostatic valve stops the circulation of the coolant through the heating lines. The boiler goes into the mode of moving water along the circuit with a plate heat exchanger, which heats water for domestic needs.

With a significant consumption of hot water for a long time, the operation of the boiler with a focus on heating can be paralyzed. The problem can be solved in two ways - to provide for the installation of a more powerful heating device or to include it in the arrangement scheme indirect heating boiler.

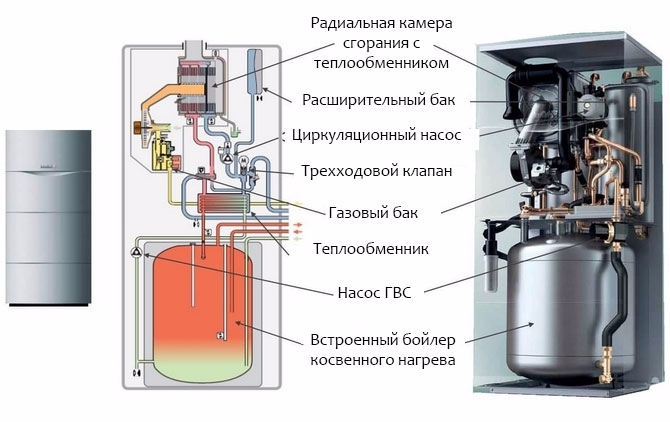

With the active use of the DHW system, it is possible to install a double-circuit boiler with a built-in boiler. In this case, the fuel consumption increases slightly due to the fact that in the pause between the cycles of operation of the heating system, the burner energy is used to maintain the water temperature in the additional gas water heater.

A certain amount of hot water in the built-in boiler allows the use of the DHW system without shutting down the heating circuit. As a result, both systems work alternately, while there is no overheating factor of the liquid and the life of the heat exchanger is extended.

A boiler with a built-in standard boiler not only provides an adequate reserve volume of hot water, but also helps to avoid prolonged shutdown of the heating circuit

The built-in standard boiler allows you to get hot water of the required temperature at any time, the supply of which is provided in automatic mode. While a continuous hot water system takes several minutes to heat the water to the required temperature.

Types of execution of gas boilers for two circuits

The peculiarities of the operation of gas equipment are largely determined by the version of the heater. Modern boilers are available in two form factors - floor-standing and wall-mounted.

When choosing a design option, you need to focus on the size of the heated area, the activity of using the DHW system. You need to understand that wall-mounted boilers are more compact, but at the same time they have much less power.

The wall-hung gas boiler of the double-circuit type is distinguished by its compact size and modern design, but effective only when heating small rooms with moderate consumption of hot water

Choice wall-mounted double-circuit boiler can be justified if the heated area does not exceed 200 m2, and the total productivity of the DHW system is not more than 14 l / min.

Although the small dimensions of the wall-mounted boiler seem to be an advantage, in fact they hide many disadvantages. The compactness is achieved through the use of thinner heat exchanger tubes. Besides the fact that they have a shorter lifespan, they are more likely to become clogged.

In floor-standing installations, more massive and reliable cast iron heat exchangers are used. This not only increases the degree of reliability of the heater, but also extends its service life.

Advantages and disadvantages of double-circuit devices

The advantages of a double-circuit heating unit are as follows:

- Economical fuel consumption. The direction for comparison is the use of a double-circuit boiler or a single-circuit one with an indirect heating boiler.

- Compact dimensions. The overwhelming majority of double-circuit boilers are wall-mounted heating devices. They are easy to place both in utility rooms and in a small kitchen.

- Versatility. There is no need to buy additional equipment and resolve issues with its compatibility with the boiler.

In one unit, an instantaneous water heater, a heater and a circulation pump have already been successfully combined into a single automated system.

Obviously, along with the advantages, there are also disadvantages:

- Impossibility of simultaneous operation of heating and a DHW circuit. As a result, a significant consumption of hot water can cause a decrease in the temperature in the house.

- Power limitations of wall-mounted models. Compact wall-mounted boilers, due to the minimum size of the burner, are not able to provide the required temperature regime at the maximum head. A similar disadvantage is observed when the water intake points are located remotely.

- Sensitivity to water quality. The secondary plate heat exchanger is demanding on the quality of the consumed water. The presence of impurities becomes the reason for the use of means for reducing its hardness, and for cleaning the coolant.

Another criterion for evaluating a double-circuit boiler is its cost. The price of a double-circuit heater is higher than the price of a single-circuit analogue.

However, if we consider the presence of a hot water supply system and ways to resolve the issue in the case of installing a single-circuit boiler, then when indirect heating is included in the assembly diagram of the boiler, the price of the double-circuit will be lower.

Conclusions and useful video on the topic

The following video will acquaint you with the structural components and the principle of operation of gas heating equipment:

The piping of a double-circuit gas boiler will be presented by the author of the video:

A detailed acquaintance with the features and principle of operation of double-circuit gas units makes it possible to determine the merits of their operation. The purchase of such heaters will help to save on the purchase of additional equipment necessary for organizing the DHW system.

If one of the circuits breaks down, the operation of the other is possible, and replacing the circuit will always be cheaper than repairing a separate heating installation. A double-circuit boiler can also be used in the warm season, operating it only in water heating mode for household needs, which is the convenience and cost-effectiveness in comparison with the purchase of individual units.

Tell us about how you chose a double-circuit gas boiler for arranging your own house / apartment / summer cottage. What was the decisive criterion in your choice for you? Please share useful information on the topic, photographs in the block below, ask questions.