Gas boilers are reliable equipment that supply heat and hot water to our country houses and part of city apartments. Unfortunately, they cannot work completely without breakdowns. And among the violations, valves often appear - devices for protecting and supplying fuel to the units.

We will tell you how and what kind of repair of a gas boiler valve can be done with your own hands. Let us examine in detail the situations that signal the occurrence of related disruptions in work. We will tell you whether it is worth making your own efforts or is it better to contact the gas workers.

In the article presented by us, you will find step-by-step guides on restoring the operability of gas boilers by repairing or replacing a gas, safety and three-way valve.

The content of the article:

- Varieties of valves in a gas boiler

-

Typical breakdowns and repair methods

- Gas valve malfunction

- Safety valve problems

- Service valve problems

- Conclusions and useful video on the topic

Varieties of valves in a gas boiler

Normal operation of gas equipment intended for heating sanitary water and preparing the heat carrier, provides a wide range of systems, parts, devices, each of which we clearly carry out the important function.

There are the following types of valves in the design of gas boilers:

- Gas valve. A component of the gas system responsible for the proportional supply of blue fuel to the gas burner, ensuring a stable combustion process in accordance with the commands of the electronic board. This electromagnetic device also includes shut-off and control valves.

- Safety valve. Component of the hydraulic system designed to discharge excess coolant from the heating circuit in case of exceeding the standard pressure values.

- Three-way valve. Detail of the hydraulic system of double-circuit boilers only. Redirects the flow of heated water from the heating circuit to the DHW during consumption for hygienic purposes. Depending on the class of the boiler, it can be with or without a servo drive.

All of the listed types of valves involved in the operation of a gas boiler can be replaced or repaired in the event of a breakdown.

Image gallery

Photo from

New generation gas boilers are essentially mini-boiler houses. In their design there are protective, control and adjustment devices that were previously installed in the heating pipeline.

A circulation pump is located in the body of a small-sized gas unit, which is responsible for movement of water through heat exchangers, and an expansion tank providing a reserve for expansion heating water

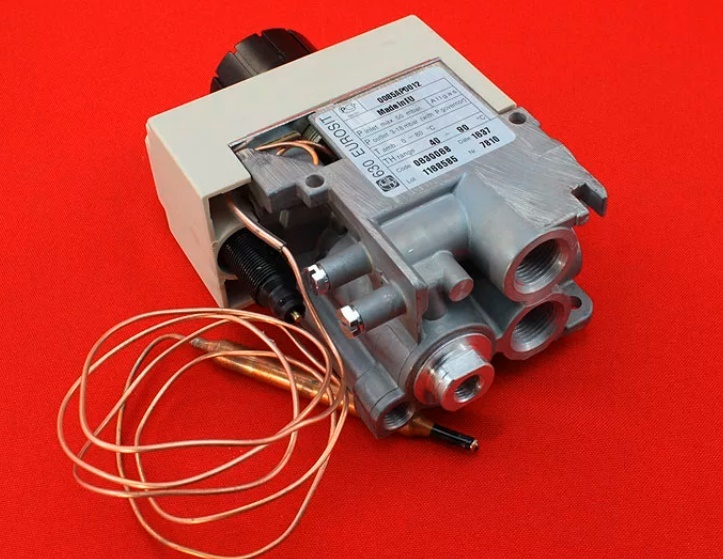

The gas valve, in the photo, is in the center, carries out a uniform supply and portion dosage of blue fuel. In other designs of boilers, it can be located in a slightly different place

The safety valve (1) allows you to get rid of the excess heat carrier, the three-way (2) valve transfers the flow through the bypass (4) from the heating to the supply to the mixers. The automatic air bleed device (3) drains excess air from the boiler

Wall hung boiler without front panel

Circulation pump and expansion tank

Heating unit gas valve

Safety and three-way valves

Let's take a look at the technology for restoring their performance. Having mastered simple repair principles and techniques, you can significantly increase the service life of the boiler itself.

Typical breakdowns and repair methods

The types of valves listed above perform ambiguous functions and differ in design. There are also differences in the reasons why they become unusable, and ways to eliminate the breakdown.

Gas valve malfunction

The main purpose of the gas valve is to regulate the pressure of the gas supplied through the nozzles to the burner. You can adjust the flow so that the chamber receives from 25 to 100% of the flow. It all depends on what type of gas is to be used in the operation of the equipment, how much air will be supplied for normal combustion.

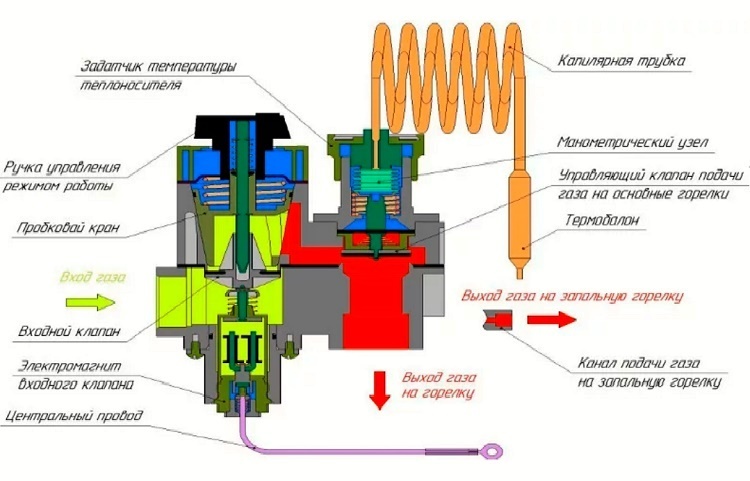

In fact, this is an electromagnetic device, the main operation of which is carried out only when connected to a power supply. However, when its solenoid coils are de-energized, the gas valve acts as a safety component. In this case, it tightly closes the channels through which the gaseous fuel moves.

The ignited igniter acts on the working part of the thermocouple, which begins to generate current. The generated electricity is transferred to the gas valve coil, which attracts the metal washer and opens the way for blue fuel.

Generated gas column thermocouple or a heating boiler, the charge falls on the solenoid (coil) of the gas valve, as a result of which the metal washer of the shut-off valve is magnetized to the coil. The washer opens the diaphragm so that the gas can pass to the igniter and burner block nozzles.

When the flame attenuates or decreases below the standard values, the thermocouple stops generating electricity. As a result, the coil holding the washer is demagnetized. The blue fuel channels are closed.

If no current is supplied to the gas valve coils, the device hermetically closes the blue fuel supply channel to the burner. In addition to the shut-off valve, there are also adjusting devices in the design of the gas valve, with the help of which the minimum and maximum gas flow is set.

The need to take action will be indicated by a drop or increase in static pressure, i.e. inlet pressure when the boiler is not in operation. For units processing main gas, it must be at least 17 mbar. For boilers powered by liquefied fuel - at least 35 mbar.

The list of typical gas valve failures includes:

- Disturbances in the electrical circuit supplying the electromagnetic device. In this case, all wiring and contacts in the connection areas should be checked with a multimeter. If a break is detected, it is eliminated in a trivial way: by replacing the damaged wire, stripping and tightening the contacts.

- Clogged gas valve. The channels of the device can periodically become clogged with mineral particles coming along with poor quality gas, elemental carbon deposits and calcium salts formed in the event of condensate in the supplied fuel. The simplest mechanical cleaning saves.

- Failure of the thermocouple. Often it requires a complete replacement due to the complete burnout of the working edge. At the same time, no current is transmitted to the electromagnet, as a result, the boiler does not ignite at all or is blocked after a couple of minutes of operation.

- Mechanical damage to the gas valve. For example, the washer shown above. It either ceases to press tightly and ensure tightness, or does not respond to adjustment, due to which an uncontrolled volume of gas enters the chamber. To eliminate it, either the valve or the damaged part is replaced.

- Short circuit to the body of the winding of the electromagnetic coil. Most often it occurs due to short-term overheating and subsequent melting of the plastic sleeve, on which the coils of the electromagnet are wound.

It is clear that the list of all breakdowns can be divided into two groups: violations in the electrical part and mechanical damage to parts.

Gas boilers go on sale with factory settings for main gas consumption. They are changed in the case of adjusting the consumption of gaseous fuel or in the case of transferring the boiler to work from a liquefied gas mixture

We immediately warn you that when carrying out any repair measures for which it will be necessary to remove the unit case, it automatically deprives the owner of the right to use the manufacturer's warranty. In addition, neither the firm nor the organization with which the service contract, will not take the slightest responsibility for a negative result.

It happens that instead of learning how to correctly repair the solenoid valve of a gas boiler, the owner of the unit tries hard to turn it on. At the same time, he continuously presses the button of the gas supply device, trying to start the burner. This is absolutely impossible to do.

If you open the path to the gas flow yourself, the boiler burner will still not ignite. But the gas will flow uncontrollably into the room, while the owner will literally hold his finger on the trigger. What is the threat? At best, mild poisoning, at worst - an explosion.

The following selection of photos will acquaint you with the steps of restoring the solenoid coil of a gas valve:

Image gallery

Photo from

As an example, we will analyze an electromagnetic locking device of the simplest design from the Rostovgazoapparat AOGV boiler

In working order, the metal washer of the valve must be magnetized to the coil when a current is supplied to it from a 1.5V battery. Due to a short circuit to the winding body, it did not magnetise

We inspect the electromagnetic part of the gas valve, we are looking for a coil closure, each of which includes 6-7 turns of a thick wire

Disconnect the threaded bushing soldered to it from the body, warming up the junction with a soldering iron

Remove the polymer sleeve that insulated the winding wire. It was deformed and caused a short circuit of the valve winding.

Instead of a damaged and deformed sleeve, we put a new part. If it was not possible to buy it, a couple of pieces of PVC pipes threaded into each other will do

All parts that have been separated from the gas valve body are put in their original places in the reverse order to that performed during disassembly.

After assembling the gas valve parts, weld the threaded sleeve back to the gas valve body

Step 1: Disassemble the gas valve

Step 2: Troubleshooting the valve

Step 3: locate the damaged coil

Step 4: Detach from the Hub Body

Step 5: Removing the grommet

Step 6: Replacing the damaged plastic sleeve

Step 7: Reassembling the Gas Valve

Step 8: soldering the threaded bushing

It is not too easy to repair a gas boiler valve, but it is much cheaper than buying and installing new equipment for the preparation of a heat carrier and hot water.

After completing the repair, for the purpose of prevention, all components of the gas system should be cleaned of contamination. The flux should be removed from the soldering areas using a suitable solvent. Next, you need to check the operation of the valve by powering it from a 1.5V battery.

Safety valve problems

In the design of a new generation wall-mounted gas boiler, there must be at least one safety valve. V gas water heaters and old floor heating units, it was not provided. After all, it was believed that this protective device should have been installed on the pipeline after the boiler.

Double-circuit units processing the heating system and sanitary water supply branches can be equipped with a pair of safety valves. One of them is put on heating, the second - on the hot water supply pipeline. In both cases, this device opens slightly against excess pressure in the system and releases excess water. Then it automatically slams shut.

It makes no sense to repair the safety valve, since in most cases its breakdowns are associated with the appearance of a crack on the body or a breakdown of the thread that breaks the tightness. This device is simply changed

Problems with the safety valve will be reported to the owners of the gas boiler by a leak in the area where this safety device is located. It is located at the bottom of the unit, near the circulation pump. The technical data sheet will acquaint you with the exact location.

If there is a serious breakdown, it makes no sense to repair the safety device. Replacement only. If a grain of sand is stuck under the seal or in the mechanical part, there is a reason to simply disassemble and re-assemble the device.

Service valve problems

We repeat - three-way valves are supplied only double-circuit boilers. Their task is to redirect the flow of water from heating to DHW and vice versa. More precisely, at the command of a three-way tap, water enters the plate heat exchanger for its subsequent supply to the points of water intake or to the main heat exchanger connected to the heating system.

Disturbances in the operation of the three-way valve can be determined:

- By reducing the temperature of the coolant in the heating circuit.

- For cold water entering plumbing fixtures when heating equipment is running.

- Due to the lack of switching effect, i.e. for heating either only the coolant, or only sanitary water.

The most common cause of 3-way valve breakage is mineral deposits on the inside of the device. This happens due to the simplest clogging, due to the fact that a filter was not placed on the water supply in front of the gas boiler.

Much less often the servo burns out or its individual components fail. If problems with the drive are identified, the three-way valve will have to be replaced completely. It is selected according to the specification specified in the data sheet by the manufacturer of the unit.

However, it is not necessary to work mercilessly in the event of a switch failure. You can try to restore the operability of such a device in order to leave it as a backup device.

The stages of repairing a three-way valve are detailed in the following photo gallery:

Image gallery

Photo from

If the three-way valve of a double-circuit gas boiler has ceased to redirect the flow of heated water from heating to hot water supply, then it requires repair. In addition to the device, the master will need a Phillips screwdriver, a soldering iron and a multimeter

We study the state of the inlet. In most cases, mineral deposits and rust are visible on it.

In order to disassemble the three-way valve of a gas boiler, unscrew four screws using a Phillips screwdriver

Using a multimeter, we check the operability of two microswitches located inside the case.

Having unscrewed two more screws, remove the three-way valve motor to check its condition

All internal parts of the disassembled three-way valve are inspected, cleaned from rust and mineral sediment

We test the performance of the valve motor. We check the resistance between its conclusions. If the tester readings are measured in Ohm units, change. The resistance of the working motor should be 15 kΩ or so

If the repair of the valve did not give the expected results and the wiring connecting the valve to the three-way valve with the wiring turned out to be in order, the problem is in the electronic board. Theoretically, it can be repaired, but it is better to change it.

Stage 1: Preparing the service valve for repair

Step 2: Inspect the inlet

Step 3: Loosen the screws from the valve body

Step 4: Checking the functionality of the microswitches

Step 5: Disconnecting the Valve Motor

Stage 6: Cleaning the internal surfaces from sediment

Step 7: Testing the operation of the crane engine

Step 8: Replacement electronic board

Do not forget that the water redirection device is connected to the power supply. This means that if the valve itself is not damaged, there may be a problem in the wiring. They are eliminated in an elementary way: first, the wiring is checked, they ring, then the damaged wire is changed.

If everything is in order with the wiring, then you need to check the contacts. All connections are checked with a multimeter. For prevention, they need to be disconnected, wiped with an alcohol-containing composition, reconnected, tightening with effort.

It happens that it is not he himself and not the electrical wiring that is to blame for the refusal of the three-way crane to do the work, but the electronic board sending the commands. In the workshop, of course, they can restore it, replace the burned out resistor. But most often they change completely to a similar model.

Conclusions and useful video on the topic

The following video will acquaint you with the device of the gas valve, the causes of malfunctions and repair methods:

Solving the problem with the three-way valve of the gas heating unit:

Dismantling and cleaning the safety valve:

Repair of valves of gas equipment will significantly extend the operating life of the units. It is much easier and cheaper to fix them than buying a new model. Not all repair operations are recommended to be carried out independently, but the simplest actions are quite accessible to home craftsmen.

Do you want to share your own experience in restoring the operability of gas boiler valves? Do you have any useful information on the topic of the article that is worth sharing with your site visitors? Please leave comments in the block below, ask questions, post photos.