Vaillant gas equipment designed for heating systems has a lot of weighty advantages. Among them, high-quality assembly and the use of reliable components that ensure trouble-free operation are in the lead. However, the resource of any equipment is not unlimited, and non-observance of the rules does not reflect in the best way on the state of the unit.

Even the most trouble-free devices gradually wear out and become unusable. You will find everything about how to repair Vaillant gas boilers in the article we have presented. We will tell you how to identify the violation, identify the error by coding and eliminate the cause of the breakdown.

You will receive detailed information on all types of damage and malfunctions typical of heating devices with the Vaillant logo. You will learn how to distinguish boiler status data from information about impending or already formed defects. Our recommendations will help you with preventive maintenance.

The content of the article:

-

Self-diagnosis system advantages

- Error warning levels

- How to monitor the condition of the equipment?

- Level 1 problem list

- List of Level 2 Errors

- Conclusions and useful video on the topic

Self-diagnosis system advantages

Wilant gas heating units are quite popular among the owners of country houses and apartment owners from the old housing stock. Reliable boilers rarely break down, do not cause inconvenience to the owners, do not let the owners down during the heating season.

The German company offers a wide range of traditional and condensing boilers to the domestic consumer. The line includes floor and wall models, atmospheric and turbine equipment of various capacities. A wide range of offers allows you to choose a suitable option both in terms of the type of performance and in terms of power.

Image gallery

Photo from

The German manufacturer of boilers and water heating equipment offers an extensive range of models for organizing autonomous heating and water supply networks

Among the trade offers of the supplier of reliable and productive equipment are atmospheric and turbocharged models suitable for the arrangement of houses, apartments, commercial and industrial facilities different areas

All units of a well-known German brand, which have earned a reputation for impeccable household appliances, are equipped with systems that allow you to monitor performance, timely identify violations

The manufacturer has thoroughly thought out a multilevel safety system for the operation of gas equipment. The complete set includes all the components to ensure a tight connection and perfect assembly.

The line presented to the consumer includes two- and one-circuit boilers. Both variants can be completed with DHW cylinders with the same logo

Boilers manufactured by Vaillant can only be serviced and repaired by craftsmen certified by the company. However, a number of maintenance and repair operations are available to owners

In the assembly of equipment for private boiler houses and water heating, high-quality components are used, although if the operating instructions are violated, even they can fail.

The fact that the boiler requires repair or correction of an operating error will be reported by the code that appears on the electronic board. In order to understand what the matter is, you need to know how to decrypt the encoding.

Vaillant equipment for heating medium and sanitary water

Gas boiler Vilant atmospheric type

Operation and technical condition monitoring system

Turbocharged boilers with coaxial chimneys

Double-circuit and single-circuit units

Vaillant gas appliance repair

Boiler working units and devices

Boiler error code on display

A significant advantage of heating equipment from a German manufacturer is the self-diagnosis system. An easy-to-learn set of letters and numbers provides an opportunity to identify violations in a timely manner and quickly correct the situation.

Let's work together to figure out the prompts encrypted by the manufacturer and what should be done to restore the boiler's performance.

Error warning levels

To detect malfunctions and monitor the state of gas boilers, the manufacturer has developed a unique warning system. All information displayed on the display of the unit is divided into two groups. The first of them is designed for owners ignorant of the intricacies of the gas industry, the second - for service technicians.

Repairs requiring disassembly of the boiler drum may only be carried out by Vaillant accredited repairers.

The principle of such a division is justified by the level of the potential repair contractor. After all, not only the manufacturer of boilers Vaillant, but also all of its “associates” warn that not all repair operations can be performed by the owners of the units with their own hands. There are breakdowns, with the elimination of which it is better for an independent home craftsman not to mess with at all.

It's not even that after the intervention of an independent craftsman, the warranty obligations are automatically canceled. It is important that gas equipment and the fuel processed in it are explosive, toxic, fire hazardous if handled improperly. And the result of the repair performed by an amateur is able to combine all the listed risks, adding to them causing damage to neighbors.

Taking into account the above reasons, the diagnostic system is divided into two parts. The first part is available to the owner of the boiler. Based on the information coded by the manufacturer, the owner can correct the malfunction using the methods available to him.

In order to obtain information of the second level, you need to enter a password, which is known only to the master who maintains the equipment according to the contract concluded before installation.

The second part of the coded information about equipment errors is available only to gas workers, with whom the owner of the equipment must enter into a contract before installing the unit. According to the contractual documentation, fuel supply, technical condition monitoring and repairs are carried out.

To access the second part of the error data, the gas service master enters a password that is unknown to the owner. It would seem that the owner does not need information about these errors at all, since all operations behind this "barrier" are still inaccessible to him.

To perform repair actions related to the second level of errors, the performer needs specialized knowledge, considerable experience and tools that are unlikely to be found in the arsenal of a home craftsman.

But! Let's remember how much money we have invested in the organization of heating. Let's think about the fact that a substantial amount was paid for the acquisition, connection, installation. And we will make sure that all work to restore the functioning of the unit is carried out in accordance with the manufacturer's instructions. Therefore, we will find out what to do when an error code appears on the display.

How to monitor the condition of the equipment?

In order to obtain information about an impending or already occurring malfunction, you need use the diagnostic programs indicated by the company's programmers in the menu range from P.0 to P.6.

The information system is entered as follows:

- We find two buttons on the control panel. One of them should have an “i” icon, the second “+”.

- Simultaneously activate both buttons. We hold them until "d.0" appears on the screen.

- Using the buttons with the "+" and "-" signs, we move in the list of faults in order to reach the point we need in the diagnosis. We confirm the found by pressing the "i" button, get acquainted with the information provided by the system.

Note that entering the diagnostic mode, even the first level, allows you to change the settings. It happens that the blocking of a double-circuit boiler, for example, occurs due to a too high temperature set during the setup before the first start. In solving such problems, it is not necessary to resort to the help of a master.

Image gallery

Photo from

Maintenance, study and assessment of the technical condition of the gas boiler should be carried out at the intervals recommended by the manufacturer of the product.

A foreman from an organization with which a contract was concluded for the supply of blue fuel, installation of the unit and maintenance must inspect the equipment at least once a year

The functional parts of the gas boiler must be cleaned of organic and mineral deposits. Acting as an insulator, they prevent the sensors from recording accurate operating parameters.

When examining the condition of the gas boiler, the wiring and electrical connections are checked. If necessary, the master cleans and tightens the contacts, changes the wires

It is imperative to check the performance of the circulation pump, gas valve, fuse, air vent and expansion tank

The company representative conducting the inspection must check the condition of the ignition system, if necessary, clean the electrodes or change

All nodes for connecting gas and water pipes to the boiler are checked for tightness during the inspection. Particular attention is paid to the connection of the gas pipe, as a potentially dangerous area

Double-circuit boilers operating on heating and DHW circuits are reconfigured at the end / onset of the heating season

Servicing of Vilant boilers under the contract

Inspection of functional units of a gas boiler

Dust affecting sensor performance

Checking electrical connections

Checking the operation of the circulation pump

Cleaning and checking the ignition system

Checking the communications connection

Reconfiguration according to the season

The operating parameters are changed by manipulating the "+" and "-" buttons already known to us. All changes made should be consolidated. The new data is recorded by pressing the button with the "i" icon and then holding it for 5 seconds at a minimum.

If the information provided by the boiler and the actions described in the manufacturer's manual did not lead to the desired result, we call the wizard. He enters a password, which opens the next level of diagnostics. A certified repairman can see all information about errors in the operation of the Vilant gas boiler and all codes assigned by the manufacturer.

In addition to errors of both levels, a high-tech system can notify about the technical condition of the unit. In this area, division is also provided. Status data is encoded with an alphanumeric combination starting with the letter "S", error information starting with an "F".

Level 1 problem list

Let us first consider what the owner will be able to “fight” with on his own, without fear of getting the product completely unusable and voiding the warranty.

In the list of situations available for correction, there are two options:

- The boiler does not work at all. Those. the device does not heat the coolant if it is single-circuit, it does not heat either the coolant or sanitary water if it is a double-circuit model.

- The boiler heats sanitary water, but does not heat the heating medium. This problem is peculiar only to double-circuit units.

Both of these positions have a number of completely removable reasons and several solutions that a zealous owner should familiarize with. However, before a detailed study of the situation, you should check whether the boiler is connected to the network at all and whether one of the functions is turned off: heating or hot water supply.

Image gallery

Photo from

The responsibility of the owner of the gas equipment used in the organization of the heating system is monitoring of the technical condition of the pipeline and the devices installed on it; all system components interconnected

The owner of a house with autonomous heating, who cares about the safety and trouble-free service of the gas unit, must monitor the pressure using a pressure gauge that is part of the safety group, or mounted in boiler

The readings of the electronic system showing the operational data on the operation of the boiler should be regularly reviewed.

To ensure the normal and safe operation of the system, it is necessary to monitor the fittings, connection nodes in order to timely detect leaks in water pipes and leakage in gas

Heating system of a large private house

Safety group with pressure gauge

Display panel showing operating parameters

Checking taps and connections

Now we will consider the typical causes and methods of their elimination for the case if the boiler does not heat at all:

- Gas valve closed. Both shut-off devices installed by gas workers on the gas inlet pipe must be opened.

- Cold water supply cut off. Solved by opening the shut-off valve on the water pipe.

- Power outages. The heating unit will interrupt operation if there is no power supply. If the electricity supply is restored, the boiler will start itself.

- Temperature set too low. The owner of the boiler corrects the mistake made when making the settings by simply transferring the unit to the required temperature regime.

- Drop in water pressure (F22). The lack of pressure in the system for the normal operation of the boiler will be indicated by the coding. Its appearance means that it is necessary to bleed air from the batteries and open the make-up valve located at the bottom of the device.

- Refusal to ignite (F28). If the third attempt to ignite the gas heating equipment does not lead to the desired result, you need to find on the control panel the button for clearing the failure, press it and keep the position at least seconds. Failure again? Call the gas workers.

- Chimney malfunction (F48). This signal is about an increase in the temperature of the exhaust flue gases. They could stagnate and overheat due to a clogged external chimney, which must be cleaned.

Note that a drop in pressure will also be signaled by the S76 indication. This code is from the boiler monitoring group. However, to restore the work, the same actions will be required as when fixing the F22 error.

For the sake of his own safety, the health and safety of his household, the owner of the boiler is obliged to monitor the smoke exhaust system. A complete exhaust of gases is necessary, since the products of processing of blue fuel are extremely toxic

The second type of violations, determined by the operation of only DHW without heating coolant, most often associated with the wizard mistakes made during the settings. You can change the temperature yourself. The manual supplied with the boiler describes in detail how to carry out this operation.

List of Level 2 Errors

Now let's analyze the problems that only the master from the service department can decrypt. Controlling the actions of the performer, if a completely expensive unit is dear to you, is also extremely useful. Especially if the repairman at first sight does not inspire due confidence.

Let's make a reservation right away that if a dash is induced on the display, then there are no violations in the functionality, most likely, incorrectly set settings are disturbing. If several codes are displayed, alternating with each other, then there are several violations. This means that the master will also have to choose the correct sequence for eliminating breakdowns.

Error F.0. Problems with the NTC temperature sensor located on the flow line. There are several reasons why the device stopped recording the temperature. The sensor could fail by itself, or the electrical connection could be broken.

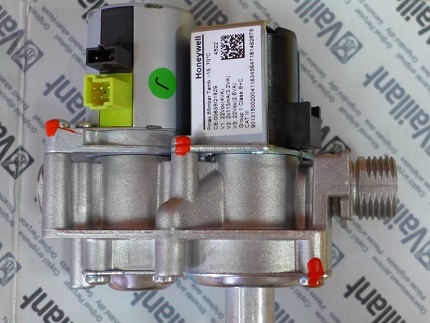

When choosing spare parts for repairing boilers with the Vaillant logo, one should not only match the type of component to the boiler model. It is advisable to give preference to products from the manufacturer of the unit in order to achieve full compatibility

In all cases, the boiler is disassembled to identify violations. If a loosening of the plug connection with the electronic board is detected, it is restored. If a device or wire needs to be replaced, it is done.

Error F.1. Problems with the NTC temperature sensor installed on the return pipe. All actions taken to eliminate the previous error are performed in the same order.

Error F.5. Failure of the flue gas sensor outside the boiler. By analogy with the previous errors, it is necessary to check the plug connection with the electronic board and ring the wiring. If the cause is not found as a result, you will have to change the sensor.

Error F.6. Opening of the flue gas sensor within the boiler. They also check the cable, cable connections, plug connection to the electronic board and the device itself. Based on the results of the identified breakdowns, contacts are restored, the wire or the recording device itself is changed.

Errors F.10; F.11; F.15; F.16. Short circuit: errors 10 and 11 - short circuit of the supply and return temperature sensors, codes 15 and 16 - short circuit of the flue gas sensors from the outside and from the inside. When registering a short circuit of all the listed types of sensors, they are replaced.

Error F.20. Temperature cutout tripped. It is necessary to check whether the temperature sensor is correctly installed and connected to the branch supplying the coolant. Most often, the fuse trips for no real reason if the assembly of this section of the circuit was made incorrectly. Less commonly, this happens due to a breakdown of the sensor.

Error F.22. Boiler operation "dry" or lack of water in the unit. This is a signal that there is a leak in the device or the pump cannot cope with pumping. However, if no leak is found, then the whole thing is in the pump: either it itself is broken, or the electrical connection is damaged. The problem is solved by replacement.

Work “idle”, ie. without water, - a direct path to burning through the walls of heat exchangers. If you do not respond to the indication of the device in time, the replacement of devices plus installation can significantly devastate the family budget.

In addition, a device that blocks the operation of the boiler when the temperature limit is exceeded could break down. It makes no sense to repair it, as a rule, this type of switch is replaced.

Error F.23. The readings taken by the temperature sensors at the inlet and outlet of the boiler differ greatly. It occurs most often due to insufficient water volume in the unit or its too slow movement. The pump is to blame - it is either broken or blocked.

Image gallery

Photo from

Has the pump begun to pump poorly or does it not stimulate the movement of the coolant at all? First you need to check if it is jammed. To do this, insert a slotted screwdriver into the axial screw of the pump and turn it. If the pump shaft turns freely, then the cause of the failure is in another

Most often, such problems are associated with a violation of electrical connections. Wires may be damaged, contacts oxidized or loose

If oxidized contacts are found, they are cleaned with zero sandpaper. All connections are tightened. If a damaged wire is found during the check, change

If all of the above actions did not lead to a positive result and the pump still does not pump water, it will have to be changed

Step 1: check pump for seizure

Step 2: Investigate the condition of the wiring

Step 3: Re-establish electrical connections

Step 4: Replacement circulation pump

Error F.26. The fuel flow supplied by the stepper gas valve is not detected. In this case, the problem must be looked for in the wiring of the gas valve or in the electrical circuit used to connect it. There may be no contact between the stepper motor and the electronic board.

Error F.28. It is impossible to ignite the boiler, even after numerous attempts, the unit does not start. The most common causes of problems include disruptions in the gas supply system to the combustion chamber. It is necessary to check the gas valve, it is possible that it is simply incorrectly configured, and not broken.

The company supplying gas to the consumer in accordance with the concluded contract can bring it down. There may be too much air in blue fuel, the proportion of which exceeds the norm for combustion. It is possible that the fire protection has worked.

If everything is in order with the gas supply system, problems must be looked for in the gas supply fittings. It is necessary to check the solenoid valve, the ignition device, including its plug, the transformer, the wiring used in the connection and its terminals. After making sure that the listed devices are working, they start testing the ionization cable and control board.

A breakdown of the gas valve threatens the uncontrolled supply of blue fuel or a complete interruption of the supply of gas to the combustion chamber. It can be repaired if the winding is burned out, but in case of more serious defects, it is advisable to change it.

Error F.29. The flame went out during the heating of the coolant, after which the unit does not ignite at all. In this case, the fuel supply is interrupted by the ignition transformer. It must be checked, the ignition device cleaned or replaced. Also worth checking out boiler grounding: is it arranged and how correctly everything is done.

Error F.36. The boiler operation is blocked by the flue gas sensor. First of all, you need to check the flue duct, if necessary, it must be restored or cleaned. If there was no congestion or strong narrowing in the channel due to burnt build-up, then the sensor itself or the line of its connection to the electrical circuit is faulty.

Error F.49. Voltage drop on the electronic bus. This is the result of a short circuit on the bus or connecting two sources of different polarity to it.

Error F.61. Gas valve control problems. It occurs due to a short circuit of the electromagnetic part of the gas valve or due to a short circuit on the cable insulation. Another reason is a malfunction of the electronic control device.

Image gallery

Photo from

If the disturbances in the operation of the Vilant boiler are associated with the failure of the electronic board, the device is repaired or changed.

Since the body of a gas boiler is not a sealed structure, it is able to pass dust, dust suspended in the air and water. They can cause overheating and burnout of components. Therefore, the manufacturer clearly stipulates restrictions on the location of the equipment.

Often it is impractical to repair an electronic board, because the parts will cost more than the device itself. It is easier and more profitable to completely change it. A replacement order can be made by both the master and the owner himself.

The installation and connection of a new electronic board can only be carried out by a repairman from the service with which a contract for the maintenance of the gas unit has been concluded

Vaillant boiler electronic control board

Location of the electronics in the boiler drum

Ordering a replacement electronic board

Installing a new electronic board

Error F.62. Changing the activation delay of the gas valve. Consequently, the tightness of the fittings supplying gas and regulating its pressure is broken.

Error F.63; F.64. Damage to the electronic board or sensors connected to it. It is necessary to check the sensors, the wiring connecting them to the board and the electronic board itself.

Error F.65. Heating up the electronics. The temperature of the electronic control device is too high due to the proximity of heating devices or due to the failure of the electronic board. The distance specified in the manual for the appliance must be maintained between the electronic control system and any equipment that generates heat during use.

If problems are regularly observed during firing up the boiler, the unit often locks up, responding to the commands of the ionization system, you should first clean the devices, removing carbon deposits

Error F.67. The ionization device does not work. Traditionally, the device itself, the electronic board and the electrical circuit connecting them are checked.

Error F.70. Not all functions are shown on the display of the electronic board and / or display at all. Solved by replacing the unsuitable option.

Error F.71; F.72. The supply and return sensor readings are incorrect. Check sensors, electronics board, wiring and electrical connections.

Error F.73. Demonstration of incorrect data by the pressure sensor. The pressure sensor itself is broken or the electrical circuit between the board and the device that records the pressure values in the system is broken.

Error F.75. The pressure sensor does not respond to pressure fluctuations. If the sensor does not react in any way to a sharp increase and decrease in water pressure, then it is faulty and will have to be changed. True, it happens that the reason is not in it, but in the circulation pump, then you will have to change the pump.

Error F.77. Breakage of the exhaust gas damper. There is a slight smoke in the room with the boiler. Immediately, you should arrange volley ventilation and call a foreman to check the device and carry out repairs.

In a room with installed boilers, be it a boiler room or a kitchen in an apartment building, a perfectly functioning natural ventilation must be organized. There must be a stable supply of fresh air and the removal of the waste mass into the exhaust openings.

We have considered only violations in the operation of atmospheric boilers. The error lists of traditional turbocharged and condensate models are somewhat different, which is justified by the difference in design solutions and differences in the principles of operation. A complete list can be found in the manufacturer's Certified Gas Engineer Accredited Repair Manual.

An important advantage: all models of Wilant boilers are equipped with a so-called "error accumulator". It displays ten extreme malfunctions recorded by the boiler electronics. You can find this position in the board menu by simultaneously pressing two buttons "i" and "-".

If, after reading the information about violations, do not press any of the keys for 4 seconds, the boiler electronics will automatically return it to the previous operating mode.

Conclusions and useful video on the topic

A video with a breakdown of error F.75 and a visual representation of the components of the unit:

Video guide for repairing the boiler control system board:

Valuable recommendations of an experienced owner for transferring the boiler to work in accordance with the season:

In order to rarely encounter equipment breakdowns, you need to strictly follow the manufacturer's instructions, thoroughly prescribed in the manual attached to the product. Compliance with operating instructions is a guarantee of trouble-free operation. But if a violation occurs, our tips will help you quickly find the cause.

Do you want to share your own experience in restoring the operation of the heating system with the Vilant boiler or a similar unit? Do you know the technological subtleties of repair, which are worth sharing with site visitors? Share useful information and photos on the topic of the article in the comments section below.