My home is my fortress, and in the fortress everything should work like clockwork. Agree, returning from work, we dream to relax and enjoy the comfort, and not to repair the tap, boiler or figure out why the gas boiler is buzzing. However, it is extremely important to understand the causes of the problem when its first signs appear.

According to the rules for the operation of gas equipment, regular inspection and assessment of the technical condition should be carried out by gas workers. But they can not reveal all the brewing irregularities in work, tk. are not required to visit clients daily. Therefore, it is very important to independently monitor the technique and know what to pay attention to.

In this article, we will tell you what the noise signals during the operation of the gas boiler, as well as why it whistles, hums, bangs or clicks. Timely identification of the cause of the sounds will help prevent breakdowns, extend the life of gas-consuming units, and make your life more comfortable and safe.

The content of the article:

-

Causes of noise in heating equipment

- Flue gas fan problems

- Scale deposits on the walls of the heat exchanger

- Lack of water in the heating system

- Consequences of low pressure

- Incorrect unit setting

- When the boiler is turned on, pops are heard

- The causes of extraneous noise in various models

- Conclusions and useful video on the topic

Causes of noise in heating equipment

The new gas boiler is virtually silent. However, over time, the unit starts to make noise.

This is a symptom of a hardware problem:

- scale formation;

- the fan is out of order;

- wear of the apparatus units;

- manufacturing defects;

- incorrect setting or installation of the boiler.

To understand why a gas boiler makes a loud noise, you need to listen to the noise that the equipment makes.

If the humming is heard directly from the boiler, then the water level should be checked and, if necessary, top up. If noise is heard from radiators or piping, then air has entered the system and must be removed. Extraneous noise in the pump itself indicates a factory defect.

Clicking sounds at small intervals indicate a problem with the fan. If the boiler hisses or whistles, it means that a lot of scale has accumulated in the device.

In the event of a breakdown of the circulation pump, it is often necessary to replace this element. The gas supply to the system needs to be adjusted from time to time. A large head is undesirable.

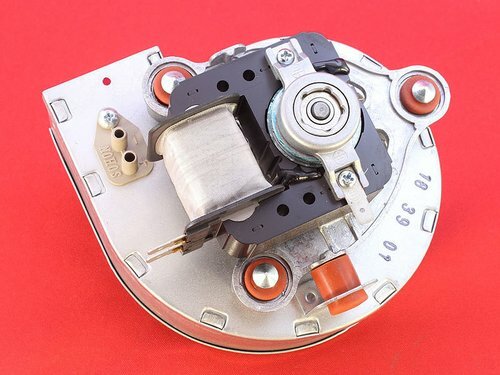

Flue gas fan problems

If extraneous noises are heard at intervals, the fan should be checked. Its task is to systematize the operation of the smoke exhaust system, due to which combustion products are removed from the boiler with an intensity necessary to ensure the full safety of others.

The fan blows through the system, cleaning it from the residues of combustion products, and also serves to remove smoke. The longer the boiler is running, the greater the wear of the fan.

The main reason is age. Most likely, you just need to replace the fan with a new one. The second reason that leads to rapid wear of the cooler is its location above the burner in the upper part of the device.

Constant exposure to high temperatures quickly dries out the bearing grease, resulting in wear. To fix the problem, a fan replacement is also required.

Another reason for the appearance of extraneous noise effects is that the part can be clogged with dust, to remove which you need to do the following:

- Examine the fan. It should be cleaned if necessary. The main blades are located inside the body. It is necessary to remove dirt and dust from them, and then lubricate the bearings.

- If the problem persists, replace the obsolete valves with brand new ball valves.

- If the previous two steps did not work, reinstall the cooler.

It is better to entrust the replacement of parts to the gas boiler repairman from the service with which contract signed for the maintenance of devices and the supply of blue fuel. Timely and competently performed replacement of worn parts will eliminate the need to buy a new unit.

Scale deposits on the walls of the heat exchanger

The heat exchanger transfers heat from gas to water. If the water is hard, limescale can build up in the heating system as it heats up. To remove mineral deposits that have settled on the walls, it is recommended to regularly carry out chemical flushing the heating system and cleaning the heat exchanger.

You can purchase a household chemical to flush the heat exchanger at the store. Craftsmen often use 4% vinegar for these purposes. After cleaning, the parts need to be rinsed with water

This malfunction is noticeable already after 15-20 minutes from the moment the gas boiler was started. The reason for the appearance of sounds is the narrowing of the water passage. This produces steam and small bubbles. Scale reduces the efficiency of the equipment, as well as its heat transfer and wear resistance.

You can descale the unit with chemicals containing soda and similar substances. You can do this yourself. To do this, remove the heat exchanger, remove the cover and loosen all connected pipes. A special chemical solution must be poured into the device for 2-5 hours.

Lack of water in the heating system

If there is not enough water running through the heating system, the boiler starts to make noise due to overheating. This is because air locks form inside, interfering with the normal circulation of the fluid in the system.

Airing the system leads to incorrect operation of the boiler. If there is not enough water in the pipe section, an air lock will form. At the same time, the heating device partially cools down, and the water cannot circulate normally in the system, therefore it overheats with the burner. At the same time, a dull whistle or howl is heard

Air blowing leads to the following problems:

- the circulation of water in the coolant decreases or stops;

- the boiler turns off automatically due to overheating of the coolant.

The reasons why air enters the heating system:

- violation of sealing during repair work;

- violation of the integrity of the system;

- drainage of water from the DHW circuit.

To adjust the operation of the device, you need to adjust the thermostat. You also need to make sure that the thermostat is installed correctly, add water, adjust its supply and circulation.

Get rid of air in the system will help Mayevsky crane, which is mounted at the end radiator. It provides a fitting, opening which you can get access to the inside of the battery. The tap is most often installed at the top of the device, where warm air accumulates.

An air separator can also be used. The device collects air that collects in bubbles during the course of water running along the circuit. When the excess air has been completely removed from the pipes, replenish the coolant through the make-up valve and make sure that the boiler works without extraneous sounds.

Prevent accumulation of air in coolant will allow the arrangement of a perfectly sealed heating system. It is troublesome and expensive, but it will eliminate the occurrence of extraneous noise in the gas boiler.

Consequences of low pressure

Reasons why the pressure in the system may decrease:

- water leak;

- breakdown of the expansion tank of the boiler;

- long interruption in the supply of electricity;

- incorrect setting of the gas boiler.

If the pressure in the system drops, the boiler starts making loud noises. Your task is to first check if there is a leak in the heating circuit. A simple napkin will help you with this, with which you need to wipe all joints and connections. Once the source of the leak is found, it must be eliminated.

If the pressure in the system drops, the boiler stops working, because it is blocked by the automatics. Lack of water in the heating circuit leads to overheating, it is detected by sensors, after which the boiler turns off automatically

Changes in pressure can be caused by cracks in the expansion tank or heat exchanger. To identify their location, all water should be removed from the system, and then air should be pumped into it using a compressor. In places where microcracks are formed, air will ooze with a characteristic whistle. The appearance of microcracks indicates wear and the need for a complete replacement.

This occurs as a result of frequent flushing of the system with chemical reagents, due to poor quality metal, a sharp increase in pressure in the line, and water hammer. If you can remove and repair the heat exchanger, then you can try to solder the formed microcracks.

In order to prevent such problems, it is recommended to regularly revise the boiler, as well as install auxiliary equipment that will allow you to control the pressure, displaying the value on screen. Standard pressure indicators are 1.5-2 atmospheres.

Incorrect unit setting

Improper setup or installation of equipment can also cause a howling valve or bypass. Extraneous noise can result from incorrect load redistribution.

If the operating power of the unit exceeds the permissible values, then as a result of excess pressure, vibration occurs and the pump begins to rattle.

If, during heating or cooling, there is a sound of metal hitting metal, an uncompensated expansion of heat is generated in the device. The reason lies in the incorrectly installed radiator hinged brackets.

If you do not know why the gas boiler is constantly whistling, you should first check the settings. The rules and sequence of actions when setting up a gas boiler can be found in the technical documentation for the unit, operating parameters - on the nameplate attached to the equipment body.

When the boiler is turned on, pops are heard

If during the turning on of the gas boiler extraneous noises are heard: pops, clicks, knocks, you should not hesitate to start looking for the problem.

The three-way valve is the main unit of a two-circuit gas boiler. Its task is to regulate the redistribution of flows during the inclusion of DHW. If the cause of extraneous noise lies in the valve, that it is out of order and the part needs to be replaced

What to do if the gas boiler slams sharply when turned on:

- Three-way valve malfunction. This device sends water in a small circle when taking sanitary water from taps. If it clicks, then it needs to be replaced.

- Continuous spark ignition. When ignited, the resulting excess gas flashes and a characteristic pop is heard. In this case, it is recommended to check the igniter, burner, electrode and all contacts.

- Chimney or filter clogged. In this case, they need to be cleaned. The chimney is checked with a lighted match. If the flame deviates, everything is normal, if there is no draft, cleaning is required.

- Installation error. If the equipment is installed incorrectly, but when heated, the metal deforms, and pops are heard. The same sound occurs when it cools as the metal returns to its original position. When switching to hot water supply, the boiler hums. The problem is solved by reinstalling the gas boiler.

- Nozzles clogged. A thin wire is used to clean them. Turn off the gas first.

If the boiler vibrates during operation, it is recommended to put a gasket under the body.

The causes of extraneous noise in various models

Why does it regularly click gas boiler Navien? Two reasons are likely: scale formation and problems with the coolant.

How to fix the problem yourself:

- disassemble the device;

- clean or replace the heat exchanger;

- check the taps;

- lower the water temperature.

Extraneous noises are also noted during the operation of Beretta brand gas boilers.

Typical reasons:

- poor heat transfer in the heat exchanger, scale formation;

- the wrong pipes are connected.

Why is the Concorde gas boiler whistling? The most common reason is increased stress in cold weather. The boiler capacity declared by the manufacturer does not correspond to reality and in practice the figures are lower.

For example, if the documentation indicates 13 mbar, then in reality it is 10 mbar. Do not set the operation of the device to its maximum.

It is recommended to clean the gas boiler at least once a year. For this purpose, you can contact the service center or carry out the procedure yourself

In the Baksi gas boiler, noise occurs most often when the heating function is turned on. To determine the cause, check the bypass and clean and adjust the valve. Users of AOGV devices often complain about whistling. The cause is limescale and a clogged filter.

Vailant boilers hum after turning on the heating function and turning off the fire. The first reason is that the heating circuit strainer is clogged, cleaning it will correct the situation. The second reason is a malfunction of the valve on the bypass line. Adjusting the valve will help solve the problem.

The reason for the noise in the Ariston boilers is in the poor circulation of the coolant. The problem will be solved by purging the heat exchanger with a compressor. If the Ardelia gas boiler hums, you should check the correctness of the pump setting. If the situation cannot be corrected in this way, then it is recommended to replace it with a new circulation device.

Conclusions and useful video on the topic

The reason for the noise during the operation of the gas boiler:

Whichever gas boiler is installed in your home, first of all, you should make sure that it is installed correctly. The equipment needs regular preventive maintenance. This will allow you to identify and fix problems in time.

It is periodically recommended to clean the coolant from dirt and scale. These simple manipulations will allow the device to work as long as possible, efficiently and without extraneous noise.

Have you ever experienced a gas boiler popping, clicking, whistling or making noise? How did you fix this problem, or which services you contacted. Share your experience with readers in the comments and ask our experts your questions.