What problems do the owners of household buildings often face: garages, utility blocks, bathhouses, small pools, summer kitchens? Indeed, in addition to carrying out a number of communications, it is necessary to deal with heating and heating. For those who have made a gas oven with their own hands, questions are solved simply and cheaply.

Anyone can buy special heating equipment. However, its cost bites painfully. Not many are ready to spend large sums of money on the device and installation of a heating system in this kind of premises.

We will tell you how to assemble and run an efficient and inexpensive heat generator in utility buildings with your own hands. The homemade designs we proposed, made according to pre-developed drawings, are easy to install and cheap. The information is confirmed by practice.

The content of the article:

- Preparatory stages of work

- Advantages and disadvantages of gas ovens

- Homemade heater from a gas burner

- Gas stove heater

- Heat gas cannon

- DIY gas fireplace

- Conclusions and useful video on the topic

Preparatory stages of work

If the room is not heated in winter, then one of the main problems is the formation of condensation on the inner surfaces of the walls and on all objects inside.

This leads to gradual rusting of metal structures and an increase in humidity inside the building. It becomes impossible to store things in winter in such conditions, as they will deteriorate.

Dampness in unheated rooms is a common problem. Most of the condensation forms on the ceiling and on the walls. If you store metal devices in such rooms, then they quickly become rusty and become unusable. The way out is to insulate the room and start heating

Some car owners use electric heaters and homemade wood stoves for heating the garage. However, such a decision subsequently turns out to be unprofitable: the power of the electrical appliance is often insufficient, and the electric meter winds up astronomical indicators.

If, in addition to everything else, the room is not insulated, then the heat loss increases several times. Then it is necessary to purchase the appropriate heater - very powerful and expensive.

In such cases, even a gas oven may be unable to maintain a temperature of at least 24 degrees Celsius. Therefore, the owners should first deal with the external and internal insulation of the building.

Better to carry out two types of insulation. But everyone carries out the procedure based on technical capabilities. Sometimes there is no access to the ceiling or side walls, for example, if the garage is insulated.

The greatest result is achieved by a combination of internal and external insulation. If there is no way to insulate the building from the outside, then you should not be upset. Modern methods of internal insulation are not only more economical, but also give a much greater effect.

It is also necessary to take into account the future heating of the building with the help of a homemade gas-powered stove. It is highly recommended to insulate walls, ceilings and floors with fireproof materials. Then the room will be fireproof, and the owner will save himself from unnecessary worries. It is recommended to plaster walls made of bricks, and to prime and paint over metal walls.

After all thermal insulation measures have been taken, the efficiency heating garage will increase markedly, and fuel costs will be much lower.

The best place to place a homemade gas stove is in the center of the room. If the heat source does not come into contact with the walls, then the heat will not escape through them and a kind of heat cap will be created in the building.

The principle of operation of the heat cap is that first warm air rises from the center of the room up to the ceiling. There, he encounters a cold stream of air and begins to go to the sides to the walls, where he again encounters cold streams. During this circulation, warm currents will gradually fill the entire room and heat it.

If all conditions are met, a so-called heat cap is created in the room. Warm air circulates almost throughout the entire building space and does not go outside. Thus, the entire room is heated.

In the image, the circulation of warm air in the room would resemble movement within a schematic mushroom-like figure. A positive heating effect is achieved even with the use of furnaces of weak power. However, they must generate an intense air flow.

Advantages and disadvantages of gas ovens

The market offers consumers a wide variety of energy sources. At the present stage of economic development, one of the most profitable and efficient fuel options is gas.

The use of gas as a power source for heating equipment is beneficial in that its cost does not hit the consumer's pocket. In addition, the gas has a high efficiency. The operation of gas-fired heating devices is easy to use, economical and safe.

This kind of homemade heater is often used for a wide variety of purposes. It can be used to heat a greenhouse, garage, box. Due to their mobility and low assembly cost, portable heaters can be taken even on camping trips

When arranging a gas oven in a room, the best option for owners will be a situation when a gas pipeline is directly connected to the building. However, in modern realities, this is a very rare case. Many will have to purchase gas cylinders and other containers for storing and supplying fuel to the furnace.

The advantages of using gas ovens include:

- fast, efficient and high-quality heating of the room;

- mobility and compactness of gas equipment;

- the ability to quickly move the oven to the desired location;

- independence from government communications, power outages and many other factors.

Gas equipment, like any other, has its drawbacks. However, they are relative and easy to work around.

The disadvantages include:

- the use of gas is strictly regulated by regulations;

- owners of non-residential premises will have to obtain a number of agreements and permits from the gas industry and other government agencies;

- drawing up the necessary project can cost a round sum;

- the use of reduced and bottled gas requires compliance with safety measures.

In order for the gas stove to perform its function as efficiently as possible in the room, it is necessary to have protective screens. Such structures are equipped with reflective surfaces, due to which warm air does not escape, but is reflected and heats the entire area of the box.

Craftsmen are constantly improving their skills and applying new techniques to design homemade units. Some modern handmade gas heaters are equipped with special blowers to control the flow of warm air.

Open burning stoves require design and installation ventilation system and providing air humidification. When the device burns oxygen, the air becomes dry. This often leads to headaches and sore throats.

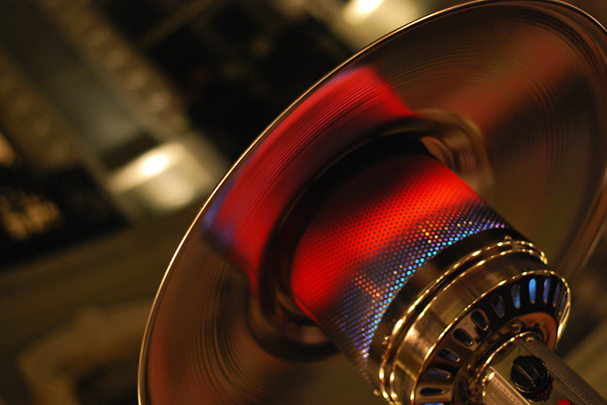

Homemade heater from a gas burner

The independent manufacture of a gas furnace from metal or other materials is carried out in accordance with pre-developed schemes. Consider one of the possible options for an independent step-by-step collection of a gas stove.

You can buy the necessary tools and materials in almost any hardware store or on the construction market. Metal scissors can simply be borrowed from friends

The assembly will require the following materials and tools:

- metal scissors and locksmith tools;

- metal sheet with a thickness of 0.5 mm to 1 mm;

- mesh netting, which will be used as a lattice;

- a metal sieve of suitable size (you can use it, but without significant damage);

- a gas burner with a safety valve, which should be purchased on the construction market;

- a gas cylinder of a suitable volume;

- reinforcement, approximately 10 mm thick, with which the structure will be connected to the cylinder.

After collecting all the necessary materials, they proceed to the immediate beginning of the manufacture of the structure.

First you need to put a sieve on the prepared metal sheet and draw a pencil around its circle. Then we mark the unfolding in the form of a rectangle. Its length should be enough to grip the sieve and the bottom of the metal stove. The reamer must be cut out neatly and without irregularities.

Next, you need to mark the attachment points of the gas burner, drill holes and fix the burner on the back of the reamer. The parts are connected to each other using rivets and a small pre-made flanging.

A drilled plate is attached to the top of the sieve with rivets. On the plate, you need to attach a mesh netting with metal plates. Next, using a riveting machine, legs of a suitable length are installed.

It is highly recommended to use a good quality gas supply hose. The best option would be to purchase a new hose from a store. Old rubberized hoses can be damaged in their structure due to exposure to the sun

The burner valve is equipped with a hose attached at the other end to the gas cylinder. After turning on the gas, it is necessary to check the tightness of all connections. This is easily done with a soapy solution.

Such an installation can also be connected to a gas pipe that removes combustion products from the apartment. However, in this case, a permit and agreement with the HOA, ZhK or ZhKK will be officially required. It will also be necessary to carry out a ventilation system, and install the stove on a separate foundation. You also need to buy a gas meter.

When installing a homemade stove, you should observe all the required distances between various surfaces. The distance from the stove to the floor or walls made of combustible materials must be within the values specified in the standards.

When using a large stove, the owner of the room will need to additionally conduct a chimney. If the gas appliance is to be installed on a wall, then the wall must be load-bearing. Installation of gas appliances on non-load-bearing walls is prohibited.

The diameter of the chimney should be sufficient for a complete and high-quality removal of combustion products from the heated room. Large homemade units are additionally equipped with a chimney

Before starting the equipment directly, you must make sure that it works properly. ventilation and in the absence of gas in the air in the room. In addition, then every time after turning off the equipment, all taps and valves should be shut off, both on the gas cylinder and on the gas oven.

A pressure reducer installed on the cylinder will protect it from kickback, and also make it possible to regulate the pressure.

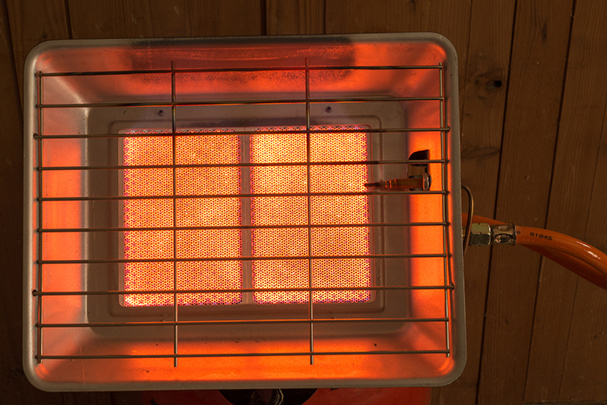

Gas stove heater

For some small spaces, a small tabletop heater may be sufficient for heating. The device is assembled using a rectangular flat tile, which is initially equipped with a grill.

The structure is assembled by connecting the tiles to the metal casing. The casing is equipped with a combustion chamber and a fan. Assembling such an installation yourself is not difficult.

First of all, you need to measure the length and width of the future hull. In this case, you need to be based on the size of the tile. After the casing is made, it must be fixed with hook strips.

On the one hand, you need to make a movable bar. This is easily done with a spring that attaches to the lift arm. This measure in the future will ensure the possibility of removing the case in case of need.

Despite the seeming complexity of assembling gas heating devices, their design is not a difficult task. It mainly consists of following all pre-written instructions correctly, step by step and carefully.

In this design, a ventilation system is provided in advance. For its device, you do not need to use any unusual materials. A handy fan will be enough. For example, from a window air conditioner. The blades can be trimmed neatly to shape and size. The fan is attached to the back of the case.

To create thrust inside the housing, it is necessary to fix a metal combustion chamber. A plurality of holes are made on the surface of the combustion chamber at a small distance from each other.

Due to the ability to connect such a heater to cylinders of different sizes, this homemade device is very mobile and easy and convenient to transport. Therefore, such mini-stoves are often taken on hikes.

The device effectively heats rooms even in winter and has a high efficiency. If you insulate the room in advance and install reflectors, then such a heater will perform its task as efficiently as possible.

Heat gas cannon

Heat gas cannons are distinguished by their high power and high level of energy release. Usually the structure is equipped with a chimney.

To independently make such a device, you will need the following materials:

- meter pipe with a diameter of 18 cm;

- meter pipe with a diameter of 8 cm;

- pipe 30 cm long and 8 cm in diameter;

- metal plates for future fastening;

- a metal sheet;

- gas burner equipped with piezo ignition;

- axial fan with a round flange.

In addition to the materials listed, you will additionally need to acquire a welding machine, a tape measure and a level with two ampoules. Some craftsmen advise using old gas cylinders or fire extinguishers instead of pipes. Their bottom and top are carefully cut off beforehand with a grinder.

If you collect all the necessary materials and tools, then the assembly of the gas cannon will not take much time.

The first step is to drill two holes in the first pipe with a diameter of 18 cm. They should be located opposite each other, and their diameters: 1 cm and 8 cm. The second meter pipe with a diameter of 8 cm is used for the manufacture of the combustion chamber. For this purpose, you will need about 30 cm.

The essence of the work of a heat gas gun is as follows. First, gas starts flowing to the burner. The fan drives the air through the heat exchanger, where it heats up. The outlet produces warm air, which heats large rooms very efficiently.

The fixing plates must be welded to the second pipe. Also, a hole with a diameter of 1 cm is made on this pipe. After that, the pipe must be inserted inside the first pipe.

The next stage is cutting out a plug from a metal sheet, which will be used as a bridging of the space between the frame of the heat gun and the combustion chamber.

Then you should use a welding machine and weld the pipe from which the combustion chamber is made to the inner frame. After that, a branch pipe is welded through which hot air will be removed to a hole with a diameter of 8 cm. Next, the plug is welded.

The gas burner must be firmly and firmly installed in the chamber. It is necessary to check the rigidity of the fastening. After that, a hose is passed through the drilled centimeter holes in the two pipes. Then a fan heater is attached to the heat gun. A chimney must be installed on the front of the chamber.

To prevent the device from turning over and standing stably on a flat surface, you need to weld the legs. You can also turn on imagination and attach wheels or other parts to facilitate the transportation of the structure.

It is convenient and simple to heat a room with a heat gas gun. Plus it's economical. However, there is always a risk of structural failure. Therefore, you should be very careful and thoughtful about the process of assembling the device.

DIY gas fireplace

Another convenient option for space heating is a gas fireplace. The purchase of such a device will cost a round amount, although the most savvy can independently assemble and equip a fireplace in their box without particularly large financial investments.

This kind of fireplace can be powered either directly from a gas pipe or from a gas cylinder.

On the Internet, you can find many different drawings of gas fireplaces. Also, some users can purchase prefabricated structures, lay out brickwork on their own and assemble a fireplace from pre-prepared parts.

The structure consists of the following main elements:

- ordinary fireplace insert or decorative, decorating the room;

- fireplace body made of refractory metals - cast iron or other alloys;

- a burner that supplies gas;

- gas supply system.

After determining the place where the structure will be installed, it is necessary to prepare it for starting the construction of brickwork. There must be a solid foundation. You also need to install the chimney. After the fireplace has been built, it can be decorated with a variety of decorative elements to the taste of the owners.

The fireplace is laid only from refractory bricks. When erecting a structure, it is worth taking care of providing a passage to the gas valve. After the internal elements of the masonry are installed, and the communication is connected to the gas burner, you should make sure that the entire system is tight.

With the help of the valve, in the future it will be possible to regulate the force of the gas supply and, therefore, the amount of heat generated. Gas workers advise turning the burners downward with holes - this will protect them from contamination and moisture.

Also, the burner should be reinforced with protective mesh elements. This will reduce the load on the burner from the decorative material.

A gas supply pipe covered with fireproof materials is fed into the fireplace insert. The gas burner is installed with the holes downwards and is masked with artificial refractory material

The introduction of some modern devices will slightly automate the work of the fireplace. So you can connect a gas supply control system, depending on the level of heat generated, or an automatic gas shutdown system. All modifications are freely available on the market, and their purchase depends on the wishes and capabilities of the owners.

Beautiful decoration of the fireplace bowl is made using a variety of stones, glass, ceramics. In addition to interior decoration outside, the fireplace can be decorated with tiles or in another way. The main thing is that it is a refractory material.

It is easy to assemble a gas oven yourself with your own hands. To do this, you need to adhere to the design and safety diagram.

Subject to all the requirements and recommendations, the assembly of the stove will be a fun and not costly exercise. Self-assembly of such a structure will save significant money.

First of all, before installing a gas oven for heating a room, it is worthwhile to carry out a number of preparatory measures. If you do not insulate the room, then even the most powerful equipment will not give a serious result. Therefore, it is important to carry out procedures for external and internal insulation, as well as equip reflective surfaces.

Conclusions and useful video on the topic

Handmade heat gas cannon:

Self-made gas oven:

Homemade gas oven with a fireclay brick body:

For heating small remote non-residential premises, a home-made heater from a gas burner and a heater from a gas stove are suitable. To provide sufficient heat for a medium-sized room, you should consider installing a gas heat gun or gas fireplace.

All considered devices can operate both from gas pipes supplied to the room, and from gas cylinders. It is worth remembering that when connecting to a gas pipe, it is necessary to install a meter and officially register the procedure with the gas control authorities. With a self-made construction device, this procedure will be much more complicated.

If you use gas cylinders, you can effectively heat your premises during the winter period. It is important to remember that compliance with safety precautions is the key to successful work with any gas devices.