Can't find instructions? Didn't the recommendations in the brochure help you? You have the opportunity to read our article on setting up boilers. If you don’t know how to deal with gas equipment, you need a master. But you must admit, it does not hurt to save time and money over and over again thanks to the knowledge of the basic settings. Effective regulation of a gas boiler is much easier than it might seem.

From the article, you will understand the principles of adjusting pressure, thrust and power during device operation. Find out the probable causes of the problems along with the options for their elimination. If you are going to set up a boiler, use our materials. Do not forget about the safety rules, and you will successfully set up the device, eliminate minor problems.

You should be interested in the settings of a gas boiler long before buying, taking into account the needs and various features. We have written what parameters can or should be changed in the device used. The new device should be set up and ready for use, and some unwanted moments can be corrected.

The content of the article:

- Setting the boiler automation and pressure

-

Preparing the boiler for operation

- How to adjust the draft in the boiler?

- Setting up an incendiary device

- Gas boiler power regulation

- Conclusions and useful video on the topic

Setting the boiler automation and pressure

Reconfiguration is performed if the automation is triggered too often. This malfunction is called clocking, and it occurs due to an excessive increase in the temperature of the coolant. Reduce the gas supply to the main burner to protect the boiler from wear and tear.

The method also has a fallback - just twist the tap in front of the boiler. Remember that incomplete combustion of fuel leads to an increase in the volume of flue gases and burning.

The place of installation of the boiler in the kitchen: the gas can be turned off with a tap after the connection, as well as at the lowering, if this does not interfere with the operation of the stove and other gas appliances

To get rid of the clock, transfer room thermostat (if available) to a colder place or lower the air temperature at the installation site. Increase the amount of heating medium in the heating system. Replace the main burner if stroking occurs due to its increased power.

Problems with automation and frequent shutdowns are observed under such circumstances:

- voltage dropped or jumped;

- a strong wind extinguished the burner;

- decreased chimney patency;

- decreased gas pressure.

To improve the operation of the automation, move the autoblock (gas valve) handle to the “spark” position. The igniter (pilot burner, pilot burner) will light up. Leave the knob in this position for 30 seconds, then return it to the "off" position - the white circle.

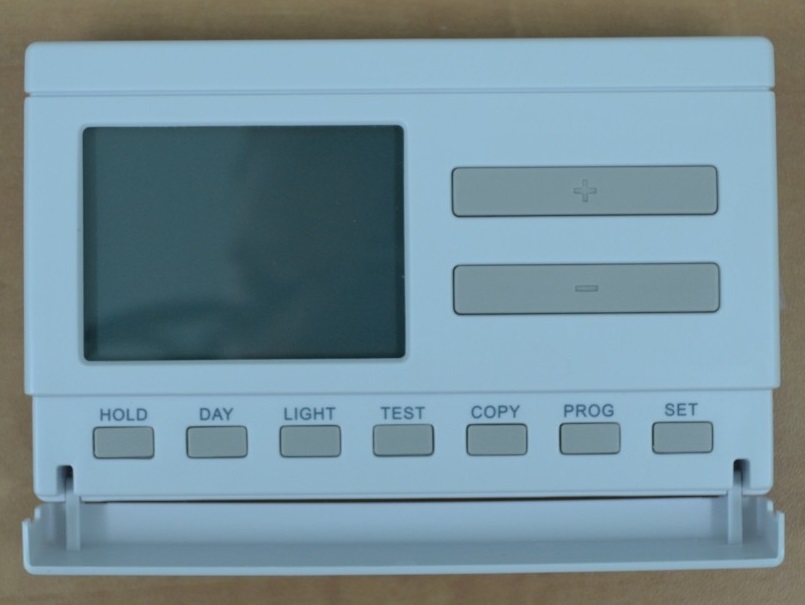

Boilers are produced with thermostats (temperature controllers), daily and weekly programmers. The thermostat turns off the boiler when the set temperature is reached, then the device turns on automatically. While the hosts are away, they can rely on a 7-day regulator. The daily device removes the need for constant monitoring of the boiler.

Weekly programmer for gas boilers Computherm Q7, on which you can select the sensitivity threshold, set the parameters for the transition between heating and cooling and lock the buttons

The pressure is adjusted on the autoblock. Take Eurosit 630 for example. The unit maintains the temperature of the water in the heating circuit and stops the gas supply in a hazardous situation. The Eurosit 630 has a knob that turns and has 7 flame modes - move it to position “1”, remove the cover and screw the screw on the left under the knob. Turn clockwise - the gas supply will be less and smoother, the automation will work better.

Also set the maximum mode. Move the knob to "7" and tighten the screw on the bottom of the unit, now counterclockwise. A decrease in the flame level will decrease the gas pressure and the efficiency of the boiler burner at the same power setting.

Determine the desired sides on the autoblock first. Consider the surface with the handle as lateral. The unit is installed in different ways: sometimes this side is on the side, sometimes on top. Do not confuse the correct screws (gold plated) with the fasteners.

The pressure must be reduced in such cases:

- the flame goes out shortly after ignition; 2

- on ignition eat cotton;

- the flame goes beyond the limits allotted to it;

- red or red-orange fire color.

The pressure usually rises in winter: gas distribution companies raise the value from 200 to 280 mm water column. Install a pressure regulator or reduce the flow through the drop.

Preparing the boiler for operation

The device is adjusted after installation, ignition and long periods of inactivity. After installation, check all sensors and fuses, the functionality of the nodes.

The connection and the first setting of the gas boiler must be carried out by employees of the company with which it was signed maintenance contract: they are obliged to check all key indicators and sensors, test the device in operation and conduct briefing

When starting up the boiler, there are five steps to be taken:

- Warm up the device.

- Open completely chimney damper.

- Adjust the flame at full power to the blue and yellow segments.

- Close the valve on the sink until the yellow part of the fire is removed.

- Check the operating modes and automation that is responsible for safety.

The same is done after installation.

Boilers need regular cleaning. After a break in the operation of the device, insects and spiders fill the chimney. Examine the pipe and fan, remove small animals. Remove plaque from combustion products and ice. Remove soot from the combustion chamber. When dirty, it causes ignition problems.

For the same reason, it is worth removing dirt from the insulator, where the wire is located, which goes into the combustion chamber. Clean the element with a soft cloth. Remove large amounts of dirt with solvent. Dry the insulator before restarting the boiler.

Delete in time scale from the walls of heat exchangers. If the boiler does not heat water well, then flush the heating circuit as well. Fill with hot water and add mineral scale remover. Check the operation of the flow sensor, and if everything is in order with it, use the boiler.

How to adjust the draft in the boiler?

Draft weakens over time, so check it in the device and chimney. Take a look through the viewing window. Clear soot from the drainage pathways. The draft is aggravated by bad weather: the gases do not always escape completely, and the incoming air can disrupt the operation of the burner. Inspect the structure of the chimney, compare it with the requirements for SNiP 2.04.05-91.

The deflector improves the draft in the chimney, as it creates the effect of a pressure drop, and besides it, smoke fans and chimney vane are also used

The draft regulator (gate) is installed with excessive draft. In this regard, the opposite problem appears. The chimney cools down excessively and gradually becomes covered with condensation from the inside. The pipe is clogged from the accumulation of soot and ice. If you forget to turn the gate at least once every 2-3 days, then this device deteriorates, changing the positions open / closed becomes impossible.

Select the draft regulator according to the principle: the longer or the height of the chimney - the smaller the diameter of the gate in comparison with the same indicator of the pipe. Then the chimney will last longer.

There are also combustion regulators, sometimes referred to as mechanical draft regulators and bellows. thermostats. Devices of this type are more often installed on solid fuel devices, but they are also used on gas devices - a water thermostat - there is no chain on it. Units for gas boilers do not affect the regulation of the chimney draft.

Setting the combustion regulator for a gas boiler looks like this:

- Before installation, drain the water from the boiler, and if the heating system cannot be isolated with taps, then remove all the heat carrier.

- Remove the plug and screw in the regulator instead.

- Then fill the system with heat carrier and light the burners.

- Scroll the knob to the desired temperature position.

Refer to the markings on the flywheel if the exact temperature is not displayed on the regulator. In summer, set exactly in the middle of the gap between low and medium values. In winter, it is between medium and high.

Gate valve: such draft regulators are used along with devices with an internal damper, which can be turned by an external handle.

Before settling on some optimal value, check all temperature modes.

Setting up an incendiary device

Prepare pliers, multimeter, screwdrivers, open-end wrenches and rubbing alcohol. Carefully remove the terminals, close together and squeeze with pliers. Start the pilot burner. Consider it and check the resistance with a multimeter. If the value is not 1-2 Ohm, replace the draft meter with a new one. If it is within the normal range, clean the sensor with a cotton swab dipped in alcohol. Reinstall and check if the ignition device is working.

Sometimes the problem persists. In this case, inspect the thermocouple breaker (traction breaker): remove the terminals and determine the resistance. If the value does not correspond to 3 ohms, use open-ended keys.

Use tool 9 to remove the nut that connects the breaker and thermocouple. Then, using the No. 12 wrench, unscrew the traction interrupter by half a turn. Then take the insert with contacts and remove the breaker. Use a No. 9 key to connect the solenoid valve and thermocouple. Check the ignition. If it does not turn on, the problem is in the thermocouple.

Remove the fasteners between the thermocouple and the pilot burner with a # 10 wrench and check the electromotive force of the thermocouple with a voltmeter. In the case of a working thermocouple, simply wipe its connection to the breaker with alcohol and put everything back together.

A portable multimeter functions as a tester, ohmmeter, ammeter and voltmeter: devices are digital, analog, sometimes in the form of measuring clamps

The gas supply to the boiler is as follows:

- The gas enters the strainer, which removes particulate matter from the fuel.

- Fuel flows further with open valve and solenoid valve.

- Gas enters the pilot burner.

- A lit igniter delivers flame to the main burner and thermocouple.

The control system fires a flame on the main burner if there is also fire on the pilot. Stops the fuel supply in the absence or a strong decrease in draft in the chimney. The automatic control circuit provides maximum safety when supplying gas to boilers and other similar devices.

Gas boiler power regulation

In this case, the task is to decrease or increase the indicator. The indirect method of regulation implies a decrease in the flow through the taps: which is after the connection to the boiler and the one at the lowering. The control range will decrease, so direct methods are better.

To increase the power, select an option:

- Set the burner to the desired value - relevant for modulating units.

- Buy a more efficient burner.

- Replace nozzles with larger ones. Remember, with an increase in heat transfer from the boiler, gas consumption will increase, the risk of breakdown ahead of time, and efficiency will decrease.

Ideally, it is better to entrust the setting to increase the power to a boiler specialist. The growth of capacity for these options reaches 15%. If this is not enough, use additional devices to heat the rooms. Remember to clean the boiler to maintain the power level.

Tubes with micro-flares for an atmospheric burner - such a device works almost silently, but has a low power, dries up the air in the room and depends on a large number of external factors

Sometimes you have to reduce the power. First, it is adjusted through the menu: by the parameters of the heat exchanger temperature and the anti-cycling time. Then set up circulation pump. If necessary, change the burner to a modulating one.

Reasons for changing the boiler output:

- Increase: it is necessary to re-equip the device at the same time as the power is increased, to connect an indirect heating boiler, the area for heating has increased.

- Decrease: rejection of one of the functions (heating or hot water supply), part of the functionality (heating of individual rooms, underfloor heating), decrease in boiler performance.

In case of excessive fuel consumption, it is worth inspecting the secondary heat exchanger and removing salt residues manually or with a chemical composition. Contamination will be indicated by the characteristic bubbling during boiler operation.

The consumption increases due to the low specific heat of combustion (calorific value) of the gas. The norm is not less than 7 600 kcal m³. With poorly drained fuel, the calorific value drops by almost two times.

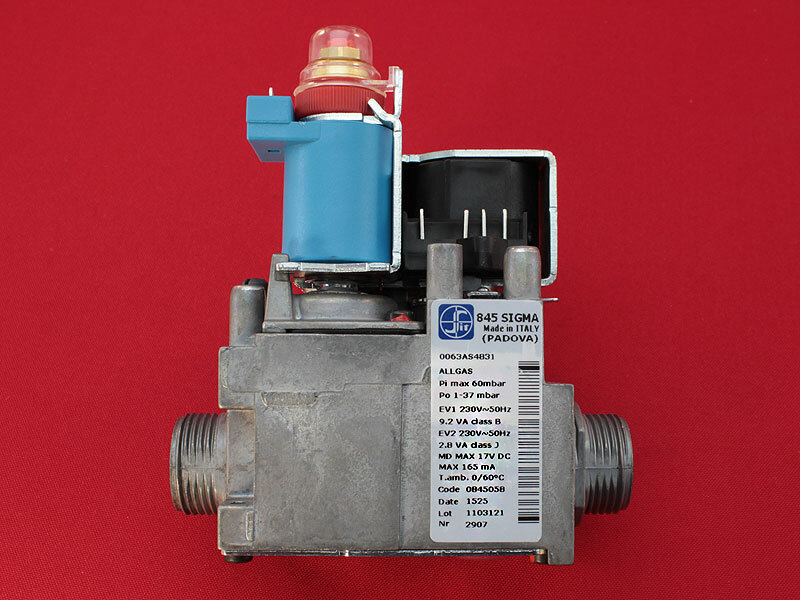

Configure also gas valve. They are regulated, depending on the structure:

- the one-stage ones have only the “on” and “off” positions;

- two-stage valves are equipped with 1 inlet and 2 outlets, and they open at an intermediate position;

- three-stage boilers have two power levels;

- With the help of modeling valves, the power can be regulated more smoothly, they have many flame modes, in addition to the "on" and "off" positions.

Look at the color of the flame. If it has a noticeable yellow part, screw on the valve on the lowering to reduce the fuel flow.

845 SIGMA Multifunction Gas Valve with Power Modulation, Output Pressure Regulator and Fuel Control Module - Multi-Thread and Flange Options

Set the heating operating temperature on the thermostat again. The principle of its operation is that the rod is included in the work. As the temperature drops, the element decreases and opens the fuel supply. An increase in temperature leads to an increase in the rod, which is why the gas begins to flow in a smaller volume.

If there is a lack of air, inspect the damper, boost and temperature regulator. Pops when igniting the main burner are due to clogged air paths. Remove dust from them and inlets.

Conclusions and useful video on the topic

Gas boiler power regulation:

Setting the room thermostat - lt08 models:

Detailed setting in the menu of the Bosch Gaz 6000 W boiler:

Now you know what kind of regulation the boilers need. You understand how you can influence the gas consumption. You can adjust the power of the gas boiler and its components without calling the master. Take care of the device so that you use the knowledge gained only for adjustments, and not for repairs. Do only what you can do. If necessary, contact your boiler specialist. Call emergency numbers if there is danger.

Write comments about setting up gas boilers. Write about the criteria by which you chose your device, about the quality of the device. Tell us how you set up your boiler and how often you do it. The feedback form is located below.