When choosing boiler equipment for a heating system, a very restless thought persistently drills my head - how gluttonous the unit will be? Surely the answer will appear when the heating starts up, and the meter starts counting the gas consumption of the floor boiler, regularly winding up the revolutions. However, it will be too late to lament if the amounts payable for gas do not please ...

Competent sales consultants, of course, answer most of the questions that arise, you can always turn to a competent engineer for help, but it's good to have at least basic knowledge yourself.

Learn from this article as much as possible about the methods for calculating energy consumption and the factors that must be taken into account in the calculations. Below you will find not only boring formulas, but also examples. In the end, what can be done to reduce gas consumption.

The content of the article:

- What affects gas consumption?

- Quick preliminary calculation

-

The boiler is connected to the main gas pipeline

- Calculation of gas consumption in formulas

- Using formulas by example

- The boiler is powered by a gas tank or cylinder

- How to minimize gas consumption

- Conclusions and useful video on the topic

What affects gas consumption?

Fuel consumption is determined, firstly, by power - the more powerful the boiler, the more intensively the gas is consumed. At the same time, it is difficult to influence this dependence from the outside.

Even if you turn the 20 kW unit down to the minimum, it will still consume more fuel than its less powerful 10 kW sibling turned on at maximum.

This table shows what is the relationship between the heated area and the power of the gas boiler. The more powerful the boiler is, the more expensive it is. But the larger the area of the heated premises, the faster the boiler pays for itself.

Secondly, we take into account the type of boiler and the principle of its operation:

- open or closed combustion chamber;

- convection or condensation;

- regular chimney or coaxial;

- one circuit or two circuits;

- the presence of automatic sensors.

In a closed chamber, fuel is burned more economically than in an open chamber. Efficiency of the condensing unit thanks to the integrated additional heat exchanger for condensing the vapors, present in the combustion product, increases to 98-100% in comparison with 90-92%, the efficiency of convection unit.

WITH coaxial chimney the value of efficiency also increases - cold air from the street is heated by a heated exhaust pipe. Because of the second circuit, of course, there is an increase in gas consumption, but in this case, the gas boiler also serves not one, but two systems - heating and hot water supply.

Automatic sensors are a useful thing, they catch the external temperature and adjust the boiler operation to the optimal mode.

Thirdly, we look at the technical condition of the equipment and the quality of the gas itself. Scale and scale on the walls of the heat exchanger significantly reduce heat transfer; its lack has to be compensated for by increasing the power.

Alas, the gas can be with water and other impurities, but instead of making claims to suppliers, we switch the power regulator by several divisions towards the maximum mark.

One of the modern highly economical models is the 160 kW floor-standing gas condensing boiler of the Baxi Power brand. Such a boiler heats 1600 sq. m of area, i.e. a large house with several floors. At the same time, according to passport data, it consumes 16.35 cubic meters of natural gas. m per hour and has an efficiency of 108%

And, fourthly, the area of the heated premises, the natural loss of heat, the duration of the heating season, weather features. The more spacious the area, the higher the ceilings, the more floors, the more fuel will be required to heat such a room.

We take into account some heat leakage through windows, doors, walls, roof. Year after year does not happen, there are warm winters and bitter frosts - you cannot predict the weather, but cubic meters of gas consumed for heating directly depend on it.

Quick preliminary calculation

It is quite simple to estimate by eye how much gas your gas boiler will consume.

We will start from either the volume of the heated room, or from its area:

- in the first case, we use the standard of 30-40 W / cu. m;

- in the second case - 100 W / sq. m.

The standards are taken taking into account the height of the ceiling in the room up to 3 meters. If you live in the southern regions, the numbers can be reduced by 20-25%, and for the north, on the contrary, they can be increased by one and a half or two times. Those. take in the second case, for example, 75-80 W / m2 or 200 W / m2.

Multiplying the corresponding standard by volume or area, we get how many watts boiler power necessary for heating the room. Further, we proceed from the standard statement that modern gas equipment consumes 0.112 cubic meters of gas to generate 1 kW of thermal power.

We multiply again - this time the gas consumption standard (number 0.112) by the boiler power obtained in the previous multiplication (do not forget to convert watts to kW). We get the approximate gas consumption per hour.

The boiler usually works 15-16 hours a day. We calculate the daily gas consumption. Well, when the daily consumption is already known, we can easily determine the gas consumption for a month and for the entire heating season. The calculations are approximate, but quite sufficient in order to comprehend the very principle of calculation and the expected gas consumption.

An ordinary calculating machine is enough to calculate the gas consumption. If you do not want to delve into the calculation formulas, use online calculator programs on the network. Enter the initial data and get the result immediately

Example.

Let's say the area of the room is 100 m².

Let's calculate the boiler power: 100 W / sq. m * 100 m² = 10000 W (or 10 kW).

Let's calculate the gas consumption per hour: 0.112 cubic meters. m * 10 kW = 1.12 cubic meters. m / hour.

Let's calculate the gas consumption per day (16 hours of operation), for a month (30 days), for the entire heating season (7 months):

1.12 cc m * 16 = 17.92 cubic meters. m

17.92 cc m * 30 = 537.6 cubic meters. m

537.6 cc m * 7 = 3763.2 cubic meters. m

Note: you can immediately determine the monthly and seasonal power consumption of the boiler in kW / h, and then recalculate it into the gas consumption.

10 kW * 24/3 * 2 * 30 = 4800 kW / hour - per month

0.112 cubic meters * 4800 kW / hour = 537.6 cubic meters m

4800 kWh * 7 = 33600 kWh - per season

0.112 cubic meters * 33600 kWh = 3763.2 cubic meters m

It remains to take the current gas tariff and translate the total into money. And if the project includes the installation of a double-circuit system, which will not only heat the house, but also heat water for domestic needs, add to the power of the equipment and, accordingly, to the gas consumption floor standing gas boilers heating another 25%.

The simplest thermal imagers cost at least $ 300, and the price for professional ones starts from several thousands, but these devices show all the places through which cold air enters the house and goes outside warmly

The boiler is connected to the main gas pipeline

Let's analyze the algorithm of calculations that allow us to accurately determine the consumption of blue fuel for a unit installed in a house or apartment connected to centralized gas supply networks.

Calculation of gas consumption in formulas

For a more accurate calculation, the power of the gas heating units is calculated by the formula:

Boiler power = QT * TO,

where

QT - planned heat loss, kW;

K - correction factor (from 1.15 to 1.2).

The planned heat loss (in W), in turn, is considered as follows:

QT = S * ∆t * k / R,

where

S - total area of enclosing surfaces, sq. m;

∆t - internal / external temperature difference, ° C;

k is the dissipation factor;

R is the value of the thermal resistance of the material, m2• ° C / W.

Dissipation factor value:

- wooden structure, metal structure (3.0 - 4.0);

- one brick laying, old windows and roofing (2.0 - 2.9);

- double brickwork, standard roof, doors, windows (1.1 - 1.9);

- walls, roof, floor with insulation, double glazing (0.6 - 1.0).

Formula for calculating the maximum hourly gas consumption based on the received power:

Gas volume = Qmax / (Qр * ŋ),

where

Qmax - equipment power, kcal / hour;

QR - calorific value of natural gas (8000 kcal / m3);

ŋ - boiler efficiency.

In order to determine the consumption of gaseous fuel, you just need to multiply the data, some of which you need to take from the data sheet of your boiler, part of the construction manuals published in the internet.

Using formulas by example

Suppose we have a building with a total area of 100 sq. M. The height of the building is 5 m, the width is 10 m, the length is 10 m, twelve windows measuring 1.5 x 1.4 m. Internal / external temperature: 20 ° C / - 15 ° C.

We consider the area of the enclosing surfaces:

- Floor 10 * 10 = 100 sq. m

- Roof: 10 * 10 = 100 sq. m

- Windows: 1.5 * 1.4 * 12 pcs. = 25.2 sq. m

- Walls: (10 + 10 + 10 + 10) * 5 = 200 sq. m

Minus windows: 200 - 25.2 = 174.8 sq. m

The value of the thermal resistance of materials (formula):

R = d / λ, where

d - material thickness, m

λ - coefficient of thermal conductivity of the material, W / [m • ° C].

We calculate R:

- For the floor (concrete screed 8 cm + mineral wool 150 kg / m3 x 10 cm) R (floor) = 0.08 / 1.75 + 0.1 / 0.037 = 0.14 + 2.7 = 2.84 (m2• ° C / W)

- For the roof (sandwich panels made of mineral wool 12 cm) R (roof) = 0.12 / 0.037 = 3.24 (m2• ° C / W)

- For windows (double-glazed window) R (windows) = 0.49 (m2• ° C / W)

- For walls (sandwich panels made of mineral wool 12 cm) R (walls) = 0.12 / 0.037 = 3.24 (m2• ° C / W)

The values of the thermal conductivity coefficients for different materials were taken from the reference book.

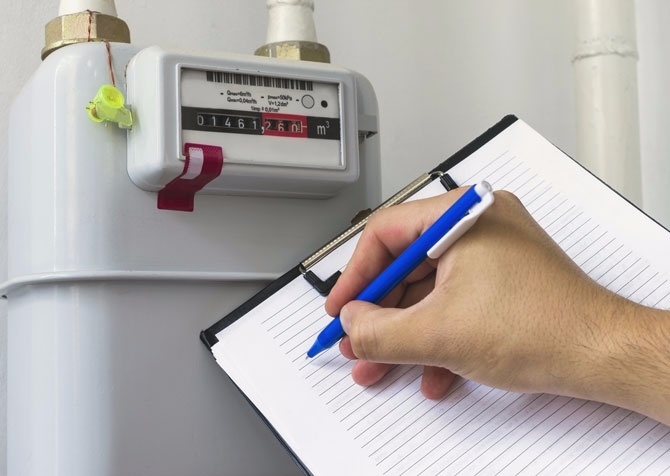

Get in the habit of regularly taking meter readings, recording them and doing a comparative analysis, taking into account the intensity of the boiler, weather conditions, etc. Operate the boiler in different modes, look for the optimal load option

Now let's calculate the heat losses.

Q (floor) = 100 m2 * 20 ° C * 1 / 2.84 (m2* K) / W = 704.2 W = 0.8 kW

Q (roof) = 100 m2 * 35 ° C * 1 / 3.24 (m2* K) / W = 1080.25 W = 8.0 kW

Q (windows) = 25.2 m2 * 35 ° C * 1 / 0.49 (m2* K) / W = 1800 W = 6.3 kW

Q (walls) = 174.8 m2 * 35 ° C * 1 / 3.24 (m2* K) / W = 1888.3 W = 5.5 kW

Heat loss of enclosing structures:

Q (total) = 704.2 + 1080.25 + 1800 + 1888.3 = 5472.75 W / h

You can also add heat loss to ventilation. To heat 1 m3 air from –15 ° С to + 20 ° С requires 15.5 W of thermal energy. A person consumes about 9 liters of air per minute (0.54 cu. meters per hour).

Let's say there are 6 people in our house. They need 0.54 * 6 = 3.24 cubic meters. m of air per hour. We calculate the heat loss for ventilation: 15.5 * 3.24 = 50.22 W.

And the total heat loss: 5472.75 W / h + 50.22 W = 5522.97 W = 5.53 kW.

After spending heat engineering calculation, we first calculate the boiler power, and then the gas consumption per hour in the gas boiler in cubic meters:

Boiler power = 5.53 * 1.2 = 6.64 kW (rounded up to 7 kW).

To use the formula for calculating gas consumption, we translate the resulting power indicator from kilowatts to kilocalories: 7 kW = 6018.9 kcal. And we will take the boiler efficiency = 92% (manufacturers of modern gas floor boilers declare this figure within 92 - 98%).

Maximum hourly gas consumption = 6018.9 / (8000 * 0.92) = 0.82 m3/ч.

The boiler is powered by a gas tank or cylinder

The formula Gas volume = Qmax / (Qр * ŋ) is suitable for determining the need for various fuels, incl. and liquefied gas. Let's take from the previous example the obtained indicator of the boiler power - 7 kW. If such a boiler requires 0.82 m3/ h of natural gas, how much propane-butane will then be required?

Approximately once a week with gas cylinders you will have to go to a gas station, which means transportation costs and loss of personal time. An unpleasant surprise can also bring a drop in temperature below zero, if the gas cylinders are on the street. In a frozen cylinder, the gas does not freeze, but it also does not evaporate, turning into a liquid. And the boiler stops working

To calculate, you need to know what its calorific value is. Ud. the heat of combustion (this is the calorific value) of liquefied hydrocarbons in megajoules - 46.8 MJ / kg or 25.3 MJ / l. In kilowatt-hours - 13.0 kW * h / kg and 7.0 kW * h / l, respectively.

Let's leave the efficiency of a gas heating boiler equal to 92% and calculate the hourly gas demand:

Gas volume = 7 / (13 * 0.92) = 0.59 kg / h

One liter of liquefied gas weighs 0.54 kg, per hour the boiler will burn 0.59 / 0.54 = 1.1 liters of propane-butane. Now we consider how much liquefied gas is consumed by a gas boiler per day and per month.

If the boiler works for 16 hours, then 17.6 liters per day, 528 liters per month (30 days). A typical 50-liter bottle contains about 42 liters of gas. It turns out that our house with an area of 100 m2 you will need 528/42 = 13 cylinders per month.

A gas tank with a volume reserve allows you to save on gas. The cost of refueling is growing in the fall, while the spring is a period of price reductions. Try to fill the tank as much as possible in the spring

Installing a gas tank is much more convenient than replacing empty cylinders with full ones. It is enough to refuel the gas tank 2-3 times during the whole heating season.

How to minimize gas consumption

To give less money for the gas consumed by the floor boiler and not round your eyes in amazement at the sight of the next payment, follow these recommendations.

First, pay attention to condensing boiler - the most economical for today. Its efficiency reaches 98-100% and higher. The price is high, but it will pay off and soon pay off. For each model, read customer reviews.

If you do not need water heating, take a single-circuit boiler. In a two-circuit system, the gas demand includes an additional 20-25% that you do not need.

Secondly, conscientiously insulate not only the walls, but also the roof, floor with foundation and basement. Install energy-efficient double-glazed windows on the windows. Use a thermal imager. All cold points must be found and eliminated. At the entrance to the house (corridor, hall, hallway), build a warm floor.

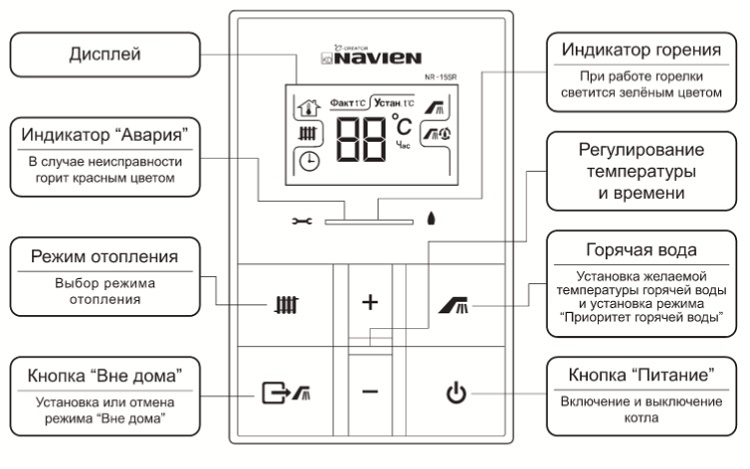

Third, use timers and sensors. The temperature you set for heating the air in the room will be automatically regulated - for example, the batteries will heat up at night and cool slightly during the day.

If you decide to leave the house for a week, you can set the heating system for the duration of your absence to a minimum, with the return of normal operation by the time of arrival. Once a year, an inspection is needed to clean up blockages and scale from the heat exchanger, traces of soot from the burner, soot from the chimney.

Do not use the boiler to its maximum. Its passport data contains 10-20% of the power reserve for emergencies, record cold winters. Do not rush to switch the temperature controller one more division. A trifle, but the average monthly gas consumption will be reflected

Fourthly, install a buffer cylinder in the heating system, which will contain a certain supply of heat carrier (hot water). Due to this "thermos", feeding the batteries for some time when the boiler is off, it is possible to save up to 20% of fuel.

Fifth, do not ignore proper ventilation. A window sash that is constantly ajar will bring more heat out into the street than a window that is wide open for five minutes.

Conclusions and useful video on the topic

The videos below are about gas consumption for floor standing boilers.

Heating with liquefied gas (propane). Fuel consumption, personal experience:

Gas consumption of a floor-standing gas boiler HOT SPOT 12 kW (user review):

Gas is a demanded energy resource, the problem of saving both the resource itself and the funds to pay for it does not lose its relevance.

Reasonable gas consumption means a good economical boiler, professional installation of the heating system, and the fight against heat loss. The high efficiency of the unit is a guarantee of long-term savings on gas costs.

If you doubt the accuracy of independent calculations, ask for help from a qualified specialist who knows the smallest nuances of the formulas. His authoritative opinion will save you from mistakes both at the design stage of the heating system and during its operation.