The three-way valve is a device widely used in a wide variety of designs of household and industrial devices. Accordingly, the same kind of device is used in household gas equipment. Along with various malfunctions of household gas boilers, users often encounter a breakdown of a three-way valve. Agree, it would be nice to find out why this device fails and try to fix it on your own.

Meanwhile, it is not always possible even for professional mechanics to establish the loss of device performance "at first sight". This requires an appropriate check. Therefore, within the framework of our article, we will consider how to check a three-way valve in a gas boiler when there is a suspicion of a malfunction of this mechanism. Let's also talk about the types of the device and its functionality.

The content of the article:

- Briefly about the mechanism of the three-way valve

- Functional use of the device

-

How is the 3-way valve test performed?

- Step # 1 - check valve actuator

- Step # 2 - checking the thread allocator

- Conclusions and useful video on the topic

Briefly about the mechanism of the three-way valve

The device of a three-way valve for a household gas boiler and other gas equipment is quite simple, despite its seemingly complex shape. It should be noted that the design of the valves differs significantly for each manufacturer, but the principle of operation actually remains unchanged.

Traditionally instrument case made of bronze. Work items such as stock, springs - are made of steel. Membrane usually made of rubber double ring element. Connecting parts (fittings) can be threaded or soldered, depending on the model of the three-way valve.

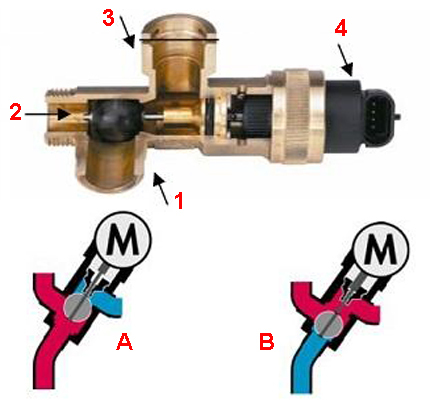

One of the widespread versions of the three-way valve: 1, 2 - angular through passage transport channel; 1, 3 - straight through transport channel; 4 - drive head; A - transport of streams in heating mode; B - transport of streams in hot water supply mode

Usually, an electromechanical drive is used in conjunction with the device. Thanks to its work, two-point control is carried out.

So, the actuator for a three-way valve can be manual, electromechanical (thermostatic, with a thermal head), electric, hydraulic.

The principle of operation of a three-way valve for a gas boiler circuit is approximately the following: when the device is in the mode of normally open transport, direct passage transport channel, respectively, open. The corner duct remains closed.

A different state of the mechanism ensures the opening of the angular transport channel and blocking of the direct transport channel, respectively. Intermediate positions of the stem and flap of the three-way valve are also possible.

We talked in more detail about the device and principle of operation of the three-way valve in following material.

Functional use of the device

If we consider the flow switching mechanism from the point of view of possible functionality, it should be noted that the devices differ according to the principle of operation:

- Separating.

- Switching.

- Mixing.

The separation principle of operation involves dividing the flow, directing it into two circuits.

The switching function provides for the organization of switching between devices that consume thermal energy. For example, switching between DHW and heating double-circuit gas boiler.

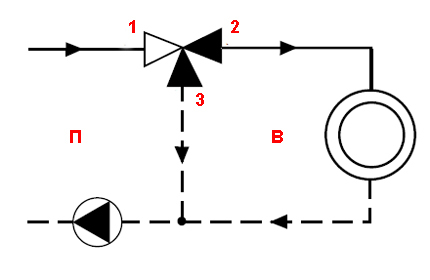

Switching valve functionality (classical scheme): P - primary circuit; B - secondary circuit; 1, 2 - direct transport channel; 3, 2 - corner transport channel

Switching functionality allows you to organize efficient switching between different devices that generate heat energy:

- water heaters;

- heat pumps;

- solar panels, etc.

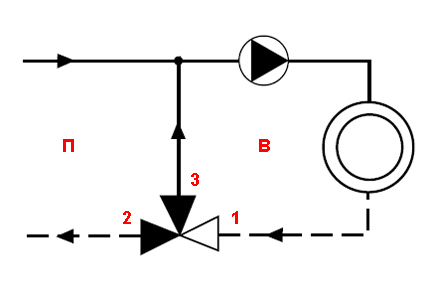

Another function of a three-way valve for a domestic gas boiler is mixing. It allows you to organize controlled mixing of the working fluid flows (mixing the return flow into the heated coolant).

To do this, it is enough to install a three-way valve on the return pipe of the heating system.

Mixing valve functionality (classical scheme): P - primary circuit; B - secondary circuit; 2, 1 - direct transport channel; 2, 3 - corner transport channel

Now, after a brief acquaintance with the structural details of the device, you can consider the features of checking the operation of the three-way valve installed in gas boiler diagram.

How is the 3-way valve test performed?

A malfunction of the device affects the operation of the gas boiler as a whole. For example, if the supply of the coolant is insufficient, the gas boiler may simply turn off due to overheating. Or, a malfunction of the three-way valve may be accompanied by a lack of proper heating temperature of the coolant in the heating system.

In any case, the device needs to be checked for operability. In this case, in order to carry out diagnostic measures, the regulating device of a gas boiler, as a rule, must be dismantled. Dismantling is relatively uncomplicated, so such work may well be done on its own.

Step # 1 - check valve actuator

Next, we will walk through the verification process step by step, starting by checking the drive. Consider the features of diagnostics of valves with different types of actuators.

Diagnostics of the three-way valve electric drive

The valve stem is traditionally driven by an electric actuator. Therefore, the integrity, availability of power, and the operability of the drive should be checked first.

The integrity of the outer part is checked visually by careful inspection, and the presence of power and the integrity of the internal mechanism - with appropriate instruments.

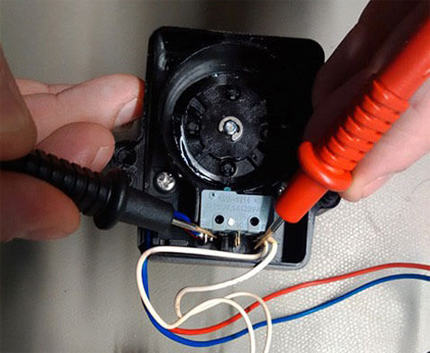

Diagnostics of the drive end of a three-way valve of a gas boiler using a widespread electrical device - a tester

The drive and all elements of this part of the structure are usually diagnosed with an electrical tester. With this device, you can check both the continuity of the circuits and the presence of the supply voltage. A serviceable actuator must demonstrate the working process when the supply voltage is applied / disconnected - the movement of the valve stem pusher.

It is permissible to check the operation of the electric drive by directly connecting the mechanism to the electric current network, using for this the connector that comes with the drive. This point is clearly highlighted in the video located at the end of the article.

Checking the thermostatic head

If the design of the three-way valve does not provide for the presence of an electric actuator, but is controlled thermostatic head, you need to check this part of the system by applying the temperature effect directly to the sensor cylinder.

Thermostatic head supplemented with a temperature cylinder. On some models of gas boilers, three-way valve designs are equipped with this type of actuator

For example, you can heat the thermostatic head cylinder using an electric hair dryer.

A working thermal head should respond to temperature changes and push / pull the valve stem in the same way as an electric actuator does this work.

Checking a Hydraulically Operated Unit

If a valve is used in the gas boiler system that regulates flows and acts on the principle of a hydraulic control of the rod, it is enough to carry out diagnostics of the operability of such a device directly in the boiler system hard.

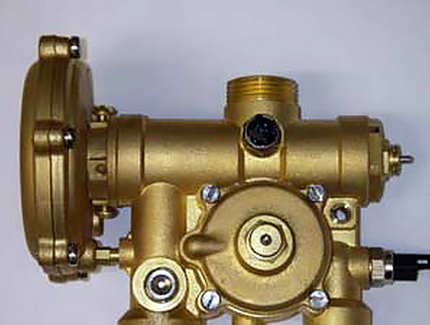

The design of the separating device of a gas domestic boiler, endowed with a hydraulic drive of the control rod. This type of device is quite widespread.

Usually, this kind of structure is subject to dismantling and disassembly, followed by a check of integrity:

- springs;

- seals;

- membranes;

- rings.

Suspicions of the inoperability of the three-way valve, in this case, can be confirmed by starting the gas boiler in test mode. If, at the same time, a violation of the thermal distribution along the working circuits of the system is noted, the valve is not working correctly by 90%.

Step # 2 - checking the thread allocator

The mechanism of the device can wear out during operation. In addition, during the transportation of the coolant, the accumulation of various debris, deposits, etc. in the system is characteristic.

All this can block the operation of the device. Therefore, first of all, it is required to carry out visually checking all available parts.

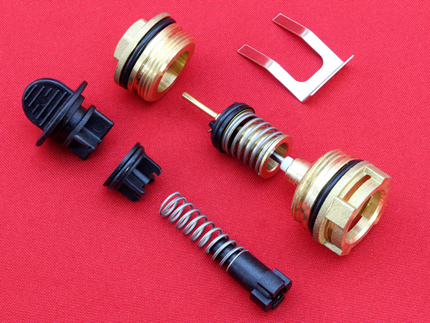

Parts of a three-way valve of one of the manufactured designs, which are subject to inspection in case of suspicion of a malfunction of the control device

Next is executed checking the normal stroke of the diaphragm. As a rule, being in working order, the rod moves smoothly, with some interference. Travel can be verified by applying light force to the end of the stem (actuator outlet) that exits through the valve body capsule orifice.

If the factors of the wedge of the stroke of the rod along the entire length are not noted and the rod independently returns to its original position from the stop point, then this part of the switchgear is operational.

Finally, the elements of the seals are checked - ball or diaphragm, depending on the design. Whereas rubber seal diaphragms usually exhibit tearing defects, ball seals can deform over time. The deformation factor leads to the loss of a full-fledged seal, respectively, the flow regulation algorithm by the device is violated.

Conclusions and useful video on the topic

Below is a useful video material for review, which demonstrates the disassembly of a device that regulates heat flows in a gas boiler. Moreover, the practice of disassembling with your own hands is given.

The distribution device described in the video is equipped with a hydraulic stem drive. Familiarization with this repair practice will help you understand how to check devices of a similar type and repair if defects are found.

Thus, a three-way valve for a domestic gas boiler can be tested in almost any design, regardless of the individual design. The main point is to correctly determine with which drive the switchgear of the gas boiler is used. Information on this issue can be obtained from the documentation for the equipment or by relying on the examples of the drive demonstrations in this article.

Do you have useful information on the topic discussed above and would like to share it with other users? Write your remarks and comments in the block below, add photos, leave your recommendations - the feedback form is located below.