We are already accustomed to frequent breakdowns of washing machines, microwave ovens, dishwashers, air conditioners, vacuum cleaners, refrigerators. But relatively simple and well-designed technical products rarely fail. Therefore, the situation when the gas water heater ignites and goes out for many users will be unexpected, right? This type of equipment belongs to the category of reliable and durable devices.

But is it worth worrying and calling the master? In this article, we will talk about the reasons for such a breakdown, look at common and rare situations. We will figure out how to independently adjust the operation of the heater and when it is better not to do this, but immediately contact a specialist. We will also give recommendations on how to prevent the occurrence of malfunctions.

The content of the article:

-

Reasons for the decay of the column after ignition

- Reason # 1 - breakdown of the flame ionization sensor

- Reason # 2 - the membrane of the water unit is worn out

- Reason # 3 - the wick is clogged with dust

-

Why does the speaker turn off during operation?

- Poor or no traction

- Accumulation of soot on the heat exchanger

- Clogged shower head and hose

- Other sources of the problem

- Methods for preventing malfunctions

- Conclusions and useful video on the topic

Reasons for the decay of the column after ignition

When identifying the cause of the malfunction, it is important to pay attention to two points: how does the ignition fade out (are there any extraneous sounds); this happens immediately after ignition or already in the process of combustion.

Reason # 1 - breakdown of the flame ionization sensor

If the device turns on and goes out, the ionization sensor is to blame for 70%.

This element is constantly in contact with the flame. Ions generated during combustion are attracted to the sensor and generate current. If there are enough ions, the device works. If there are few of them, the column does not function.

The ionization sensor is a thermocouple that is heated by a flame. It is also called a gas sensor because it prevents the appliance from leaking when the burner is off.

Malfunction symptoms:

- the burner went out 3-5 seconds after ignition;

- when restarted, the device works longer;

- it is worth starting the device several times and it already functions normally;

- problems appear only after a long break.

It is necessary to inspect the wiring that runs from the part to the control board. Why check all contacts. Then we unscrew the retaining screws, place the heating electrode at the hottest point of the flame.

Such a technique can extend the life of the sensor by another year. If everything is in order with the contacts and connection, the element needs to be replaced.

Reason # 2 - the membrane of the water unit is worn out

The polymer part must have sufficient elasticity. Over time, this property is lost - the element becomes hard, cracks, and becomes overgrown with scale.

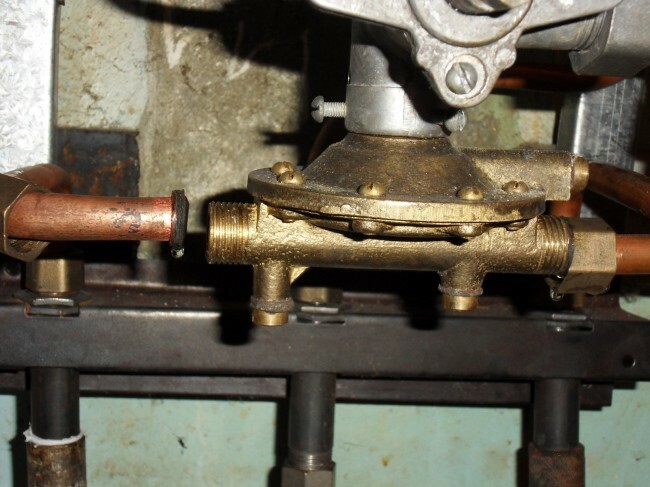

The water block or "frog" is a fairly simple device. The cover is fastened with screws, which can be unscrewed to reach the membrane

If the element becomes unusable, the heater will go out. Need to inspect and replace the membrane if necessary, for a more durable silicone.

Reason # 3 - the wick is clogged with dust

In models with an igniter, this part is often clogged. The flame becomes weak and a yellow tint appears. But a change in the color of the flame may also indicate a lack of air in the gas-air mixture.

The result is that the device is either not at all capable of igniting the burner, or performs its function after a large volume of fuel has been supplied. In the latter case, a characteristic pop is heard.

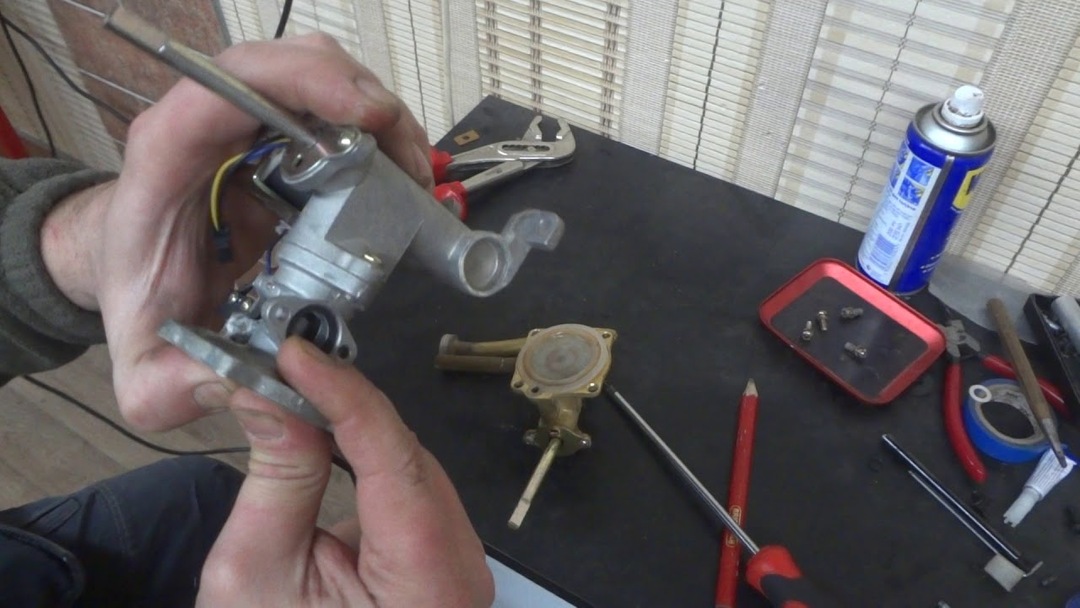

To clean the element, you will need two screwdrivers (Phillips, slotted) and an adjustable wrench.

The algorithm is as follows:

- Remove the case - take out the adjusting knobs, unscrew the bolts in the corners from the bottom, lift and remove the cover.

- We unscrew the thrust sensor tube and the one that supplies fuel to the wick.

- We unscrew the screws and disassemble the structure.

- We clean the nozzle, blow through the tee, assemble.

There may also be a blockage in the draft sensor, which causes the igniter to smoke. After removing dust and dirt, the igniter should burn with a stable blue flame.

The appliance may make a little noise after cleaning. The sound is emitted by air, which is sucked in through slots in the wick guide cover. There is no danger, but the noise can be eliminated by slightly tightening the wick with the screws

If desired, all structural details can be washed. But do not forget to dry them well before assembling.

Why does the speaker turn off during operation?

If the gas water heater ignites normally, but for some reason goes out during operation, this may indicate a serviceable functionality of the device's security system.

There is a sensor in the design of the column that is triggered when the internal temperature rises. Inside the system, there are two plates that repel each other, stop the power supply, turn off the column. This happens when the internal temperature rises quickly and uncontrollably.

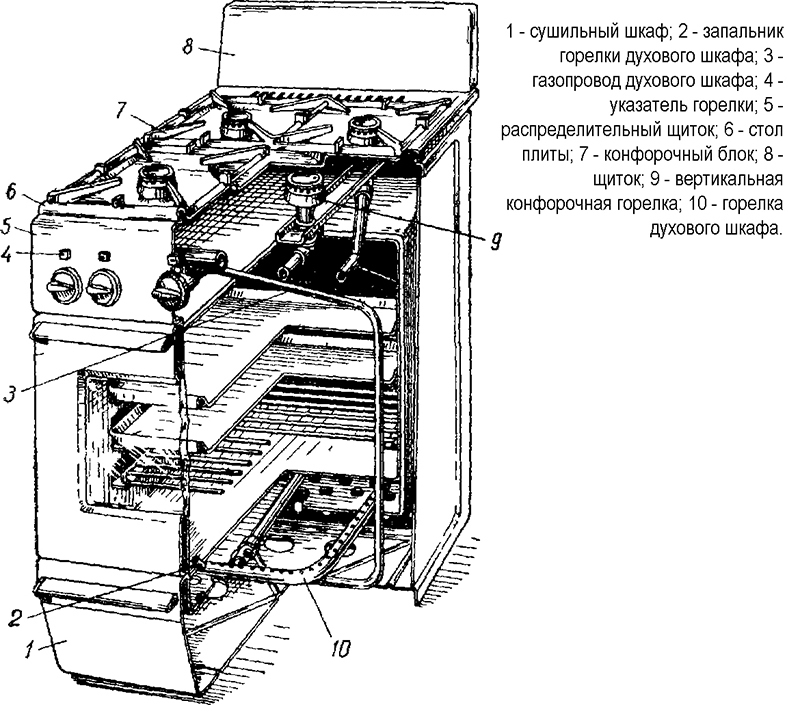

The geyser's automation system includes three sensors: draft, flame, overheating. Plus two valves: gas and discharge. They ensure safe operation of the device

You can check the sensors by resistance. A defective part shows an infinity sign. When a different value is highlighted, we call the wizard.

If the device works long enough, and then turns off, check the settings. Sometimes users accidentally set an automatic shutdown after a certain time.

What else leads to disconnection:

- poor water or gas pressure;

- violation of contact between the thermocouple and the solenoid valve (you need to clean the contacts, tighten the connections);

- oxidation of the contacts of the power supply when the device clicks, but does not light up.

It is also useful to check the batteries. Standard replacement of power supplies held every six months. The batteries keep the charge longer.

Poor or no traction

The accumulation of combustion products is most often associated with the clogging of the chimney with soot, soot, debris. When there is no thrust or it is insufficient, the development is not output.

To check the traction, you need to bring a burning match, a lighter to the control window of the column. If the flame deviates to the side, there is a thrust. It remains to burn exactly - it is not there

It is important to remember that the flame can go out due to external factors - gusts of wind, for example. The thrust in the mine increases or decreases also under the influence of a draft.

You can clean the chimney through the "pocket" located 25 cm below it. If such manipulations did not help, call the utilities.

Accumulation of soot on the heat exchanger

The heat exchanger accumulates soot, soot, scale during operation. When it becomes clogged, the color of the flame changes from yellow to blue.

How to clean the heat exchanger:

- Remove the cover.

- We unscrew the screws holding the casing.

- We shut off the water supply.

- We open the mixer to drain hot water.

- Disconnect the heat exchanger thread and the tap. You will need a stand - water may flow.

- Prepare a solution of hydrochloric acid (3-5%).

- Take a 1/2 ”pipe or use a hose.

- We connect one end to the input, the other to the output.

- Pour the solution into the funnel. If foam appears when rinsing, this is normal.

- As soon as a strong pressure appears at the exit, we stop the procedure.

During work, be sure to wear gloves. After descaling, thoroughly rinse the heat exchanger to remove acid residues.

If, during the cleaning process, defects were noticed on the tubes, then it is necessary to perform heat exchanger repair.

You can use citric acid to descale the heat exchanger (you need 80 g of powder for 700 ml of water). Boil the radiator in the solution for half an hour, leave to cool and rinse

Cleaning work is recommended to be carried out once a year. Regular service will help the device to function normally.

Clogged shower head and hose

It happens that the gas water heater turns on and for some reason immediately goes out when you switch to the shower. This may be due to clogged watering holes.

You need to unscrew the watering can, clean and rinse the holes. Soaking metal elements in citric acid solution is also effective.

Scale on the watering can is caused by the increased hardness of tap water in some regions. To prevent this from happening, put filters or buy a mixer with a shower equipped with a built-in anti-scale system

The next part, due to which the wick can go out, is the shower hose. If it is entangled or clogged, the head power decreases and the column goes out.

The mixer can also break or become clogged. You need to disassemble it, check it, clean it if necessary.

At the entrance to the water supply unit, there is a filter that traps small debris. It is also useful to clean it periodically. To do this, unscrew the screws, remove the element, rinse, clean with a brush with citric acid.

Other sources of the problem

Let's consider other problems causing the problem of column attenuation after firing up.

The extinction of the wick may be due to the presence of powerful ventilation near the column. The exhaust air is drawn into the ventilation, which leads to attenuation. It is necessary to turn off the ventilation or screw its power to the minimum for the duration of the gas heater operation.

For the same reason, you should not place a powerful hood next to the column. During its operation, sensors can be triggered, diagnosing a malfunction.

Sometimes the reason is hidden in the absence of natural ventilation. You need to open the window or install supply valve.

The extinguishing of the wick can also occur in models with piezo ignition. The button must be held for at least 10 seconds.

"Smart" gas water heaters may not light up due to a burned out control board. They are sensitive to the quality of the electric power supply, so they must be connected through a stabilizer and not turned off at night.

Also, during the operation of the heater, it is not recommended to mix hot and cold streams. This leads to a drop in line pressure and attenuation of the wick.

The problem is solved by adjusting the indicators to a comfortable level and reducing the pressure with a special handle. If you still have to mix water, you need to leave the main hot stream.

Attenuation can cause malfunction of the solenoid valve or servo motor. Only the call of the master will help here.

Methods for preventing malfunctions

When buying a device, you should pay attention to the indicators of the minimum water pressure, which is required for the normal functioning of the device. Passport data must be compared with indicators water pressure in the apartment.

For the column to work properly, you must:

- once a year or more often, carry out preventive work;

- inspect the chimney a couple of times a year and clean it if necessary;

- clean parts from scale, soot;

- provide adequate ventilation.

And do not forget to change the batteries in time.

Conclusions and useful video on the topic

How does a gas water heater work: the principle of operation of the device:

How to correct the position of the flame adjustment sensor:

Analysis of two not obvious reasons why the gas column can turn on and immediately go out:

How to diagnose a malfunction by removing the heater cover:

The main problems with heater fading are listed. In most cases, they are independent of the device model or manufacturer. Some you can handle yourself. But if you are not sure about this, it is advisable to contact a service center or gas service.

Would you like to tell about your personal experience in diagnosing the cause of the attenuation of the column and the method of your own repair? Or do you have questions that we have not covered in this article? Write your comments, participate in the discussion - the feedback form is located below.