Have you ever filed a situation where a suspicious smell came from a gas boiler? If it seems, then it does not seem! Gas is widely used for domestic purposes.

More than once we have seen in news programs how its leak caused poisoning, asphyxiation and even explosions with victims. Correct actions in case of gas smell in the boiler room will help you to avoid the listed catastrophic and negative situations.

We will show you how to identify a leak and pinpoint its cause. You will learn how to proceed if the entry of blue fuel into an enclosed space is detected. Our recommendations on the proper operation of gas equipment and the prevention of leaks will ensure the safety of you, your household, and your property.

The content of the article:

- Signs and Causes of Gas Leaks

- Leak detection

-

Leak detected: what to do?

- Shut off the gas supply

- Mandatory room ventilation

- Do not light electricity, do not allow sparks

- Informing the alarm center

- Eliminating the problem and further threats

- Standard boiler faults

- Prevention for safety

- Conclusions and useful video on the topic

Signs and Causes of Gas Leaks

The most common gas used is methane, which is supplied by pipeline. Since natural methane is odorless, it is odorized - supplemented with gaseous compounds that do not affect the “flammability” and flammability. But thanks to natural gas odorants we can sense the presence of gas in a confined space.

A strong characteristic odor is the first sign of gas spreading throughout the room. Gas can be heard in some cases. Each gas supply system operates under pressure. Whistling or hissing may be heard when leaking.

Natural gas is odorless. To be able to detect leaks, odorants are used - additives with a characteristic unpleasant smell of rotten eggs

The gas is completely invisible to human eyes. However, this will not be a problem to visually locate the leak. First, you should assume where the gas is coming from. If the intended place is chosen correctly, then when smearing it with soapy water, bubbles will appear.

It is harmful to breathe in gas vapors - the head immediately begins to hurt, dry mouth and a feeling of suffocation appear. That is why, in case of an unreasonable deterioration in well-being, the first thing to do is to check the gas equipment. It often happens that a gas leak is the real reason for feeling unwell.

In most cases, the exit of gas from the pipes becomes the cause of not household, but professional defects associated with poor-quality installation of equipment.

Let's consider the main reasons why a gas boiler can smell of gas:

- Improper use of equipment.

- The internal connections of the boiler are loose.

- The nut of the connecting gas hose has loosened or the threads have worn off.

- Cracked rubber hose.

- The boiler installation technology has been violated.

- The boiler is malfunctioning.

- The gas cock has already run out of time, so the blue fuel supply is not completely shut off.

- O-ring in the gas cock is worn out.

- The gasket in front of the gas hose is torn or loose.

Unfortunately, it is not always possible to repair a gas boiler on your own. Yes, if the malfunction is noticeable and simple, there are no questions. However, a complex breakdown can only be dealt with by a foreman from a gas supplying organization with which an agreement has been concluded for the maintenance and supply of gaseous fuel.

Leak detection

The method for locating a leak is extremely simple. You just need to dissolve the soap in water and whip up the foam. A brush is taken, the solution is applied to the alleged problem areas. First of all, the gas pipes, the faucet and the connections between the boiler and the meter are checked.

The solution will begin to foam at the leak. With a strong leak, there will be a lot of bubbles. If the bubbles inflate slowly and are small, look elsewhere. gas leaks. Yes, there was a depressurization here, but all the equipment needs to be checked. In the place of depressurization, a characteristic whistle may be present.

The slightest spark can ignite the gas at the point of leakage. Strike with matches or a lighter, even turn on the lights or just a flashlight - the gas will explode. If it is not possible to shut off the fuel supply, immediately leave the premises and call an emergency worker

If there is a smell in the boiler room, it is imperative to identify the malfunction of the gas boiler. If a pungent smell comes from the boiler itself, you will have to find out what is out of order.

If there is a strong smell from behind the boiler, there may be a problem with the shut-off valve. If the boiler is off but odor is present, the source is most likely the hose and its connection.

If, when removing the boiler casing, the smell intensifies, then the problem is a possible depressurization of the internal gas pipeline.

Leak detected: what to do?

Natural gas can pose a serious threat. He himself has neither color nor smell, but is characterized by psychotropic effects. A person may not notice the new smell and take timely action.

What to do if it smells menacingly of gas from a gas boiler? The main thing is not to panic. Reckless, hasty actions can lead to serious, often irreversible consequences.

Plastic windows contribute to the rapid accumulation of gas. Their airtight seals interfere with the natural flow of air from the street. When leaving home, be sure to leave the windows ventilated.

Basic Procedure for Gas Leaks:

- Shut off the gas supply, if possible.

- Open all windows and doors to ventilate the room.

- Do not use electricity or open fire in a gas-polluted room.

- Leave the danger area.

- Inform about the danger gas service.

People should be taken out of the building, and pets should be taken care of. Only after leaving the danger zone can you call the emergency service.

Shut off the gas supply

Your actions depend on where the gas comes from. If the reason is an extinguished fire and an unclosed gas control valve, this is the easiest option. You just need to shut off the gas supply. If the pipeline is damaged, then the valve is shut off, through which gas flows into this pipeline.

Mandatory room ventilation

The boiler room should be ventilated quickly to prevent the formation of an explosive mixture. If an explosion does occur, opening doors and windows will help reduce the damage.

After making sure that gas is no longer flowing, it is enough to ventilate the room for 30 minutes. This time is enough to replace the air with clean air.

Do not light electricity, do not allow sparks

Even an electric spark can be a source of ignition. This is enough to ignite the gas in the room, followed by an explosion. To prevent this scenario, after detecting a gas leak, it is impossible not only to turn on, but also to turn off electrical devices and pull the plug from the outlet.

Household gas explodes if its concentration in the room reaches 5-15%

Please note that every time you turn it on or off, small sparks appear at the contact points. If a light is on in a gas-polluted boiler room, it is safer to leave it on than to turn it off. Shutdown may cause sparks.

Such situations can occur in kitchens, since wall-mounted gas boilers are often installed here. The refrigerator poses the greatest threat from an electrical point of view. The fact is that the compressor periodically turns on and off in it. The process is accompanied by a spark. The safest way is to turn off the electricity in the entire house or apartment.

Informing the alarm center

When informing the alarm center, the following information should be provided:

- What happened (smell, explosion, visible damage).

- Where the smell of gas is noticed or where an accident occurred (in the basement, indoors, in the boiler room).

- Availability of valves to shut off the pipeline leading to the leak.

- What electrical equipment works in the room.

- The presence of sources of open flame (stove or fireplace).

- When the leak was found.

- Your contact details.

If, after shutting off the gas supply and ventilating the room, the gas concentration has not decreased, it is necessary to urgently evacuate people from the house.

The gas cock (yellow), which cuts off the blue fuel supply, is usually located right next to the boiler. Your task is to close it as quickly as possible, and not to look for a leak +

As strange as it may sound, there are many people who, due to negligence or ignorance, light matches. They argue their actions with the desire to find the place where the gas is coming from. If the concentration of methane is too high, even an explosion is possible.

It doesn't matter when you found a gas leak day or late night - call emergency services. If the valve is closed, but the gas continues to flow, all people must leave the premises before the arrival of emergency workers.

Damage from a gas accident is hundreds of times more critical than from a fire. Unconscious actions of one person have more than once become the cause of the destruction of apartment buildings.

Eliminating the problem and further threats

Only a competent gas service technician certified to work with gas equipment should work with gas equipment. It is not recommended to repair a gas boiler with your own hands. Depending on the place of depressurization, a method of eliminating the leak is selected.

Defects in gas pipes cannot be corrected by yourself. Using the tool can strike a spark and provoke an explosion

In case of leakage through the threaded connection, it should be unscrewed, remove the remnants of the sealant, gaskets and winding. Old gaskets and rings are replaced with new ones.

After assembling the connection, a check is carried out using a soapy solution. If a leak is found in the hose, it must be replaced.

Standard boiler faults

The smell of gas appears when it is incompletely burned. There may be several reasons:

- Incorrect installation of the jets (yellow or red flame).

- Air regulation knocked out (yellow or red flame).

- The fan operation sensor is faulty (blocking the boiler operation).

- Fan speed too low (blocking the boiler operation).

- The heat exchanger is clogged (blocking of operation or too low heating).

When repairing a gas boiler with a gas leak, any manipulations with parts and assemblies should be performed with extreme caution.

Prevention for safety

Accidents must be prevented, otherwise the consequences will have to be eliminated later.

Compliance with the rules of prevention is the key to safety:

- All gas appliances should be purchased in good working order with a warranty from the manufacturer. Appropriate certificates must be attached to the equipment.

- If you need to install or configure a gas boiler, always contact gas workers, with whom you should conclude a contract for equipment maintenance and gas supply. Craftsmen must have permission to work of this type.

- The master servicing the unit must periodically inspect the gas equipment.

- Gas equipment must always be clean.

- Check the condition regularly flue gas boiler and the performance of the smoke exhaust system.

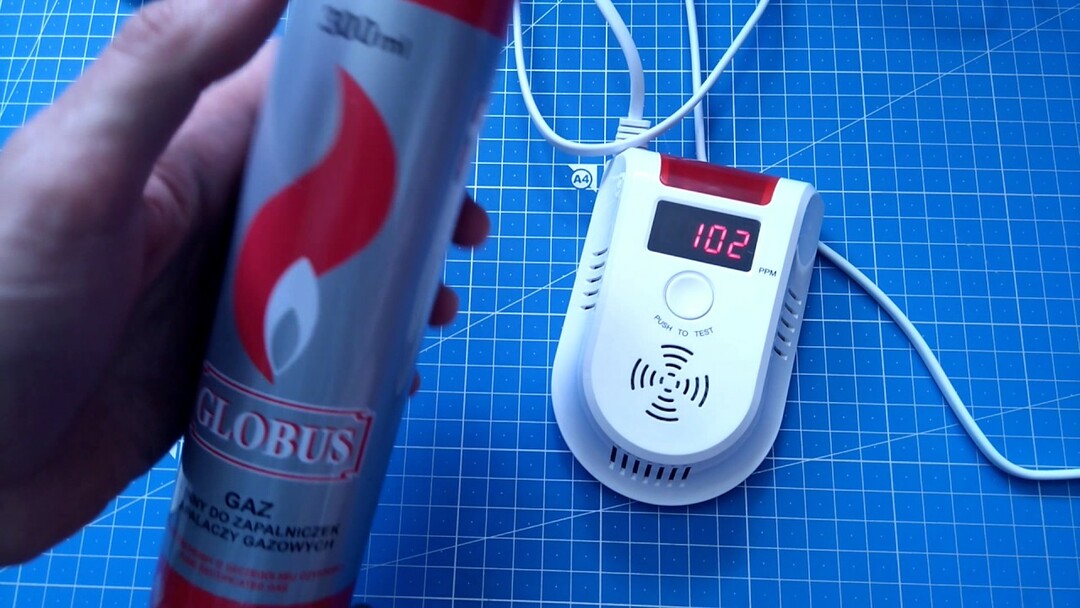

Buy a gas leak alarm to prevent leakage. The gas analyzer instantly reacts to the appearance of a toxic substance in the surrounding space.

Household gas analyzers differ in sensitivity equal to those of gas workers. The assortment presented to the consumer includes stationary and mobile devices, devices with sound and light alarms

The gas analyzer is installed in the boiler room itself or in the kitchen next to the gas water heater or boiler. More expensive models are equipped with a function to automatically turn off the fuel supply when the gas concentration in the room is exceeded. The slightest leak is detected by sensors, after which the gas supply to the combustion chamber is blocked.

The owners of the gas boiler are responsible for the general condition of the equipment. They can clean all components from carbon deposits, for which maintenance it is not necessary to disassemble the case. It is impossible to replace devices on your own; all work must be performed by locksmiths and gas workers from the gas supplying organization.

The owners are responsible for the safety of operation between scheduled maintenance of gas equipment. Maintenance should be done every 36 months. For equipment that is covered by the warranty, it is recommended that maintenance be performed every year.

Conclusions and useful video on the topic

An efficient way to detect gas leaks:

Whether you have at least one hundredth boiler in a row, always read the instruction manual. Perhaps the manufacturer has come up with something new. The best way to repair is to call a gasman. Blue fuel jokes are bad. Don't skimp on qualified service. Excessive frugality can turn sideways.

Do you want to share your own experience in leak detection and timely action taken to prevent catastrophic consequences? Do you want to share useful information on the topic of the article? Please write your comments in the form below, post photos and ask questions.