Even the most careful and careful use of gas can lead to accidents. Its leak is a serious problem, which is vital to know before the concentration of gas in the room reaches a critical level.

A good gas leak detector with shut-off valve is an almost indispensable device that can prevent tragedy. Such a device not only signals an emergency, but also prevents its development by shutting off the fuel supply. After its installation, every homeowner will feel more confident and calmer.

In this material, we will talk about the device of a sensor with a shut-off valve, consider the structure and principle of operation, and give practical advice on selection and installation.

The content of the article:

- Features and types of household gas sensors

- The device and principle of operation of the valve

- The subtleties of choosing a gas analyzer

- Gas leak detector installation

- Conclusions and useful video on the topic

Features and types of household gas sensors

At its core, a gas leak detector is a small, sometimes mobile device that reacts to changes in the composition of the air in a room. A special shut-off element (valve), complementing the device, makes it possible to stop the fuel supply in time if its excess is found in the air.

A gas leak monitor equipped with a shut-off valve can alert owners of a leak by audible or light signals. Some models can work in the system "Smart House».

Gas analyzers that are integrated into the smart home system are able to inform the owner of a leak by sending messages. Additionally, installing a special application on a smartphone allows you to monitor the air condition in real time

The presence of a cut-off device makes the work of the gas analyzer extremely autonomous: the sensor will automatically shut off the gas supply without human intervention, which is especially convenient if the homeowners are not at home. Additionally, modern devices can turn on forced ventilation in the room and transmit an alarm signal to the appropriate services.

The device itself consists of the main functional units.

- primaryconverter - a sensor that captures gas in the ambient air and records its concentration;

- measuringmodule - reads information from the primary converter and compares it with the permissible nominal values;

- executive unit - a valve that directly stops the supply of blue fuel;

- battery - power supply unit, battery or galvanic cell.

The sensor can react to various types of gases, so that the detectors can be classified according to the type of fuel absorbed.

Devices can be of the following type:

- analyzers of natural gas content;

- carbon dioxide detectors;

- detecting sensors carbon monoxide;

- combined devices that react to different gases.

The latter type is more popular, as it makes it possible to fully monitor the safety of the air composition.

Combined gas leak detectors usually detect the presence of methane and carbon monoxide in the air, signaling that the permissible concentration of these substances is exceeded.

Additionally, modern devices are also divided according to the method for determining the gas concentration:

- Catalytic Gas Analyzers (or thermocatalytic) - their surface of the sensitive element is covered with a catalyst layer (tin dioxide, platinum, palladium). The gas, which increases in concentration during a leak, is oxidized by atmospheric oxygen, which causes heating. Which, in turn, is a signal for the sensor to be triggered.

- Semiconductor detectors are triggered by a sharp decrease in the resistance of the sensitive element made on the basis of tin oxide. The resistance decreases with an increase in the concentration of CO, which is further oxidized. To ensure the speed of the sensor, a heater is provided in its design - a resistive layer of inert materials.

- Electrochemical sensors with solid or liquid electrolyte - the former use a solid electrolyte in conjunction with a heater, and the latter use an acidic or alkaline solution as a sensitive element.

- Infrared sensors set the current concentration of the fuel by analyzing the medium that is within the infrared spectrum.

By the way of power supply, gas analyzers are wired and wireless. The former operate on the network and are dependent on the availability of electricity. Sensors of the second type function due to the battery, are more reliable due to their autonomy.

Equipping the device with a shut-off valve significantly expands the functionality of the device and makes its operation more rational. After all, just one shut-off valve that worked on time can save dozens of lives. Therefore, it is worth dwelling on the principles of operation of this unit in more detail.

The device and principle of operation of the valve

The most popular for domestic use are solenoid and pulse operated slam-shut valves.

Locking mechanism solenoid valve allows you to immediately block the fuel supply when an emergency leak is detected. The unit is mounted at the entrance to the gas pipeline. As soon as the sensor detects the maximum rate of gas concentration, the mechanism closes the electrical circuit, after which the valve closes.

The slam-shut valve is a fairly small unit. Usually, after triggering, it must be re-cocked manually, after which it will be ready for operation again.

Gas analyzers with valves designed for use in a house / apartment, cutting off gas due to the operation of an electrical impulse, work in a slightly different way. The valve is in the open position thanks to a mechanical latch. If the sensor detects a leak, a short current pulse is transmitted to the solenoid coil, after which the latch is triggered, and the valve itself moves to the closed position.

Valves of this type are conventionally divided into normally open (NA) and normally closed (NC). The device of the first type does not provide voltage supply to the coil, gas cutoff occurs when the sensor is triggered. In the second case, to open the valve itself, an impulse is required, and the gas is cut off by the valve when the voltage in the coil disappears.

NA valves are more suitable for home use, as even an unexpected power outage will not shut off the gas. Additionally, gas analyzers with similar valves are considered more economical: if the constant maintenance of the voltage in the coil, then for the functioning of the NA valve in the open state, the power supply is not needed.

The subtleties of choosing a gas analyzer

The selection and purchase of a gas analyzer with a shut-off valve requires a responsible approach. You should not save on the sensor, because such a technique should last for years. Therefore, the search for the cheapest device is not always justified.

In inexpensive models, sensors are often used that lose sensitivity too quickly and become unusable. This happens especially often with models ordered on the popular Aliexpress website.

For domestic conditions, users most often choose sensors that respond to the outflow of natural gas, which arrives at apartments on the highway or located in liquefied state in cylinders.

In addition to the type absorbed by the device gas type the user should pay attention to such important characteristics inherent in a high-quality analyzer:

- limit value gas concentration, at which the device signals an emergency;

- ability to analyze gas content in volume and mass fraction in the air;

- possibility fixing the current state of air at several points in the room;

- autonomy of work and her time;

- possibility tracking increase in concentration various types of gas.

An equally important role is played by manufacturer's reputation and reviews real users. Detailed gas analyzer reviews will help you select the best model for your specific application.

Warranty service Is an equally important component of the service. It is worth paying attention and cost of spare parts, their availability in stores.

Since the gas leakage sensor is almost always in sight, it is also of great importance. appearance. In addition to the aesthetic component, it is worth considering such characteristics of the case as moisture and dust protection.

Additional functions will be useful for a modern gas analyzer, for example, automatic switching on forced ventilation systems or sending an emergency notification of a gas leak to the owner's phone housing

An acceptable glazing valve is selected for its key characteristics:

- valve type - NA. or NC .;

- nominal bore diameter;

- type of food;

- the threshold of the permissible gas pressure.

All the necessary information about the valve is indicated in its passport and on the label.

As stated above, normally open valves are more ergonomic to operate. However, when paired with a sensor, which, when turned on, will automatically check its own outputs, sending a pulse, an unplanned fuel shutdown can occur without the occurrence of leaks. Therefore, before purchasing a gas analyzer, it is necessary to study the sequence of its operation.

Gas leak detector installation

Only a certified gas service technician may install the slam-shut valve. And in the case of unauthorized installation of the valve on the gas pipe, the consumer faces fine for interfering with the gas supply system.

But the installation of a sensor that signals a gas leak can be done independently. When placing the device, it is necessary to rely on the recommendations from the passport for the device. This document contains all the information necessary for connection, describes the connection diagrams for additional devices.

Traditionally, the device is fixed on the wall in the place where fuel leakage is most likely. This can be a zone near a gas water heater or boiler, stove, meter, in the attachment points of which leaks can often form. In this case, the distance from the gas equipment sensor should be no more than 1.5 m.

The sensors are mounted quite easily: usually, to fix the device with dowels, it is not even necessary to disassemble the analyzer case

The height at which the sensor is mounted depends on the type of gas being analyzed, since different fuels have their own weight and are concentrated in the air at different levels. You should also be guided by the recommendations given in the instructions for a specific model of the gas analyzer. For example, for methane, the installation distance is set within 0.3-1 m from the ceiling.

The sensor for propane and other gases that are heavier than air is mounted at a height of 0.3-1 m from the floor. For combined devices that measure the concentration of methane and carbon monoxide, a location 0.3-0.5 m to the ceiling is suitable.

It is strongly not recommended to install the sensor in the following places:

- near a window or opening in the ventilation system;

- near an oven or gas burners (distance up to 1 m);

- in an area subject to the accumulation of dust, fumes, grease or ash produced during the cooking process;

- in rooms used for storing paints and varnishes, gasoline, all kinds of solvents.

In addition, you can find out about the location of the sensor-signaling device in the project documentation for gasification and other regulatory documents of the gas service.

Conclusions and useful video on the topic

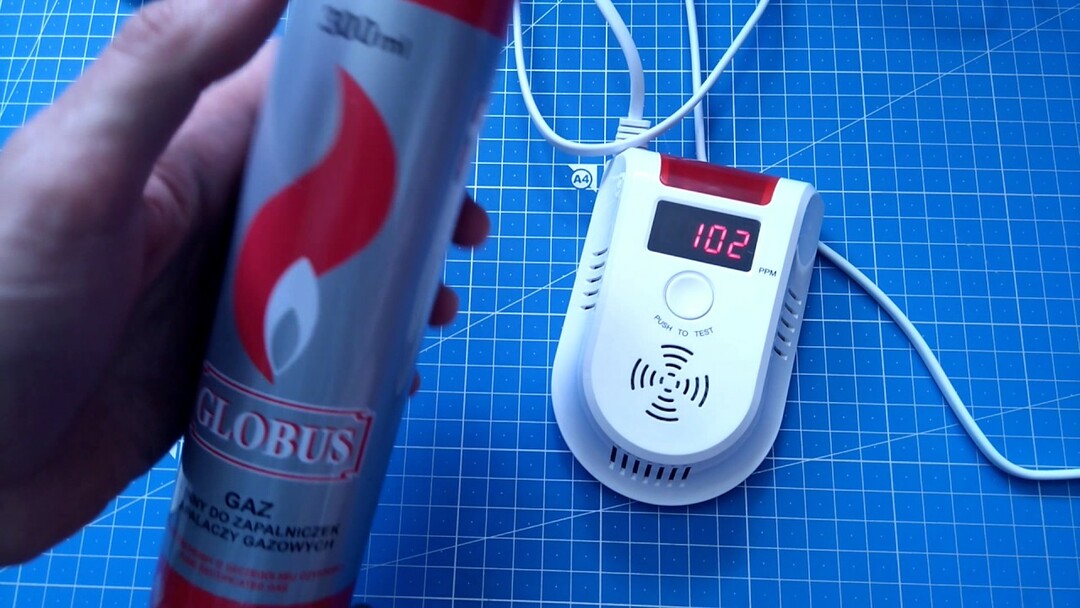

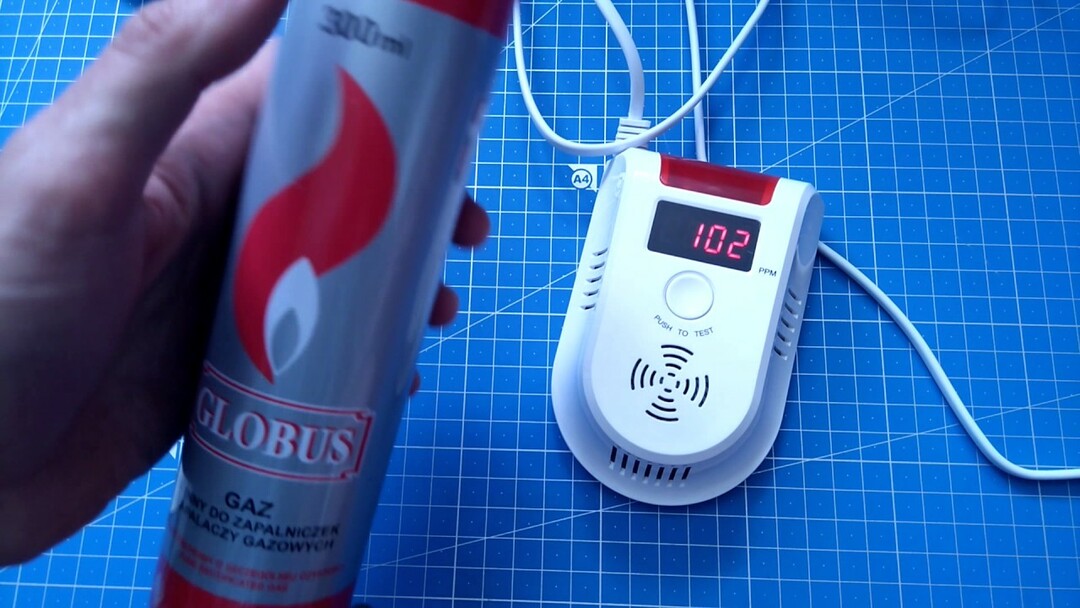

An example of how the gas leak sensor is triggered and the fuel supply is cut off is shown in the video below:

Installing a reliable, high-quality gas analyzer, complete with a shut-off valve, can be a key point in preventing gas leaks. Indeed, a timely detected fuel leakage can not only reduce material damage in the event of explosionbut also save someone's life. Therefore, in the realities of the state of the modern gas supply system and subject to the increasingly common malfunctions in the gas equipment itself, users of familiar fuel should seriously think about their security.

Are you using a gas leak detector? If so, please share with our readers your experience and impressions of using it, tell us if you are satisfied with its work, how often false positives occur. Write your recommendations, add a photo of your gas analyzer, ask your questions - the feedback form is located just below.