We are sure you have heard a strong smell from the burners more than once. The stench does not mean that the gas stove is leaking gas - you probably know what to do in such a simple situation. The first steps in case of a gas leak are taught in school, but you and your children will be better off if you read this in more detail.

Critical situations are also not uncommon. The likelihood of an explosion decreases as residents quickly and accurately locate the leak and eliminate the cause. It is necessary to study this area at least in order to completely eliminate the risk, right?

If you read the article, you can use one or two signs to determine the cause of the fuel leak. In a short amount of time, you will prevent the worst-case scenario. Certain actions require the intervention of gas workers and foremen, and some of them can be repaired on their own. Find out what exactly.

The content of the article:

- Why is the gas stove leaking gas?

- How to understand that the stove is poisoning gas?

-

Methods for eliminating gas leaks

- Method number 1 - elimination of leaks on the burners

- Method number 2 - repair the handles of the stove

- Method number 3 - replacing the shut-off valve

- Method number 4 - replacing the gas line

- Conclusions and useful video on the topic

Why is the gas stove leaking gas?

Gas stoves are made up of many tubes and assemblies. Any threaded connections will lose their tightness over time, and some fuel will seep through them. The functionality of modern stoves protects from many unpleasant moments, but even they let gas pass. If you constantly use household tools, then effectively and relatively quickly eliminate the leak.

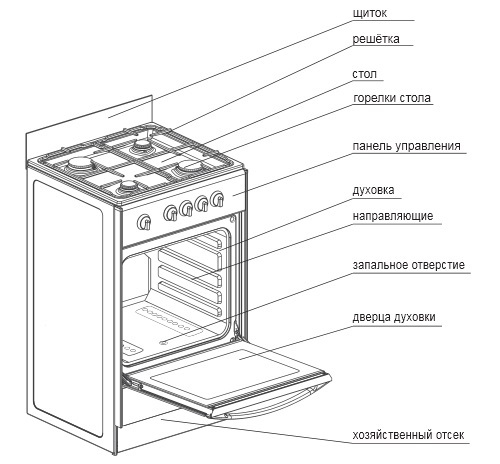

Traditional gas stove has a hob with burners (burners), control knobs, grate, lid and oven. The operation of the equipment is influenced by the correct installation, details, and assembly quality. Due to breakdowns and problems with equipment, gas can partially escape.

The gas stove consists of a hob with burners, a control panel with handles and an oven, and the gas enters the appliance through a supply pipe

The owner should find out where exactly:

- through the burners and their nuts;

- knobs that control burners;

- gas stove shut-off valve;

- hose or place of its connection;

- internal elements.

Unauthorized people lead to problems installation of plateswhich safety rules prohibit. For old gas stoves, some kind of insulation violation is the norm. It is better to replace or repair the equipment through a service center. A defective stove cannot be left unattended when it is switched on. You can rely on built-in protection, but only for a short time.

Consumers experience leaks if there is not enough lubricant in the valve plug or the valve itself is loose. Nuts often loosen and seals wear out. It can be difficult to solve such difficulties, but internal breakdowns also cause great difficulties.

A faulty burner is simply not used if it is not possible to repair or replace with a new one. Gas escape through the burners occurs when the stove is used inappropriately. For example, if liquefied gas is supplied to the device under the gas network.

How to understand that the stove is poisoning gas?

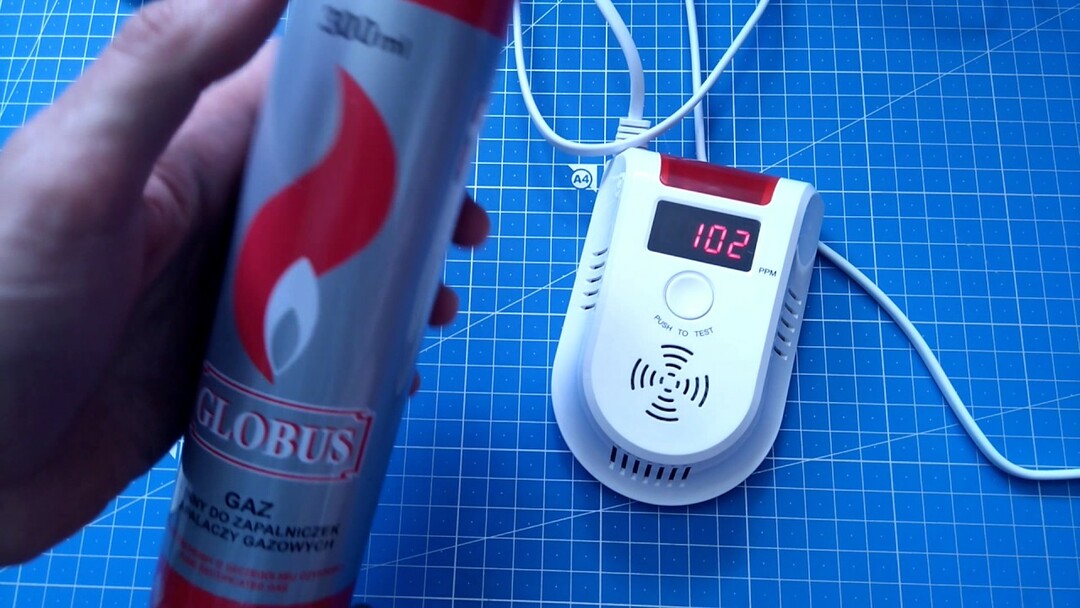

A person does not smell natural gas. The safety of household stoves is increased by the odorant ethanethiol (ethyl mercaptan). The odorant emits a strong, unpleasant odor. Carbon monoxide is produced due to combustion problems. It is also obnoxious, but does not indicate a domestic gas leak directly.

When there is a choice, to ventilate the kitchen or keep it closed in order to hear extraneous odors, it is better to stop at the first option.

Modern stoves have gas control: the system works by a fire sensor and an electromagnetic valve, which acts on a spring and shuts off the fuel supply

The concern about leakage is when the ethanethiol odor is retained in the air for more than 5 minutes, especially during cooking. The gas-polluted room is ventilated. Natural gas will collect in the corners, so there is no point in focusing on perfume. Waving your hand will do nothing.

You can find out about the state of household appliances in 3 other ways:

- manipulations with the stove;

- tightness check;

- by sound.

The hob is switched off to check the burners. If there is a smell of odorant near the burners or if it intensifies, there is a leak in this place. Modern stoves have valves that prevent excess gas from entering the burner and shut off the fuel when the fire goes out.

The accumulated gas will still make itself felt. Methane with impurities will collect under the hob, and the owners will hear it next to the control knobs, control panel joints. In a dangerous situation, emergency service personnel will help.

The slab should be moved away from the wall. An increased odor will indicate a leak at the connection point of the unit. If there is no visible damage, then simply replace the gaskets. New hoses and fittings will be needed if there is a serious defect.

The state of the stove tap is determined by the smell from an open oven. Its strengthening means a violation of the density in the parts, possibly a lack of lubrication.

Gas operators are required to inspect gas appliances in accordance with the contract and at least once a year: they must be required to complete a complete inspection of the stove and supply lines

The tightness test provides comprehensive information on leaks. Use a solution of dish detergent or soap. It is applied to threaded joints of a gas pipe, a hose, pipes under the burners. When the first bubbles appear, it makes sense to shut off the gas and call the gas workers. The wizard will identify all problem points himself.

The gas does not come out silently, so a quiet environment can be created. The pressure in the unit will poison everything that is superfluous outward, and a person will be able to find the approximate place of the leak. The strongest and most dangerous fuel movements are accompanied by a whistle. In a room with a distinct sound of gas, open the window wide and close the door. At the other end of the dwelling, the owners will be the safest.

Methods for eliminating gas leaks

Gas workers sometimes violate the installation rules, which is why leaks appear, interruptions in the flow of gas. You cannot reinstall yourself. Re-installation is requested from the company - the parties maintenance agreement.

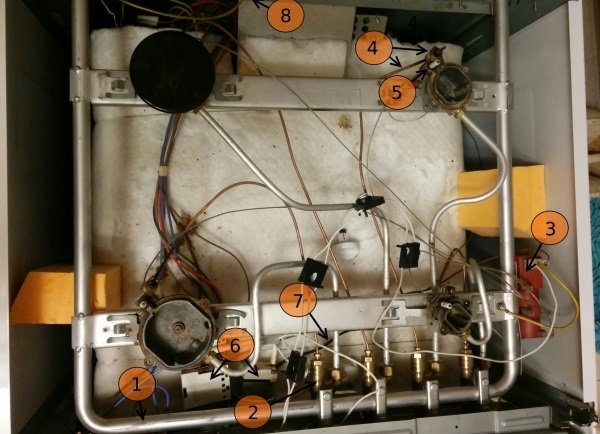

In the case of leaks in the internal nodes, the equipment is disconnected from the gas supply and disassembled, the problem connections are tightened more tightly. It is possible to act alone, but it is better to leave the work to the craftsmen who know how to repair a specific model of the stove.

First, prepare sealing materials, gaskets, pastes, linseed tow, as well as tools and accessories for the stove. All of this can come in handy.

In the figure, the upper part of the plate is disassembled: 1 - collector pipe, 2 - side of the control knobs, 3 - arrester coil ignition, 4 - gas control thermocouple, 5 - spark plug ignition, 6 - selector, thermostat, timer, 7 - temperature sensor tube, 8 - wire grounding

They repair the control panel on their own, burners and a supply hose. In the case of a shut-off valve on the lowering, it is better to immediately contact the gas workers. The problem with the crane arises from a lack of lubrication, wear of gaskets, and looseness.

To breakdown supply tube many factors are cited. Its seals crack, decrease in volume, and wear out. Parts of the hose lose integrity or tightness. The eyeliner should not be constantly moved or touched, put pressure on it. Burners need timely cleaning, panel handles need adjustment.

If everything that you can do with your own hands has been tried, and the gas stove still lets fuel through, then the parts must be assembled in their original position. Then the gas workers will not have any questions.

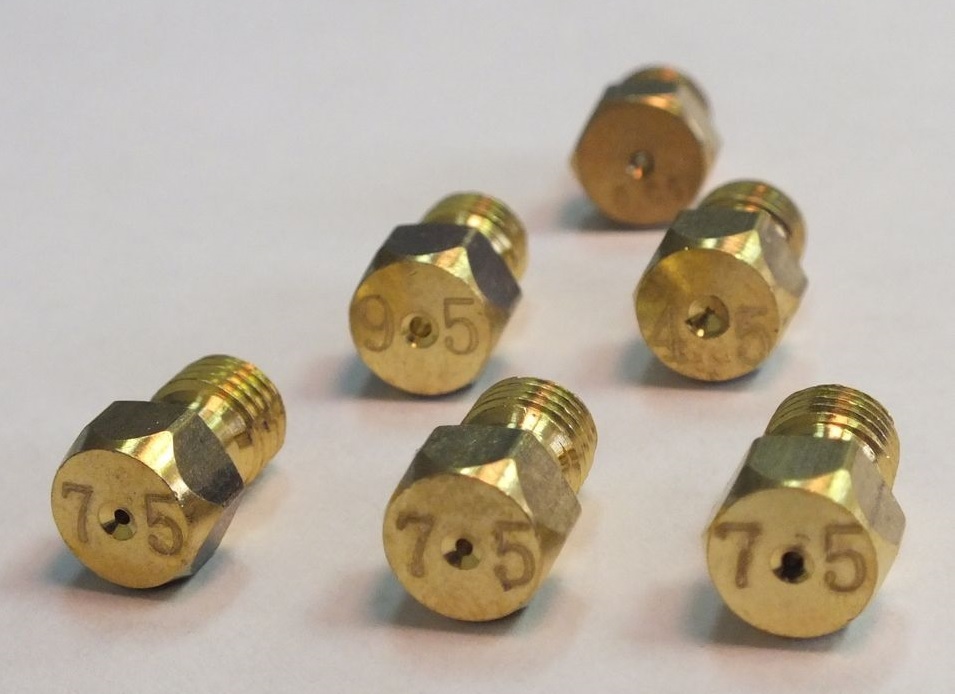

The gas flow is influenced by the size of the burner nozzle. A larger diameter is chosen for fuel from the gas network. Smaller nozzles are better for machines that run on cylinders.

When pipeline fuel is supplied through narrow nozzles for liquefied gas, the burners go out, which causes emissions. In the opposite situation, when gas comes from cylinders and passes through a wide opening, the smell in the room is greatly deteriorated. The internal design of the plate determines the justification for using other nozzles.

A set of jets (nozzles) for the stove burner: to change them, use a Phillips screwdriver, 7 and 8 mm spanners and open-end wrenches

If the oven is powered by cylinders, and there are no leaks anywhere, it is worth checking the capacity. Leaking necks are blocked, wrapped with wet linen cloth, taken out of the house or placed on the far side of the house.

If there is a leak at the connection between the tank and the tube, the joint is insulated with 4-5 turns of a well-moistened rag. The container is left in place. The emergency gas service will deal with the problem. The hose is left in the stove or closed with a pointed wine stopper at the outlet.

In some stoves, ovens also run on gas. The burners of old ovens often go out, thereby endangering the owners.

Method number 1 - elimination of leaks on the burners

Temporary problems with the tightness of the burners are considered the norm. The regularity of this situation cannot be explained by the specific cause of the leaks. The first step is to clean the burners and get rid of fat. The sodium contained in microparticles at high temperatures shines with a bright yellow tint. The substance thereby gives the wrong impression that the device is not working properly.

Burners lose their tightness due to nuts. In this situation, they act simply: the gas is shut off, and the fasteners are tightened all the way. With old slabs, this defect happens often, so you need to be more careful with tools, damaging the thread means making it even worse.

Due to uncleaned burners, leaks and fires occur, at best, the appearance of the cooking will deteriorate, at worst - there will be an explosion

Sometimes the gas exits through the supply pipes inward. To check if there is a leak, the gas is turned off and the hob is removed from the stove. The movement of the fuel is determined by ear or using a soap solution. If there are bubbles, then you will have to tighten all the pipe fasteners more tightly.

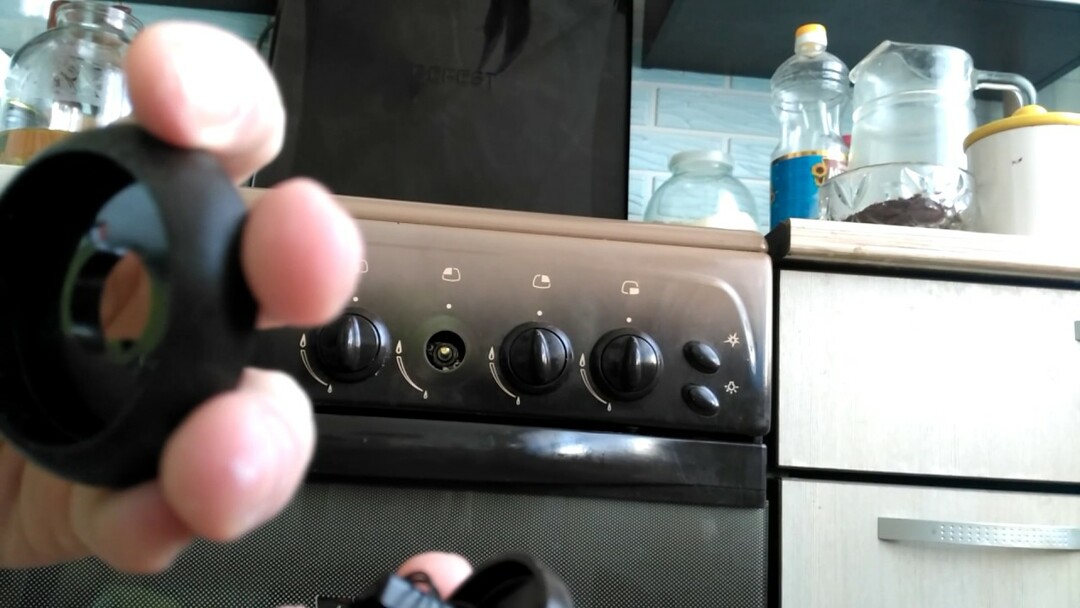

Method number 2 - repair the handles of the stove

In this situation, they partly act independently. Together with the leak, the handles begin to scroll more difficult. Both complications are eliminated by lubricating the control panel mechanism.

The order of independent actions looks like this:

- We turn off the gas.

- We remove the fasteners and remove the control panel and handles.

- We separate the flywheels from the console frame.

- We take out the pin that holds the stem.

- Somehow we fix the position of the plug and the spring in order to further install them as needed. We take out these elements.

- We remove old grease and dirt from the cork. We do without knitting needles and needles. Damage and scratches will exacerbate leaks later.

- Lubricate the cork with a new product, bypassing the holes.

- We clean the stock. We use dry napkins.

- We put the plug as needed, then the spring, at the end we install the stem. Repeat steps 4-9 for each handle.

- We connect a semi-assembled panel without handle caps. Checking her work.

- We install the handles and completely assemble the stove.

If the stove continues to let gas through, then you need to immediately call 112 or 104.

Handles with rigid springs cannot be removed without rough force, in which case you can push the handle of a teaspoon under the pad around the handle

When reassembling, sometimes they experience a problem with a flying out rod. A part pops out of the plug if there is an imbalance in the stud connection or serious damage to the threads.

Method number 3 - replacing the shut-off valve

The problem occurs on different stoves, including new and old ones. It is better to replace the valve. To work, you will need a gas wrench for the stove (No. 1) and the tap (No. 2). All this concerns the valves between the lowering and the supply of the plate, in no case those that are in the middle of the lowering or the pipe from which it departs.

You should act like this:

- First, close the valve.

- We take the key number 2 and catch the crane.

- Using the key No. 1, grab the union nut of the outlet to the plate and unscrew it. We work so that the eyeliner does not twist.

- We take the ring, tightened with soapy water. We bring it to the outlet of the tap. The bubble began to inflate - we call the gas workers. There is no movement - you can try to do everything yourself, but only if you have experience.

Until the gas master comes, you should buy a new tap, flax for sealing, and paste for flax. The gasman will unscrew the valve, close the pipe and insulate it. It will take seconds to install a new crane.

The gasman will connect the new valve to the pipe, set the valve handle in the desired position, connect the hob hose and check the tightness of the connection with soapy water. The joint is usually coated with oil paint.

You can close the pipe with any dense and well-moistened rag, the gas will not be able to squeeze water out of the fabric and the plug will block the entire exit area

Front valve replacement on your own it is worth checking the speed of action. How quickly can you dip wet cloth into a cut half-inch pipe and wrap sealing tape around its threads.

As a result, you will have to remove the old tap, quickly close the pipe and seal it. Then - bring the valve, remove the plug and quickly but carefully screw it on. After - connect the hose for the stove.

In the process, they resort to small "tricks". The old valve is not removed immediately, but partially unscrewed. The entrance is plugged with a wet rag. Gas will go out in a minimal amount. The hole can still be closed with the palm of your hand. The position of the partially unscrewed valve is kept unchanged in relation to the axis, otherwise the thread may suffer. The flywheel is removed from the new crane before installation. This is done for accelerated installation and always in the closed position of the handle.

Method number 4 - replacing the gas line

Tubes for supplying gas to the stove are denoted with a yellow shell or inclusions, sometimes with stickers of this color. Hoses are metal corrugated with a plastic coating and rubber with a metal thread or braid.

The first option has a longer service life, but is prone to segment damage. Both types of hoses sometimes poison the gas, often at the point of connection. Insulation deteriorates in the pipes, damage appears near the fittings and along the entire length.

For small defects, the insulation is restored. In case of serious damage and violation of the integrity of the connecting nodes, they resort to replacing the hose.

Hose lines lose their integrity due to lack of space between the wall and the stove, so in order to extend the service life, you need to buy more flexible pipes and experiment with the angle of attachment to the stove

The gas-pickling tube, which is not damaged, is repaired and done in 2 ways. Worn gaskets are replaced. If it does not help, go to the second method - cover the thread with flax with sealing impregnation.

It is impossible to hide the gas hose in the casing, so if there are visible defects or not, but the gas continues to come out, then the tube will have to be changed.

We connect the new liner like this:

- We put a gasket on the hose fitting and screw it into the stopcock. External or internal thread, depending on the configuration.

- We bring the tube to the outlet of the stove. For a 3/8 "(inch) assembly, use a 1/2" adapter sleeve, which is the size of the hose. The direct connection or adapter is also sealed with a gasket.

- We connect the hose directly to the collector of the plate or to the case. We work with an open-end wrench.

- Check for fuel leaks. Lubricate all links with soapy water and turn on the gas.

The best gaskets for these purposes are considered to be paronite with a metal mesh against pollution. On the side of the connection to the plate, much depends on the straightness of the angle or its inclination. It is worth following this and connecting it so that there is no bending.

A direct exit is inconvenient for the hose, and then a metal elbow is also installed. From the side of the crane on the lowering, additional structures are installed only with the permission of the gas service.

The additional connection on the side of the shut-off valve is useful for the plate on wheels: the adapter will reduce the dangerous load on the crane

Do not hide the hose behind stationary panels or sheets; for this, collapsible boxes are used. Tubes must not be painted anywhere other than at joints. Painted eyeliner sometimes cracks.

You can read detailed instructions on how to replace a gas hose with your own hands in this material.

Conclusions and useful video on the topic

Dismantling the gas stove to find a leak:

Lubrication of control handle valves for elimination or prevention of leaks:

Leaking under the brew - Lubricate, gasket, seal nuts and check for leaks:

You learned what to do if the gas stove starts leaking gas, read about the causes of leaks. In an unpleasant situation, the main thing is to stay calm and find the point where the tightness problems have arisen.

Fuel is poisoned by burners, control knobs, a shut-off valve and a supply hose that is connected to the tap. You can identify a leak visually, by sound and smell, by checking the draft and special manipulations. Normally, there should be no leaks, so immediately think about the operating conditions. Excessive loads on parts and careless installation by a gasman will sooner or later lead to malfunctions.

If you had to fix a gas leak - tell us about your experience. Write how serious the problem was and how you solved it, whether you needed the services of repairmen. Leave comments on the topic of the article. The contact form is located below.