Explosions, destruction and ruined lives are all tragic consequences of improper use of gas equipment. Their likelihood decreases significantly as the leak is quickly identified and repaired. But is it that simple detect a leak?

You have heard many times that the gas smells on its own and when it leaks, the smell comes from it, right? But this opinion is erroneous - a component known as natural gas odorant is added to the final composition for the smell.

The presented article discusses in detail the properties and composition of odorants, the main methods of their introduction to ensure safety both at industrial facilities and in everyday life. The norms of odorization of natural gas, as well as the latest changes in legislation, were scrupulously reviewed. For easy reading, the text is supplemented with videos and illustrations.

The content of the article:

- The main properties of odorants

- Norms and composition of odorizing substances

- Determination of odorization quality

-

Natural gas odorization methods

- Method # 1 - drip injection of a substance

- Method # 2 - using a wick odorizer

- Method # 3 - bubbling odor into the gas

- Conclusions and useful video on the topic

The main properties of odorants

The gas is widely used in everyday life and is capable of provoking severe poisoning, and its high concentration creates an explosive environment. Initially household gas (methane with other impurities, including propane, ethane, butane) is odorless, and any leak from a closed system could only be detected using special sensors.

They solve this problem by adding a component with a pronounced odor to the gas - an odorant. And the direct process of entering the stream is called odorization. Mixing is carried out at a gas distribution station or at centralized points.

Ideally, odoriferous substances should have the following qualities:

- Have a pronounced, specific smell for clear and quick recognition.

- Provide a stable dosage. Odorants must be chemically and physically resistant when mixed with methane and transported through a gas pipe.

- Have a sufficient level of concentration to reduce overall consumption.

- Do not form toxic products during operation.

- The additives should not show a corrosive effect in relation to containers, fittings, which will ensure a long service life of gas equipment and pipelines.

There is no odorant that fully meets all these criteria. Therefore, technical specifications TU 51-31323949-94-2002 and the Operational Regulations were developed for Gazprom. WFD 39-1.10-069-2002. But these are Gazprom's internal documents, which are binding only by organizations that are part of the Gazprom Group.

The document WFD 39-1.10-06-2002 contains the basic requirements for the manufacture, storage, transportation and use of additives.

To neutralize the strong odor of the odorant in the places of its leaks, a solution of potassium permanganate or bleach is used. In this case, you will definitely need a gas mask and other protective equipment.

The correct use of odorants is regulated in the Rules of Operation of Main Gas Pipelines STO Gazprom 2-3.5-454-2010, where it is indicated that the explosive limit of a flammable liquid is 2.8-18%, and the MPC is 1 mg / m3.

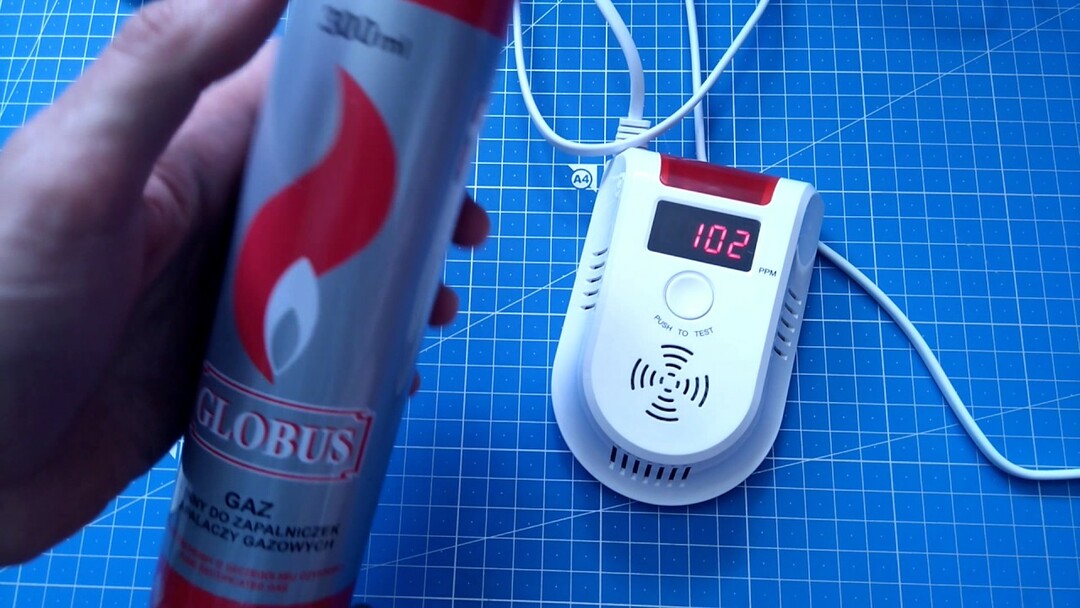

The ANKAT-7631 Micro-RSH gas analyzer can be used to determine the intensity of the odor of the odorant in points, as well as to measure its mass concentration.

Inhalation of vapors can provoke the urge to vomit, loss of creation, in large quantities, the substance causes convulsions, paralysis and death. According to the degree of impact on the body, these are hazardous substances of the 2nd hazard class. Their concentration in a room can be determined using a gas analyzer of the RSH type.

Norms and composition of odorizing substances

Natural gas should be detected by smell in the air when its concentration is not more than 20% of the lower explosive limit, which is equal to 1% of the volume fraction of an organic compound. What to do if your apartment smells of gas, we have described in detail in next article.

The amount of odorant in the gas supplied to the consumer depends on the chemical composition of the mixture.

The Regulations on the technical operation of GDS of main gas pipelines VRD 39-1.10-069-2002 indicate that the commissioning rate ethyl mercaptan equals 16 g per 1,000 m³ of gas.

This odorant was one of the first industrial additives to be used in the former USSR, but EtSH has several significant disadvantages:

- shows easy oxidation;

- interacts with iron oxides;

- has high toxicity;

- dissolves in water.

The formation of diethyl sulfide, to which ethyl mercaptan is prone, reduces the intensity of the odor, especially when transported over long distances. Since 1984, a mixture of natural mercaptans has been used almost throughout Russia, which includes isopropyl mercaptan, ethyl mercaptan, tert-butyl mercaptan, butyl mercaptan, tetrohydrothiophene, n-propyl mercaptan and n-butyl mercaptan.

The odorant complies with TU 51-31323949-94-2002 “Natural odorant of Orenburggazprom LLC”. The rate for this multicomponent supplement does not differ from the recommended amount of ethyl mercaptan.

Loading of barrels for filling with odorant, transportation of hazardous cargo, its rearrangement on the site should be carried out exclusively in a mechanized way. This is done to ensure that there is no damage to the containers, each of which must also be marked.

So called mercaptans produced on the basis of hydrogen sulfide, sulfur and sulfides. But modern production is based on the use of sulfur-free compounds, for example, in Germany they make an environmentally friendly product called Gasodor ™ S-Free ™.

GASODOR ™ S-Free ™ Odorant is based on ethyl acrylate and methyl acrylate, which, when burned, form water and carbon dioxide. Despite good performance characteristics, some polymeric materials can cause a sharp decrease in the concentration of acrylates, and as a result, a decrease in the intensity of the gas odor

This odorant has a pungent specific odor, remains stable even during prolonged storage, does not change its qualities when the temperature changes.

The additive is also highly valued for the fact that it does not dissolve in water. During the tests, which confirmed the suitability of the substance, at one of the domestic facilities of Gazprom, an odorant concentration of 10-12 mg / m³ was used.

Ethanethiol is transported in road and rail tanks, cylinders, containers. The maximum allowable storage volume is 1.6 tons in cylindrical ground tanks, the filling factor should be 0.9-0.95

Crotonic aldehyde viewed as a potential odorant. Flammable liquid with a pungent odor, belongs to the second class of hazard in terms of the degree of impact on the body.

Has several significant advantages over ethanethiol:

- there is no sulfur in the composition;

- differs in less toxic effects;

- slightly volatile under normal conditions.

The maximum level of emissions from crotonaldehyde does not exceed the maximum permissible norm and is 0.02007 mg / m3. The possibility of the practical use of the substance as an odorant has not yet been studied in detail.

Determination of odorization quality

Complaints about the highly regulated norms for odorization of domestic gas are coming in more and more often.

Instead, it is proposed to focus on several factors affecting the quality of natural gas odorization:

- Gas pipeline condition and length. The intensity of the odor may decrease as a result of chemical reactions between the walls of the gas pipeline and the odorant, in which case it will be necessary to increase the rates of introduction of the substance into the gas stream.

- The need to change the rate can also be associated with the specific gravity of mercaptan sulfur in the composition. Knowing its percentage, you can reduce the amount of odorant. In case of poor fuel quality or accumulation of condensate in the gas pipeline, on the contrary, an increase in the concentration of the substance will be required.

- The intensity of the odor is also influenced by the conditions of transportation and storage.. The use of unsuitable containers, including black steel, sudden changes in temperature and exposure to atmospheric precipitation, adversely affect the quality of the odorant.

As for the factor of change in the composition, significant costs will be required for the analysis. It is possible to reduce the unjustified consumption of additives with the help of an automated process of their introduction, this will also allow solving the issue of ecology and safety.

The concentration of the odorant can also be determined in a closed container under pressure. The sensor, the principle of operation of which is based on the hydrostatic method, with the help of a microprocessor control unit calculates the volume, level and mass of liquid

The odorization efficiency also depends on the equipment base, the degree of automation and the mixing method, we will consider the last parameter in more detail.

Natural gas odorization methods

The type of odorant is chosen based on several requirements:

- the required level of accuracy;

- sufficient performance;

- material opportunities.

The additive is used both in liquid and vapor form. The first method involves drip injection or the use of a metering pump. For saturation with vapors, an odorant is introduced into a part of the gas stream by branching or blowing off a wetted wick.

Method # 1 - drip injection of a substance

This input method is relatively inexpensive and simple to use. The principle of operation is based on counting the number of drops per unit of time, which makes it possible to obtain the required flow rate.

To transport gas in large volumes, the droplets are transformed into a stream of liquid; in such cases, a level gauge scale or a special container with graduations is used.

The dropper is used for visual control of the consumption of aggressive substances, including when dispensing an odorant. All parts, including the body, are made of resistant materials

This method requires constant manual adjustment and verification of the flow rate, in particular when the number of consumers changes.

The process does not lend itself to automation, so its accuracy is low - it is only 10-25%. In modern installations, the dropper is used only as a backup in the event of a malfunction of the main equipment.

Method # 2 - using a wick odorizer

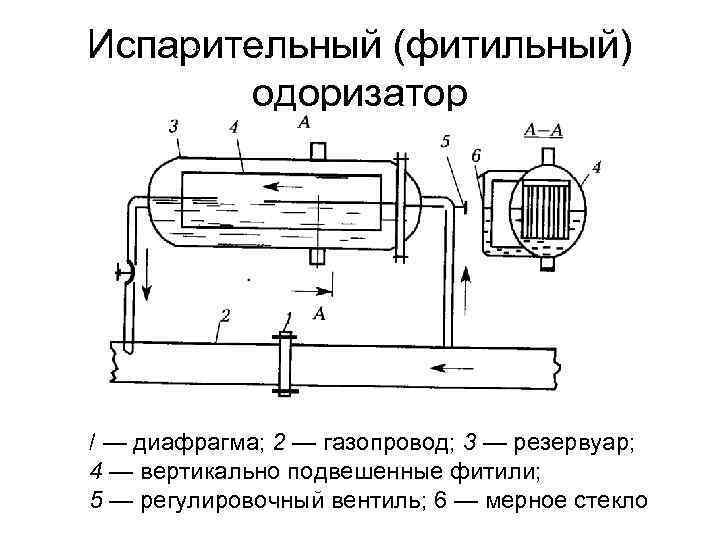

The use of a wick odorizer is another method that is suitable for small volumes of gas. All operations are carried out manually. The odorant is used for vapor and liquid state, its content is determined by the amount of consumption per unit of time.

Evaporation in wick odorizers, unlike other devices, occurs directly from the surface over which the gas passes. The cover often consists of flannel wicks

The flow is controlled by changing the amount of gas that is passed through the wick.

Method # 3 - bubbling odor into the gas

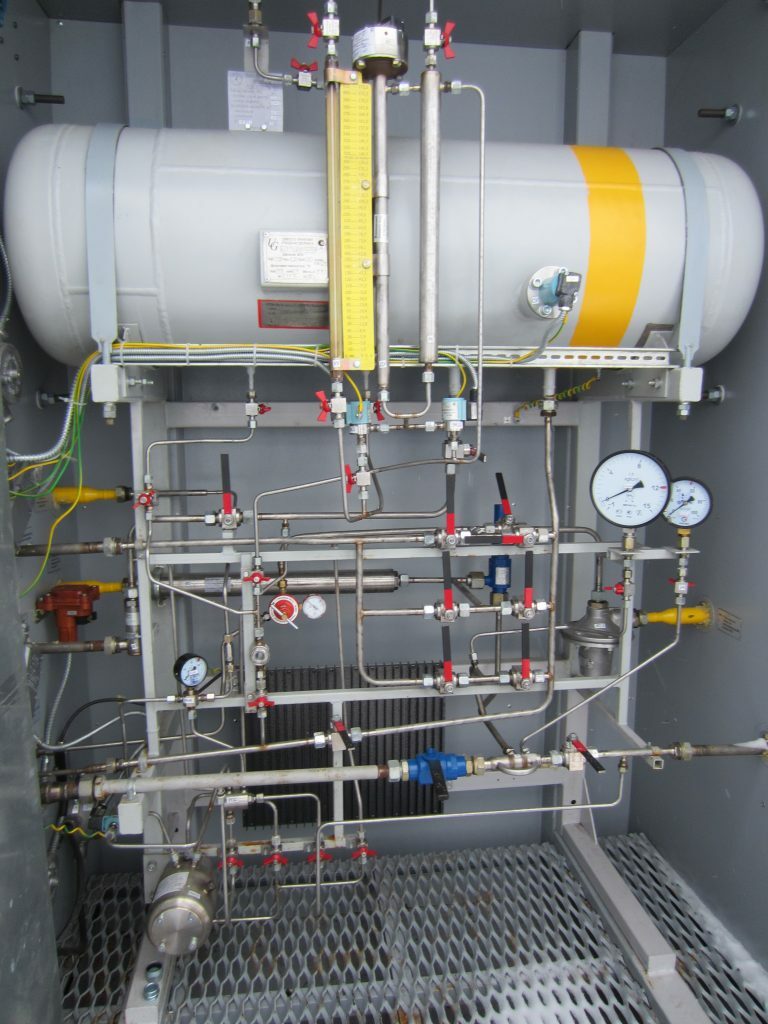

Installations that use bubbling, in contrast to the two previous ones, can be automated.

The odorant is supplied using a diaphragm and a dispenser, its amount is calculated in proportion to the gas flow rate. The substance is supplied by gravity from the supply container. The ejector is responsible for the filling process.

Diagram of a bubbling odorizer. The main elements include the diaphragm, gas line, valve, chamber and filter. Various sizes of devices are produced depending on the performance of the gas distribution station

Among the latest developments to improve the odorization process is the use of metering pumps. They consist of a cleaning filter, an electronic control unit and a control device - a magnet or a valve.

Conclusions and useful video on the topic

An employee of the Museum of Main Gas Transportation will tell you in detail about the transportation of fuel, how and how natural gas is odorized:

An interesting story about the modernization of the odorization unit:

The installation of the odorizing device can be seen in the video clip:

The appearance of a characteristic odor during a gas leak in a room is one of the key conditions safe use gas at home. For the timely detection of unplanned gas release, odorants are used.

The intensity of the gas odor must be sufficient for detection and at the same time not exceed the permissible explosive threshold. As the temperature drops, the smell weakens, so in winter the amount of odorant introduced should be several times lower than in summer.

If you have any questions on this topic or want to add useful information on the odorization of natural gas, please leave your comments. The block is located below the text.