Do you think that the lack of gas in the village is a serious reason to refuse the use of blue fuel? Agree that even in the absence of a gas main, you can always organize the operation of a gas stove, heater or water heater. It is enough to purchase and fill up a household gas cylinder to feel all the benefits of civilization.

We will tell you about the existing types of cylinders, how to properly use a gas cylinder in everyday life. The article we have proposed describes in detail how to connect equipment and refuel an empty cylinder.

More and more frightening news about gas explosions is being heard on TV screens. We have listed all the safety measures for the operation of gas equipment. Knowing the requirements, it will be possible to use gas cylinders without fear and not worry about your life, health and life of loved ones.

The content of the article:

- Types of household gas cylinders

- Advantages and disadvantages of gas cylinders

-

Safe operation of household gas cylinders

- Connecting a gas cylinder to consumption devices

- Safety requirements for the operation of gas cylinders

- What to do if a gas leak is detected?

- Features of the operation of gas cylinders

- Refueling gas cylinders

- Conclusions and useful video on the topic

Types of household gas cylinders

In its overwhelming majority in everyday life, gas cylinders are used to organize the work of kitchen stoves. Therefore, this review will be devoted to just this method of operation.

By the type of material used, gas cylinders are:

- Steel;

- Polymer composite;

- Metal-composite.

The most widespread are steel (metal) cylinders. It was with them that the era of mobile gasification began.

Despite multiple disadvantages (heavy weight, insecurity, susceptibility to corrosion, opacity) it is these cylinders that are in great demand due to their availability and low price.

Steel gas cylinders are distinguished by their availability and the ability to choose a tank of various capacities

Polymer-composite cylinders are 35-40% lighter than steel ones, because fiberglass filled with epoxy resin is used for their manufacture. Such cylinders are explosion-proof and impact-resistant, which are provided by a protective casing.

They are non-corrosive, transparent and equipped with a bypass valve. True, they have a smaller volume than steel counterparts, and their price is an order of magnitude higher.

Polymer-composite gas cylinders, due to the presence of a protective casing, are characterized by high impact resistance and safety

Metal-composite cylinders are a cross between polymer-composite and steel. In terms of safety and impact resistance, they are inferior to polymer-composite products.

Advantages and disadvantages of gas cylinders

To answer the question of whether it is possible to use gas cylinders in everyday life, you need to deal with all their strengths and weaknesses. An autonomous gas cylinder is an irreplaceable thing in the absence of a centralized gas supply.

But it will not interfere with the farm and, so to speak, just in case of fire. After all, it often happens that gas supply is suspended for maintenance and repair work.

The main advantages of using gas in cylinders:

- Mobility - the tank can be transported, rearranged;

- Storage duration - a cylinder filled with gas can be stored for several years;

- Big choice - you can purchase a cylinder of various sizes.

Disadvantages are mainly related to the danger that can arise from connection and operating errors:

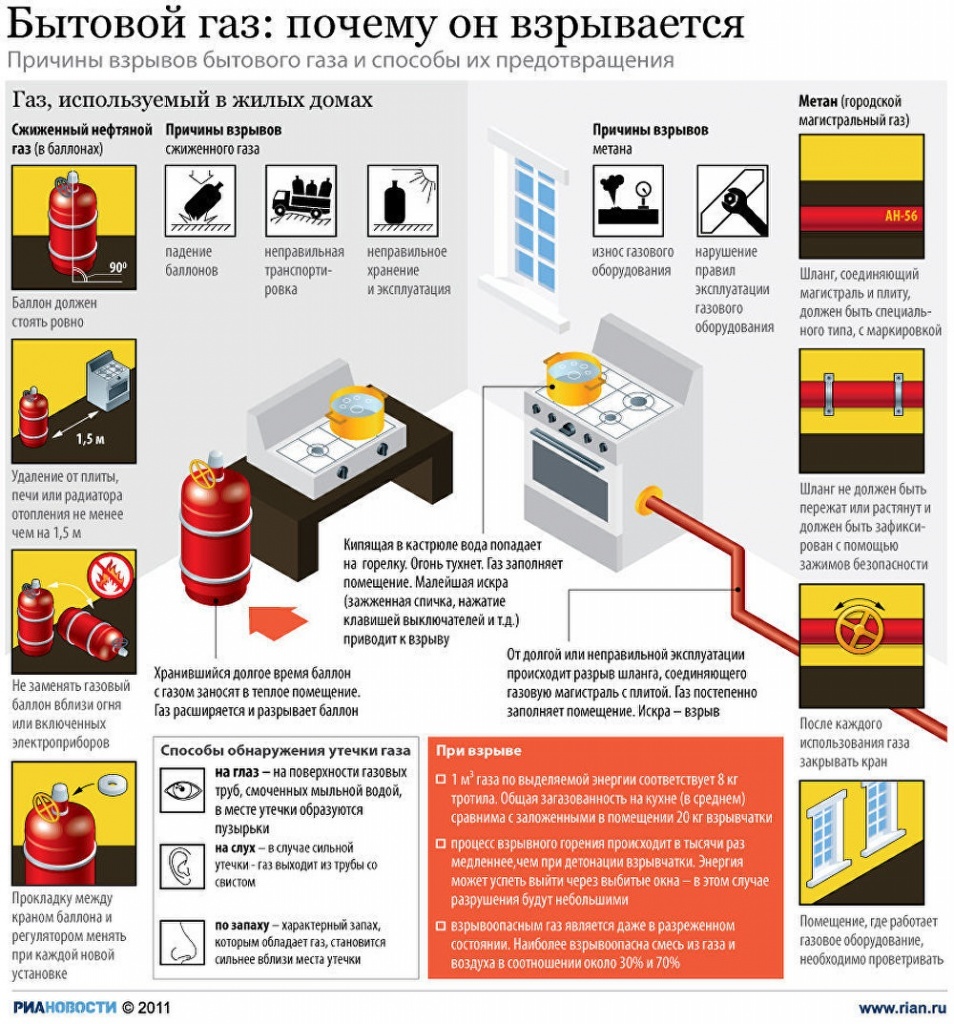

- Fire and explosion hazard. In the event of a sudden temperature jump or fire, a metal cylinder can explode, causing significant damage to the home and health of people in the area of the explosion.

- Risk of inhalation of gas. Cylinders can leak gas, and propane-butane mixture at high concentration can lead to death. This is possible in the event of a leak when the cylinder is in a residential area.

- Danger from sudden overturning. A surge in pressure can cause a sudden burst of flame, which can damage the gas equipment.

When the rules and regulations for the operation of gas equipment are met, the risks from their use are minimized.

Safe operation of household gas cylinders

To figure out how to safely use a gas cylinder, you need to dwell in more detail on their connection, installation, operation and refueling.

Connecting a gas cylinder to consumption devices

It is not enough to have gas bottle and the device to which it will be connected.

Autonomous gasification presupposes the presence of a whole system of equipment:

- A device that will be "powered" by gas (stove, water heater, grill, etc.);

- Gas cylinder;

- Gas hose;

- Reducer;

- Hose clamps.

The pressure in the gas cylinder depends on the temperature and is not constant. Therefore, to align it, apply gas reducer, which not only lowers, but also equalizes the pressure to the value necessary for the normal operation of the equipment.

A simple gas reducer (frog) reduces and equalizes the gas pressure to the norm required for the operation of gas equipment

The reducer is screwed onto the valve union and is connected to the gas consumption device using a hose. All threaded connections are pre-wound 3-4 layers of gas fum-tape. The connecting hose in the place of fixation must be additionally secured with steel clamps.

When connecting threaded connections, you must first wind 3-4 layers of gas fum tape and tighten the nut with sufficient force

All joints should be checked for tightness. The reliability of the connection is checked by applying soap foam - the presence of bubbles indicates insufficient tightness. To eliminate the leak, tighten the nut that connects the fitting to the gearbox with great effort.

If a gas leak is found in the area of the connecting hose, then tighten the clamp bolts. After completing the adjustment, recheck with soap suds. This check must always be performed when connecting the gas cylinder, both for the first time and after replacing it.

Soap solution always helps in identifying insufficient tightness of the joints

Some gas technicians use a lit match to check for gas leaks. This method of testing the tightness is prohibited by safety standards. Firstly, in daylight, small tongues of flame can simply not be noticed. Secondly, a significant gas leak can lead to fire and even an explosion.

Safety requirements for the operation of gas cylinders

One of the most important safety criteria for the operation of a gas cylinder is constant monitoring of overheating and possible leakage. By her own propane-butane mixture has no odor, but the presence of a mercaptan hydrocarbon in the composition makes it possible to detect a leak.

Basic safety requirements for the operation of bottled gas:

- Equipment related to gas consumption must be in good working order. Technical inspection of cylinders should be carried out at least once every 5 years. When connecting the cylinder or replacing it, check the tightness of all connections using a soap solution.

- Do not use cylinders with traces of rust, with a faulty valve, in the absence of a gas marking.

- You need to store the balloon in a special ventilated cabinet that protects the balloon from exposure to direct sunlight and precipitation. The distance from the cabinet to the window or door must be at least 1 m.

- When placed indoors, the distance to a source with an open flame must be at least 5 m. Also, the distance to heat sources (radiators heating, electric heaters, etc.) must be at least 1 m.High capacity cylinders should be placed in a special cabinet on the outside housing.

- It is forbidden to store cylinders in the basement or bury them in the ground.

- In working order, the cylinder must be in an upright position.

- When replacing the cylinder, you need to make sure that there are no sources of ignition.

Never neglect the above rules for the safe operation of bottled gas, as even the slightest violation can endanger life.

What to do if a gas leak is detected?

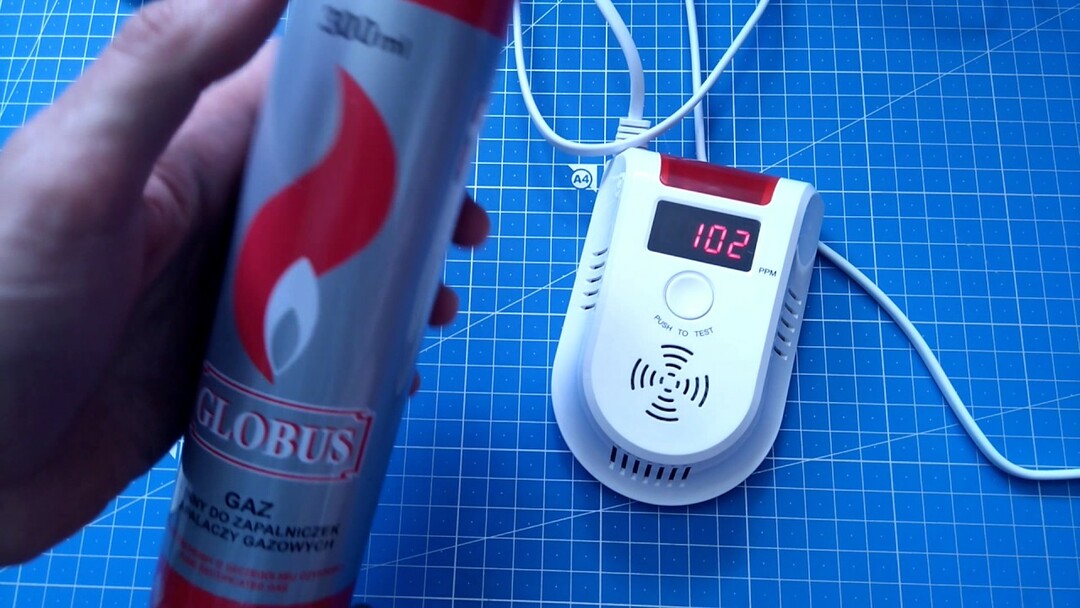

Gas leaks can be visually detected using soap suds. Most often, leakage occurs in fittings or hose connections.

Severe leaks can be detected by ear, as a minimum, this will serve as a clue to the location of the application of the soap solution. Another factor in controlling leakage is the appearance of a characteristic odor.

Compliance with safety standards allows not only to avoid gas leaks, but also to prevent possible negative consequences

The danger is that the propane-butane mixture is heavier than air, therefore, if it leaks, the gas rushes to the floor, it can accumulate under the floor or in the basement. One spark will be enough to provoke an explosion. The main cause of a gas explosion is most often negligence and disregard for safety standards.

To avoid the risk of carbon monoxide poisoning and to prevent the possibility of an explosion, set yourself the following rules for using a gas cylinder in your home:

- Installation of gas alarms near the floor;

- Ventilation of the room before opening the cylinder valve;

- The switched on gas appliances must be under constant supervision;

- Gas stoves cannot be used for heating or heating a room;

- Gas cylinders, like gas equipment, should only be repaired by specialists;

- In case of a long absence of residents, gas cylinders should be taken out of the house.

If, nevertheless, a gas leak occurs, then it is forbidden to use any electrical appliances. Do not perform actions that contribute to the formation of sparks.

If a leak is found, the cylinder must be closed immediately. gas cylinder valve, disconnect it from gas powered appliances and take it outside. Everything must be done quickly and accurately, as the fall of the cylinder can lead to its fire.

If gas leaks from the cylinder, it may catch fire. The first step is to try to close the valve. In case of a small flame, you can try to extinguish it with a wet towel, and then take the cylinder outside. It is risky to extinguish a large flame, as the accumulated gas in the room can explode.

Remember that overheating of the cylinder up to 180 degrees can cause it to the explosion. While the gas is burning, the probability of an explosion is minimal, an explosion is possible if the cylinder overheats from objects burning nearby. Therefore, immediately after the fire, it is necessary to close the valve, remove the cylinder from the room and call the emergency service.

Features of the operation of gas cylinders

The liquefied gas in the cylinder is under pressure, and when it is supplied to the gas equipment, it goes into a gaseous state.

This process is accompanied by a sharp drop in temperature, and with intensive use of equipment temperature can drop to a critical value at which further conversion will become impossible.

The simplest solution is to reduce gas consumption. You can also resort to additional heating of the cylinder, but it is forbidden to use heating sources with an open flame. Insulation of gas cylinders is not allowed, but it is possible to use special "heating jackets" and thermo-covers.

Thermal covers protect gas cylinders from a critical drop in temperature

Owners of gas cylinders may face similar difficulties in winter, if the cylinders are in an unheated room. In this case, it is best to use special propane-butane mixtures with different percentages of components.

The standard gas mixture for the warm season contains 60% butane, 40% propane. A winter cold-temperature mixture can contain 80% propane and 20% butane, but this mixture is much more expensive.

Refueling gas cylinders

Refueling of domestic gas cylinders is recommended to be carried out in specialized "gas filling points". In addition to compliance with the filling standards, each tank is guaranteed here for leaks, compliance with the service life, the presence of sediment in the form of heavy fractions.

When filling a cylinder with a propane-butane mixture, it must be borne in mind that filling should be made no more than 85%. Not every gas station has the necessary cut-off devices, and refueling is done by volume, not by weight, which is fraught with increased pressure in the cylinder.

The filling of the gas cylinder must be controlled by means of an electronic scale.

If you are sure that the cylinder is in good working order, the gasoline has been checked and removed, then refueling can be carried out at the gas station.

but refueling at a gas station permissible provided that the refueling process is carried out not by the volume of blue fuel, but by its weight, which is monitored using electronic scales.

Conclusions and useful video on the topic

Marking of technical examination of household gas cylinders:

Safety rules for the operation of household propane-butane cylinders:

Requirements and rules for the operation of gas cylinders: myths and reality:

Gas cylinders are an essential attribute of any owner of a summer cottage or house whose housing is outside the centralized gas supply.

Compliance with the rules for connecting and replacing cylinders, the norms of their operation and refueling, not only guarantees the safety of residents, but also provides comfort from the use of almost any gas appliances.

Please write your comments in the block form below the text of the article. Tell us about your experience with bottled gas. Share useful information that may be useful to site visitors, ask questions, post pictures on the topic of the article.