If you use gas cylinders at home, then you probably know that safety should come first. Agree, nothing adds confidence like peace of mind for yourself, your loved ones and property. In this sense, everything is decided by laying on a gas cylinder - a very cheap and simple tool. The safety of using the equipment directly depends on its quality and size. It would be nice to protect yourself from explosion, destruction or possible fire, wouldn't it?

We will tell you about the requirements for gaskets and the rules for their use. You will find out what sizes they are, what types they have, and what features they have, depending on the materials used. Together with this information, it will be easier for you to make a choice to buy a new or replace an old seal.

Gaskets are used on many joints. In the gas sector, seals are used on cylinders, hoses, pipelines. This is done for the sake of safety and in order to minimize fuel loss. Read the article and find out more about it.

The content of the article:

- What are cylinder gaskets for?

- Materials for the seal

- Range of sizes and models of gaskets

- Requirements for sealing products

- Gasket replacement procedure

- Conclusions and useful video on the topic

What are cylinder gaskets for?

They are used as sealing parts at the points of connection of the valve (tap) to the neck of the gas cylinder and to the reducer. In the first case, the seal is mounted on the container body and in a horizontal position, in the second - between the valve union and the gearbox, vertically. There are also gaskets inside the valve: under the flywheel, in the body of the unit and in its valve.

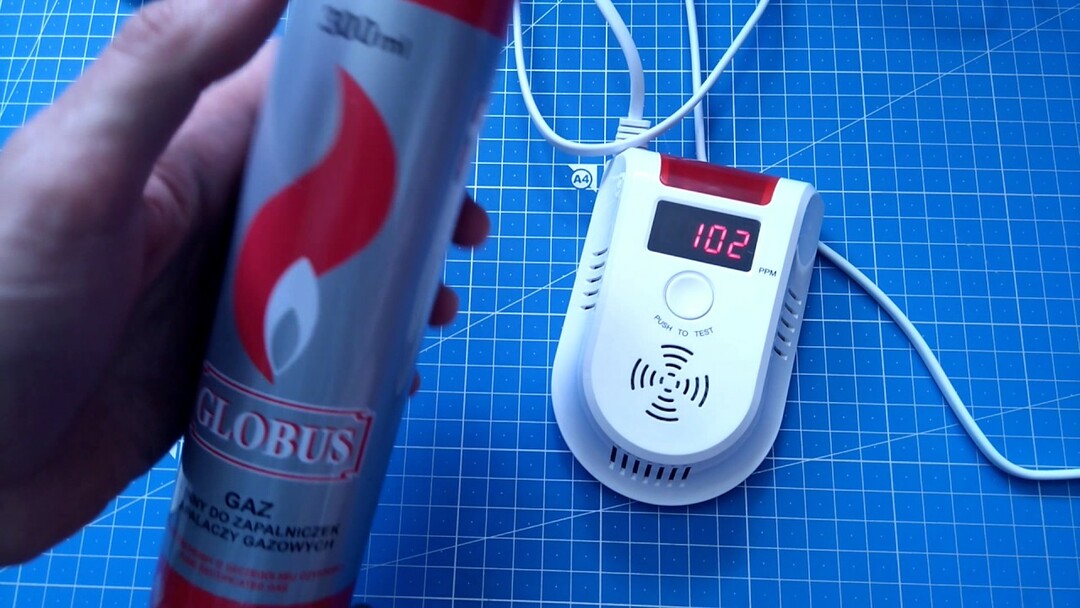

The seal eliminates or prevents gas leakage. Rubber gaskets increase tightness, improve mechanical characteristics, and keep connection parts in working order. Oil seals are indispensable in rooms with or without small windows, rooms with stagnant air, and unventilated areas.

Consequences of an explosion of a gas cylinder: what can happen as a result of a small leak, a violation of storage conditions and an incorrectly selected room

Gaskets improve performance gearboxes. The latter are connected when gas is supplied through a hose to reduce or stabilize the pressure. In the process, the usual indicator of 16-50 or the limit of 150-250 atmospheres reaches values from 1 to 16, and the probability of an explosion increases compared to the state when the cylinder is not used. The seal reduces the risk.

After long-term operation of the cylinders, the seals are deformed. They are changed about as often as cylinder taps.

In addition to sealing, transport gaskets are used with gas cylinders: the rings are put on a wide part of the body, in 2 places.

Materials for the seal

In production, paronite, rubber and fluoroplastic are used.

Due to its adhesiveness, paronite tightly fills cracks and gaps. The joints are specially protected with graphite so that the material does not stick to them. Biological and climatic factors affect the paronite weakly, and the sealant with mineral additives will survive after contact with aggressive hydrocarbons. Above the ideal size of the washer, its effect becomes minimal.

Rubber is used because of its elasticity, ability to restore shape. Among the properties, amorphousness and elasticity are also noted. The latter indicator grows with the temperature of the environment. The hardness is controlled by the degree of vulcanization, plasticizers and fillers.

Seals are made of nitrile butadiene rubber with an upper temperature limit of + 120... + 130 ° C and fluoroelastomer, which can withstand up to + 150... + 200 ° C.

Paronite gaskets are used not only on gas cylinders, but also on stoves, meters, columns, hoses and connections

Fluoroplastic is resistant to chemical and corrosive processes. The material also showed weather resistance, heat and frost resistance. Due to the low gas permeability, fluoroplastic began to be used in private houses and household gas distribution systems. After ignition, it quickly decays, and the coefficient of friction is in the range of 0.4-0.05 at a load of 1-20 kgf / cm².

In practice, silicone profiles are also used, but general safety standards prohibit the installation of material on gas and fire equipment. Silicone seals reliably, exhibits high temperature resistance, but is highly flammable.

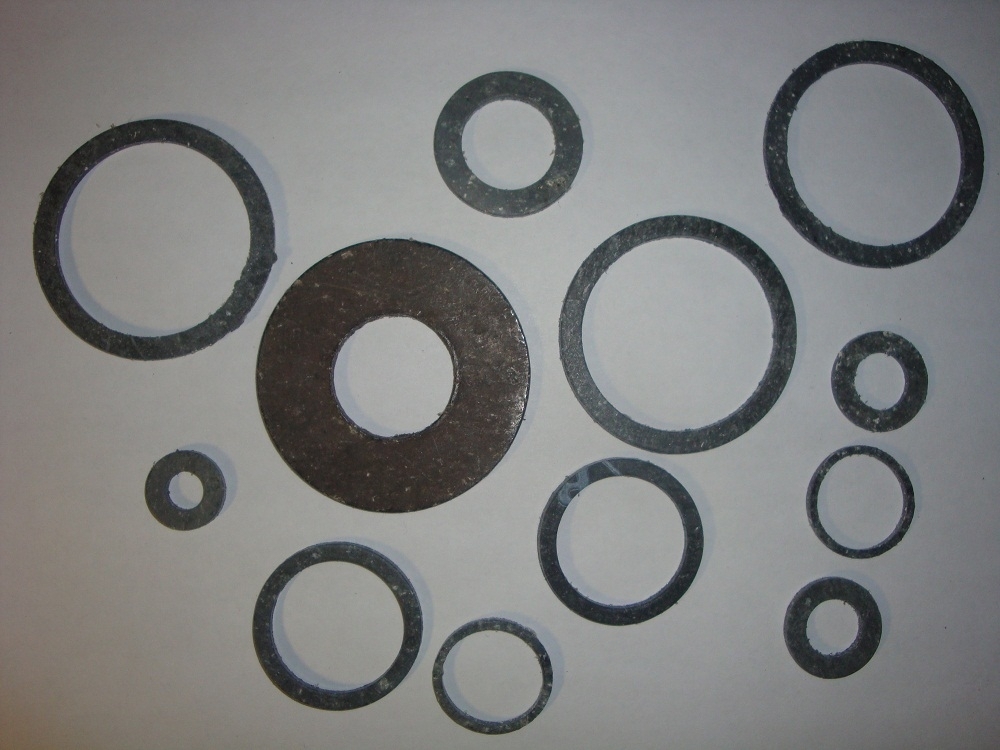

Range of sizes and models of gaskets

The effectiveness of the gasket for gas bottle depends on its dimensions and the dimensions of the unit. In the case of transport rings, the inner diameter should be slightly smaller than the cylinder diameter. For O-rings within the joints, exact fit is important.

Washers for external structures are selected according to the outer and inner diameters. All types of gaskets are subjected to heavy loads, therefore their compatibility with equipment depends on the pressure indicators.

The throat and reducer rings are flat. Their size is regulated by GOST 15180-86. The document described the parameters of flat elastic gaskets made of fluoroplastic, paronite, rubber and materials based on them. Standardized products are used to seal flanges and connecting parts, which are gas cylinder valve elements and various fittings.

Gas cylinders are high and low, wide and narrow, with parts of different proportions - the gaskets for them differ markedly in configuration, even if they have the same purpose

The size range of gaskets is related to the nominal bore (DN, Dу) in millimeters and the nominal pressure (PN, Pnom, Pу) in MPa. Both indicators are also called nominal.

The first one displays the inner diameter of a structural element along which the gas moves. The nominal pressure acts as a conditional indicator, which was established based on strength calculations at a temperature of +20 ° C.

Dimensions of gaskets in accordance with GOST:

| Nominal bore (DN), mm | Nominal pressure (PN), MPa | Outer diameter of the gasket (D), mm | Inner diameter of the gasket (d), mm |

| 10 | 0,1 – 0,63 | 38 | 14 |

| 10 | 1,0 – 4,0 | 45 | 14 |

| 15 | 0,1 – 0,63 | 43 | 20 |

| 15 | 1,0 – 4,0 | 50 | 20 |

| 20 | 0,1 – 0,63 | 53 | 25 |

| 20 | 1,0 – 4,0 | 60 | 25 |

| 25 | 0,1 – 0,63 | 63 | 29 |

| 25 | 1,0 – 4,0 | 69 | 29 |

| 32 | 0,1 – 0,63 | 75 | 38 |

| 32 | 1,0 – 4,0 | 81 | 38 |

| 40 | 0,1 – 0,63 | 85 | 45 |

| 40 | 1,0 – 4,0 | 91 | 45 |

| 50 | 0,1 – 0,63 | 95 | 57 |

| 50 | 1,0 – 4,0 | 106 | 57 |

| 65 | 0,1 – 0,63 | 115 | 75 |

| 65 | 1,0 – 4,0 | 126 | 75 |

Shipping pads are used for transportation and storage. The rings protect the cylinder from damage and damage to the paint layer, impact on other containers. Products for gas cylinders are produced in accordance with TU 2500-376-00152106-94. The peculiarity of these rings is their circular cross-section.

Some products:

- OH-1101: 25 ± 1.3, 215 ± 3.

- OH-1102: 25 ± 1, 210 ± 3.2.

- OH-2202: 15.6 ± 1, 285 ± 3.

- OH-3303: 25 ± 1.6, 140 ± 2.5.

The first indicator displays the cross-sectional diameter of the ring in millimeters, the next one shows the inner diameter (mm). The specified products are used in conditions of normal external pressure and temperature range -40... + 40 ° C.

Requirements for sealing products

The gasket must match the drawing. Form displacement is allowed within the size, which is indicated in special tables.

Reducer on a gas cylinder: the gasket at the junction of the converter and the valve has to be changed more often - usually use disposable seals, but some gearbox models do not need gasket on this at all connection

Washers with cracks, bubbles or porosity must not be placed on work surfaces (P). In the case of non-working (HP), only gaskets with cracks are not used, and an exception is made for other parameters.

On both types of surfaces, it is possible to install gaskets with some defects, if they do not exceed the permissible values:

- Imprint on the surface of the product. With a depth, length and width allowed for the size of the spacer.

- Chip length up to 0.3-1.5 mm, depending on the thickness of the seal.

- Extrusion up to 0.3-1.5 mm high. The value also depends on the thickness of the washer.

- Depressions, elevations and inclusions. Up to 0.3-5 mm.

- Unfinishedness. Up to 0.3-5 mm, based on the thickness of the gasket.

- Retractable hem. With a size of up to 0.3-1 mm.

Before installation, the gaskets are cleaned of dirt and dust and the target surface is prepared in the same way. Rings are fastened without shock loads, with short stretching.

The condition of the gasket can be determined by the assembly in which it is installed. After changing the unit or removing the product itself, it is subject to further operation if the appearance remains unchanged, the dimensions are preserved.

The criteria also apply to seals and transport rings for propane gas cylinders for 2, 5, 10, 12, 15, 20, 27, 40, 50 liters and more. Products for methane cylinders of 47, 50, 67, 80, 85, 96, 100, 123, 132, 160 and 185 liters fall under the standards.

Gasket replacement procedure

Changing the O-ring on the body throat often coincides with valve replacement. The gasket is updated if a problem is identified with it or the tap.

Before connecting a gas cylinder to any gas-using device, worn parts should be replaced on the container: their appearance will be the best guide

The valve is replaced if:

- it is not possible to move the flywheel, it has become more difficult to scroll it;

- there is deformation of the valve or its parts;

- there is a smell of gas in the room;

- the scheduled technical inspection did not take place.

The gaskets are changed with a precise algorithm of actions. First, the balloon itself is carried as far from the buildings as possible. The valve flywheel is slowly unscrewed, after which the gas is released. The valve is carefully dismantled, smoothly and without damaging the body.

Remaining in the cylinder condensate is poured. Then there are simple technical steps: install a new gasket, another valve (if necessary). At the end, check the tightness.

Self-manipulation is prohibited by the rules, but as a last resort and if you have the skills, you can not wait for specialists. Some types of valves can be partially disassembled indoors and without gas bleeding, for example, to replace internal glands.

Replacement of cylinder parts may need to be at least once every two years, and, in addition, there are limitations in terms of independent actions and storage conditions for the container.

Replacing the gasket between the valve and the gearbox will take less time. It will be enough to close the flywheel, disconnect the gearbox and install a seal between its nut and the valve union.

Some reducers do not work through the valve, but directly from the cylinder. In this case, it should be taken outside to release the gas.

Conclusions and useful video on the topic

Eliminating gas leaks using the tools at hand and replacing the internal valve gasket:

Sealing elements on gas cylinders should be replaced at the first sign of damage or loss of tightness. They are made from non-flammable materials such as paronite, fluoroplastic and special rubber. Rings are produced for containers and assemblies of any size, so there is no doubt about the quality of the seal.

Household stores have gaskets for 12, 27, 50 L gas cylinders and containers with less common sizes. The cylinders themselves should be stored outside residential buildings, apartments and technical floors, away from escape routes.

Write comments on the topic of the article, ask questions, share important information. If you bought a gasket for a gas cylinder, tell us what material you purchased the product from and whether you are satisfied with its quality. The communication block is located below.