Having your own country house, there is a need for reliable and high-quality gates. It is about such gates that will be discussed in this article.

Content:

- Scope and types of pipes ↓

- Varieties of gates ↓

- Swinging ↓

- Recoil ↓

- Advantages and disadvantages ↓

- Manufacturing technology ↓

- Step-by-step instruction ↓

- Tips & Tricks ↓

The main material from which the gate is made on the basis of profile pipes is a profiled sheet. The choice of a profiled sheet is explained by its characteristics, namely, its ease, and the absence of the need to install a foundation, also, the material is relatively inexpensive.

With the help of a professional sheet gate, you can make the site more aesthetic. The gate will complement the concept of the constructed fence.

Installation of a gate made of shaped pipes can be done independently without the help of qualified specialists.

To erect such a gate, you need:

- profile pipe (100 * 100) to create supports;

- profile pipe (50 * 50) for the frame of the structure

- profile pipe (40 * 20) for the stability of the structure, lintels are made of pipes;

- professional sheet for sheathing the fence;

- paint and primer;

Scope and types of pipes

Profile pipes come in two types of sections: round and rectangular. The advantages of these types of pipes include their high strength and low weight. Profiled pipes can be used instead of a metal bar, such a replacement will significantly reduce costs.

Profile pipes come in two types of sections: round and rectangular. The advantages of these types of pipes include their high strength and low weight. Profiled pipes can be used instead of a metal bar, such a replacement will significantly reduce costs.

The area of application of profile pipes is very diverse:

- In various types of industry - food, light and furniture.

- During construction.

- In agriculture.

- During the creation of decorative items.

Of all the listed areas of application, the largest percentage of use is in construction, namely, the construction of sports and commercial areas. Also, pipes can be used during the construction of foundations, floors and spans of buildings, as well as for the construction of fences and barriers. Such a wide range of uses is due to their strength and at the same time, lightness.

The first subdivision of pipes is according to their shape:

- rectangular;

- square;

- flat-oval;

- oval;

For each type of pipe in the form of its own area of application. For example, flat oval pipes are highly flexible, which is why they are used in the furniture industry. In turn, square and rectangular are used to create structures, which are then laid on a flat surface.

The second type of pipes is according to GOST:

- seamless, produced by the method of hot deformation;

- seamless, produced by the method of cold deformation;

- electrowelded;

- electrowelded, produced by the method of cold deformation;

Varieties of gates

Choosing the type of fence made of shaped pipes, you need to rely on the following factors:

- Territory and its type.

- The presence of various buildings, including a garage.

- Personal taste preferences.

For areas with outbuildings, a terrace near the house, as well as a garden, a high fence with sliding or swing gates is assumed. These types of gates are inappropriate to use in small areas.

If you constantly need to drive a car into the territory, then it is best to use sliding gates, also, you can install an automated system for opening such gates.

Swinging

This type of gate has the simplest design; the help of qualified specialists is not needed for their manufacture. They are used most often for the arrangement of suburban areas.

For the manufacture of such gates, the following sequence of steps must be followed:

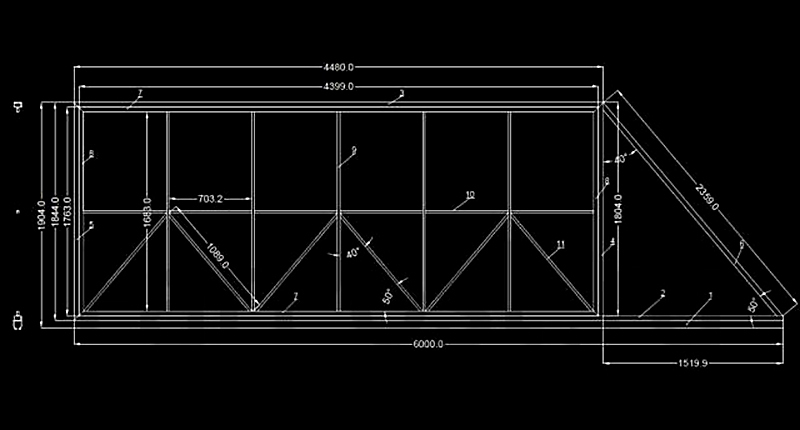

- Draw up a sketch and drawing.

- Calculate all the stages of fastening mechanisms.

- Prepare all elements of the gate for processing.

- To clean pipes from rust, for this you can use a solvent or grinder. If new pipes are used that do not require cleaning, then they must be degreased.

- Cut the material and mark it.

- For the racks, you need to dig two holes (50 * 50 and 1 meter deep). The posts are installed vertically on the level. The racks are fixed with concrete mortar.

- Carry out welding work to secure all structural elements to each other.

- Removal of welding slag.

Recoil

Not so long ago, sliding gates became part of the general consumer goods, until recently they were considered an element of luxury. It is recommended to buy a sliding gate already assembled, and only perform some elements yourself. Sliding gates are highly durable, they will serve for many years.

Advantages and disadvantages

As with any design, sliding gates have advantages and disadvantages.

It is worth highlighting the advantages of the product:

- High structural safety, difficulty in opening for strangers.

- High strength, the gate has a high bearing capacity.

- The gate is absolutely safe for cars, there is no likelihood of an accident when leaving and entering the car.

- Such gates do not require territory clearing. in the winter season.

In addition to the pros, do not forget about the cons:

- There is no wicket in such gates.

- Difficulty arises in the selection of the lattice for the direction.

- Sliding gates reduce fence space.

The most important point is that all the shortcomings are solvable, the main thing is to make the necessary efforts for this.

Manufacturing technology

For the construction of the gate, you will need the following materials:

- profile pipe (100 * 100), for the installation of supports;

- profile pipe (50 * 50), for mounting the frame;

- profile pipe (40 * 20), for the manufacture of jumpers;

- mechanism for sliding gates or hinges;

- material with which the frame will be sheathed;

- latch and lock;

- self-tapping screws;

- dye;

Required tools:

- welding machine;

- electrodes for welding production;

Step-by-step instruction

- The first step in manufacturing will be the installation of load-bearing pillars, if they are not available, then they must be made.

- The finished pillars are poured with concrete, the depth of concreting should be at least one meter.

- It is best to use a profile pipe with a cross section of 100 * 100 for bearing pillars.

- For concreting, you will need to initially prepare a solution, for this you need: river sand, crushed stone (proportion 1: 4) and cement.

- To dry the concreted post, you need to take about a week.

- While the concrete solution is drying, you can start making the door leaf.

- The next step is to weld the door frames.

- After welding, the seams must be sanded.

- When the frame is completely ready, you can proceed to staining.

- The next step is to mount the structure on the pillars. This procedure is performed using a welding machine.

This is exactly what the general meaning of manufacturing and installing doors from a profile pipe looks like. Sometimes, such a fence seems to be very difficult to implement, but in fact, their manufacture is not so difficult and problematic. The main thing is to take responsibility for every little thing in the manufacturing process.

Tips & Tricks

As it turned out, making a gate from a profile pipe is not such a complicated process as it seems at first glance. The procedure by which gates are made from a profile pipe is similar to the procedure for manufacturing a wicket, the only difference is in the size of the leaves.

However, no matter how simple everything was, there are some nuances that should be taken into account:

- When making a gate, the leaves must be the same size.

- It is necessary to hang the gate leaves at the same height and level.

In order for the sashes to be the same, it is necessary to make the gate from a single sheet of profile, which is cut when the gate is completely ready (hinged).

Advice:

- If, if you want to build a gate from a profile pipe, you have all the necessary tools and materials, then the work will not be costly, but at least a little construction skills are needed to properly perform the work.

- For the convenience of performing installation work, assistants are needed to ensure that the structure stands level (during installation, you need to hold the pillars and the sash in order to fix it correctly).