Today wood-like materials are widely used in decoration, construction and furniture manufacturing, which combine quality, durability and affordable cost. Chipboard is very popular, which stands for laminated chipboard. In this article we will tell you about this material and briefly describe its benefits. Also previously considered The difference between MDF and laminated chipboard.

Today wood-like materials are widely used in decoration, construction and furniture manufacturing, which combine quality, durability and affordable cost. Chipboard is very popular, which stands for laminated chipboard. In this article we will tell you about this material and briefly describe its benefits. Also previously considered The difference between MDF and laminated chipboard.

Chipboard - what is it and how is it deciphered?

Laminated chipboard is made from shavings and pressed sawdust, for which formaldehyde resins are used. Despite the use of formaldehyde, this material is environmentally friendly, which makes it possible to use it in the decoration of residential premises. In the production of such chipboards, modern production equipment is used, which ensures the durability, strength and environmental friendliness of such material.

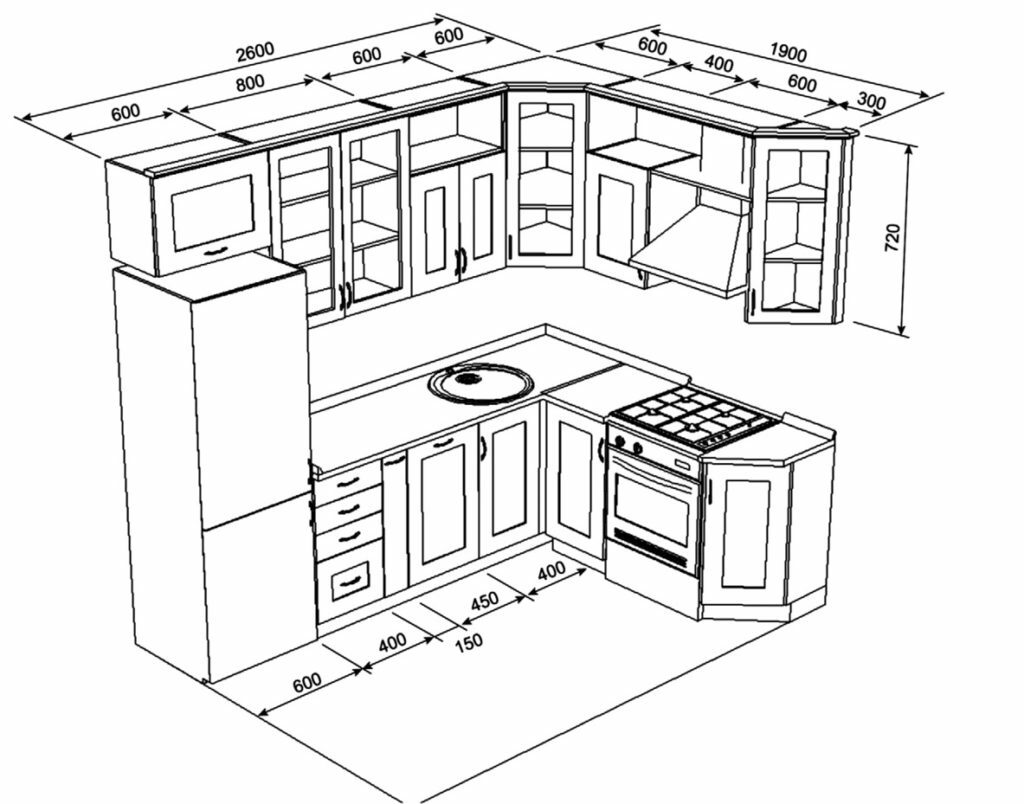

Attention! Earned on our website kitchen designer. You can familiarize yourself with it and design your dream kitchen for free! May also come in handy wardrobes designer.

The most widespread today is multilayer chipboard, which consists of three layers with large fractions in the center. This variety is moisture resistant and does not fade in the sun. This multi-layer structure of MDF provides the necessary strength and durability.

The most widespread today is multilayer chipboard, which consists of three layers with large fractions in the center. This variety is moisture resistant and does not fade in the sun. This multi-layer structure of MDF provides the necessary strength and durability.

Chipboard lamination is performed on paper impregnated with melamine resin. Due to the presence of such lamination, this material can imitate the appearance of an expensive natural solid wood of various types of wood.

Classes of laminated particle board

Today, there are several classes of MDF, depending on the content of formaldehyde in it. Deciphering laminated chipboard, depending on its environmental class, is not particularly difficult.

- E1. It is the cleanest environmentally friendly material that contains a minimum of formaldehyde. It can be used for interior decoration and furniture making.

- E2. This variety is used to decorate utility rooms.

- E3. In accordance with modern standards and norms of GOST, laminated chipboard of class E3 must not be used inside residential buildings. The proportion of harmful formaldehyde resins can be up to 30%.

Depending on the facing, the slabs are usually divided into:

- Rough MDF, that is, without a decorative front cover.

- Veneered with a thin layer of natural wood.

- Laminated with paper and plastic.

Also on sale you can find standard, moisture resistant and fireproof chipboard. The moisture-resistant material has a corresponding treatment with a paraffin emulsion, which protects the wood fibers from swelling under the influence of moisture.

Note that moisture-resistant laminated chipboard has a high cost, therefore, it is not economically feasible to use it for the manufacture of furniture and decoration of rooms with natural moisture indicators.

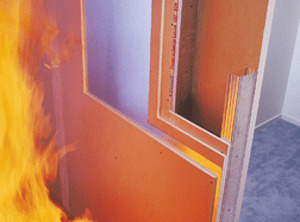

The refractory type of chipboard can withstand an open flame for 5 minutes, while it can be used in rooms with high temperatures. Such a refractory chipboard is manufactured using a special technology, which somewhat increases its cost. Due to its high cost, such refractory material is practically not used in construction, decoration and furniture.

The refractory type of chipboard can withstand an open flame for 5 minutes, while it can be used in rooms with high temperatures. Such a refractory chipboard is manufactured using a special technology, which somewhat increases its cost. Due to its high cost, such refractory material is practically not used in construction, decoration and furniture.

The advantages and disadvantages of this material

The proliferation of wood-like materials is due to its excellent performance characteristics. If we talk about the advantages of using laminated chipboard, we can note the following:

- Excellent durability of MDF.

- Resistant to moisture.

- Attractive appearance.

- Affordable cost.

- Possibility of choosing laminated chipboard with different texture and appearance.

- Versatility of application.

Of the shortcomings, we single out only mediocre environmental friendliness in materials with class E2 and E3, as well as the need use in rooms with high humidity of the corresponding expensive moisture-resistant variety Chipboard.

Choosing laminated MDF for furniture

Today on sale you can find various options for laminated chipboard, which differ in their performance characteristics, board sizes and appearance. You can pick up standard slabs with a thickness of 10-38 millimeters and sheet sizes of 280 by 207 centimeters. Their processing and cutting is not difficult, which allows you to subsequently independently make furniture and interior items from such a tree-like material.

The use of chipboard in finishing work or for the manufacture of furniture can significantly reduce the costs of the homeowner. Subject to the correct choice of this material, the repairs and furniture elements will serve for a long time. Unlike conventional chipboard, such laminated boards do not swell from moisture and do not fade in the sun.

The use of chipboard in finishing work or for the manufacture of furniture can significantly reduce the costs of the homeowner. Subject to the correct choice of this material, the repairs and furniture elements will serve for a long time. Unlike conventional chipboard, such laminated boards do not swell from moisture and do not fade in the sun.

Conclusion

Chipboard is an inexpensive, practical and versatile wood-like material with excellent performance characteristics. Subject to the right choice, such plates will be distinguished by their durability, strength and environmental friendliness. Remember only that it is necessary to choose the correct type of MDF used, depending on the humidity in the room.

Video: Chipboard - decoding, difference from chipboard and MDF

average rating 0 / 5. Number of ratings: 0

No ratings yet. Be the first to rate.