Most buyers purchasing plumbing hosedo not think about the diameter of the flexible liner. At first glance, there is not much difference, especially since the connectors look almost the same. But the lateral dimension of the sleeve is important, it must be taken into account for connecting household appliances.

The content of the article:

-

What you need to know about choosing a flexible hose diameter

- Inner diameters of rubber liners of different sizes

-

How to choose the diameter of a flexible hose, taking into account its type

- Restrictions

- Consumption

-

How to independently determine the diameter of a flexible liner and what else to look for when buying

- Pay attention to the little things

-

How is the installation and operation of flexible hoses of various diameters

- Operational problems

What you need to know about choosing a flexible hose diameter

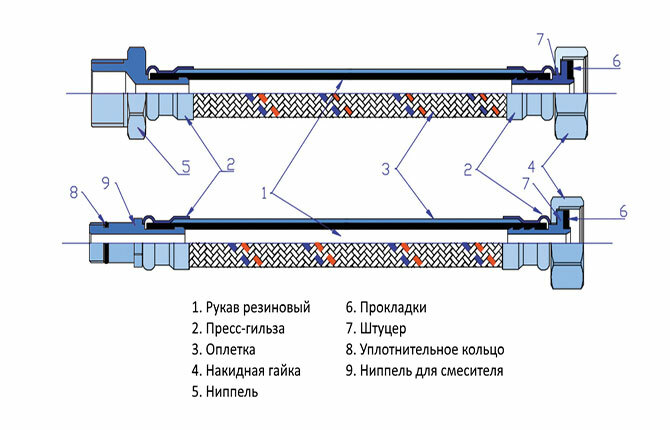

To connect plumbing fixtures, faucets and household appliances, soft braided hoses or metal flexible bellows-type connections are used. In both cases, union nuts or fittings are used for connection.

The diameter of the nut on a flexible hose made of food grade heat-resistant rubber can be of several standard sizes:

- 1 inch - used to connect consumers with a high water flow rate, for example, a bath or a gas water heater;

- 3/4 and 1/2 inches - most of the plumbing and household appliances are connected;

- 3/8 "- separate models of mixers and taps are connected.

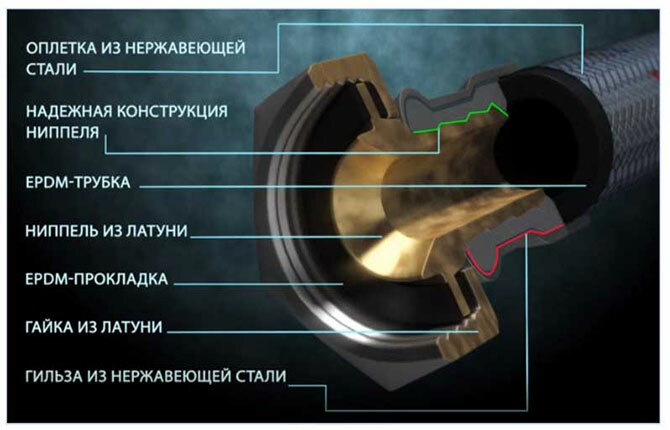

To connect a rubber sleeve in a braid, a threaded nipple with a reduced diameter is used, usually M10x1 or M9x1 in size, with a threaded section length of 18 mm or 35 mm.

On bellows-type flexible tubing, the size of the nipple nut can be from ½ "to 2½".

In the case of metal corrugated hoses, the inner and outer diameters differ by the wall thickness. Usually, stainless steel 0.3 mm thick is used for the manufacture of a bellows. Therefore, the throughput can be estimated from the cross-section or the cross-section at the inlet.

| Size (DN, mm) | Outside diameter, mm | Inner diameter, mm | Wall thickness, mm | Minimum bending radius, mm |

| ¾” (20) | 19.5 | 16.2 | 0.3 | 50 |

| 1” (25) | 26.5 | 21.8 | 0.3 | 65 |

| 1 ¼ “(32) | 34.2 | 28.5 | 0.3 | 86 |

| 2”(50) | 40.7 | 40.1 | 0.3 | 120 |

The flexible rubber sleeve made of food grade EPDM rubber is another matter. In this case, the wall thickness for a hose of different cross-section can be 1.5-3 mm. Accordingly, a different inner diameter of flexible liners is obtained. As a result, the conditions for safe operation change, and most importantly, a different water consumption is obtained.

Inner diameters of rubber liners of different sizes

The device of the flexible connecting hose is such that fixing nipples are installed at its ends. Basically, it is a tube with a rim at the end. The nipple is made of brass or galvanized steel. With its help, a nut is fixed at the end of the rubber hose.

Since the nipple is pressed into the hose, the throughput of the supply line will largely depend on the inner diameter of the hole in the brass tube.

For models of well-known brands, information on the dimensions and diameters of the hose is indicated in the product passport. High-quality products will have this document, otherwise the product will not pass certification and will not receive admission for sale.

For example, for products of the well-known trade mark "STOUT" (Italy), the following information on the liners is given:

- for models with 3/8 "and 1/2" nut - the inner and outer diameters of the sleeve are 8.5 mm and 11 mm, respectively. Through hole in the nipple - 6.2 mm;

- for a 3/4 ″ nut or nipple - the inner and outer diameters of the sleeve are 19 mm and 25 mm. Hole in the nipple - 15 mm;

- for a 1 ”threaded nut, the diameters are 25.5 mm and 32 mm. Hole in the nipple - 21 mm;

- for models with 1 ¼ ”nut, the inner and outer dimensions are 32 mm and 40 mm. Nipple - 27 mm.

This is enough to estimate the approximate water consumption and make the choice of a specific hose model. But when buying a rubber liner, in addition to the section, you have to take into account the safety conditions of operation set by the manufacturers of flexible hoses for their products.

How to choose the diameter of a flexible hose, taking into account its type

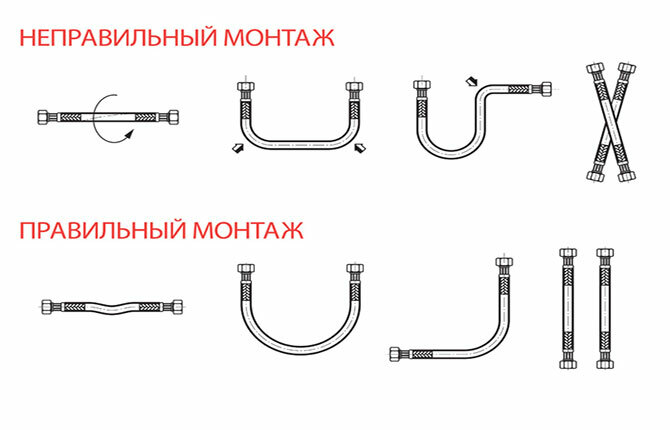

Even the highest quality stainless steel wire-braided rubber sleeve reinforced with polyester filaments will sooner or later fail if installed incorrectly.

Restrictions

Two conditions related to diameter:

- it is impossible to install a hose in a metal sheath if the bending radius is less than five transverse dimensions. If, according to technical conditions, there is no other way to place the sleeve or choose a model with a smaller pipe diameter, you need to use a hose-line with an angle fitting;

- do not put short hoses on household appliances if vibrations or vibrations occur during operation. In this case, the ratio of length to diameter must be at least 100.

When replacing hoses with a M10x0.5 fitting on a kitchen mixer, it makes sense to use brass adapter and a hose with a larger diameter. In this case, it is possible to install a flexible liner with a minimal risk of crushing or breaking the rubber under the sleeve.

Consumption

More often, a hose-line is chosen for a specific type of equipment. You just need to know the length and size of the union nut. As a result, the first available sleeve of a suitable length with the smallest nut size screwed onto the fitting of the drain mechanism is bought on the compact tank.

It is believed that the smaller the transverse dimension, the higher the flexibility of the hose connector, the easier it is to hide it. In this case, it is better to choose a long hose for a union-nut of at least ½ ”.

A taps or a faucet in a bathroom sink will require a lot of capacity, so models with a ¾ ”nut are used.

It is often necessary to know exactly the water flow rate when choosing the right connector sleeve. In this case, you can calculate the value yourself or use data from the online store.

The most reliable information will be information about the water consumption taken from the passport for flexible connection:

- for models with a 3/8 "or 1/2" union nut, the flow rate of the nipple on the spout is 28 l / min;

- for models with 3/4 ”nut-union, the flow rate is 200 l / min;

- for a 1 ”hose, water outflow - 280 l / min.

The water flow rate is calculated at an inlet pressure of 3At (3 bar). If you use data from an online store, you must always specify at what pressure the water throughput is indicated.

Using the data shown, the water flow rate for the bellows can be calculated. It is only necessary to calculate the coefficient of how much the sectional area of the corrugation is greater or less than one of the rubber sleeves. The water flow through the corrugated hose will change proportionally.

How to independently determine the diameter of a flexible liner and what else to look for when buying

Often it is necessary to put a hose already in use on the plumbing. Brand flexible eyeliner lasts a long time, does not rot, so there is no point in throwing away the hose if it can still serve for 5-7 years. The only problem is that the passport or certificate has not been preserved. You will have to determine the diameter manually.

Three ways to determine:

- measure the size of the nut with a vernier caliper and convert the value to inches using the metric and inch scale correspondence table;

- measure the holes at the entrance to the nipple. Knowing the size, you can establish which model it fits;

- measure the outside diameter, then subtract the braid thickness. We get the outer size of the rubber pipe, which can be used to determine the diameter of the flexible liner.

In practice, it is usually easier to do. They take a sleeve of unknown diameter and compare it with those installed on the equipment. In any apartment or house, there are several flexible connections that can be used as a reference.

Pay attention to the little things

When buying flexible liners, you need to be careful. Even if the pipe is sealed in plastic wrap, this does not prevent you from carefully examining it.

What needs to be done:

- feel the braided pipe with your hands. Make sure that there are no hernias or bends on the rubber that have formed during prolonged storage in a bent state;

- inspect the braid. If it is made of nylon, then the color of the filaments should be bright, without spots or breaks. If the outer sheath is made of metal wires, then there should be no torn barbed ends;

- inspect the nickel plating. For quality products, nickel looks the same over the entire surface, without gray and yellow spots. If somewhere on the nut brass is exposed, even with a barely noticeable risk, then it is better to refuse such a hose.

After the purchase, you need to bend the eyeliner along the radius approximately as it will stand on the plumbing or on the tap. Make sure the rubber tube is not pinched to block the inner channel.

How is the installation and operation of flexible hoses of various diameters

The eyeliner can be applied in two ways. In the first case, the hose connects the outlet on the water pipe with the fitting on the shut-off mechanism of the tank or boiler inlet. In this case, use a flexible hose with two nuts at the ends.

For installation, it is enough to lay the winding on the fittings, lay the gasket, screw one of the nuts. Align the position of the flexible hose, then lay the gasket and tighten the second nut. If a drop appears after turning on the water, tighten it with a wrench by a quarter of a turn.

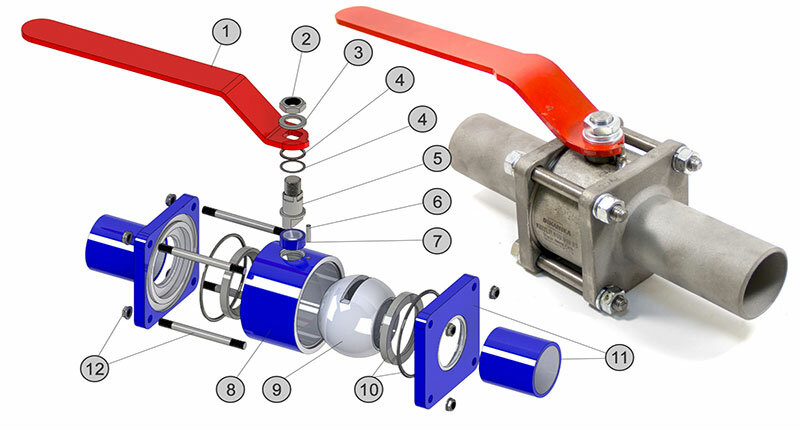

Installation of flexible eyeliner looks a little more complicated with ball valve or a valve. In this case, a hose with a nut and a union at the ends is used. We wrap the fitting with packing tape and wrap it tightly inside the ball valve. Install the valve on the pipe. Lastly, the nut is screwed onto the union of the tank or boiler. To prevent the hose from twisting when tightening, it is fixed with an open-end wrench. Pliers or pliers cannot be used.

The installation of the flexible connecting hoses to the mixer is carried out in the same manner. First, you need to screw the M10 threaded fittings into the body of the tap, then install the mixer on the sink or sink, after which you can fasten the nut to the water outlet.

Operational problems

Trouble with a flexible hose arises in the event of a marriage or improper installation of the flexible hose. The most common case is too small a radius of curvature. In this position, the rubber is deformed on the liner, cracks appear. To avoid this, you need to use a flexible hose of a small diameter, at least one meter long. Even with an average water pressure of 1.5 Atm, the flow rate through the ½ ”flexible hose will be at least 12 l / min.

The second most common case is the case of water leakage from the back side of the nut from the gap between the wall and the sleeve. It is treated by sinking the nipple into rubber using a wooden mandrel and a hammer. At the same time, you can check the diameter of the gasket.

Have you had any problems when using plumbing, the water supply to which is connected through a flexible hose?

Yes, it was leaking.

0%

There were no problems.

0%

I do not use flexible hoses.

0%

Voted: 0

The diameter of the flexible hose can always be read from the certificate sheet glued under the nut. The information is minimal, but it is enough to choose the right size. All that remains is to put the hose correctly.

Flexible eyeliner, what to look for when choosing: video.

Write about your experience and problems with flexible sleeves in the comments. What are the preferred sizes for home use in your opinion? Save the article in bookmarks so as not to lose useful information.