Couplings for metal pipes have been used in the joints of pipe blanks for a long time. They became an alternative to welded joints and made pipelines detachable. When using them, there was no need to use welding, which not everyone can use, meaning doing the work with their own hands.

On the market, couplings are presented in different types, which differ from each other in the material of manufacture and in the methods of connecting metal pipes.

The content of the article:

- What do metal pipe fittings look like?

-

Types of couplings

- Threaded

- Compression metal couplings

- Press couplings

- Couplings for cast iron pipes

- Couplings for copper pipes

-

How to install couplings for metal pipes

- Connection of cast iron pipelines

What do metal pipe fittings look like?

Couplings belong to the category of fittings. They are connecting elements. And since pipelines are cylindrical, all couplings offered today are also hollow cylinders. They are all metal.

Previously, they were mainly used with threads cut at their ends, which could be internal or external. Today, the range has expanded with the advent of new technologies for connecting metal pipes.

Types of couplings

Manufacturers offer three types of couplings used to connect metal pipes:

- threaded;

- compression or clamping;

- press couplings.

Since metal pipes are a broad concept, which includes products made of steel, cast iron and copper, accordingly, not all of the above-mentioned couplings are used to connect all types of pipelines. Cast iron is also thick-walled, but their installation is carried out in ways other than threaded ones.

Threaded

They are used only for connecting steel pipes, because the latter have thick walls on which threads can be cut. Threaded couplings are made from:

- become;

- cast iron;

- brass.

The first are thick-walled cylinders, more often with identical internal threads. The walls are thick. The raw material is black or stainless steel. Withstand great pressure.

Minuses:

- to create a tight joint, it is necessary to use additional insulating materials;

- during operation, a space filled with rust is formed between the threads of the coupling and the pipe, which leads to the “sticking” of metals.

The second is the same as the first. They are made of gray cast iron, where soft graphite is added. This material composition allows the couplings to withstand temperatures up to +300 ℃ and pressures up to 25 bar. Service life - up to 80 years. Manufacturing technology - shaped casting. The thread is cut on lathes.

Do not install these couplings on copper pipes. The reason is a large difference in the speed of electrochemical processes, under the influence of which corrosion occurs quickly.

The third type of threaded couplings, namely brass, has been on the market relatively recently. They can be classified as universal fittings, because they are used to connect not only steel, but also plastic pipes. In its pure form, brass products are not sold, because this metal does not have high corrosion resistance. Therefore, it is treated with chrome or nickel on top.

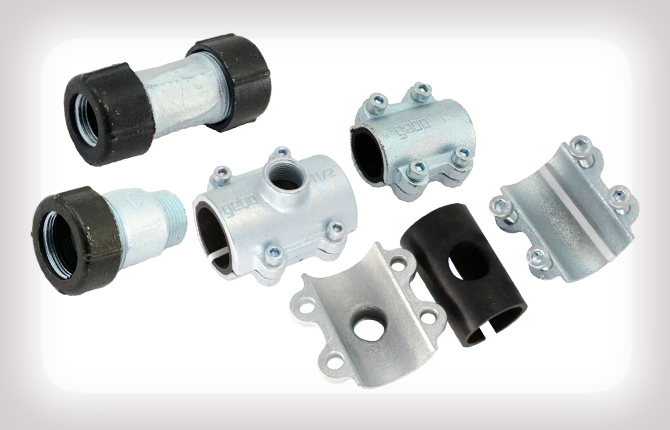

Compression metal couplings

This type of couplings for metal pipes belongs to the group of threadless ones. They appeared on the market relatively recently and among the masters are called the Gebo coupling (according to the first manufacturer). More precisely, the German company Gebo Armaturen.

The problem with this fitting is the difficulty of connecting metal pipes with a threaded coupling. That is, in order to carry out this process, it is necessary to weld spurs to the ends of the pipes, which is not always possible. Especially when repairing pipelines. You can cut the thread with a lerka, but this method can not always be used.

Compression couplings consist of two main parts - this is the coupling itself with external threads at the ends and two nuts. Three elements fit under the latter:

- clamping ring;

- metal washer;

- rubber cuff, it is also a sealant.

A big plus of this type of connectors is that they are detachable. If necessary, they can be disassembled and changed, or one of the parts can be replaced. It is also convenient when dismantling the pipeline.

Half couplings, which were also developed by Gebo Armaturen, can be included in the same category. The fitting consists of two identical parts, which are interconnected by four bolts with nuts. A sealant is placed inside each part in the form of gaskets, which ensure the tightness of the joint.

They are more often used when it is necessary to eliminate the leak of a metal pipe. In compounds, they are used less often. Although it was for this that the Germans developed them. In terms of ease of use, half fittings are better than others. Especially when the joint is in an inconvenient place.

Press couplings

The name speaks for itself. To work with them, you need a special tool - collet pliers. With their help, a sleeve is crimped into which a metal or metal-plastic pipe is inserted. Press fittings, if we talk about metal pipes, are used only for connecting copper pipelines.

There are push fittings. They differ from press couplings in that no pliers are used to apply them. Inside, cuffs are laid from the edges, which ensure the tightness of the joints.

Installation is simple - the end of the pipe is inserted into the fitting to a certain depth. The cuff compresses the pipe surface. This option is used more often for temporary pipeline installation or when repairs are needed.

Couplings for cast iron pipes

Pig-iron pipelines are connected in a socket way. Therefore, in their design, one end of the tubular billet is expanded. The second end of the next pipe in the pipeline is inserted into it, which has a straight section. But manufacturers produce cast iron products without sockets. To connect them together, you need a metal coupling, at the end of which there are these sockets.

The second option is half models made of either cast iron or steel. They also fit rubber or plastic gaskets. The halves of the fitting themselves are interconnected by several bolts on each side.

Socket couplings cannot be dismantled without dismantling the pipeline. Half-hearted allow you to do this.

Couplings for copper pipes

In copper pipelines, three types of couplings can be used to connect sections:

- compression;

- press fittings;

- soldered (they are also capillary).

The first two were introduced. There remains a third type, which uses soldering. This is one of the most reliable ways to connect copper pipes with 100% tightness. Plus - high mechanical strength, hence the durability of the joints.

Cons of soldering:

- high financial costs for consumables;

- soldering cannot be done without experience and knowledge.

To connect copper pipes, copper couplings must be used. This is the only way to ensure the long-term operation of pipelines. Fittings from other materials can be installed, but temporarily.

How to install couplings for metal pipes

Threaded metal fittings are easy to install:

- FUM tape is wound on the pipe thread.

- The coupling is screwed on so that the edge of the pipe reaches the middle of the length of the fitting.

- On the opposite side, the drive is also screwed into the latter to the middle. Sealing material is preliminarily wound on it.

- Sgon is welded to the second pipe.

The second run must be long so that during welding, when the temperature of the metal rises, the latter does not reach the junction, which can cause the sealing tape to burn out.

Cast iron fittings are installed in the same way. But there is also a difference. Nuts must be purchased with them. They support the ends of the coupling, creating an increased tightness of the connection.

The process goes like this:

- The nut is screwed onto the thread to the end.

- FUM tape is wound.

- The fitting is screwed on.

- First, the second nut is screwed onto the drive, then the FUM tape. It screws into the clutch.

- Both nuts are tightened to the edges of the fitting.

Now about how to install a compression coupling for a metal pipe. There are a couple of requirements here:

- The ends of the pipes are cut strictly perpendicular to the axis. Their surfaces are cleaned of paint, rust and other layers.

- The installation of the coupling itself is carried out strictly along the axis. Deviations are allowed, but not more than 3º, otherwise 100% tightness of the connection cannot be guaranteed.

The installation itself is carried out as follows:

- The ends of the pipes are put on in order: a clamping nut, a ring with a chamfer towards the nut, a washer and a cuff with a chamfer towards the coupling.

- The fitting is pressed against the end of the metal pipe. It is put on in order: cuff, washer and clamping ring.

- The nut is screwed on until it stops.

The same process is carried out on the other side. No tools are required here.

Press fittings on metal pipelines are also easy to install. They are put on the ends of the connected pipe elements and clamped with tongs.

Connection of cast iron pipelines

The first option is chasing. When pipes are connected by a socket method, a gap is formed between the connected elements, which becomes a leak area. It is filled in, creating a tight joint. It is done like this:

- A tourniquet is laid inside along the circumference, which is pre-treated with technical oil or resin. Laying height - ⅔ of the length of the connection.

- The laid tourniquet is compacted with the help of chasing and a hammer.

- The cement mortar is being prepared. This is cement grade M300-400, mixed with water. Proportions 9:1.

- A thick mass is poured into the gap and minted until a dense layer is formed. Filling is carried out until the cement is equal to the end of the socket.

There is another option that uses cement and asbestos fiber. Both materials are mixed in a ratio of 2:1, respectively. After that, water is added to the mixture - 10-15% of the total volume of the mass. The compound is minted with this solution.

Cast iron joints are easier to connect with half fittings. The latter are disconnected - the bolts are unscrewed and disassembled into two parts. Pipes are laid in the lower half so that they touch with their ends. The top element is placed on top. Both halves are compressed with bolts. It is important here that the gaskets do not move when laying metal pipes.

Of all the designated ways to connect metal pipes, soldering is the most difficult. The rest of the options are simple. Do-it-yourself docking using the fittings indicated above is easy. Some do not require tools. You will have to tinker with chasing, but it is not a difficult process either. The main task is to strictly follow the technology and requirements.

Threadless compression connection: video.

I would like to know from our readers if anyone had experience in connecting metal pipelines using the methods described above? Share your experience in the comments. Bookmark this article so you can return to it at any time.