Polypropylene pipes superior to steel in a number of criteria. The blanks are easy to cut to the desired size, soldered into the most complex plumbing or heating circuit.

The only drawback is that the fastening of polypropylene pipes requires special attention. The material is quite plastic and soft, which is why hot water and heating pipelines can sag under their own weight.

The content of the article:

- What are the fastening standards?

- How fastening is carried out

-

Distance between fasteners

- How the distance between fastener points is calculated

- Last check before assembly

- How to calculate the dimensions of the loop on a polypropylene pipe

- When is the best time to use clips?

- When is it appropriate to use clamps for fastening

- How is the fastening of polypropylene pipes for heating and plumbing in a hidden way

What are the fastening standards?

It all depends on the working situation. If you do plumbing in a private house, in a country house, or an individual heating circuit in an apartment, then the craftsmen will determine the attachment points for polypropylene pipes, as they say, at their own discretion.

For serious projects for laying heating mains and hot water supply lines, you will definitely need a foundation that best defines a regulatory document. This is the only way to justify the number of pipe attachment points and, accordingly, to include the purchase cost of fasteners in the estimate.

Two documents can serve as the basis for choosing the number of attachment points:

- Recommendations, tables, calculation formulas given by the manufacturer in the technical data sheet for polypropylene blanks. Usually these are average data for pipes of a certain diameter mounted on clips.

- Code of Practice SP 40-101-96 dated 09/04/1996 "Design and installation of pipelines made of polypropylene "Random-copolymer"".

The latter document can be recommended for professional installers. It contains all the necessary information on polypropylene pipes:

- calculation method for elongation during heating;

- recommendations on the choice of distances between fixing points, both for horizontal and vertical sections.

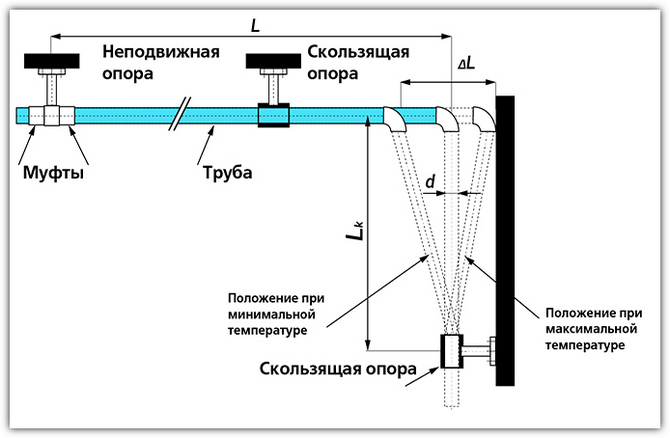

You also need to know how to properly fasten polypropylene pipes in corners or in corner areas. You can’t put it at random, moreover, you need to use two types of fasteners - fixed and sliding.

How fastening is carried out

The easiest way is to fix the polypropylene pipeline with cold water. It is enough to use the recommendations of the pipe manufacturer for the distance between the attachment points. The above information applies mainly to sliding types of fasteners at room temperature of 20 ℃.

One of the extreme side mounts on the wall, from corner to corner, is fixed. Usually this is a collar or a self-tightening clip. At other points, sliding fasteners are installed.

The process of fastening polypropylene pipes for hot water supply or heating looks somewhat more complicated:

- Make up a scheme for laying the pipeline along the wall.

- According to the recommendations of SP 40-101-96, the number of fastening points is counted according to the recommended distances between fasteners for a certain water temperature.

Additionally, it is necessary to calculate the dimensions of the compensation loop in the corners, taking into account the installation of fixed and sliding supports.

For polypropylene pipes, two types of fasteners are used - clamps and clips. The first is a steel clamp, consisting of two halves. On one of them a stand is screwed or welded, usually a stud or dowel. With their help, the clamp is screwed into the cork hammered into the wall.

Fastening a polypropylene water pipe looks like this:

- Mark the fastening points on the wall, drill holes for plugs with a puncher.

- They wrap inside the cork, hairpin or dowel of the clamp.

- Polypropylene pipes are laid on the supports, the mating part of the clamp is installed and the fasteners are fixed with a screwdriver.

Almost all models clamps Complete with internal rubber gaskets. Their use is mandatory. Soft rubber compensates for inaccuracies and deviations that occurred when installing clamps on the wall.

Clips are also installed using plugs and self-tapping screws. They can be self-locking or with tape preload. In the first case, no additional actions are required - it is enough to press the polypropylene pipe on the clip until the side mustache clips snap into place.

In the second case, the pipe must be laid on a plastic support and the clamping tape must be tightened.

Before assembling the water supply, it is necessary to determine the distances between the fasteners.

Distance between fasteners

The number of attachment points must be determined separately for horizontal and vertical sections of a polypropylene pipeline.

For a vertical section, the attachment points are placed at a distance of no more than 100 cm for polypropylene pipes with a diameter of up to 32 mm, in other cases, the gap between the supports can be increased to 150 cm.

How the distance between fastener points is calculated

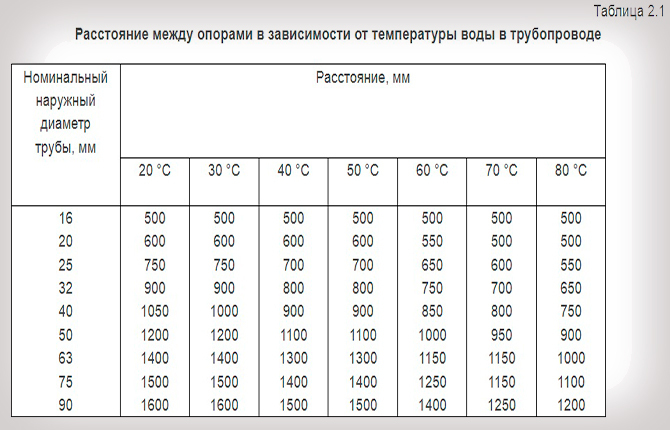

For a horizontal section of a polypropylene pipe, the recommended distance is selected from Table 2.1 of the Code of Practice SP 40-101-96.

The recommendations refer only to the minimum distance between supports. If necessary, the number of attachment points can be increased and even redistributed unevenly. But the minimum distance must comply with the recommended values.

Last check before assembly

Upon completion of the calculation, it is necessary to check the correctness of the location of the selected attachment points relative to fittings, couplings, taps. Initially, the polypropylene pipe will be installed cold. In working condition, the pipeline of the hot water supply system heats up to at least 60-70 OWITH. As a result of thermal expansion, the line will lengthen.

All elements embedded in the main line - tees, taps, bends with a fitting will also shift to a certain distance to the left or right, depending on where the fixing support and compensation a loop. Therefore, a coupling, a tap, a triangle with a fitting for a flexible outlet should be located at a distance greater than the pipe extension from the mount.

It is impossible to neglect the lengthening of the pipeline, even if the usual pipe billet PN30 SD6 is supplied for hot water (which is essentially wrong) for reasons of economy. The increase in length will be significant, so embedded fittings can break the fastener.

For example, a 6 m polypropylene pipe lengthens by 52-55 mm when heated from 20℃ to 70℃. If the clamp or clip is closer than 5 cm from the coupling, then the fasteners will be torn off the wall.

You can determine the amount of elongation by the nomogram. The value of the temperature change during heating is indicated along the vertical, the length of the section is selected along the graph line. Then, horizontally, you can determine the elongation of the section in millimeters.

How to calculate the dimensions of the loop on a polypropylene pipe

Thermal expansion is considered the most serious disadvantage of polypropylene. Even if tube blanks with aluminum or fiberglass reinforcement are used, the elongation problem will not disappear.

For example, a six-meter reinforced polypropylene blank from the above example, when heated to 70 ℃, will increase in length not by 5 cm, but by only 1 cm. But this is enough to break off the fastener support or deform the threaded fitting on the heating radiator.

Therefore, a compensation loop is necessarily placed in the circuit. It is best to make a compensator in the corner. Movements of 10-12 mm are almost imperceptible to prying eyes, and in general the system looks more aesthetically pleasing than putting a ring or a U-shaped compensator.

Section length Lk pipe diameter d is determined by the formula Lk=25(d∆L)1/2, ∆L - the value by which the workpiece was elongated at maximum heating at T = 90-95 ℃.

One fastener must be fixed, and the second must be made according to a sliding pattern. Sometimes, to block movement, the seat on the pipe is scalded on the left and right with two couplings.

Polypropylene pipes with a diameter of up to 32 mm can be installed with a homemade compensator ring. The radius of the annular loop along the center line is calculated as the diameter of the pipeline, multiplied by the coefficient K=8.

When is the best time to use clips?

This type of fastener is used mainly for pipelines of small diameter - from 16 mm to 50 mm. Polypropylene lines of large diameter cannot be held with clips due to the low strength of the fastening. Pipes less than 16 mm are fixed on the walls with loops.

Clips are ideal as sliding supports. The fastening design is such that the outer surface of the pipe contacts the ring only through the lamellar protrusions. Even with a slight inaccuracy in the installation of fasteners, additional distortion load on the pipeline will not appear.

Clips are practically not used as fixed supports due to their low strength. If it is not possible to purchase a special stationary support or put a clamp, then it can be replaced with clips for fixing copper pipes.

Separate models of clips, for example, with a tape and a lock, are convenient to use for fixing polypropylene pipes tightened with soft thermal insulation.

Clip-on fasteners are made of cast polypropylene, so the coefficient of thermal expansion does not differ from the material of the pipeline. Accordingly, when heated, the pipe does not wedge inside the clip.

The average price for one clip is 10 cents; fasteners are usually sold in packs of 10 or 20 pieces.

When is it appropriate to use clamps for fastening

The advantage of this type of fastener is its versatility. Clamps can be used to fasten both metal and plastic pipes. Clamp supports can be made both in a stationary version and in a sliding one. In the first case, soft rubber gaskets are installed inside, in the second - a Teflon or split polypropylene ring.

Metal clamps are able to withstand significant axial and radial loads. Fasteners are not afraid of ultraviolet radiation and low temperatures. Therefore, all external pipelines are placed only on clamps. The service life of the fastening is several times higher than that of propylene pipes.

Of the minuses of clamp fasteners, one can note:

- high price - from 50 cents apiece;

- the clamp is designed for a polypropylene pipe of a certain diameter;

- increased installation complexity.

The reliability of the clamp largely depends on the quality of the assembly. A stud or dowel is usually welded to the lower half ring during the manufacture of the fastener. In case of inaccurate installation and strong blows with a hammer when upsetting the dowel inside the cork, the welding seam may peel off or crack. Accordingly, under the weight of the polypropylene pipe, the support will simply collapse.

How is the fastening of polypropylene pipes for heating and plumbing in a hidden way

Due to its high chemical resistance, polypropylene pipelines can be laid directly in walls, under plaster, or directly into the ground. In any case, before laying the polypropylene pipe, a strobe or groove is pre-cut with a perforator. The dimensions of the cavity should be twice as wide and deeper than the transverse dimension of the line.

Before sealing the cold water supply, it will be enough to grab it to the wall with a temporary fastening - a wire or plastic loop. As soon as the initial sections of the strobe are plastered, it can be removed. In an unheated room or when laying a water pipe in the ground, the pipe is put on a heat-insulating cover made of polyethylene foam.

Polypropylene pipes for hot water supply and heating are laid in plastic boxes. In the same way, hidden laying is carried out in the walls and behind the plasterboard lining. Often, fasteners for polypropylene pipes for hot and cold water can be installed in one channel, as well as wiring in a protected corrugation.

When laying polypropylene pipes in the ground below the freezing depth, it is better to use an additional PVC sewer channel. So that condensate does not accumulate inside the protective PVC sheath, stakes are hammered into the bottom of the trench, the PVC pipe is suspended using wire fasteners with a certain slope to drain moisture. A sand cushion is poured to the bottom. After that, it is possible to lay a polypropylene pipeline inside and fill the trench with soil.

Fastening polypropylene lines should provide both a loose fit in the axial direction and a rigid fixation in the radial direction. Due to fluctuations in temperature, the pipes always experience additional loads, therefore, the reliability and long service life of the pipeline depends on the correct choice of the type of fastener.

The main secrets of the installation of polypropylene pipes. Master class for fastening polypropylene pipes: video.

Share your experience - how do you attach polypropylene to walls? What problems arose and how were they solved? Write in the comments. Bookmark this article so you don't lose any useful information.