In the construction of water supply and heating systems, steel is being replaced everywhere by polypropylene, low-pressure polyethylene and even composite metal-plastic. For each type of pipe blanks, new connection methods had to be developed. Compression pipe fittings are increasingly being used instead of welding. The connection scheme has become somewhat more complicated, but at the same time more convenient and practical in installation or repair.

The content of the article:

- What are the advantages of compression fittings for HDPE pipes

-

How HDPE pipes are connected with compression fittings

- Pipe preparation

-

Installation of compression fittings for HDPE pipes

- Installing a one-way ferrule

- Connection of two polyethylene pipes with a two-way coupling

- Compression fittings for metal-plastic and PE pipes

- Compression fittings with built-in nipple

- Threaded crimp adapters

- Compression fittings for steel pipes

- Is it possible to use compression fittings for copper pipes

What are the advantages of compression fittings for HDPE pipes

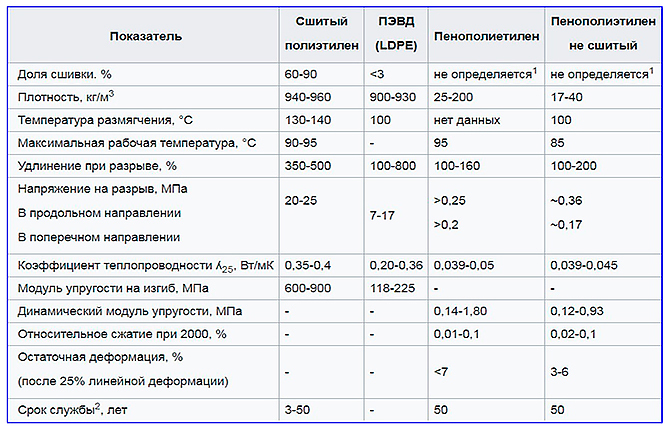

Low-density polyethylene (HDPE) is considered a rather inconvenient material in terms of connection. But the polyethylene pipe itself has high performance characteristics:

- bending strength - 120-170 kgf / cm2;

- plasticity, elongation to the moment of rupture can be up to 500%;

- upper limit of working temperature 130-140℃;

- withstand freezing.

But at the same time, polyethylene is poorly welded. In order for the seam on the HDPE pipe to turn out to be monolithic, it is necessary to use turnbuckles, to accurately control the temperature. If for industrial pipelines the use of special equipment and trained personnel is considered acceptable, then for domestic water pipes it is difficult and expensive to weld HDPE pipes.

Therefore, welding was replaced with a compression fitting for polyethylene pipes. Practice has shown that the rejection of soldering in favor of a compression fitting simplifies the process of laying pipelines from HDPE by an order of magnitude.

Benefits of using a compression fitting:

- installation process on pipes and connections takes 3-5 minutes;

- low price - the compression fitting is not made of HDPE, but of more durable and rigid PPB polypropylene or block copolymer;

- simple design - consists of 5 parts, including a rubber gasket;

- the possibility of disassembly, revision, repair, reuse.

Any person can put and remove a compression fitting on a HDPE pipe, even one who first encountered the problem of connecting polyethylene water pipes. A minimum of tools is required. Experienced craftsmen manage with a cutter and calibrator. For a beginner, you may need a mounting spring and wrenches.

The cost of a compression fitting is low. For example, a coupling for a 20 mm HDPE pipe costs $1.5-2.

How HDPE pipes are connected with compression fittings

The scheme for connecting polyethylene pipes with compression fittings cannot be considered ideal, there are also disadvantages. For example, to ensure the tightness of the joint, rubber gaskets are used, which eventually dry out and lose their elasticity. Therefore, during operation, the joint may begin to leak, the union nuts must be tightened to seal the joint.

Compression sleeves, adapters, elbows, tees on polyethylene lines must not be subjected to mechanical stress - the joint must be unloaded by installing expansion supports.

Pipe preparation

The holes in the compression sleeve must match the outside diameter of the pipe. But this is only in theory. In fact, both fittings and HDPE pipe blanks are produced by a huge number of small and medium-sized enterprises, so there may be deviations in size.

Before buying, you need to cut off a small piece of HDPE pipe, on which the coupling is planned to be installed, and in when choosing a compression fitting, check how tightly the end of the pipe blank fits inside corps. The rubber sealing ring should be put on the prepared edge of the pipe with little effort.

Most amateurs who undertake to install a compression fitting on a PE pipe neglect the preparation. It is erroneously considered that it is enough to cut off the edge evenly, and you can insert the workpiece inside the coupling.

An unprepared pipe fits tightly inside a high-quality coupling-connector - if you apply a lot of force, you can even break the rubber seal. You can't do it.

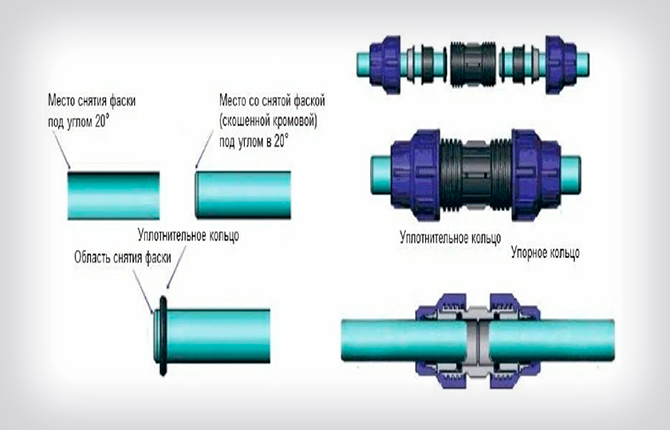

Coupling edge preparation sequence:

- Using a cutter, we cut the pipe so that the cut line is strictly perpendicular to the axis of the pipe blank.

- Using a calibrator, chamfer at 20O. If the sealing ring is not put on the pipe due to the increased diameter of the workpiece, then it will be necessary to remove a part of the polyethylene at a distance of 4-5 mm from the end.

- If there are sags on the polyethylene pipe, or the shape is clearly different from the round one, calibrate that part of the surface that will go inside the compression fitting.

After processing, the surface of the chamfer and the first 4-5 mm of the workpiece should be as smooth as possible. No lubricants, adhesives, sealants or sealants are used when installing the ferrule on the pipe.

The pipe connection is made due to the wedging action of the rubber ring. When screwing along the thread, the nut moves forward and presses through the bushings on the end surface of the rubber. The force is large enough that the pressure on the elastic material is transferred to the leading edge of the pipe and clamps it inside the housing.

Installation of compression fittings for HDPE pipes

The advantage of using a compression coupling is that it can be used to make a simple and reliable connection of two branches of a water supply system or to make a transition from HDPE to another type of pipe.

Installing a one-way ferrule

The most common version of a compression fitting is a body in the form of a cylindrical cup with a thread and a union nut. For a one-way coupling, the PE pipe is connected only on the nut side. The opposite part of the body has a fitting for upsetting the PVC hose.

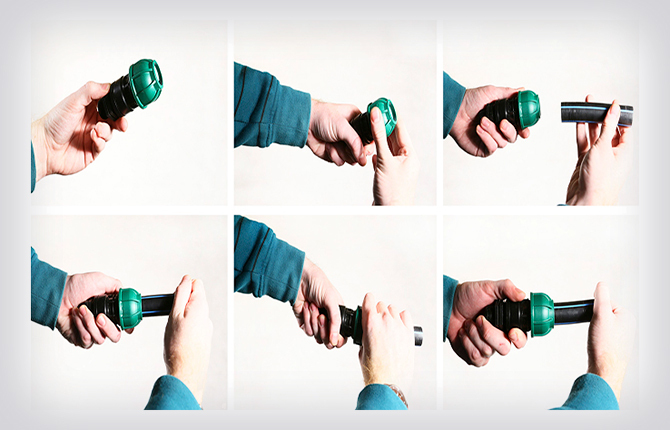

To assemble, we put on a nut, usually blue or green, on the pipe. Next, you need to put on the parts in the following sequence:

- Crimp ring in white color with oblique ribs located around the perimeter.

- Insert the leveling sleeve-fungus.

- The last we put on the pipe is a rubber seal ring.

It remains to bring the end of the pipe billet with the ring inside the body, align and upset it to a depth. After that, we put the nut on the thread and wrap it with a little effort.

If the preparation and assembly were done correctly, then the fitting will be firmly held on the PE pipe - it is difficult to pull it out of the body. If the end came out of the coupling with relatively little effort, then the assembly was not done correctly - the ring did not fit on the PE pipe.

Connection of two polyethylene pipes with a two-way coupling

A common pattern for using compression fittings is the usual joining of two pipes of the same diameter. Masters are often advised to make a connection using an additional pipe trim, but larger. In this case, its inner diameter must be equal to the outer size of the workpieces to be joined.

The connection is made with glue or sealant. In theory, everything is simple, but in practice, despite the simple scheme, minimum costs and availability, this method does not guarantee a reliable connection. Therefore, for joining two pipes, it is better to use a two-way coupling.

The assembly of the fitting is carried out in the same way as for the one-way model. The only difference is that some manufacturers use additional conical rubber rings that seal the gap between the nut and the outer surface of the pipe. In this case, they are put on the pipe blank immediately after the nut.

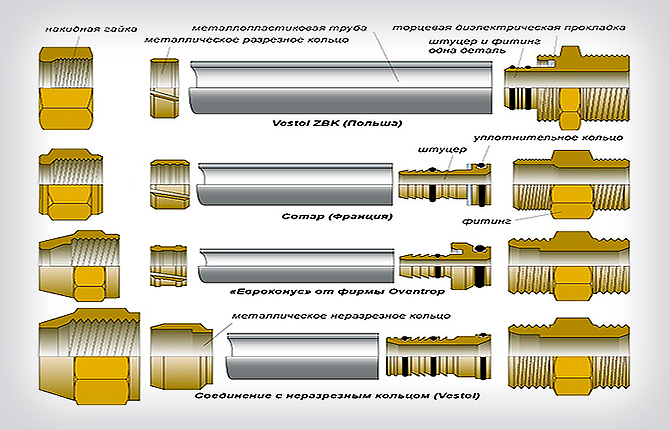

Compression fittings for metal-plastic and PE pipes

The backbone of metal-plastic pipe blanks is an aluminum sublayer sealed between the outer and inner layers of soft polyethylene PE. As a result, the metal-plastic pipe acquires relatively greater rigidity and strength, therefore it is able to withstand high internal water pressure.

At the same time, the presence of polyethylene does not allow a large compressive force to be applied - it will simply break the polyethylene surface, and aluminum will collapse due to contact with water.

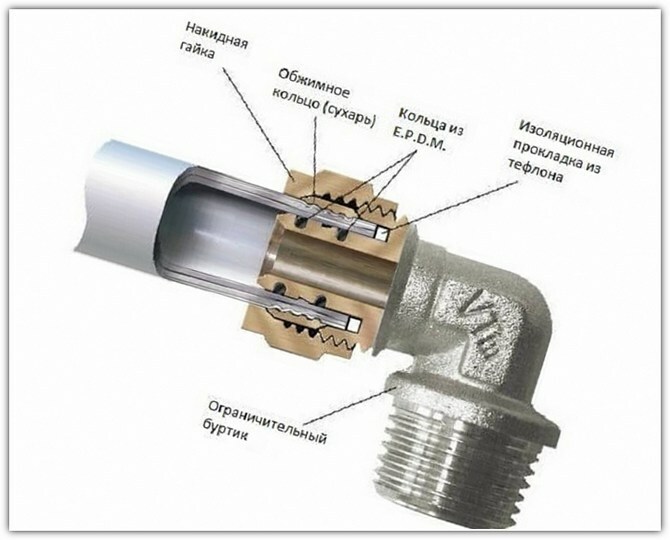

Therefore, two types of compression fittings are used to fix metal-plastic:

- with a split cracker and a compressing outer nut;

- with compression of the outer surface by a steel sleeve.

In both cases, fixation inside the fitting is carried out due to the deformation of the metal-plastic wall. Due to the radial compression, the aluminum layer acquires a wavy shape and engages with the details of the compression adapter.

In the first case, the compression is performed by tightening the union nut, which presses on the split sleeve. The method is simple, but not very reliable, since there is a risk of damage to the polyethylene coating by the sleeve.

Conveniently, if necessary, compression fittings for metal-plastic pipes can be disassembled, removed and reused. Crimp adapters of the same design are used for joining PE water pipe sections.

In the second case, fixation is performed by pressing and crimping the steel sleeve. In contrast to the scheme with a split sleeve, the force is distributed more evenly, so the risk of damage to the polyethylene when installing the pipe blank inside the fitting is practically minimized.

When assembling the most critical sections of water pipes or heating systems, it is recommended to use fittings with a sleeve, tools and metal-plastic pipes from the same manufacturer.

Sleeve adapters are not universal - they are used only for metal-plastic and for a certain pipe diameter.

Compression fittings with built-in nipple

This type of connector is used for relatively soft polyethylene blanks. The problem with using classic PEX pipe fittings is that XLPE walls, even in the presence of mesh reinforcement, do not have sufficient rigidity to withstand mechanical bending load. Simply put, if you install a soft PEX pipe in a sleeve, then when you try to make a turn in the pipeline, a crease and squeezing of the flow area may occur.

Therefore, for PEX pipes, compression fittings with an increased length of the seating surface are used. After assembly, the edge of the part turns out to protrude beyond the end surface of the nut by 4-5 mm.

For assembly, a nut and a split retaining ring are put on the pipe blank. Next, the end of the soft pipe is put on a fitting with a rubber seal, the split sleeve is pulled by hand and the union nut is screwed on. Thanks to the protrusions on the inner surface of the retaining ring, the wall material of the PE pipe is securely held inside the fitting, without crushing or through-cutting.

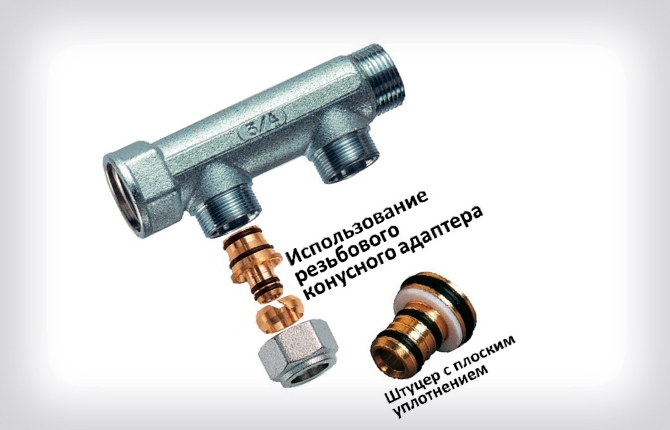

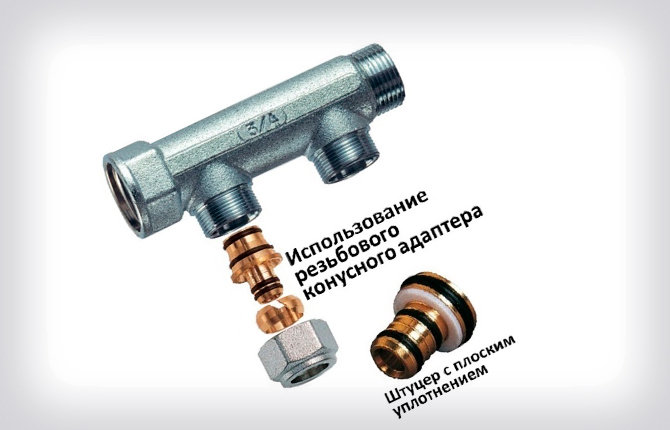

Threaded crimp adapters

They are mainly used for connecting pipes to threaded outlet fittings located on collectors or heating radiators. Structurally, the adapter consists of a brass adapter with a reverse cone and two rubber seal rings, a collet-type crimp split sleeve and a threaded union nut.

The dimensions of the thread on the manifold fitting and on the inner surface of the nut must match both in diameter and in the pitch of the turns. When the parts are twisted, axial and radial force is generated, which is transmitted to the collet body.

Fastening polyethylene pipe on the adapter is provided due to the compression of the walls with a collet bushing. Unlike other models of fittings, the sleeve has not one through cut, but several small cuts evenly spaced along the perimeter. As a result of radial pressure from the nut, the edges of the sleeve are compressed and securely fix the pipe on the seating surface of the adapter.

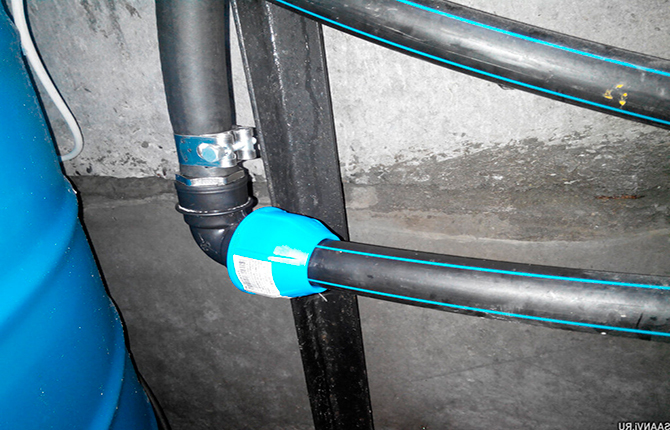

Compression fittings for steel pipes

The idea to use collet fittings was to develop a quick connection between two metal pipes. In its design, the compression fitting resembles two-way couplings used for quick splicing of low-pressure polyethylene (HDPE) sections. But since all parts, with the exception of the seal rings, are made of metal, the design, unlike HDPE, turned out to be compact and durable.

A crimp fitting for joining two parts of a steel water pipe consists of the following parts:

- a cylindrical body in the form of a glass with two inlets and a thread on the outer surface;

- two captive steel nuts with internal thread;

- two steel split bushings;

- two clamping rings;

- two pairs of rubber seals.

If we are talking about a transitional coupling, then the nut, split sleeve and rubber ring will be one copy each.

How a compression fitting works - an annular conical groove is made inside the nut. The split sleeve has an asymmetric shape, one of the sides has a rounded surface.

For assembly, a nut, a split sleeve, a clamping ring, and a rubber seal are successively put on the pipe. All this is inserted into the body and twisted along the thread until it stops.

You will need to tighten it with effort, but the last half-turn should be soft. Gaps are selected between the parts, and the main load falls on the deformation of the rubber. If the resistance is hard, then most likely the clamping ring is skewed, and the connection needs to be disassembled. Steel fittings are initially twisted by hand until they stop, then they are pressed with a pipe wrench.

Do not try to simplify the design of compression fittings for steel pipes. For example, if a rubber or pressure ring was lost. Any attempt to replace the gum with sealant, and instead of the pressure ring, put the first one that came to hand or cut out of a tin, ends in an accident.

The body of the compression fitting is made of brass or stainless steel. Ordinary steel is rarely used, since the metal quickly rusts when it comes into contact with black rubber. There are steel models with an anodized finish, but they are significantly inferior to stainless steel adapters.

Is it possible to use compression fittings for copper pipes

Steel crimp adapters must not be used on copper pipes. Direct contact of two dissimilar metals in an aqueous medium causes the development of electrochemical corrosion. Steel will collapse quickly, in just a few weeks.

Copper is widely used in heating systems, so bronze and brass compression fittings for copper pipes are used for joining. Moreover, several types of adapters can be used.

The simplest option is press fitting or sleeve adapter. The design of the connector is similar to a sleeve for soldering copper joints, with the only difference being inside a sealing ring is placed under the pipe, not solder, and the thin-walled body is crimped press tongs.

The second type of compression fitting is used for joining copper pipes with a high phosphorus content. This is the so-called solid copper. In this case, compression couplings with joint sealing by elastic EPDM rings are used. The design of such a fitting is similar to the devices used for steel pipelines.

To connect thin-walled pipes made of soft copper, compression adapters with a conical sleeve are used. The nut is put on the pipe billet, after which the end of the latter is flared until a landing cone is formed.

It remains only to insert the cone bushing into the body, then the pipe is placed, the nut is put on and tightened with a wrench until the copper settles. The connection is reliable, withstands heating to any temperature. The only disadvantage is that this type of compression connection is applicable only for pipelines of small diameter.

The idea of using compression fittings to connect pipes turned out to be quite successful in practice, easy to implement and reliable in operation. Connecting pipes with an adapter is easier and more convenient than using soldering or a welding machine.

The method of connecting a fitting and a HDPE (PE) pipe: video.

Tell us about your experience with compression couplings - how durable was the connection, and what problems did you encounter when using adapters? Bookmark this article so you don't lose any useful information.