The emergence of a new technology for forming products from cast polypropylene has led to the fact that in modern realities, a polypropylene pipe PN10, as well as PN20, PN25, practically replaced steel blanks from such an important area as laying water pipelines in houses and apartments citizens. But what are its benefits?

The content of the article:

-

Scope of a pipe polypropylene PN10, PN20

- Water pipelines

- Heating

- Industrial highways

- Folk art

-

Polypropylene pipes characteristics PPR PN10, PPR PN20, PPR PN25

- Polypropylene pipes PPK for 20 atm

- Pipes for 25 At for the main with cold and hot water

- What are the advantages of the PN10 pipe

- How to install PPR PN10

Scope of a pipe polypropylene PN10, PN20

First of all, it should be noted the high strength, chemical resistance and excellent weldability of polypropylene. Working with polymer does not require special training. That's why polypropylene pipes PN10, PN20, PN2 (GOST 32415-2013) have long been used in everyday life both for their intended purpose - for assembling water supply lines - and in a non-standard way. For example, for the manufacture of frame structures.

Advantages of the PPR polypropylene pipe:

- low price. The cost of PN10 is lower than similar half-inch and inch steel pipes used for arranging water communications;

- high resistance to aggressive chemicals. Polypropylene does not interact with water, even chlorinated, easily withstands heating up to 60 ℃, and in the case of PN25 - up to 90 ℃;

- stability. The cross section and length of a pipe under water pressure at room temperature do not change for decades.

At high temperatures, up to 90 ℃, the cross section and length of polypropylene pipes may change upwards. But the changes do not occur due to the increased fluidity of the polymer, as, for example, in the case of polyvinyl chloride, but because of the large coefficient of thermal expansion.

Therefore, PN 20-25 is taken for hot water, the walls of which fiberglass reinforced or aluminum foil.

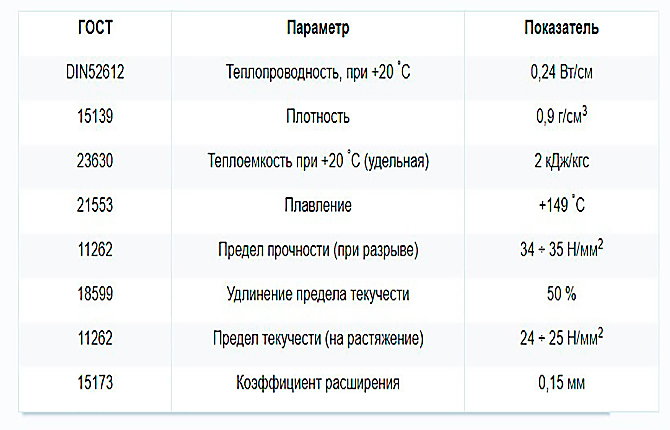

The marking "PP-R" means that a random copolymer of polypropylene is used for the production of products. One of the most resistant polymers used in industry. In terms of chemical resistance, the ability to withstand acids and alkalis, it is second only to cross-linked polyethylene.

Water pipelines

Polypropylene pipes PPR PN10, PN25 are mainly used to replace steel water mains both in high-rise apartments and in private households. Pipe blanks with a diameter of 10-25 mm are so flexible that the pipes are supplied wound in coils.

In this case, neither a break in the walls nor cracks on the surface is formed. But this applies only to conventional PPR PN10, PN 20 and PN25 blanks with aluminum foil reinforcement must be handled more carefully, avoiding excessive bends and impacts on the outer surface.

PPR polypropylene pipes are welded with fittings, couplings, corners using an electric soldering iron. The quality of the seam turns out to be almost monolithic, therefore, if PN10 is designed for a working pressure of 0.1 MPa, then you can be sure that there will be no leakage at the welded joints.

Heating

For hot water supply and heating systems, polypropylene products PN25 with a reinforcing layer of fiberglass or aluminum are used. Fiber-reinforced tube blanks are easier to install. They are cheaper, but more often designed for temperatures no more than 90 ℃.

Polypropylene with fiberglass is mainly used for hot water, but only inside residential premises. The reason is simple - PPR PN20, 25 does not tolerate ultraviolet light, therefore, if pipes are to be installed in open spaces, then it is better to use a screen or covers.

Aluminum foil reduces temperature deformations and at the same time provides more uniform heating of the walls, so hot polypropylene pipes practically do not sag. They can be used to equip a warm water floor. It will turn out a little more expensive than when using polyethylene heating channels, but in general the quality and durability of the pipeline will be higher.

Industrial highways

Polypropylene pipes PN10 are widely used for arranging pneumatic lines. In paint shops, in warehouses, in carpentry areas, restrictions on the use of power tools are often set. Therefore, pneumatic drills, hammers and screwdrivers are used.

Medium pressure steel air ducts were replaced with polypropylene ones. Again, condensate does not accumulate inside the line, there are no fistulas of through corrosion.

PN25 is suitable for irrigation and hot water supply in greenhouses, saunas, car washes. Often, polypropylene pipes are used to supply disinfectant solutions and drain dirty water when washing parts.

Folk art

Simple welding technology and the availability of polypropylene pipes have made PPR PN10 PN25 the most popular material for homemade homemade products.

Craftsmen do unusual things from ordinary PPR polypropylene blanks:

- frames for greenhouses and country greenhouses;

- garden and country furniture;

- crafts and toys.

In this case, no additional equipment is required, a standard set of an electric soldering iron, polypropylene couplings, corners, crosses is enough. Although the design of the products does not fit into the latest fashion trends, the furniture and frames of the greenhouse are durable.

The durability and strength of a home-made greenhouse on PPR scraps is several times higher than wooden, aluminum structures. Even steel pipes with a galvanized surface are inferior to PPR polypropylene.

Polypropylene pipes characteristics PPR PN10, PPR PN20, PPR PN25

The two digits present in the brand indicate the pressure for which the polypropylene product is designed. To select the diameter of the pipes, it is enough to know the cross section and the design pressure of the future water supply. In this case, it is 10 At for PN10, 20 At and 25 At for PN20 and PN25, respectively. The larger the cross section of the pipeline, the thicker the walls should be.

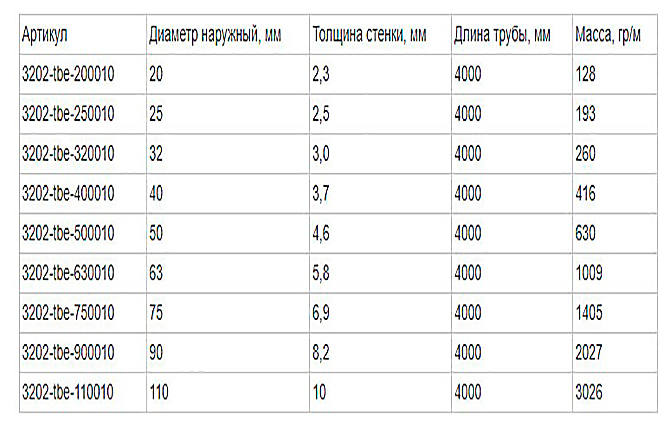

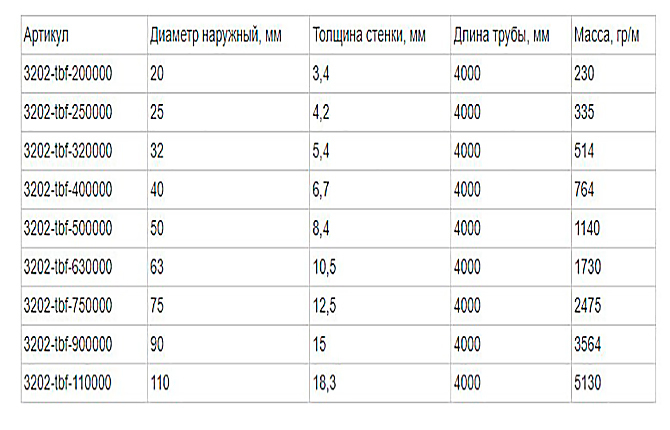

PN10 refers to lightweight types of pipes with thin walls. It is used mainly in domestic water supply systems. Where there are no pressure surges and water hammer. The dimensions of the blanks depending on the section are given below.

Polypropylene pipes PPK for 20 atm

PN20 is produced for pumping hot and cold media under pressure up to 20 atm. Pipes without reinforcement are available in white and gray colors. They are used primarily for cold water supply, but can withstand flow with a limiting temperature of up to 80 ℃. More often on blanks, the material is marked as PPRC.

In addition to the 20 Atm pipe blank, for cold water supply, you can find polypropylene PN20 with a characteristic cellular surface pattern on sale. This is a polypropylene pipe reinforced with a layer of perforated foil.

Due to the presence of holes in the foil, the adhesion with polypropylene is sufficient to avoid delamination of the pipe even with strong heating up to 95-98 ℃. Therefore, the coefficient of linear expansion of the material is almost half that of unreinforced PN20.

Pipes for 25 At for the main with cold and hot water

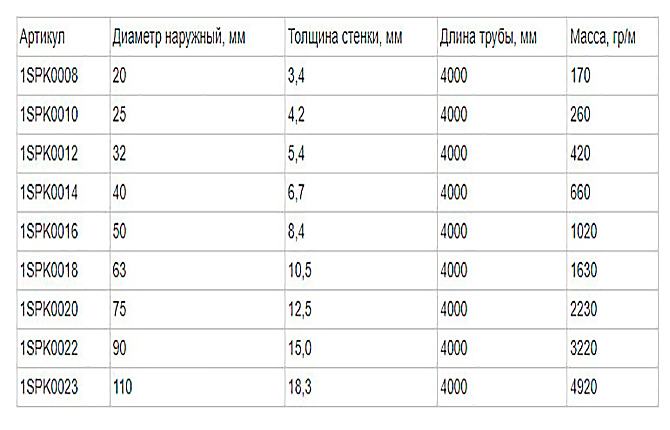

Reinforced PN25 is used primarily in heating systems and the supply of cold liquids under high pressure. The main properties of the tubular billet are shown in the table below.

Reinforced pipelines are created for heating. The maximum temperature and pressure of the pumped medium are 25 atm and 95 ℃, respectively. A polypropylene pipe can be reinforced with an intermediate layer of fiberglass impregnated with polypropylene.

During the production process, the underlayer is necessarily colored, usually red. Therefore, the fiberglass-reinforced workpiece is easily distinguished by the cut.

Polypropylene blanks with aluminum foil are produced with perforated and solid sheets. In the latter case, the temperature of the pressurized liquid can reach 100℃.

Perforated PN25 for heating are less popular, although they are cheaper.

The characteristics of pipes with a perforated sublayer are not inferior to blanks with solid reinforcement. The reason for the decline in interest is the more complex welding technology. At a minimum, you need to remove the aluminum layer before soldering two polypropylene parts.

What are the advantages of the PN10 pipe

You can hear a lot of conflicting opinions about how safe it is to use polypropylene water pipes, how long heating systems with PPR pipe piping last. But it would be correct to evaluate the result of using PN10 based on the results of operation in 20-30 years.

Polypropylene pipes PN10 have a whole list of positive qualities:

- resistance to corrosion under the influence of water, oxygen and chlorine dissolved in it;

- simple assembly technology - anyone who has learned how to handle an electric soldering iron can assemble a water pipe;

- PN10 pipe is very durable. Breaking a polypropylene blank with your hands is difficult even for a physically strong person.

In addition, the material practically does not age. Manufacturers of PN10 polypropylene pipes give a 10-year warranty on their products, regardless of operating conditions. This means that the material will last at least twice as long.

How to install PPR PN10

Plumbing assembly diagram from PPR pipes is the same as in the case of using metal blanks. Initially, the length of the line from the input to the consumer is measured. Then a diagram is drawn up and places for soldering individual segments are selected.

But there are also differences:

- at the points of insertion into the line of couplings, taps, gate valves, valves, it is necessary to make an allowance for the shrinkage of polypropylene during soldering. For PPR PN10 - at the welded joint, the polypropylene blank loses 15-20 mm on one side;

- PN10 has a high coefficient of thermal expansion, therefore, when planning a water supply line, it is necessary to make compensating loops or pockets to avoid deformation from hot water or high temperatures air;

- the quality of the connection depends on the exact observance of the soldering technology.

It is best to master the technology on scraps of polypropylene blanks. In this case, the material is cut with special scissors, otherwise everything can be ruined.

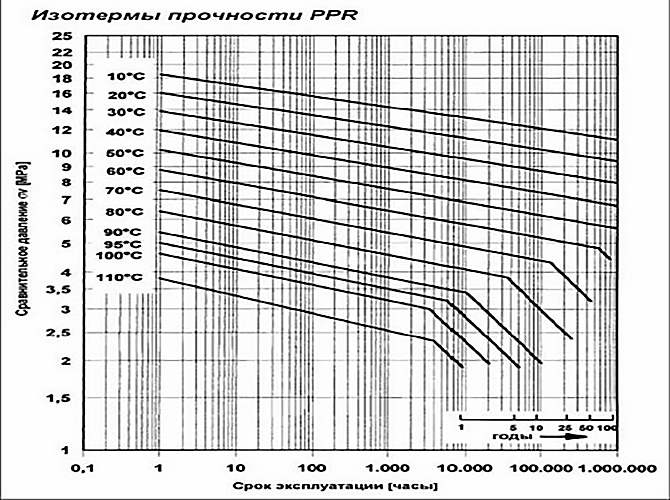

PN10 polypropylene pipes age like any plastic. But there is nothing to worry about, you just need to correctly select the operating mode from the table so as not to exceed the maximum allowable pressure. On the other hand, polypropylene, especially in the form of a copolymer, is not the best choice for drinking water supply.

What do you think - better water supply from polypropylene or steel pipes? Write in the comments. Bookmark the article, share it on social networks.