Supply and exhaust ventilation of the house - this is when fresh air from outside the building enters the inside, displacing the exhaust. In this way, the air space in the premises is cleaned, plus - the standard concentration of oxygen is ensured.

But at low temperatures outside, the supply air masses reduce the temperature inside the house. To prevent this from happening, a heat exchanger is installed in the ventilation network. And to raise the efficiency of work, you need to use only the best recuperators.

The content of the article:

-

What is a recuperator

- Advantages and disadvantages of recuperators

-

Types of recuperators

- Plate recuperator

- Rotary

- Recuperator with intermediate heat carrier

- Chamber

- Freon

- Compact heat exchanger for an apartment

-

What to look for when choosing

- Material

- Functional

- Installation Methods

- Choice for room type

- Selection by manufacturers

- Rating of plate heat exchangers

- Rating of the best rotary heat exchangers

- Breezers rating

What is a recuperator

This is equipment in which the supply and exhaust air flows are separated by a metal wall. The incoming air has a lower temperature and the outgoing air has a higher temperature. To raise the temperature of the first one, it is necessary that the second stream give up its thermal energy before being released into the street.

Since this cannot be done directly, without intermediaries, heat transfer is carried out through the metal. Because it has the highest thermal conductivity. And the thinner the metal wall, the larger its area, the more efficient the transfer occurs.

It turns out that the recuperator is a simple heat exchanger. The main purpose of its creation is to save on heating costs. Because the supply air is heated without using any energy.

This system can only work in the supply and exhaust ventilation network. If there is one in the house, then installing a ventilator in it is not difficult.

For a private house, recovery is an opportunity to help the main heating. During its operation, the saving of thermal energy is up to 6 kW per day. It depends on 3 factors:

- the number of people living in the house;

- the number of rooms in the house;

- how many living rooms are in the building, how many utility and service rooms.

Manufacturers offer heat exchangers with high efficiency - 70-80%. The temperature of the air that leaves the heat exchanger into the house depends on this indicator.

There are special formulas by which you can calculate the temperature indicator, taking into account the efficiency of the device. One of them: t=efficiency x (t1-t2) + t2, where:

- t1 is the temperature inside the rooms;

- t2 - street temperature.

For example, if it is 0º outside, +22 ℃ inside the house, efficiency is 75%, then the temperature of the air coming from the heat exchanger will be: t=0.75 x (22-0) + 0 = 16.5 ℃.

Taking into account different heat losses, this figure in reality will be less. Approximately +15 ℃.

Advantages and disadvantages of recuperators

The ventilation network with a heat exchanger has strengths:

- assistance to the heating system of the house without additional energy investments;

- saving money on heating;

- ease of installation and maintenance;

- practically zero costs for the operation of the recuperator;

- full automation of processes;

- the equipment is quiet;

- long service life.

Among the minuses of the recuperator, the following should be highlighted:

- The heat exchanger inside the ventilation system creates aerodynamic resistance. But it is not large - up to 100 Pa. And yet, you need to choose a fan for the system, taking into account this indicator.

- The ventilation network without a heat exchanger costs less than with it. Plus - the complexity of maintenance increases. Not by much, but there is an increase. Although all this is compensated by obtaining additional heat without investment.

- In some types of recuperators, there is a possibility of air flow overflows - air from the exhaust circuit can enter the supply circuit. For private housing construction, this is not so critical. But if ventilation with a heat exchanger is installed in infectious diseases hospitals, special laboratories, then this shortcoming can be dangerous due to the ingress of viruses and pathogens into the building. Therefore, at such facilities, equipment of a freon type or with an intermediate coolant is installed.

- Some types of recuperators have large dimensions. For example, plate. Therefore, appropriate space is required for their installation.

Types of recuperators

Manufacturers offer 5 types of recovery units:

- lamellar;

- rotary;

- with an intermediate coolant;

- freon;

- chamber.

The first two are used in private housing construction. They are energetically independent. Easy to install and maintain. The price is low compared to other models and types.

Plate recuperator

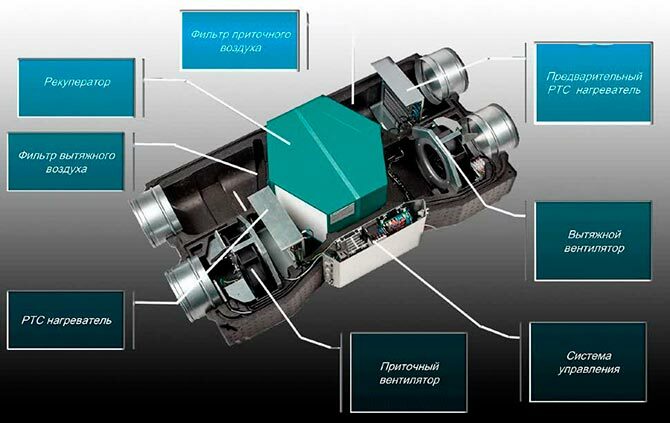

The name of the device was given by design features. The main heat exchange body consists of several plates between which air passes from 2 circuits of the ventilation system: supply and exhaust.

The plates are placed in a special closed box. There are gaps between them. Plates form cells through which air moves. The movement takes place in a checkerboard pattern. In one cell, the air flow moves from the supply circuit, in the next cell from the exhaust circuit, then from the supply circuit, and so on in turn.

Air streams from different circuits do not mix. They are in contact with each other through plates made of a material with high thermal conductivity. Through it, thermal energy is transferred from the air from the exhaust network to the air from the supply network.

So that the heat exchanger itself does not become clogged with dust over time, filters are installed in it. One is on the supply side, the other is on the exhaust side. In any case, the air enters the rooms of the house purified.

The temperature difference in the 2 circuits, especially in winter, causes condensation to form. To do this, a pallet is installed in the recuperator, connected to the sewerage of the house.

The condensate formed on the plates increases the thermal conductivity of the plates themselves. The efficiency of equipment increases dramatically.

Plate heat exchangers do not have the highest efficiency. It does not exceed 65%. Suitable for private houses. After all, recuperation is just an addition to the heating system.

The efficiency of work can be increased by adding an additional cassette of plates to the heat exchanger, thereby increasing the area of contact between media with different temperatures. The larger the area, the more intense the heat transfer.

The advantages of the model include:

- the absence of rotating, moving parts, multi-level or multi-block nodes, which guarantees long-term operation of the device;

- no blocks that require power supply.

Flaws:

- in winter, the heat exchange unit is covered with ice from the inside and outside, which reduces the efficiency;

- difficult to make by hand.

With the first minus, manufacturers began to fight effectively recently. To do this, the unit uses the "defrost" mode. This is a separate channel operating in inflow mode. It is bypass, passing in addition to the recuperator. Cold air from the street is supplied to the rooms of the house directly, lowering the temperature inside for a while. The lower the temperature, the lower the humidity. Accordingly, the formation of ice is reduced.

There is another option. To do this, instead of metal plates, plates made of hygroscopic cellulose are used. The latter absorbs moisture well, passes it through itself and gives it to the air flow of the supply circuit. This type of recuperators is recommended to be installed in residential buildings.

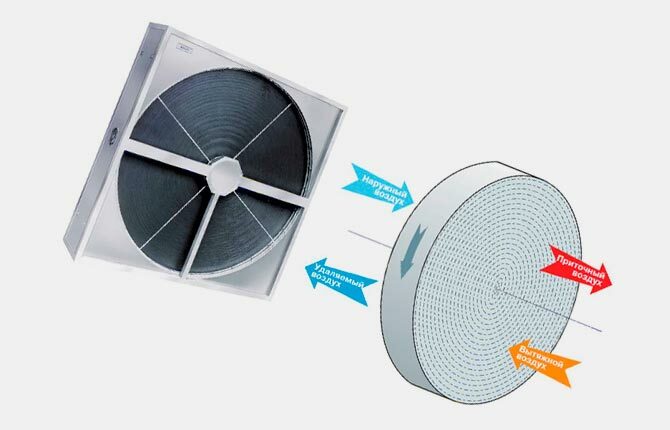

Rotary

The name of the recuperator comes from the word "rotor". This is a part in the form of a shaft rotating about its axis. Such a shaft is present in the rotary heat exchanger. It has a large number of plates or pipes installed on it. Their location is along the axis of the shaft.

Structurally, a cylinder with a large number of longitudinal gaps is obtained. Through them, air from 2 circuits passes through.

The principle of operation of a rotary heat exchanger:

- Cold air from the street and warm air from the rooms of the house pass through the plate cylinder.

- Each medium has exactly half of the cylindrical part.

- Warm air heats up its part.

- The rotor rotates and moves the heated half to a position where cold air flows into the rooms.

- Here, the heated plates give off heat to the cold air, which causes the temperature of the latter to rise.

- At this time, the second half is heated, which then moves to its place.

- The rotor part of the recuperator works like this constantly without stopping, in a cyclic mode.

The uniqueness of the design is that the heated air also pulls moisture into the rooms, which remains in the form of condensate on the walls of the plates. This eliminates the need to install humidifiers in the building. The efficiency of the rotary model is higher - up to 80%.

In this case, the efficiency and intensity of heat transfer can be adjusted. To do this, reduce or increase the speed of rotation of the rotor. The faster the shaft rotates, the less heat transfer occurs. And vice versa. If we compare the lamellar design and rotary, then the latter is more compact.

Speaking of high efficiency, it must be noted that this indicator is not so smooth. It's all about the design of the recuperator itself. When the rotor rotates, some of the air from the exhaust system remains in the cylinder and returns through the inflow back to the premises.

To reduce this effect, manufacturers install purge sectors in the design. Their task is to expel the remaining air from the exhaust circuit back into the hood. But with the air flow, heat also goes into the hood. Hence the decrease in efficiency. It is small, but present.

The design of the rotary heat exchanger itself is complex. In addition to the cylinder on the shaft, it includes a housing, a belt drive and a motor. The unit is energy dependent. And although the engine power is small, but with frequent power outages, especially in suburban villages, there is a problem. No power - the heat exchanger does not work.

The recuperator has rotating parts. This reduces service life and increases maintenance complexity. And although there are no problems with the latter, everything can be done by hand, most consumers use the services of specialists. And these are expenses.

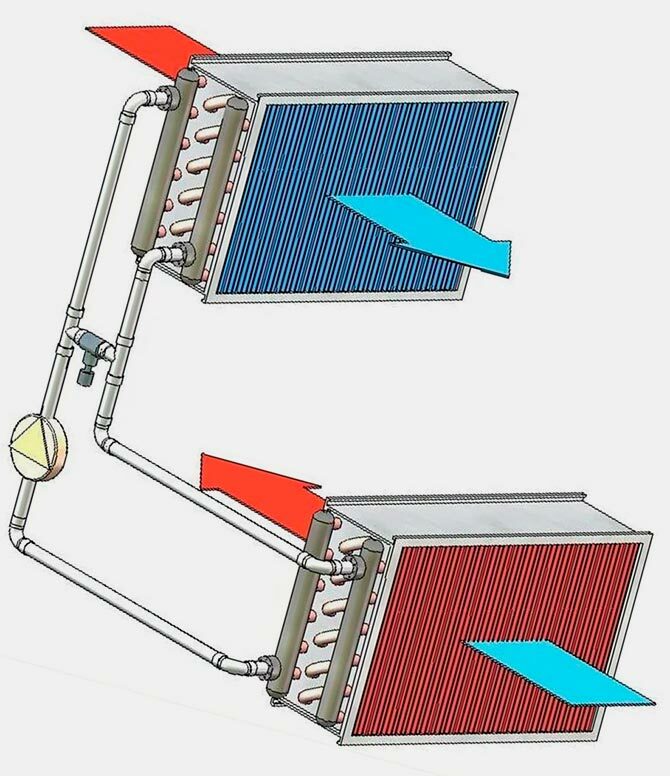

Recuperator with intermediate heat carrier

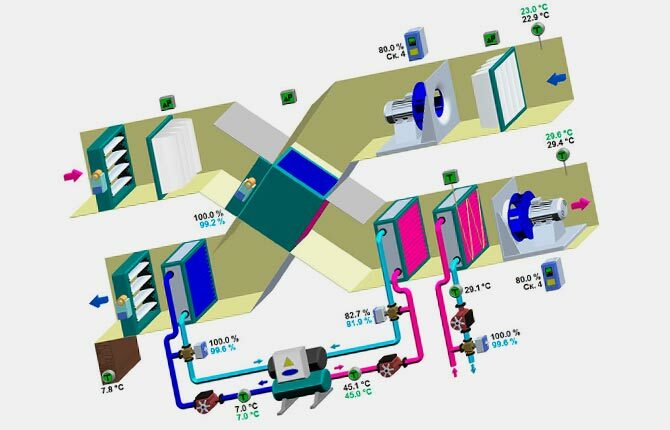

Structurally, these are 2 classic heat exchangers interconnected by pipes and valves. The essence of the operation of the unit is that one heat exchanger is installed in the ventilation wire of the exhaust system, the second - in the supply. Water or an aqueous solution of glycol moves inside. The movement is provided by a circulation pump.

It turns out like this:

- water in the heat exchanger installed in the exhaust network is heated from the air from the house;

- it is pumped through pipes to the second heat exchanger, where it gives off thermal energy to the air from the street;

- after which it moves through another pipe to the first heat exchanger;

- the process is repeated.

Model advantages:

- threads can never move;

- exhaust and inflow pipelines can be located far from each other;

- installation of heat exchangers and pipes can be carried out in a vertical position or in a horizontal position.

There is only one drawback of the recovery unit - low efficiency due to the intermediate coolant. It makes up 45-55%. The fork is wide, because the efficiency in this case depends on the speed of movement of the coolant, and therefore on the pumping speed. The unit is energy dependent.

Chamber

The simplest design. A valve is installed inside the chamber-chamber. It rotates around its axis, opening one part of the chamber, then another. Air from the hood enters one part, heating the walls and space. Then the valve moves and opens the heated half for cold air from the street. At this time, the second part is heated. And everything repeats with the movement of the valve.

The efficiency of the chamber heat exchanger is up to 80%. But it has several disadvantages:

- rotating parts;

- mixing of flows due to which efficiency decreases, odors are transmitted.

Freon

This is the most expensive type of recuperators, structurally complex. Heat transfer technology is based on the physical capabilities of the refrigerant. Freon in this case. It quickly boils at low positive temperatures and also quickly condenses, releasing great thermal energy.

The freon recuperator is a vertical coil. Its lower part is blown by warm air coming out of the premises of the house. Top - cold from the street.

At the bottom, freon boils from heating, turns into steam, and moves to the top. Here it collides with cold air, condenses, releasing heat. The latter is transmitted through the walls of the coil to the outside air. Having turned into a liquid, freon, under the influence of physical forces, descends to the lower part. The process is repeated.

Compact heat exchanger for an apartment

All of the above units are used for installation in private homes. They are bulky and require free space for installation. Therefore, most often they are installed in the attic, where ventilation ducts are installed.

For apartments, manufacturers produce separate recuperators - breathers. There are several models. The simplest is a unit that works on the exhaust and air supply alternately.

Variability is 40-70 seconds. For example, 40 seconds from the room the air is brought out, heating the channel through which it flows. The next 40 seconds are vice versa - from the street, cold air is pumped into the house, passing through a heated channel, heating up.

Such breathers can also work either only for inflow or only for exhaust.

Another model with 2 channels: exhaust and supply. But they are all compact. They don't need a ventilation system. They are installed in a through hole made in the wall.

From the inside, the device is closed with a grill in a beautiful frame. From the outside only the grille. Inside the tubular body there is a duct fan that drives air flows back and forth. Works well with air conditioning.

Recuperators of this type are not the best. Located in only one room, they create problems in others. In apartment buildings there is a central ventilation network.

The recuperator is its competitor, which creates either vacuum or pressure at one point. Accordingly, in other rooms, the flows operating along the lines of the ventilation system are confused. The most unpleasant moment in this situation is the stagnation of air in distant rooms.

What to look for when choosing

There are several indicators and characteristics that are the criteria for choosing a recuperator. The most important is air exchange. This characteristic is laid down in sanitary norms and rules that apply to all objects, regardless of purpose.

For each room, a complex calculation is made taking into account 3 factors:

- volume;

- ceiling height;

- number of windows.

That's why ventilation system narrow-purpose specialists are counting. They will also take into account the presence of a recuperator in the network. The easiest way to choose air exchange for residential premises is 30 m per person3/час. This is the minimum value. The optimal one is 60 m3/час. For the kitchen, bathroom and other service rooms, the value is greater.

If 4 people live in the house, then the performance of the heat exchanger should be 60x4 = 240 m3/час. Usually, when calculating, another 20% is added to the resistance of various devices and devices: filters, gratings, taps, and so on.

And other selection criteria:

- the material from which the recuperator is made;

- unit functionality;

- installation method;

- room type.

Material

The body of the heat exchanger is made of galvanized metal sheets or aluminium. For lamellar models, the main selection criterion is the material of the plates. There are 3 types used here:

- aluminum;

- plastic;

- hygroscopic cellulose;

- polymer membrane.

The first two are frozen over in winter, and this is a big problem. The last two pass through themselves not only heat, but also moisture. This is a plus. At the first today, manufacturers solve problems. A recent proposal is additional heating of the plates with low voltage electric current. That is, the plate heat exchanger becomes volatile. But these are small expenses with an increase in the efficient operation of the unit.

Since the heat exchanger is usually installed in unheated rooms, its body is insulated. This also applies to ventilation ducts.

Functional

It is better to give preference to models that have built-in sensitive and reliable automation. With it, it will not be necessary to constantly refer to the ventilation system for various reasons. Automation will do everything itself.

Options to consider when choosing a heat exchanger:

- devices responsible for the operation of the fan, adjusting its power and the speed of rotation of the impeller;

- devices that monitor air flow;

- effective filtration system;

- timers.

Recuperators on the market are presented in different versions, which take into account the operating conditions. That is, high or low temperature, humidity and so on. Therefore, recuperation units can be additionally equipped with humidifiers, heaters, dehumidifiers, coolers.

Manufacturers have recently offered recuperators that can be connected to the Smart Home system. In any case, all of the above options make it possible to use the system without human intervention, with their help, the quality of ventilation at home increases, and maintenance costs are reduced.

Installation Methods

Recuperators can be wall-mounted, they are also hinged, floor-mounted. Horizontal installation type or vertical. You will have to choose according to the specific parameters of the ventilation of the house, at the place where the ventilation network itself is located.

More often it is recommended to carry out installation in attics or basements. Boiler rooms, pantries and other outbuildings, outbuildings or rooms inside the house are suitable.

The main thing is to place the heat exchanger away from bedrooms and children's rooms. After all, the equipment works with a little noise that will interfere with rest.

In apartments, breathers are mounted on external walls - preferably from the side of a balcony or dressing room.

Choice for room type

Ventilation of any type works according to the same principle - fresh air from the street enters the house from one point, and exhausted air from the premises is removed from the other. There are clear standards for where to locate the openings of the exhaust circuits, where the supply ones.

The first are located in office and utility rooms: kitchens, bathrooms, toilets, corridors, hallways. The second in living rooms - bedrooms, living rooms, children's rooms, offices and more. The thing is that residential should be ventilated as the main premises, office and household as indirect, that is, in small portions.

Often, if living rooms are large, experts recommend installing both supply and exhaust ducts in them. This is the first thing to consider.

Secondly, kitchens, bathrooms and toilets must be equipped with separate hoods. The latter are installed either in the central ventilation system of the building, or in windows or external walls. In general, you should not connect the kitchen and bathroom to ventilation with a heat exchanger. Wet vapors on the surfaces of the parts of the unit will begin to collect dirt, the layers of which will quickly begin to grow. This will reduce openings and gaps, which will cause a decrease in the efficiency of the heat exchanger and a decrease in efficiency.

And one more piece of advice - the correct location of the external openings of the supply system. They must be located;

- away from chimneys, kitchen hoods;

- not from the side where the wind blows - less dust and dirt.

Selection by manufacturers

There are many offers on the market. Picking the right one isn't easy. But there are companies that are well-known in the field of home appliances. They also manufacture recuperators of various types. It is these manufacturers that lead the ranking of the best recuperators in 2021.

It is impossible to make TOP 10 models in one category. But you can compose several in each separately.

Rating of plate heat exchangers

In the first place - Electrolux EPVS-1100. This is a monoblock heat exchanger of small dimensions, which makes it possible to place it even between the base ceiling and the false ceiling structure. It has double insulation: inside and outside, which causes noise reduction.

Advantages:

- Efficiency - 90%;

- warranty period - 2 years;

- two-speed fan;

- the shape is a hexagon, which made it possible to increase the area of the unit by a third;

- remote control;

- a timer is installed in the design;

- automation;

- frost protection system.

Drawback two:

- the most expensive plate-type heat exchanger;

- no heating system.

In second place is Mitsubishi Electric Lossnay VL-50SR2-E. A simple design in which a damper is inserted into the supply channel. With its help, you can regulate the supply of fresh air from the street. This is true in winter, when it becomes necessary to reduce the supply of cold air masses to the house.

Advantages:

- vertical or horizontal mounting;

- Efficiency - 80%;

- internal insulation.

There is only one drawback - it makes a lot of noise when it works at full power.

The third position in the 2021 ranking is Shuft UniMAX-P 1500 SW-A. The same small-sized unit, in which the nozzles can be located either on the left or on the right. It is completed with a heating element: either electric or water.

Advantages:

- installation or hinged, or floor;

- high quality thermal insulation;

- fine filters are installed at the inlet and outlet, which are changed once every six months;

- fan with low operating noise;

- separate line for condensate drainage.

The rating of four closes the Royal Clima Soffio RCS 950 2.0. A compact heat exchanger that can be hung on a wall or installed between the base and finishing surfaces of the ceiling. Plates are membranes that conduct moisture through themselves. The unit works well with cold air temperature -20℃. It does not require a heating system.

Advantages:

- three-speed fan;

- well-thought-out condensate drainage system;

- two-level timer;

- supply and exhaust fans operate independently of each other;

- well-functioning automation;

- reusable filters - you just need to vacuum them out.

- No deficiencies found.

It is necessary to add one more recuperator brand Vents PR 700x400 to the list. He was in the TOP 4 of 2020. Unit with a cross-shaped passage. Made of steel covered with aluminum plates. Simple design without heaters and coolers, hence the low price. What attracts consumers.

Rating of the best rotary heat exchangers

There are no places or positions given out. Just created a rating that includes four models. The first one is Lessar LV-RACU 400 VER. It is made at factories located in different countries: China, the Czech Republic, Sweden and Lithuania.

But in all models, fans from a German manufacturer are installed, which work very quietly. At the same time, electric motors are economical. Savings up to 60% of the face value.

Advantages;

- Efficiency - 75%;

- insulation - mineral wool 5 mm thick;

- body - galvanized;

- warranty period - 3 years;

- simple structure, convenient to maintain.

No deficiencies were found.

The next model is the Breezart 2700 Aqua RR. This is a Russian brand that is produced at a Russian factory. One of the advantages is high-tech automation, which makes it possible to connect to the "smart home" system, control operation of the heat exchanger via smartphones or computers, control the quality of the filters, make settings unit.

Other benefits:

- 2 operating modes - Comfort and Restart;

- insulated body;

- control through the remote control, which has a built-in monitor;

- coarse filters G4;

- week timer.

The only drawback is the high price.

Next - Systemair Topvex SR06 L-CAV. This is one of the most expensive recuperators. The reason is that high-quality components are used. The case is steel with high reliability in terms of protection and burglary. There is no condensation inside.

Other pluses:

- Efficiency - 80%;

- the doors in the body are large, which makes it easy and convenient to get inside for maintenance;

- built-in automation.

And the last one is Blauberg Komfort Roto EC LE1000-4.5. German brand, which ensures the operation of the heat exchanger even in severe frosts. A heater is built into the design.

Advantages:

- Efficiency - 80%;

- automation;

- noise level is low;

- small heat losses;

- fan settings;

- filter status control;

- protection class - high;

- built-in alarm system, notifying about the accident.

The cons of the recuperator were not found.

Breezers rating

To bring the TOP 10 best recuperators to a complete list, you need to add two best breathers to it.

The first is Ballu ONEAIR ASP-200 from a Chinese manufacturer. This is a household inverter-type heat exchanger. Does not freeze even at -45 ℃. Designed to work in rooms up to 75 m2.

Advantages;

- air ionization;

- the presence of a UV lamp;

- ceramic heater;

- in the presence of the "smart home" application via WI-FI;

- noise does not exceed 45 dB, this is with a performance of 200 m3/час;

- aromacapsule, which aromatizes incoming air flows;

- efficient filter system.

The price in the segment is above average, which many consumers consider a disadvantage.

The second is Blauberg Winzel Expert Wi-fi from a German manufacturer. This is a bestseller of 2022 due to high energy saving.

Advantages:

- two fans - doubled the power of the heat exchanger;

- humidity sensors that control this indicator indoors;

- several modes of operation;

- WI-FI module, with which you can configure and control the operation of the heat exchanger systems;

- Efficiency - 93%;

- minimum power consumption - 5-7 W;

- low noise level - at night 11 dB, during the day no more than 30 dB;

- ease of management and maintenance.

The only drawback is the high price.

Energy saving has become an important component in people's lives. Therefore, recuperators are equipment that today is becoming part of the house, offices and other facilities.

There are many offers on the market, it is difficult to choose something worthwhile. Therefore, ratings are created, which are based on the opinions of specialists, consumers, and manufacturers. A classification is created that takes into account the technical characteristics of the unit, its price, its design qualities and other indicators. But, in any case, everyone decides for himself which recuperator to buy for a house or apartment.

In the comments, please leave your thoughts about recuperators. Maybe someone will share their own experience of using this device.