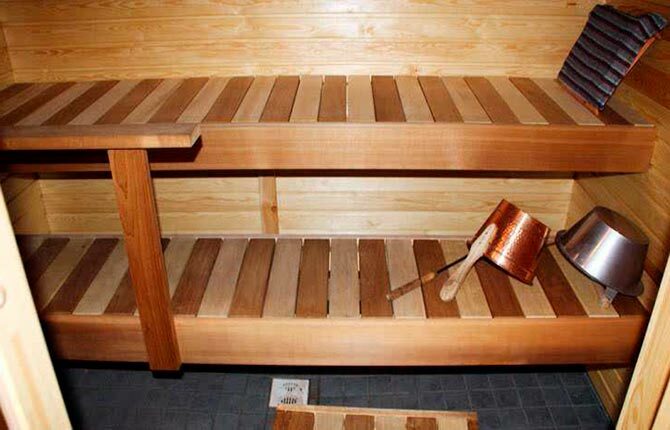

Steam room - heart baths, in which 2 important elements are installed: an oven and shelves. One warms, on the other they sit or lie, taking bath procedures. And if everything is clear with the stove - it must warm the room to a certain temperature, then you need to figure it out with a wooden shelf. Especially if the task is to make shelves in the bath with your own hands.

The content of the article:

- The choice of durable material for the shelf in the bath

-

Step-by-step instruction

- Choosing a drawing and design

- What materials are needed

- Collection of shelves in the bath

- How to make a supportless shelf in the bath

- How to make fasteners

- How to take care to last longer

The choice of durable material for the shelf in the bath

The classic material for making a shelf in a bath is wood. No replacement has yet been found for him. Therefore, it is not worth resuming the search among modern materials. You just need to know what kind of rock you need to use for this structure.

More often shelves are made of aspen, alder or linden. The reasons:

- high concentration density of fibers per unit volume;

- low thermal conductivity of the material;

- resins are present in wood, but in small quantities;

- easily tolerate high temperatures.

Recently, an African species called Abashi has appeared on the Russian timber market. The price is high, the characteristics are inferior to aspen.

From conifers, you can use cedar. It contains resin, which will begin to stand out at high temperatures, which will negatively affect the quality of use of the shelf in the bath.

To avoid this, you need to choose the right cedar lumber. Typically, resin is present at the junction of the main trunk with branches. That is, the fewer knots in the material, the less resin emissions will be.

Characteristics by wood species:

- Aspen. It is important to choose high-quality material for the shelf in the bath, because aspen boards can hide invisible defects, which, under the influence of changes in humidity and temperature, will go into the category visible. And this will subsequently affect the quality of the shelf in the bath.

- Linden is the best option. The material is beautiful, retains smoothness for a long time, is easy to process, which is important when building a shelf with your own hands. Gives off a pleasant smell.

- Alder. It has been used since time immemorial. We can say that this is the traditional wood used in baths. It practically does not absorb moisture, so it rarely cracks. If you make shelves in the bath with your own hands for a long service life, then this is one of the best options. Alder is black and light, the color practically does not change with time.

- Birch. Lumber from this tree is the cheapest. And although birch is considered a furniture tree, in the extreme conditions of the bath, it will not last long. Cracks, warping, peeling - not a complete list of what you can expect.

- Oak is the strongest and most durable, but expensive, so its popularity among bathhouse owners is low.

- Maple is not the most popular type of wood for baths. He's just underrated. Its advantages: not afraid of moisture, wide palette of shades, beautiful texture, long service life, price in the middle segment.

- Cedar also costs a lot of money, but is not inferior to oak in strength. Easily withstands high humidity and bath temperature, under the influence of which it emits a pleasant smell.

- Larch. Advantages: high strength and density, not afraid of high humidity and temperatures, long service life (other breeds cannot be compared with it). There are two disadvantages: high price, difficulty in processing. The latter is important if the manufacture of the shelf is done by hand.

Step-by-step instruction

First of all, you need to choose the type of shelf. There are three of them:

- bench, she's a shop;

- couch;

- deck chair.

The latter began to be installed in baths, as a tribute to popularity, although their practicality is low. The other two are usually combined into one shelf. Benches are installed at the bottom, deck chairs at the top. For example, if the shelves are a two-tier structure, then the two lower shelves are benches, the upper one is a bench. A lounger is a wide shelf on which you can lie down and relax. Bathing procedures take place on it - they whip with brooms, wash and so on.

As for the step-by-step instructions, after choosing the type of shelf, you need to decide on the size of the wooden structure. It all depends on the size of the steam room in the bath and the installation site of the structure. It is better to make a drawing to scale, where both dimensions and location are indicated.

Next, the necessary materials are purchased in the amount indicated in the drawing. This applies not only to lumber, but also to fasteners and impregnations. The last stage is the assembly of the structure.

Choosing a drawing and design

Before you make shelves in the bath with your own hands, you need to decide on the version of the drawing that does not seem the most difficult. The more difficult, the more money you have to invest, the more time you spend.

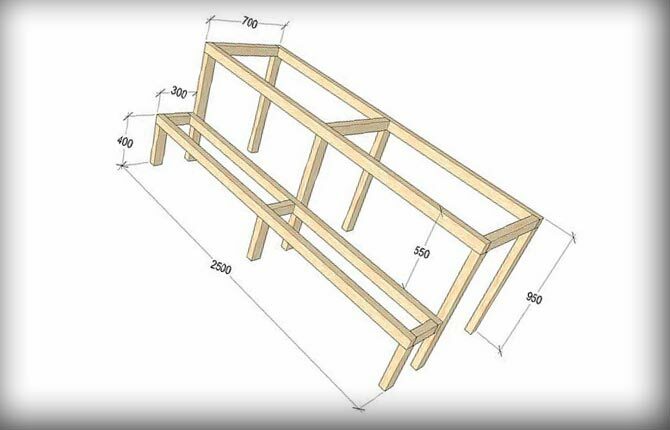

The first thing you need to pay attention to is the dimensions of the shelf - its height and depth. With the first parameter, so - if a person sits on the top shelf, then a distance of 30-40 cm should remain from his head to the ceiling of the bath. Speaking approximately, then from the ceiling surface to the surface of the upper shelf should be somewhere 1.2-1.3 m. The lower shelf from the floor should be at a distance of 20-40 cm. The distance between the shelf tiers is 40-60 cm.

Now with depth. The upper level should be wide - 80-90 cm. So it is more convenient to lie down and take bath procedures. Lower within half a meter.

The length has no restrictions. A two-meter shelf in the bath is an ideal design. But it all depends on the size of the steam room. If a two-meter structure fits in it, then it should be there.

If we talk about a simple design that you can do with your own hands, then it is a frame. A frame is made of bars or boards, which is sheathed with shields of slats or boards. Shields can be fixed or removable. The second option makes it possible sometimes to dry the flooring on the street, to repair it outside the bath.

Structurally, you can make shelves in the bath in the form:

- Stairs, that is, steps. Traditional model, easy to manufacture, convenient and practical.

- Coupe. This is when one shelf is directly above the other, like couches in a railway car. The option saves space in the bath. But in order to climb onto the top shelves, you need to substitute a chair or stool.

- Angular. This is an increase in seats in the bath, increased functionality of the steam room, the opportunity to get together with a large company to chat.

If there are window openings in the steam room, then there is no need to install shelves next to them. There is a possibility that the glass will crack and crumble, resulting in personal injury.

The frame of the shelf in the bath is attached to the wall, because the structure must be stable. But this is optional. Wooden decking is attached to the frame, but you need to leave free space between the shelf and the wall. Its size is 8-10 cm. This is a kind of ventilation, plus - the condensate flowing down the wall of the bath will not collect on the seat. To increase the possibility of runoff, it is better to do flooring with gaps - leave gaps of 1 cm between the boards.

There is another kind of construction. It is also framed, only the back of the shelf is not vertical racks, but a horizontally laid board that is attached to the wall. It is the supporting element on which the rest of the main structure will rest.

What materials are needed

To make a frame, you need bars or boards. Blocks are called square or rectangular lumber, the maximum size of one of the sides of which does not exceed 100 mm. Anything more than this parameter is a bar.

It is better to choose a running material for this - bars with a section of 50x50 mm. They have a high load-bearing capacity, which is easy to increase by installing vertical posts more often. But it all depends on the model of the bath shelf. Because sometimes it is necessary to use bars of a larger section, for example, 50x70 mm, in order to make ledges on which panel decks will be laid.

If the second type is taken as the basis for manufacturing, that is, not with rear support posts, but with a carrier beam, then you need to choose a board for the latter. Here it is - the thickness is at least 50 mm, the width is selected based on how many load-bearing elements will be used.

For example, if you make a three-tier model, then 2 load-bearing boards with a width of 70-100 mm will be fine. If you reduce the width to 80 mm, then it is better to install 3 supporting elements, under each level. They are simply laid on the wall of the bath at the level of the shelves, they are also attached to it - more often with metal dowels.

The amount of lumber depends on the size of the shelf in the bath.

Further materials for flooring. They sit on them, they lie on them, and all this is in a naked state. Therefore, sharp protrusions and corners will only be a hindrance. Hence the conclusion - we need material where there are no sharp protrusions. This is a planken - a kind of lining. It is more expensive than a floorboard, but not so much as to reduce a comfortable stay in the bath. Therefore, the recommendation is to purchase a plate with a thickness of 15-20 mm.

The width does not matter, because it must be selected based on the multiplicity of laying boards, taking into account a gap of 1 cm, so that it is not necessary to cut the lumber in width. But even here it is necessary to take into account the distance between the support posts. If the deck boards are laid in the longitudinal direction, it is better to use them wider. The bearing capacity is higher. If laying is carried out across, then the width can be chosen less. The same goes for planken thickness.

Now about fasteners. The metal gets very hot in the steam bath, and if you touch it, you can get burned. But there is no better metal fastener. Therefore, it must be applied in such a way that it is not visible and it would be impossible to touch it. Self-tapping screws, bolts and nuts, steel corners and tapes - all this can be used in the process of assembling the shelf in the bath.

Collection of shelves in the bath

Before proceeding to the step-by-step manufacturing instructions, you need to prepare the tools:

- tape measure and pencil;

- screwdriver;

- chisel;

- drill;

- saw;

- wood grinder.

The first stage of the assembly scheme is the preparation of the necessary lumber. It is necessary to cut structural elements from bars and boards, taking into account their dimensions according to the prepared drawing. For this, a saw is used.

The second stage of the assembly guide is the processing of lumber. It is necessary to remove burrs, splits and other flaws that, during the operation of the shelf, can leave unpleasant splinters in different parts of the human body. For this, a grinding machine is used. More attention to flooring. And although the planken is a finished and smooth wooden product, cuts with a saw will leave sharp edges and burrs on it. You need to get rid of them first.

At this stage, it is necessary to treat the wooden elements with impregnations from natural ingredients so that they protect the wood from decay and cracking. Chemical compositions at high temperatures will begin to release harmful elements into the steam bath, which can lead to poisoning of people.

For information - on the packaging or label of liquid impregnations, you need to look for the composition. It should include vegetable or mineral oils (linseed, vaseline), turpentine. Such a composition penetrates deeply into the wood, making it waterproof.

Many bathhouse attendants with extensive experience do not recommend treating the flooring with impregnations. The tree must be, if I may say so, alive. It should be in direct contact with the human body, giving off the accumulated heat. But over time it will darken. It only says that the bath is used.

How to make a frame

The first frame view, only on support posts, is made in the form of a bookcase, taking into account the protrusions for the seats and the sunbed. For example, like the one shown in the picture below. Make it easy.

First you need to make a frame under the sunbed. Three high racks are tied around the perimeter with exactly the same cross-section bars. An additional cross member is installed inside the resulting structure, increasing the rigidity of the structure. Its location is intermediate racks.

All connections are steel corners with self-tapping screws. Do not use wooden pins here, because the metal fasteners will not protrude.

Next, you need to make a frame for the bottom shelf. Here it is better to first make a frame for the flooring, then attach 3 short supports to it. A rectangular structure is assembled with the installation of a cross member. Racks are mounted along one of its edges. All the same fasteners are used here.

It remains only to attach both parts to each other. Make it easier using steel corners and self-tapping screws.

How to make flooring

There is an opinion that the thicker the boards of the seat and sunbed, the better. This is actually true, because a thick board absorbs heat and remains in this state for a long time. It effectively warms up the human body.

To make a flooring is to assemble a kind of lattice. The connection of the parts of the structure will be carried out with self-tapping screws. Therefore, they must be screwed from the back. How to do it right:

- Longitudinal elements are laid - the upper main ones, on which they will directly sit or lie. The distance between them is 1 cm.

- The same boards as the top ones are laid on them in the transverse direction. Their number is determined by the distance between them - 50-100 cm, that is, 2 at the edges, the rest are intermediate.

- All elements are interconnected with self-tapping screws.

Here it is necessary to say separately about the fastener. If a 20 mm planquet is selected for the seat deck, then the total thickness of the 2 planks will be 40 mm.

Therefore, to fasten them, you need to take a self-tapping screw 35 mm long. It will fix both boards well between themselves, and its sharp end will not protrude beyond the top.

The wooden flooring for the bath is ready - it must be laid on top of the shelf frame. It turned out to be removable seats and a sunbed. If you attach the flooring to the frame from the bottom side, you get a fixed model. Install to the back of the hinge - there will be a reclining design.

How to make a supportless shelf in the bath

In fact, this is a frame made under the flooring of a seat or lounger. It is a rectangular lattice. The same as in the previous version, only without racks.

To make such a frame so that it is strong and reliable, you need to use the widest possible bars with a thickness of 50 mm. The best width is 90-100 mm. And the already finished frame under the flooring is attached to the wall of the bath, and they are attached to it. Fastening method - any, even for nails 200 mm. This is where safety is important. But to increase it, you need to add jibs to the design. They are clearly visible in the photo. The more jibs, the more reliable the shelves.

If the bath is small, then the shelves can also be made without racks. Again, a seat or lounger is made in the form of a flooring with a frame base. And this whole structure is attached to the walls, but not to one, but to 2-3, as shown in the picture.

You can make the shelves removable. Then, under each of them along the perimeter of the installation along the walls of the bath, supporting horizontal bars are attached. The seats are placed on them.

The third version of the unsupported design of the shelf in the bath. It is combined - there are racks, but they are not present everywhere. Namely, against the wall. The load falls partially on the wall, because it acts as a support.

To do this, the entire structure is assembled without installing and attaching the rear support elements. The frame of the top shelf is attached to the bath wall. Self-tapping screws, nails, using steel corners - any fastener will do.

How to make fasteners

The main task is that the entire structure does not adjoin the surface of the bath wall. A gap should form in this area. You can do it with a spacer. These are small wooden inserts. They are installed between the shelf and the wall. Most often, installation is done near fasteners.

How to make it easier:

- Through holes are made in the frame board under the flooring, for example, for long self-tapping screws.

- The shelf is applied to the wall and screws prepared in advance are screwed through these holes.

- They do not twist completely, here the main task is to determine the exact location of the fastener.

- Spacers are inserted between the wall and the shelf next to the fasteners.

- The self-tapping screws are screwed in until they stop, the spacers are pressed against the surface of the bath wall with a shelf.

Some useful tips:

- the more fasteners, the more securely the structure is attached to the wall;

- it is better to make small spacers that fit on both sides of the self-tapping screw;

- to increase the strength of the construction of a pair of jibs from the outer racks to the back board of the shelf.

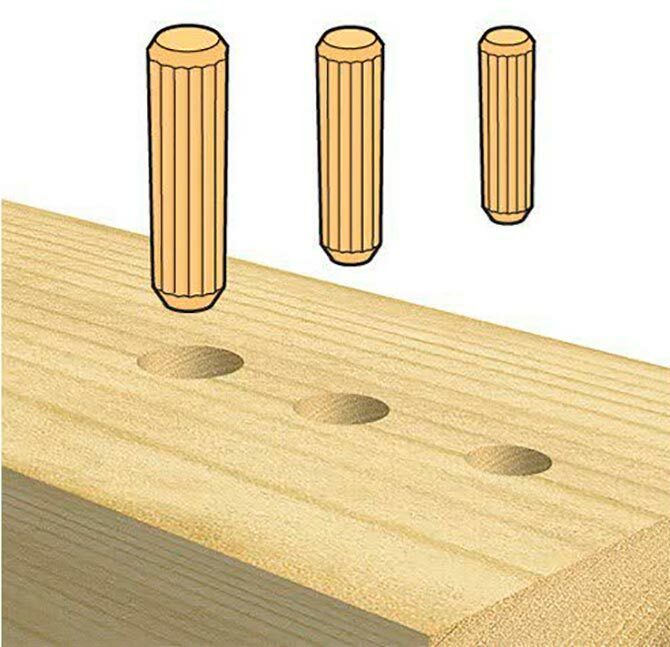

How to make a connection with pins

To get away from using metal fasteners, you can try using wooden pins for connections. On the whole structure, their use is unjustified, but in this way it is possible to make flooring for the seat.

To do this, you need the pins themselves - cylindrical wooden sticks. In hardware stores, fasteners are sold in different diameters. For a bath it is better to use oak.

How to make a pin connection:

- 2 wooden elements are applied to each other, which must be connected.

- The joint should only overlap.

- A through hole is made exactly in the center of the connection with a drill.

- A pin is driven into the hole.

A few notes;

- The pin should fit into the hole with an interference fit, for which the diameter of the latter should be slightly smaller than the diameter of the fastener.

- The installation site of the pin is filled with glue for wooden products - but it is better not to use the adhesive composition for furniture in the bath.

- It is better to use grooved or spiral pins rather than straight smooth ones. The former have higher bond strength.

How to take care to last longer

Wooden bars, boards, slats and other lumber under the influence of humidity and temperature changes inside the bath lose their characteristics. First of all, their appearance changes - the wood darkens. Then strength decreases. Colonies of harmful microorganisms, cracks and other defects appear on the surface. The tree exudes an unpleasant smell.

The main enemy of the tree is water and high humidity. Previously, the elements of the bath shelf were dried, taking them out into the street. What we recommend doing now. The more often, the better. Optimally - after each bath procedure.

The treatment of wooden parts and parts with impregnations is important. Pure linseed oil will do. After application, it takes time for the composition to soak into the wood and make it waterproof.

There are many folk methods on how to extend the life of a regiment in a bath. One of them is to take a terry towel, soak it in hot water and wipe all surfaces of the wooden structure with effort. After drying the building.

Well-functioning ventilation in the bath solves this problem in the bud. Efficient removal of moist air will create conditions for reducing humidity inside the steam room. The shelves in such a room will dry quickly, will not rot. It is not difficult to make ventilation in the bath - one through hole in the wall where the front door is located, one on the opposite one. The first should be near the floor, the second under the ceiling.

A huge number of shelf designs makes it possible to choose and make the one that is most suitable for a particular bath. Building something serious and complex with your own hands is not worth it.

Not the fact that it will turn out what is shown in the picture that you liked. It is better to stick to the position - to make an inexpensive option, but practical and functional.

Respond those who have already made shelves in the bath with their own hands. What materials and fasteners were used? What design was chosen? Was it difficult or not? What difficulties did you have to face? Share your experience in the comments.