There can be quite a few reasons for installing a door closer. But most often, the braking mechanism and smooth finishing of the door are used to avoid hitting the door frame and, as a result, damaging the hinges or the leaf itself. Installing a door closer is not difficult, but it will take patience and the ability to adjust the mechanism.

The content of the article:

-

Choice of door closer installation options

- Standard installation

- Top installation

-

Step by step installation guide

- Selecting an installation scheme

- Installation

- Adjustment and tuning

- Common Installation Mistakes

- Results

Choice of door closer installation options

First of all, you need to choose the right door closer model. All soft landing mechanisms of doors are divided into seven categories (classes) EN1-EN7, depending on the weight and width of the door leaf. The higher the class, the heavier the sash can be braked and held by the mechanism.

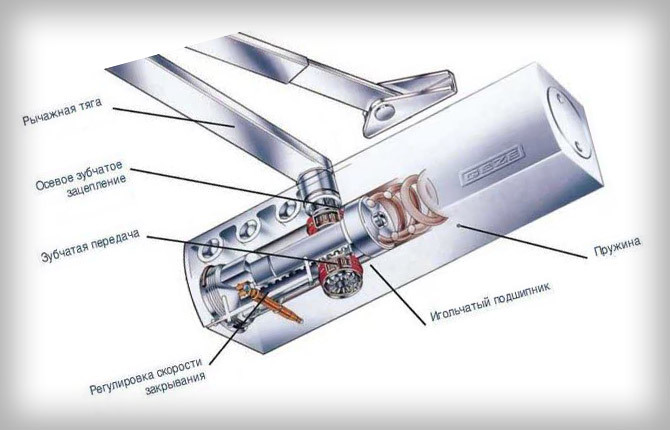

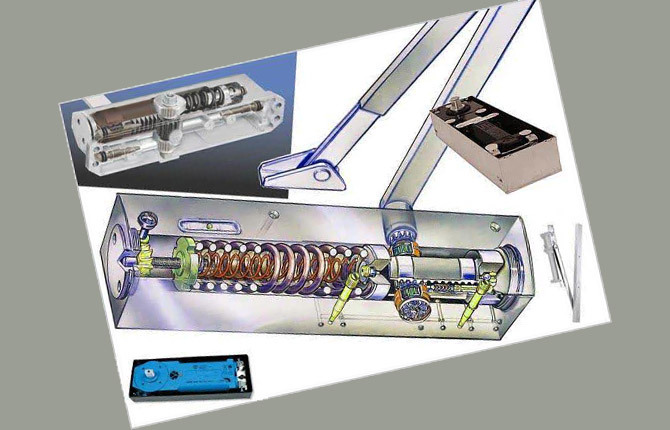

This is important, since installation on an ordinary metal-plastic door weighing 40-45 kg closer class EN3, based on more than a long service life usually leads to the destruction of the door leaf lining due to excessive loads on the site mounts. There are quite a few designs of closers; in most models, a spring and a gear drive, also known as a brake, are used to create resistance to the opening force.

The installation itself is simple, you just need to fix the body and the thrust bracket on the door frame and the leaf itself. In any case, before starting work, it will be correct to read the recommendations of the manufacturer abouthow to properly install door closers of the selected model.

You need to pay attention to the following nuances:

- The included template must be used to mount the mechanism housing. Marking and drilling holes only after leveling the position of the template using a building level or plumb line.

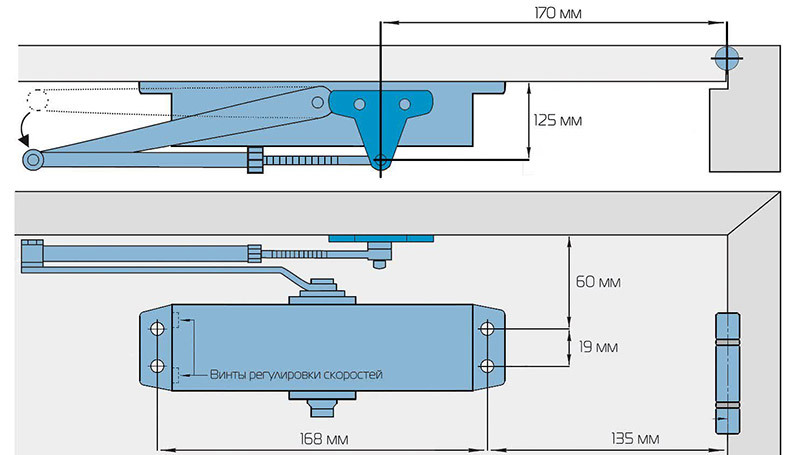

- The axis of rotation of the stem on the body must coincide with the conditional line passing through both door hinges.

- When installing, the bracket will also need to be aligned so that a pair of movable levers move in planes (each in its own) perpendicular to the axis of rotation of the rod on the body.

The installation requirements of the manufacturer must be observed. Otherwise, the resistance will be very large, in order to open the door, you will need to apply twice as much effort, and most importantly, the canvas will not close completely.

In addition, the wear of the braking mechanism will occur much faster than the warranty on the closer expires. At the same time, it will not be possible to return the device, since the cause of premature wear will be a violation of the requirements for the installation of the door closer.

Standard installation

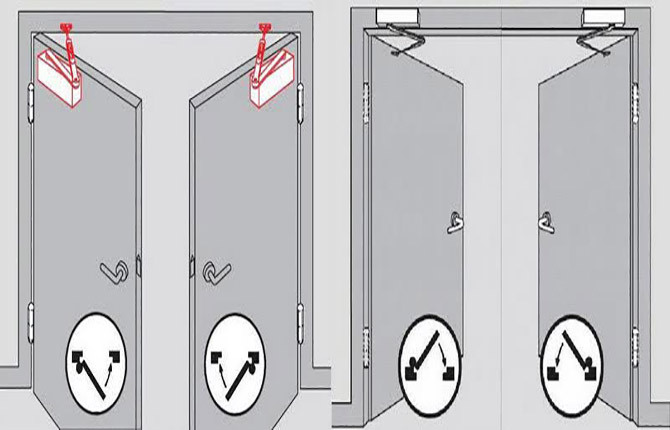

Most models of closers are designed in such a way that the linkage, which is fixed on swivel rod of the body, could be rearranged and used for doors with right and left arrangement loops.

As a standard, for example for interior doors or on the door leaf at the entrance to the kitchen, the closer is installed on the sash (moving part). In this case, the door with the door closer attached to it opens "on itself" at the entrance to the room.

In the same way, the door closer is installed on iron doors, door panels with a glass insert and plastic doors. The reason is quite simple: any door leaf has an internal frame, wooden or plastic, with a lath width of at least 90 mm.

This is more than enough to install the body of the finishing mechanism. But the loot (door frame) is always thin, the thickness of the crossbar is a maximum of 40-50 mm. This may not be enough to install the case. And for a support bracket, the width of which is usually no more than 20 mm, it is much easier to find a place for installation on the box.

An exception may be cases of installation on metal doors with an armored insert, entrance doors, insulated or with a special finish of the door leaf. In this case, it is better to study again the step-by-step instructions from the model manufacturer.

Top installation

The scheme with the location of the body on the loot is less common and is used mainly for entrance doors that open outward (when leaving the apartment). These are the requirements of fire safety regulations. The upper installation of the closer on the door simplifies the fastening of the mechanism and the bracket. It is believed that such a scheme is safer, since the force of opening and finishing the door often reaches 70-80 kg.

In addition, if the front door is made of good quality metal, then drilling a couple of holes for installing the bracket is easier than drilling at 5-6 points.

There is also an opinion that the upper installation of the closer saves the mechanism from street dust. This is not entirely true.

Any front door has the largest gap - the one above the top edge. Through it, dust can enter the body when the door closer is installed lower. But dust has little effect on its operation, since most models are dust-proof.

But cold or frosty air blowing through the gap can seriously freeze the grease or oil inside the mechanism. To open the door, you have to make an effort twice as much. When mounted on top, the door closer remains protected from cold air. But for the front door, it is still better to look for a special model.

Step by step installation guide

It is clear that before starting work, you need to put the door and the hatch in order. After installing the closer, the load on the hinges and the door frame will increase several times. Therefore, it is necessary to tighten the ties, it may be necessary to re-adjust the lock.

Selecting an installation scheme

There is not much difference, but there is personal preference. For example, for a right-handed person it is more convenient to open the door with the right hand, which means that the hinges and the door closer should be on the right.

As for interior doors. According to the laws of ergonomics, it is much easier to open the door away from you when you enter the room, and towards you when you leave it. The exceptions are:

- Entrance to a house or apartment.

- In the bathroom or bathroom.

- When using double entrance doors. In this case, the closer is installed on only one of them, usually on the inside.

In addition, you need to inspect the loot and the door leaf. Sometimes there is enough space for mounting the mechanism housing for only one installation option.

You also need to consider the location of the regulator on the body of the mechanism. In order to properly adjust the operation of the braking system, it is necessary to see the position of the regulator. Therefore, there must be a free space of at least 25-30 cm from the wall or from the ceiling surface to the case.

Advice! When choosing an installation scheme, many experts recommend paying attention to the direction in which the draft blows in the spring and summer.

The very idea of installing a door closer involves the smooth closing of the door with braking precisely as a means of slamming a gust of wind. Therefore, before making a final decision, you need to once again check the direction of the air flow inside the house or apartment.

Installation

All that is required is to correctly install the housing and support bracket on the opening door. Since the operation of the levers depends on how wide the door swings open, it is impossible to choose a place arbitrarily. Otherwise, you can greatly reduce the angle of plowing, and it will be inconvenient to enter and exit through the doorway.

Therefore, you need to take a paper sheet with a template diagram for the location of the body on the door and fix it so that the upper edge and side of the door leaf coincide with the control markings of the template. The template must be secured with tape.

The next step is to transfer the drilling points to the door leaf and loot. If the closer is attached to a metal-plastic door, then the points can simply be pierced through the paper with a sharp awl. Marks will be clearly visible on soft plastic or aluminum. If in doubt, you can lightly punch the points with an ordinary nail and hammer. For a steel door, you will need a locksmith core and a hammer of 400-500 g.

Further, without removing the diagram, holes are drilled, the diameter is selected for a specific size of the self-tapping screw. Usually fasteners are included with the door closer, so the drill can be selected in advance. In theory, the drill should be smaller than the outer diameter of the screw notch on the self-tapping screw.

It remains only to remove the template and tighten the screws first with a screwdriver, and after the final adjustment, you can compress with a screwdriver. A pair of levers is put on and fixed on the drive shaft, the support end is threaded through the axle and locked with a nut on the bracket.

You can try how the device works. Usually the mechanism brings and almost closes the door, you just need to adjust it correctly. It takes about three times as long as the installation itself.

Adjustment and tuning

Often the planes in which the bracket and the body are fixed do not coincide. In theory, the difference can be adjusted by unscrewing part of the threaded stem and fixing it with a nut. Such a scheme works in about half of the cases, so craftsmen often cut out gaskets from fiberboard or plastic to put under the bracket (case).

Next, you need to properly adjust the length of the levers. The first (adjustable) lever from the body with the door fully closed must be located perpendicular to the door leaf. Therefore, we unscrew the threaded part so that the first knee is perpendicular to the plane of the door frame, and the second is effortlessly attached to the housing shaft.

The next step is to adjust the closing speed of the door leaf. From the end or on the upper plane of the closer housing there is a regulator knob or a pair of screws. Turning by hand or a screwdriver, you need to select the required closing speed - door snaps into place.

It is clear that when adjusting the closer, the canvas cannot be accompanied by hand. Although most people do it automatically when they close their doors, without thinking.

Common Installation Mistakes

Most often, the door closer is simply not adjusted during installation. A lever with a threaded rod can still be tightened if the door design allows, and usually no one adjusts the speed of closing and pressing the door leaf. As a result, the door does not close completely, and often the door closer causes the door latch (ball) to break.

Often there are problems with the use of adjusting pads. Many apartment owners put closers as they are. If the installation planes do not coincide with a big difference, then instead of the lining, the stem is simply turned out to the limit. As a result, it is not possible to normally adjust the door pressing force.

Often problems arise if the wrong type of self-tapping screws are used to install the door closer.

Included with the mechanism, as a rule, is the usual galvanized fasteners of a universal type. It can be used on wooden or panel doors.

If fastened to a metal-plastic box, then it is advisable to use special fasteners with fine threads. It is necessary that at least 4 turns of threads enter into engagement with the metal.

After the final adjustment of the mechanism, the fasteners must be crimped with a screwdriver. Screwdriver "reach" the screws will not work.

Results

It is not difficult to understand how to install a door closer if you follow the instructions and do not try to make changes to the door device. The mechanism serves on average up to 10 years for a residential building and 5-6 years for offices, shops, cafes.

Tell us about your experience with installing a door closer. What do you think should be the first mistakes to avoid? Bookmark the article and share it on social networks.

Reading: How to independently install a latch in an interior door.