Due to its ease of manufacture, plastic paving slabs have become a popular and affordable replacement for masonry and porcelain stoneware. You can choose such a coating for any design. It does not require the involvement of experienced builders for its laying.

The content of the article:

-

Produced types

- Manufacturing

- Main advantages and disadvantages

- Installation of polymer sand coating

Produced types

The basis for the production of plastic paving slabs is polymers, which are used as all sorts of waste. Recyclable materials significantly reduce the cost of the process, making it affordable for many entrepreneurs.

Plastic paving slab

The color of the pavement is given by various dyes. Additionally, sand, solvents, in particular nitric acid, are used for its manufacture. There is no single recipe. Each manufacturer has his own.

Manufacturing

Production of paving slabs from plasticcarried out in 5 stages:

- Crushing components.

- Connecting elements in a concrete mixer.

- Melting the resulting mixture. For this, special equipment for paving slabs made of plastic is used. It is called "extruder".

- Forming products by pressing.

- Drying.

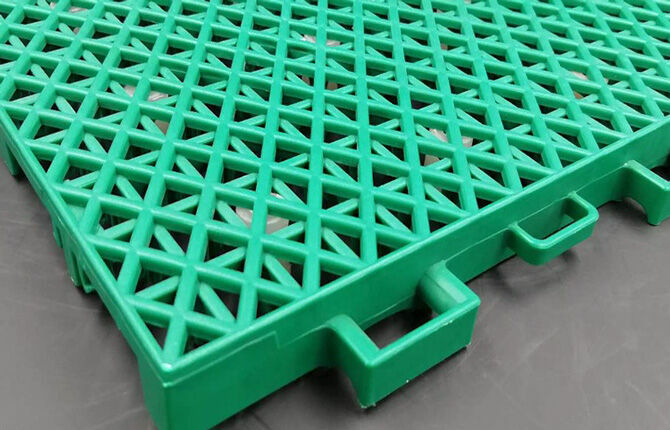

There are 2 main types of pavement coatings made of plastic.

Latticed, having symmetrical through holes:

Deaf, having the appearance of a regular tile:

Differences relate to shape, size, color. Depending on the patterns used, paving slabs can have bizarre shapes - butterflies, some kind of animal. The most popular is the standard square shape with dimensions of 300x300x30 or 500x500x50.

Main advantages and disadvantages

Plastic paving has a number of advantages over products made from other materials:

- Ease. This greatly simplifies the delivery and installation process.

- Low cost. Not everyone can afford to make a stone or ceramic coating, and plastic is available to everyone.

- Ease of installation. Laying does not require special preparation, complex organization of the concrete cushion. Dismantling the tiles, if necessary, is also not difficult.

- Relative strength, long service life. Plastic can withstand significant loads, it is not afraid of frost, temperature changes.

- Waterproof. The plastic product is not "afraid" of water. During its operation, fungus and mold are not formed.

- Ease of maintenance. This coating is easy to wash, clean, clean.

- High abrasion resistance.

This product also has disadvantages:

- Increased slip. But this negative effect is absent in paving slabs with a relief surface.

- The occurrence of a reaction when interacting with certain chemicals. Acetone and other liquids can damage tiles.

- The strength of the tile is not strong enough to support the weight of a heavy machine. Truck, other transport can cause bending of elements and refraction of docking locks.

- Reduced resistance to high temperatures, UV radiation, fading.

Installation of polymer sand coating

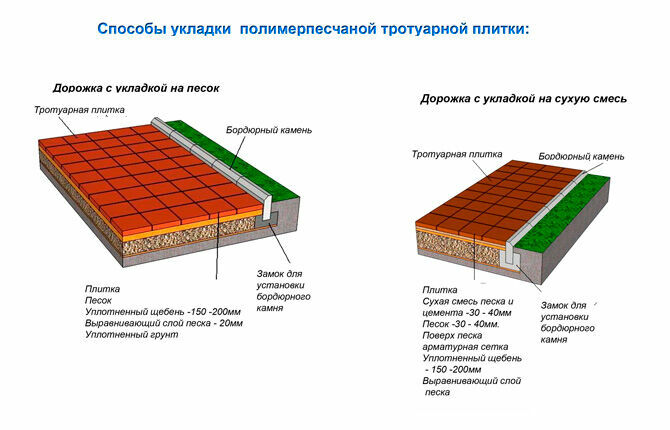

Laying of paving from plastic is carried out on:

- concrete;

- wood base;

- compressed sand;

- cement-sand cushion.

In the case of concrete or wood, no additional materials and work are required. The most important thing is a smooth, clean surface without oil and acid traces. It remains to apply tile glue on it and you can mount the paving polymer sand coating.

Work starts from the middle, moving evenly in different directions, tapping the surface of the tile with a rubber mallet, removing excess adhesive with a rag. After every few rows laid, it is necessary to walk over them with a tamping roller.

If the owner of his own site has chosen one of the last 2 ways installation, for this he will need:

- sand;

- crushed stone of medium fraction or gravel;

- cement;

- geotextile;

- border.

Whatever way a person stops, he will have to perform the work in the following order:

- Apply markup.

- Remove the top layer of soil to a depth of about 25-30 cm.

- Install a border around the perimeter.

- Lay geotextile on the bottom of the pit.

- Lay out a drainage layer represented by crushed stone or gravel. Its height should be 10-15 cm.

- Cover the drainage with a geotextile.

- Pour, compact a layer of sand 5-15 cm thick. If necessary, add cement to it.

- Mount the tiles, leaving a gap between the individual elements.

As a rule, this is enough to get a durable, high-quality coating. But if there are unstable, heaving soils on the site, the top layer must be made of monolithic concrete with mandatory reinforcement.

After the plastic paving is laid, sand must be scattered over its surface. With the help of a panicle, it is distributed over the cracks formed between the joints of individual elements. After they need to be spilled with water.

Most of all, plastic tiles are suitable for areas located in areas with harsh winters and cool summers. Ease of installation and affordable price make it an indispensable finishing coating.

If you have already installed plastic tiles, share your experience with others, help those who are just choosing the right material for their site.

This video clearly shows how plastic waste is recycled, and paving slabs and tiles are made from them:

Do-it-yourself water supply of a private house: rules for arrangement and the best schemes. You can read about it in our previous article. link.

Links to sources:

- https://tplitka.com/trotuarnaya-plitka/plitka-iz-plastika

- https://stroy-podskazka.ru/trotuarnaya-plitka/plastikovaya