It's time to mow the lawn fuel pump not working? It’s even scary to imagine how you can keep your lawn in perfect condition with a hand tool, especially when you haven’t had to do this before. If it doesn't start trimmer, the reasons can be very different, but most of them you can eliminate on your own.

This does not require any special tools or highly specialized knowledge. A little courage and free time to read this material - and the trimmer will not need to be taken to the master.

In this article, we will tell you how to determine what exactly is interfering with the launch, give instructions for repairing each node, and recommendations on how to avoid problems in the future. For clarity, photos and videos are waiting for you, where the most common breakdowns are clearly disassembled.

The content of the article:

-

Common causes of breakdowns

- Option number 1 - a problem in the ignition system

- Option number 2 - you need to replace the filters

- Option number 3 - blockage of the breather and muffler

- Option number 4 - a problem with the carburetor

- Other instrument malfunctions

- Servicing and Preventing Startup Problems

- Conclusions and useful video on the topic

Common causes of breakdowns

The first step is to make sure of the simplest things: the availability and quality of fuel, the correct procedure.

Use only those fuels and lubricants recommended by the manufacturer. Gasoline with too high an octane number is sometimes no less harmful than 80th. Instructions missing? Universal can be called AI-95 from a gas station with a good reputation.

Fill only with suitable engine oil. The vast majority of gas trimmers have a 2-stroke engine, so regular car oil cannot be used. For a 4-stroke engine, the oil is poured separately from the fuel. Moreover, it is not worth pouring “working out” - used, used oil.

Remember, the repair of the piston group will cost 30 - 70% of the cost of a new lawn mower. Savings on the quality of fuel and lubricants are unlikely to cover these costs

Accurately observe the proportions of mixing gasoline and engine oil, do not pour "by eye". For most lawn mowers, a ratio of 1:25 is recommended, that is, 40 ml of oil for every liter of gasoline.

Do not prepare a lot of mixture at once: ideally, it should be worked out in 1 day and stored with a dry tank. The maximum shelf life of the finished mixture is 2 weeks, so it makes sense to mix more than 2 liters at a time, except for public utilities who mow city lawns.

If you have not used a scythe for a long time, and there is gasoline in it, it is better to pour it out. The mixture has already been divided into fractions and has lost its properties, even the most thorough mixing will not save it.

After making sure that the gas tank is in order, try to start a scythe. For this you need:

- Pump fuel into the carburetor with the primer button 5-6 times.

- Close the air damper.

- Turn on the ignition on the handle.

- Pull the starter cord 1-7 times until starting.

- After 5 -10 seconds, turn off the startup system.

After idle, if the engine cannot be started normally, try opening the throttle and pressing the gas trigger. Without releasing the trigger, pull the starter cord.

A fully serviceable trimmer starts up 1-2 times, even if the cord is calmly pulled, and not pulled as sharply as possible

It is also recommended to start the engine with the gas handle clamped, if it has not cooled down after the previous work cycle.

If the engine does not start at 5-7 jerk, it is worth looking for a breakdown.

This is interesting! TOP 12 best brush cutters: review, quality, price.

Option number 1 - a problem in the ignition system

The first thing that suspicion falls on is that the candle does not produce a spark, and therefore the fuel mixture does not ignite. Most often, the problem is in the candle itself.

To check, unscrew the spark plug from the cylinder, after disconnecting the wire from it.

A thin layer of brown soot indicates normal engine operation, red or pink soot - an abundance of additives in the fuel, change refueling. If the element is covered with black or white scale, the motor did not work correctly.

A wet candle indicates overflow, excessive fuel pumping with a primer. In this case, the candle must be dried, but not ignited. Pour out excess gasoline from the cylinder by turning the lawn mower over.

When cleaning, pay the most attention to the part of the top electrode that is directed towards the center contact, but do not overdo it

The contacts of a dried candle should be cleaned of soot with a needle file, sandpaper or a lady's file. The gap between them should be 0.7 - 1 mm - this is the thickness of a standard coin. Bend the top electrode if necessary.

Before assembly, it is worth checking the performance of the candle. Connect it to the power supply (put on the cap), attach the body to the cylinder or any metal part of the engine, turn on the ignition, pull the starter. At the end, between the electrodes, a bright, powerful spark should jump with each jerk.

It is very important to follow safety precautions. When checking, there should not be a drop of gasoline on the neck of the candle hole and the body of the lawn mower!

If there is no spark after drying, cleaning and setting the gap, buy a new candle. It happens that a spark does not appear on a new candle. In this case, check the quality of the contacts, try replacing the armored wire - it's inexpensive and easy.

If there is no spark with the new wire, you need to buy a new ignition coil. It happens that the cable is not disconnected from the coil, they are sold only as a set. It is somewhat more difficult to replace it yourself, because you need to accurately set the gap of 0.25 - 0.4 mm to the starter flywheel.

The normal gap corresponds to the thickness of a plastic bottle (cut a piece out of it for measurement) or 4-5 layers of masking tape

Install the coil with a spacer, try it on. Spin the starter: it should touch the spacer but turn fully. Remove the paper tape or plastic and finally assemble the knot.

It happens that when checking the candle gives out a small but stable spark, but the start does not occur. After you screw the candle into the cylinder, in an enclosed space, a weak spark may disappear. In such a situation, it is also worth replacing the coil: a new one will give out a more powerful impulse.

Option number 2 - you need to replace the filters

If there is a spark, but the scythe does not start, the problem is most likely in the fuel supply. The easiest way is to check the air and fuel filters - that's where we'll start.

Testing their condition is quite simple: remove the filter elements and try to start the engine. If so, it needs to be replaced or at least cleaned.

The fuel filter may become so clogged that the filter housing cannot be seen. Naturally, cleaning attempts in this case are useless.

When removing the fuel filter, do not accidentally disconnect the fuel supply pipe from the line - in some models this is possible

The fuel filter is located directly in the tank, at the end of the fuel supply pipe. Carry out the following operations:

- Pull out the gas tank cap together with the restrictor.

- Take a piece of stiff wire and bend one end into a hook.

- Feel with a wire and pull out the tube with the filter.

- Assess his condition by eye. With visible blockages - immediately replace.

- Try blowing it in both directions. The air should exit through the mesh on the sides, with small bubbles of gasoline, the resistance is minimal.

- If the store with a new filter is far away, and you need to mow urgently, try washing the old one with clean gasoline and blowing it with compressed air.

- Insert the filter into the tube, clamp securely collar and return to the tank.

The air filter often causes unstable operation, floating speed, but if it is heavily clogged, it can also prevent starting. It is located on the side, above the carburetor (pre-fuel pumping button).

Do not work with a scythe with the air filter removed - you risk damaging the motor with dust! If there is not a grill on the cover above the filter, but an air intake valve or just a hole, clean it with a needle

The plastic cover is held on by a latch - remove it. The filter itself usually consists of 2 layers: a thick dense foam rubber and a flat rigid mesh. If it looks dirty or the engine only starts without it, replace the cleaner or blow it out with compressed air.

On average, it is recommended to change both filters to a new one every 2 years.

Option number 3 - blockage of the breather and muffler

A breather is a non-return valve that allows air to enter the gas tank, but does not let fuel out. It is located most often on the lid, but sometimes on the gas tank body.

When it clogs, the tank becomes airtight, a vacuum is created inside and the carburetor valve does not have enough power to suck in fuel.

The following symptoms indicate a malfunction:

- The trimmer starts normally for the first time, but after a short period of time it stalls and will not start again.

- The outer opening of the breather is clogged with dirt.

- The scythe works fine if the gas tank cap is not fully tightened.

- If you disconnect and point down the fuel supply pipe from the carburetor, gasoline drips from it in a thin stream or does not flow at all.

The problem is solved simply: the hole is cleaned from the outside with a needle, slightly pushing the valve inward, blow through with a compressor. If this does not help, you can pick it out of the lid along with the rubber seal.

Disassemble the breather over the table, it has several small parts. Try to pull it out with your fingers so as not to damage the thin rubber

Rinse with clean gasoline both the rubber parts and the built-in filter. Blow everything out, dry it and put it back together. If after that it is not possible to blow air through the breather, buy a new cap.

The muffler or exhaust port is located on the opposite side of the carburetor. On older models, it is often clogged with soot, soot. As a result, the engine chokes on exhaust gases and cannot start or stalls almost instantly after starting.

The problem lies in the anti-spark grid on the engine exhaust. It can be cleaned with a needle or completely removed.

Option number 4 - a problem with the carburetor

Many owners, at the first problems with starting lawn mowers, immediately disassemble the carburetor. We recommend that you first check if the problem is really in the fuel supply, as well as rule out simpler breakdowns, above.

To check, draw 3-5 ml of a mixture of gasoline and oil into a syringe, unscrew the spark plug and pour fuel directly into the combustion chamber.

To deliver fuel directly to the cylinder without scratching or staining anything, instead of a needle, put a thin silicone tube on the syringe

Install and connect the candle, and then try to start the trimmer 6-8 times. If the engine starts and soon stalls, the problem is really in the fuel system (carburetor, fuel filter, gasoline supply pipes). This often happens after the winter, especially if the fuel mixture is not drained: it breaks up into fractions, heavy oils literally stick up small holes and parts.

If direct refueling of the engine did not help the start, return to the ignition test, and also make sure that the combustion chamber is tight, that there is compression, and that the piston group is in good condition.

Having determined that the problem is with the carburetor, disconnect it from the body. To do this, remove the air filter and unscrew 2 or 4 long bolts. Disconnect the 2 fuel pipes, as well as the throttle cable. Remove the carburetor, do not lose the paronite gasket between it and the motor.

To disassemble the carburetor, unscrew the 4 bolts located around the fuel pre-priming button. Carefully disassemble and fold all the layers in order so as not to lose anything. You can immediately soak them in a bath of gasoline for cleaning.

It is not necessary to remember which side the parts were turned to: they have an asymmetric outline and will not be turned upside down

Assess the condition of the gaskets, if necessary, buy a repair kit and replace them.

On a metal plate with a round recess there is a needle on a spring-lever. She is on the verge of a circle and is responsible for the fuel supply. To check if it is stuck or moving, press the opposite end of the spring lever, in the center of the circle. If mobility is limited, use a special fluid and compressed air for flushing, or just gasoline.

It is very convenient to fill with gasoline a special spray gun. With such a “high pressure washer”, even a very old motor can be cleaned to a new condition.

In addition to the needle, the inlet spray valve is located on the same part. It is best seen from the reverse side of the part - a hole in the center, often cruciform. To check the operation of the valve, attach a flexible thin tube, rubber or silicone, to it, and try to blow it in both directions. Air should pass only on inspiration - from the concave side of the part to the flat one.

If air does not pass, cleaning is necessary. A simple way is with a match, not a toothpick or a needle, only with a blunt end, from the side of the hole. A more complex and reliable option is with disassembly. Unscrewing the small screw next to the needle, pull it out and the spring.

Find a small hole in the center of the circle and gently, with a blunt object, such as a cut wire, push the nebulizer membrane out of the valve through the hole on the opposite side.

The valve itself is tiny, push it over a clean, light-colored surface or a plastic container so you don't lose it. It is not sold separately, it is not included in the repair kit.

After thoroughly washing with gasoline, blowing and drying all the parts, put the membrane and the needle with the spring in place.

Assemble the carburetor in reverse order: rubber gasket, transparent gasket, metal part with needle and valve, thin rubber membrane, thick plastic membrane, primer button.

Screw to the trimmer body through the gasket, connect the fuel pipes and the throttle cable. Try start a brushcutter as usual. If the problem is fixed, be sure to replace the air filter.

Most likely, you will need to adjust the parameters of the fuel mixture using the adjusting screw on the carburetor. Start the trimmer and, periodically revving, tighten the screw to a position in which the engine gains maximum speed (by ear). Then do a half turn back so as not to overload the motor.

Other instrument malfunctions

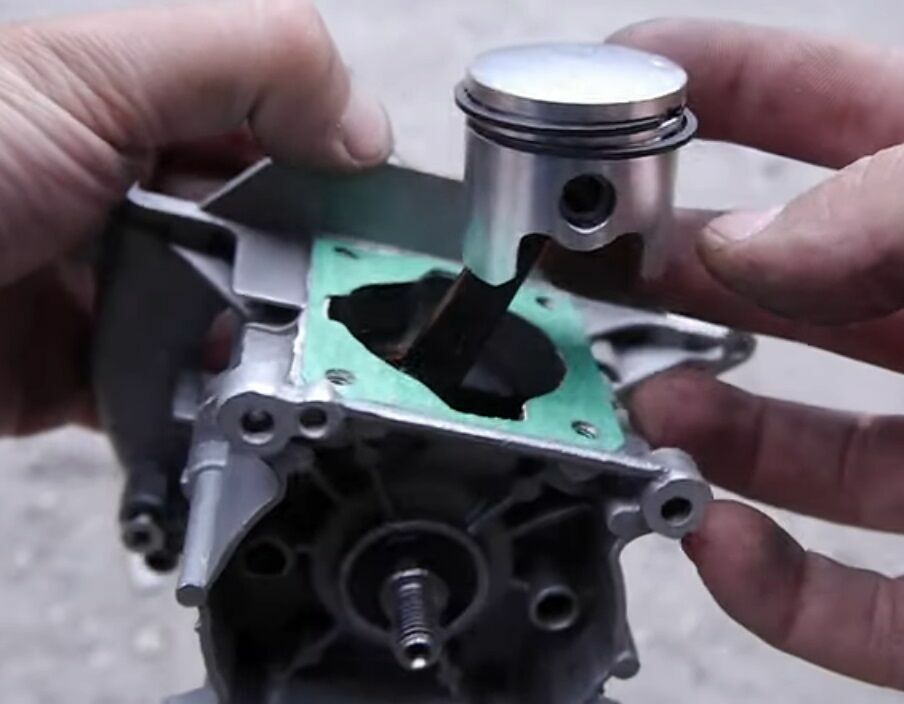

If all the problems described above are checked and fixed, and the trimmer still does not start, there is probably a problem with the engine itself. Compression may be reduced in it due to the destruction of the crankshaft seals or damage to the piston group.

This often happens with trimmers that are used very actively or for a long time: for example, in utilities. Use a compression gauge to diagnose.

The oil seal protruding from the crankcase must be replaced - it has already hardened too much, lost its elasticity and cannot fully perform its function

In most cases, such repairs should be entrusted to the workshop, if only because in almost all trimmers, in order to access the glands and the cylinder, you need to unscrew the nuts with the thread lock. This can be done either with an electric wrench, or by warming them up properly.

Oil seals are located on both sides of the crankshaft: under the starter and on the drive, and it is better to change them in pairs. Having reached the place of their installation, evaluate the condition by eye: they should sit tight, without play and not stick out, not be cracked. Oil leaks around also indicate the need to replace the seals.

When reassembling, be sure to use thread lockers wherever they were - this is a safety issue.

To easily pull out the seal, screw 2 screws into it from opposite sides. Pull the screws one by one with the pliers.

The restoration of the piston group requires a specialized tool. If you are not a motor mechanic at a service station, entrust the restoration of the trimmer motor to a specialist.

When opening the cylinder, check all surfaces for chips, scuffs, scratches. To determine if the piston rings are worn, shake the connecting rod. The slightest play in the piston indicates the need to replace the rings.

Servicing and Preventing Startup Problems

To ensure that your tool lasts longer and does not cause problems, keep it clean and service it regularly.

Do not store a fueled lawn mower: leaving it for more than 2 weeks, and even more so for the winter, drain the remaining fuel from the tank, then start the engine and let it run until it stalls. When leaving the tool in the shed for the winter, wrap the motor and knives with oiled rags.

To lubricate a 2-stroke engine before storage, remove the spark plug and use the starter to raise the piston to the very top. Drip a little engine oil from the syringe and turn the crankshaft several times using the starter.

In the spring, before the first use after a downtime, it is advisable to check the spark plug and filters, disassemble and flush the carburetor, even if there are no problems with starting.

Conclusions and useful video on the topic

For clarity, we offer a video with an analysis of common problems:

To check the carburetor or if you decide to change the oil seal yourself, this video will come in handy:

Disassembly and cleaning of the carburetor is described in some detail here:

If your lawn mower does not start, do not rush to look for a master to repair it. It is quite possible that finding and eliminating the cause on your own will not only be much cheaper, but also faster and easier.

Most trimmers are almost identical, the structure of small parts and, of course, the quality of their workmanship may differ. Use and store your tool with care, save money on fuels and lubricants and time for minimal maintenance, and the trimmer will become a trouble-free assistant for many years.

Have you ever had to deal with a situation where the lawn mower stopped starting? How did you fix the situation? Share your opinion and experience in the comments below!