Before applying finishing materials, plasterboard walls must be prepared. To do this, gypsum putty is applied to the surface. It hides the recesses formed from fasteners, mounting seams and other irregularities. You can putty the walls with drywall yourself. Any person with minimal technical knowledge and skills in construction will cope with this with their own hands.

The content of the article:

- Which finish is suitable for plasterboard walls

- How to prepare the walls

- Necessary tools and materials

- How to properly and quickly mix putty

- Wall putty technique

- Puttying Tips

Which finish is suitable for plasterboard walls

Plasterboard leveling is popular due to the good characteristics of the material.

After mounting with your own hands, you can get a surface with a minimum number of recesses. The following types of finishes are suitable for plasterboard walls:

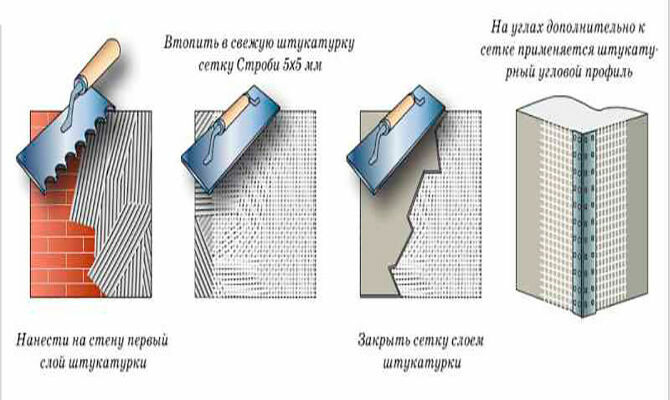

- Ceramic tile. The elements are placed on the adhesive composition. There is no need to putty the canvas. Finishing of this type has a lot of weight. To increase the degree of adhesion to the cardboard surface, a reinforcing mesh is additionally mounted.

- Dye. Apply water-based, acrylic or oil enamel. To obtain a smooth canvas before painting, it is necessary to putty drywall. The gypsum composition is polished after drying.

- Wallpaper. Glue on in advance prepared wall. Violation of this rule will cause irregularities to be visible through the wallpaper layer. This worsens the appearance of the walls. Before puttingty plasterboard walls under wallpaper, a reinforcement mesh should be placed at the joints.

- Decorative plaster. It is superimposed on carefully polished putty.

- Plastic panels. Does not require pre-alignment. When installing plastic panels, you will need to apply putty to the joints and fastening screws.

Finishing material is selected separately for each case. The operating conditions are taken into account. For rooms with high humidity, ceramic tiles, paint or plastic panels are suitable.

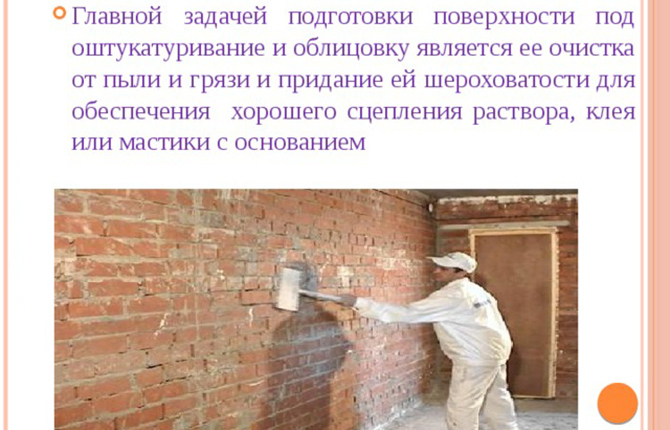

How to prepare the walls

For high-quality adhesion of putty to cardboard, it is necessary to carry out a number of preparatory measures. To do this, check the evenness of the surface. In places of recesses, you will need to apply a large amount of solution. They are puttied in several layers.

The canvas is inspected, checking the protrusion of the heads of the fasteners. Screws must be screwed so that the cap is deepened into the cardboard layer by no more than 1 mm.

To improve the degree of adhesion to the solution, the wall is cleaned of dust and small abrasive particles. They are removed by hand with a dry cloth or compressed air. The cleaned outer layer is treated with soil. Apply a spray gun, hand sprayer, roller or paint brush.

Necessary tools and materials

The list of devices is selected separately for each case. To speed up the work, hand tools can be replaced with electric ones. To putty the walls with your own hands, you will need:

- Gypsum mix. Apply starting and finishing composition. In the first case, a rough surface is obtained. The final mixture is applied with the outer layer. After sanding, it becomes smooth.

- Container for mixing solution. Choose a vessel with a wide mouth. The inner surfaces of the container must be smooth. So it will be easier to collect all the putty with a spatula from the walls and bottom.

- Screwdriver. It is used for screwing self-tapping screws with your own hands to the desired depth. To speed up the work, use a screwdriver. The bit is selected taking into account the type of fastener.

- Putty knife. Drywall walls are puttied with tools with a narrow and wide working edge. The composition is applied with a small spatula. A wide tool level the putty layer.

- Reinforcing mesh.

- Mixer or nozzle on an electric drill for mixing the solution. It is difficult to cook it with your own hands without tools.

- A trowel with sandpaper installed. Necessary for processing the finishing layer. You can remove small irregularities with a grinder.

Materials and tools are located near the workplace. So during work you do not need to waste time searching.

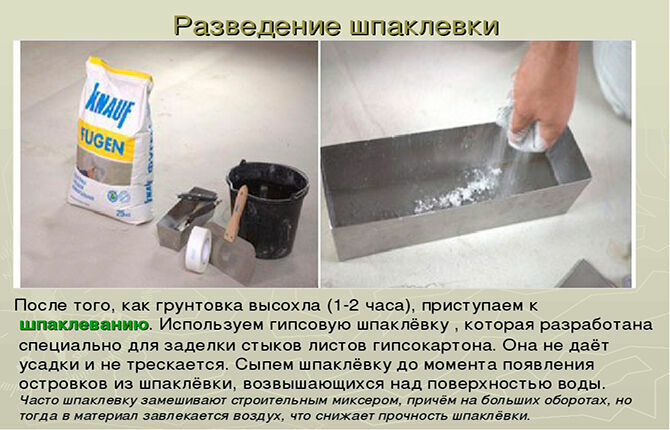

How to properly and quickly mix putty

The mixture is prepared in a vessel with a wide neck. A plastic bucket works well. The putty is kneaded with a specialized nozzle on an electric drill. The method of preparation of products from different manufacturers is different. Before doing the work with your own hands, you must study the instructions.

Water is taken into the container. Gypsum mixture is served in small portions.

The composition is kneaded until a homogeneous consistency is obtained. The density of the solution is regulated by adding a gypsum mixture. The goal is to get a homogeneous mass. It must be borne in mind that the gypsum-based composition hardens in a short time. Knead such an amount that can be used up in 30-40 minutes.

Wall putty technique

To determine how to properly putty plasterboard walls with your own hands, inspect the surface for irregularities. The composition is applied in a thin layer. In places of large depressions, several layers are applied. At the same time, they wait for the drying of each previous one.

Work starts from the top. First of all, the mounting seams and the installation sites of fasteners are puttied.

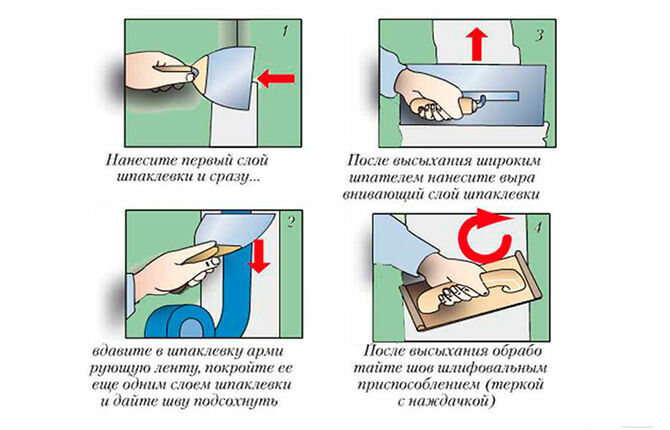

Improving the strength characteristics is achieved by installing a reinforcing mesh. It is attached at the joints. This prevents cracking of the finished web. The material is fixed in the following sequence:

- A primer is applied to the plasterboard wall. Preference is given to deeply penetrating compounds with antifungal action.

- A thin layer of putty is laid on the joints of drywall sheets. Its thickness should be 2-3 mm.

- Lay reinforcing mesh. Glue the edge in the upper part and, unwinding the roll, press it over the entire surface.

- Level the mesh with a spatula. This prevents the formation of wrinkles.

- Wait for the solution to harden.

- Lay a second layer.

- Remove irregularities with a wide spatula.

After arranging the joints and holes from the fasteners, the plasterboard wall is puttied over the entire area. The final step is the application of the finishing layer and its polishing.

Puttying Tips

It will be possible to get a high-quality coating with your own hands, observing a few rules. Properly puttied drywall walls have a long service life. Helpful Hints:

- Use personal protective equipment. When grinding, a large amount of gypsum dust and abrasive substances are released into the air. When working, wear a respirator.

- Knead the mixture until a homogeneous consistency is obtained. In the presence of lumps of different fractions, it will not be possible to make a flat surface. The mixture with which drywall is putty should not be too thick.

- Eliminate large irregularities before the composition dries with a wide spatula. So it will be possible to spend less effort on grinding the surface with your own hands.

- Clean off the protruding parts after drying with sandpaper or an abrasive mesh. The evenness of the surface is checked by a long rule.

You can putty plasterboard walls with your own hands. This will require standard tools and minimal skills in construction. When working, you must strictly follow the sequence of actions.

Have you puttyed drywall walls with your own hands? What finish was the surface prepared for? Leave comments, bookmark the article and share it on social networks.

We also recommend watching a selection of videos that will consolidate knowledge and answer the remaining questions.

How to putty drywall under the wallpaper?

Plasterboard plasterboard. Detailed description of work from A to Z.