To make the coating pattern original, the template is made independently. Before making a mold for paving slabs, a detailed drawing is created. It indicates the overall parameters of the products and the type of material used. During the production process, strictly adhere to a pre-prepared drawing.

The content of the article:

- Applicable materials

- Wood products

- Gypsum mixes

- Plastic templates

- metal molds

- Tips for making and using

Applicable materials

On an industrial scale, molds for paving slabs are made from various materials. Products made of plastic, metal and silicone are in demand. They have a long service life and are resistant to mechanical damage.

In domestic conditions, apply:

- metal;

- wood;

- gypsum mixture;

- plastic.

When choosing a material, the degree of its water absorption is taken into account. If liquid quickly leaves the solution, its strength characteristics will deteriorate. The inner surface must be made smooth. This makes it easier to remove the product after the solution has solidified.

Wood products

Formwork is made from boards, beams, particle boards, etc. Before assembly, the parts are treated with varnish or paint. This will make the surface smooth and prolong the life of the wood. Formwork is made in the following order:

- Creating a drawing. Before you make the mold for paving slabs yourself, a detailed drawing is made. It takes into account the pattern and dimensions of the formwork. At this stage, you should choose the right form. After manufacturing, the tile elements should fit well with each other.

- Wood selection. For a single use, the formwork is assembled from wood of any species. For a large amount of work, solid wood is selected. It is less susceptible to mechanical damage. This increases the service life of the formwork.

- Preparing details. Bars or boards are cut into pieces of the desired length. The wood is sanded and varnished. This removes irregularities on the inner surfaces.

- Assembly. The parts are fastened according to the specified parameters. For connection, metal corners and threaded fasteners are used. For repeated use and to facilitate the process of removing tiles, the formwork is collapsible.

After assembly, the formwork is checked for compliance with the dimensions indicated in the drawing. At the same time, the overall parameters inside the imprint are taken into account.

Advantages and disadvantages of plastic paving slabs. About this in our article. link.

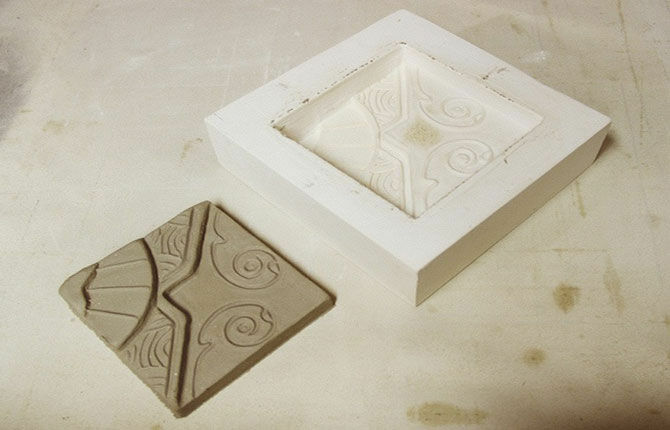

Gypsum mixes

In some cases, gypsum mortar is used. It is flexible and dries quickly. With the help of a gypsum mixture, you can make paving slabs with any pattern.

Gypsum template for tiles

The disadvantage of products of this type is fragility. Under mechanical action, the edges of the template crumble. This requires periodically manufacturing new parts. To make an impression from a plaster solution, follow the following step-by-step instructions:

- Select a container. You can use a wooden crate installed on a smooth surface.

- The inner surfaces are lubricated with oil. It is applied with a sprayer. This eliminates the possibility of leaks. Lubrication is applied to facilitate demolding.

- Dilute the gypsum mixture with water. The solution is prepared before pouring.

- A pre-prepared form with a pattern is placed in a container.

- Cover the contents of the container with the solution. The layer thickness must be at least 10 mm.

- Waiting for complete solidification. For hardening, you must wait 60-90 minutes.

- Dismantle the finished template for paving slabs.

After manufacturing, the template is inspected for the presence of shells and damage. For ease of use, the sharp outer edges are cut and ground.

You can make an impression after pouring. To do this, you have to wait until the gypsum mixture becomes viscous.

Plastic templates

The print for paving slabs made of polymeric materials is resistant to mechanical damage and has a long service life. Plastic parts have a smooth inner surface. The disassembly process is effortless.

You can make a template for paving slabs from liquid plastic. Manufacturers supply it in the form of 2 components - the main mass and the hardener. After hardening, a durable material is obtained that is resistant to mechanical stress.

The walls of the plastic template do not absorb moisture, which has a positive effect on the strength characteristics of the hardened concrete. Forms are made in the following order:

- Prepare a container with smooth inner surfaces. Its dimensions should be at least 20 mm larger than the future form for paving slabs. So it will be possible to make the walls of the resulting product durable, resistant to damage.

- An imprint with the required pattern is placed at the bottom of the container.

- A lubricant is applied to the surface.

- Mix liquid plastic with a hardener. Different manufacturers have different ways of preparing the mixture and proportions. Read the instructions carefully before preparing.

- The resulting composition is poured into a vessel. The liquid level must be at least 1 cm above the impression.

- Wait for the complete hardening of the plastic.

- Dismantle the finished form. Inspect it for damage and cut off sharp edges.

After that, the plastic mold for paving slabs is ready for use. Templates of this type have a long service life. They can be made to produce paving slabs for commercial purposes.

During the preparation of liquid plastic, harmful substances are released. It is necessary to take care of the normal ventilation of the room, use personal protective equipment, incl. respirator.

metal molds

Metal templates are resistant to mechanical stress and serve for a long time. To protect the metal from corrosion when interacting with a humid environment, the surfaces of the molds for paving slabs are varnished or painted.

metal template

To make templates, profile pipes, corners, strips, etc. are suitable. Parts are connected by welding of any type. To facilitate the process of disintegration, products are made collapsible. To do this, install loops and connecting elements.

To make a metal mold, you need:

- Create a detailed drawing with dimensional parameters. During the assembly process, strictly adhere to the drawing.

- Pick up material. Select metal parts without cracks, shells and other damage to the surface.

- Cut pieces to desired length. The evenness of the corners is provided by using a miter box.

- Clean parts from corrosion. The blanks are cleaned of rust and polished. Fine abrasive particles are removed with compressed air.

- Mark the attachment points for hinges and connecting elements.

- Connect the workpieces by welding. Welding parts will require specialized equipment and experience in this type of work. If not available, contact a qualified welder. Use personal protective equipment to avoid injury and burns.

- Install hinges and connecting elements.

After that, the internal dimensions of the mold are checked for compliance with the drawing. The correct ratio of sides and angles will allow in the future to easily join the individual elements of paving slabs.

Tips for making and using

By independently creating a form, you can make an original product design. Compliance with several rules facilitates the stamping of paving slabs:

- Make carrying handles. The template is equipped with handles. This simplifies the removal of finished products.

- Enable multiple templates at the same time. This speeds up the work, allows you to get a larger volume of products in the same time.

- Make sure the side surfaces are even. The walls of the template can be moved outwards. If you tilt them inward, after the concrete has hardened, it will be impossible to remove the tile without disassembling the shape.

- Use a vibrating table. Use to remove air bubbles from solution vibrating table. This increases the strength of concrete.

- Lubricate internal surfaces before each pour.

A person independently determines the material from which he wants to make a template template. For long-term operation, molds made of materials resistant to mechanical damage are used. Given a few rules, it will be possible to facilitate the process of manufacturing paving slabs.

Tell us in the comments why you decided to make a mold for paving slabs yourself. Bookmark this article so you can come back to it later.

Related video: Do-it-yourself mold for paving slabs