Paving slabs are used to make smooth surfaces that are resistant to mechanical damage and temperature changes. You can make it yourself. The work will be performed by a person with minimal technical skills. Before you make paving slabs, you will need to prepare the necessary tools, materials and equipment.

The content of the article:

- factory technology

- Equipment and inventory for work

- Necessary materials

- Work site organization

- Forms for making

-

Manufacturing instructions

- concrete mix requirements

- Recommended proportions for kneading

- Placement of ready-mixed concrete in molds

- Tile coloring methods

- Placement of completed molds on a vibrating platform

- The process of curing concrete

- Forming and further storage of finished products

factory technology

On an industrial scale, paving slabs are made in several ways. In this case, automated equipment is used. This makes it possible to produce large volumes of products in a short period of time.

- Vibropressed products

Tiles are made by pressing concrete mix under high pressure. At the same time, the amount of moisture in the solution is minimal. Pressing together with vibration has a positive effect on the strength characteristics of products.

As a result, plates are obtained that are resistant to mechanical damage and temperature extremes. It will not be possible to independently make a vibropressed type tile at home. The production technology involves the use of specialized equipment.

- Vibrocast plates

The technology involves pouring a liquid concrete mixture into pre-prepared forms. After pouring, the mold is subjected to vibration. This allows you to make the mixture dense and remove air bubbles from it. The density of the finished product improves its strength characteristics.

You can make paving slabs by vibrocasting at home. So it will be possible to make elements of a unique design.

- Clinker panels

The technology provides for the manufacture of slabs with subsequent firing at a high temperature. In production, a solution is used that has clay in its composition.

It will not be possible to make such paving slabs on your own. Production requires specialized equipment.

Equipment and inventory for work

Before the production of paving slabs, it is required to prepare tools and fixtures. Their list is different and is determined by a person separately for each case. For work you will need:

- Forms. Purchase ready-made products or make them yourself.

- Mixer. You can knead the concrete mix by hand. This will increase the production time.

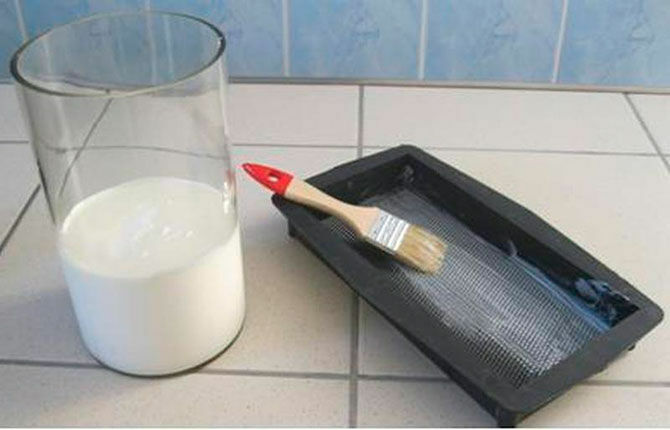

- Paint brush. Used to apply lubricant to the inside surface of molds. To speed up the process, a spray gun is used.

- Water tank.

- Spatula or mason's trowel. Necessary for laying the finished mixture into molds.

- Concrete container.

- Sieve for sifting sand.

- Measuring capacity.

- vibrating table.

To make a small batch of paving slabs, you can use the simplest design (vibrating table). Forms are placed on the surface and create vibrations by hitting it with a hammer or perforator

When working, observe safety precautions. They use personal protective equipment (glasses, gloves, a respirator, etc.). This way, it will be possible to avoid injury during work.

Necessary materials

To independently make paving slabs using the vibrocasting method, use the following materials:

- cement;

- sand;

- a substance that plasticizes the concrete mixture;

- dye;

- crushed stone of fine fraction;

- motor or sunflower oil.

The strength of the finished product depends on the quality of the selected materials. To make paving slabs, use M500 cement. There are no special requirements for the quality of sand. Bulk material with a minimum amount of large fraction impurities is chosen.

Plasticizers are used to reduce voids in concrete. Manufacturers produce plasticizer in powder and liquid form. In the first case, the substance is added to the dry mixture. The liquid is poured into the mixer while mixing with water.

Plasticizer - additive for mortars

You can make the product colored by adding a pigment to the solution. There are synthetic and natural dyes. Organic compounds are more expensive, so mineral or metal dyes are more often used.

Work site organization

To speed up the production process, you should properly organize the workplace. All tools, materials and equipment should be at a small distance from each other. So it will be possible to make a large number of tiles without putting physical effort on its transportation.

The manufacturing technology provides for the use of equipment powered by an electrical network. For safety, provide shelter for electrical equipment from precipitation. The workplace is located under a canopy or indoors. When using the finished structure, provide good ventilation.

The mixer is located next to bulk materials. A container is installed at the place where the ready-mixed concrete is dispensed. The vibrating table is placed next to the container for collecting the solution.

To harden the cement-sand mortar, the molds are placed on a workbench or rack. The workbench is located next to the vibrating table.

Forms for making

Manufacturers produce forms of various configurations. For details of unique design templates make their own. To make a mold for paving slabs, proceed as follows:

- Select material. The template can be made from metal, wood, gypsum mix or polymers.

- Prepare a drawing. At this stage, a detailed drawing is made. It includes the pattern and dimensions of the template. In the manufacture of adhere to the drawing.

- Prepare details. For molds made of gypsum and polymers, an impression is used. Metal or wooden templates are assembled from parts.

- Connect workpieces. To facilitate the removal procedure, the template is made detachable.

The inner surfaces of the mold must be smooth. The presence of roughness will lead to a change in the pattern and complicate the process of forming.

When making templates yourself, the method of laying the plates on the surface is taken into account. This is how curbs, gutters for the drainage system and halves of the slab are made. They are used in places of adjunction to vertical surfaces.

Slab halves

Manufacturing instructions

At the initial stage, a detailed plan is drawn up. It indicates the sequence of actions. At the next stages strictly adhere to the drawn up plan.

concrete mix requirements

To make paving slabs on your own, take into account the quality of the concrete mixture. Cement-sand mortar must be plastic. To do this, specialized chemicals are added to the composition - plasticizers.

The solution is placed in the template in 2 stages - first the front layer, then the draft. For the front layer, purified fine sand is used. The presence of stones in the sand is unacceptable. For the rough layer, there is no need to sift the sand.

It is important to determine the consistency of the concrete mixture. The liquid is added to the dry mixture in several stages. When mixing, the solution should not be dry. But the situation when excess water is separated is also unacceptable. A large amount of liquid reduces the strength characteristics of the product, increases the hardening time. Lack of water in the mixture will make the boards brittle.

Recommended proportions for kneading

On an industrial scale, the solution is kneaded by adding components in certain proportions:

- sand is 56%;

- crushed stone of fine fraction - 23%;

- cement - 21%.

The amount of dye or plasticizer added is calculated separately for each case, taking into account the instructions supplied by the manufacturer.

In domestic conditions, the ratio of cement, sand and gravel is taken as 1: 3: 1.5. For the front layer, cement and sand without crushed stone are used in a ratio of 1: 3.

Placement of ready-mixed concrete in molds

At the initial stage, templates are prepared for pouring. Their internal surfaces are lubricated with motor or sunflower oil. Store-bought solutions, such as Vestenol, can also be used. This is necessary to facilitate the disassembly process.

The lubricant layer must be thin. The presence of drops will spoil the appearance of the facial layer. Oil is applied with a paint brush or sponge. To speed up the process, use a spray gun. So it is possible to make a tile with a smooth front layer. Laying the mixture in molds is carried out in 2 ways:

- One-time. The template is filled with cement-sand mortar.

- In 2 stages. At the bottom of the mold, a solution without crushed stone is poured. They fill about 25% of the volume. The second layer is laid concrete with crushed stone.

In the first case, to make the paving slabs colored, the entire solution is dyed. With phased laying, the front layer is painted. In this way, production costs can be reduced.

The mixture is applied to the molds with a spatula or stone trowel. In this case, after laying, they press on the concrete from above. So the hard-to-reach places of the template are filled as much as possible.

Tile coloring methods

The production of colored elements allows you to make different drawings on the equipped site or path. Dyes are used to change the color of the plates. The method of their application is different for each case. You need to study the instructions. You can paint paving slabs in several ways:

- Add dye to the solution.

- Apply paint to the inner surface of the template before pouring. After hardening, the dye will remain on the front layer;

- Apply paint with a solvent after the paving slabs have cured.

A person independently determines how to make colored paving slabs. If the plates are to be painted for a long time, a dye is added to the solution. The outer coating of the product has a short service life.

Placement of completed molds on a vibrating platform

The production technology provides for the installation of templates with a mixture on a vibrating table. So the concrete fills all hard-to-reach places and clearly follows the contours of the impression. Under the action of vibration, excess air is released from the composition. This improves the strength characteristics of paving slabs.

The templates are placed on a vibrating surface next to each other. Contact of the side surfaces is allowed if this does not damage the structure. After placing the templates, the electric motor of the vibrating table is started.

When working, do not allow displacement of forms to the edges of the table. To prevent the template from falling when moving under the influence of vibration, the upper part of the table is equipped with a side.

Making tiles on a vibrating table

The process of curing concrete

Complete hardening of the mixture occurs in 3-4 days. At this time, the forms are placed on a rack or workbench. To make paving slabs durable during the solidification process, you must adhere to several rules:

- Avoid direct sunlight.

- Maintain a constant moisture content of the solution. Periodically paving slabs are irrigated with water. With a rapid loss of moisture, the degree of strength decreases.

- Do not allow the composition to freeze. Maintain positive temperature in the room. When freezing, the water in the solution crystallizes.

- Exclude mechanical impact on the uncured composition.

After complete solidification, the elements are removed from the mold and placed on a storage tray.

Forming and further storage of finished products

Details are removed from the templates without difficulty. Pre-applied motor or sunflower oil prevents paving slabs from sticking to the mold.

If the molding process is difficult, the template can be heated. To do this, use hot water. Rapid heating of the material contributes to its expansion. In this case, the unheated plate is easily removed.

When unforming, the template is turned over and tapped on its surface with a wooden or rubber mallet. Forming is carried out over a rubberized surface. So it is possible to exclude mechanical damage when paving slabs fall on the surface.

After manufacturing, the parts are stored on wooden or metal pallets. To avoid mechanical damage to the lower rows, the upper one is laid with dressing. The storage location is protected from direct sunlight.

You can make paving slabs yourself. This allows you to get products of a unique shape, pattern, color. You will need tools and electrical equipment for the job. To make high-quality tiles, strictly adhere to the instructions.

Do you make paving slabs? What proportions were used in the manufacture of concrete mix? Write comments, share the article on social networks and bookmark it.

Do you have any questions? Watch a selected thematic video that will complement our article.

How to make paving slabs, concrete composition, molding, vibrating table:

Paving slabs without vibrating table and plasticizer:

How to lay paving slabs? Read about installation methods + instructions on how to carry out work Here.