For outdoor recreation, furniture is required. You can dig in a table, knock down a couple of benches or buy plastic furniture, thereby turning the rest area into a kind of street cafe. One of the possible options is to make a transformer shop with your own hands. The thing is practical and extremely convenient for country gatherings over a cup of tea.

The content of the article:

-

Transformer shop options

- Bench-transformer from the profile

- Wooden variant

- The choice of material for the manufacture of a wooden transformer bench

- Preparation for the construction of the structure: drawings and dimensions

- Material calculation and tools

-

Stages of making a bench-table

- Making side supports for a small bench

- Assembling a double support for a second bench and table

- Frame assembly

- Assembly of a transforming table and benches

-

Finishing Tips

- Painting

- Vinyl wrapping

- Varnishing

- Impregnation treatment

- Results

Transformer shop options

There are quite a lot of projects, and it is not surprising, because the idea of a relatively simple design of a transformer shop made of bent aluminum pipes appeared 40 years ago. Of all the projects, the most popular (practical) were:

- a classic transforming bench with a frame made of a profile pipe, an overturning table top and a bench;

- country version of a bench with a wooden table with a rising bench and a table;

- a bench with a reclining back in the form of a table.

Transforming benches with sliding benches made of wood are not very popular. Firstly, much more materials are spent on the construction of a transformer shop. Secondly, the hinged design is much more convenient to unfold and fold than a retractable one.

Before you make a transformer bench, you need to choose the right dimensions, material and design scheme.

Bench-transformer from the profile

One of the options for a folding table with two benches can be made from a profiled pipe 20x20 mm. When unfolded, the width of the metal table will be equal to the height of the back of the bench. The width of each of the benches is approximately half the transverse dimension of the seating area of the video.

In the folded position, as in the photo, the transformer is a fairly wide bench with a high back, in the unfolded position there are two narrow benches with a relatively narrow and long tabletop.

A rather serious advantage of metal transformer models is the increased size of the lower arch, which acts as legs. Plus, the bench has quite comfortable side armrests from the profile.

Wooden variant

You can make a transformer from plywood, edged boards, and even from pallets broken into planks. It is best harvested from aspen or ash, although there are no restrictions on the use of wood. It is important that the material is dry, without cracks and fiber bundles.

The choice of material for the manufacture of a wooden transformer bench

The advantage of a wooden folding transformer bench is the light weight of the structure, it can be disassembled and transported to the country house or country house. Among the shortcomings: smaller sizes, more details and connections.

If made from plywood, then a material with a thickness of at least 18-20 mm is required. There is a plywood sheet of 20 about three times more expensive than pine. In addition, some parts will need to be double-thick, so there is a lot of trimming. It is best to use beech or oak, ash, acacia for a transformer shop. The tree is heavy in processing, but the transformer shop will turn out to be quite strong and reliable.

Preparation for the construction of the structure: drawings and dimensions

The design of the transformer consists of three main parts:

- Benches with a support strut that acts as a tabletop support.

- A simple shop with additional consoles.

- The table, which in turn consists of a tabletop and two short supports.

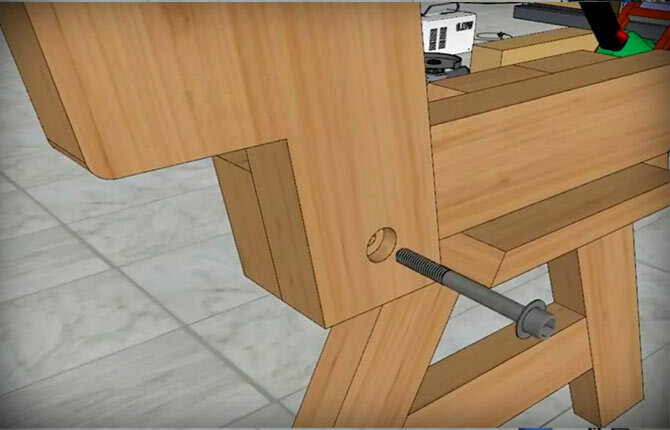

- All three base parts are interconnected by three pairs of hinges. If the wood is hard, then threaded studs or bolts can be used without removing the threads in the bearing. For pine, aspen, ash parts, it is better to use special axles with a smooth surface and threaded ends.

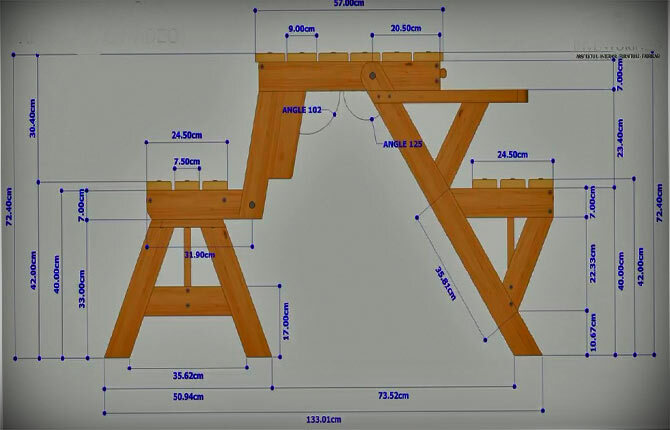

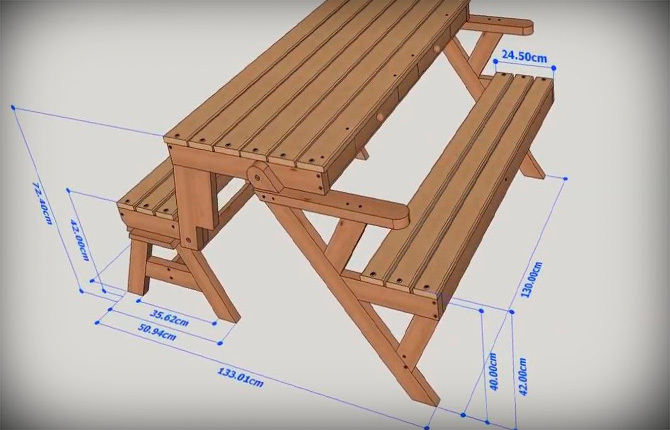

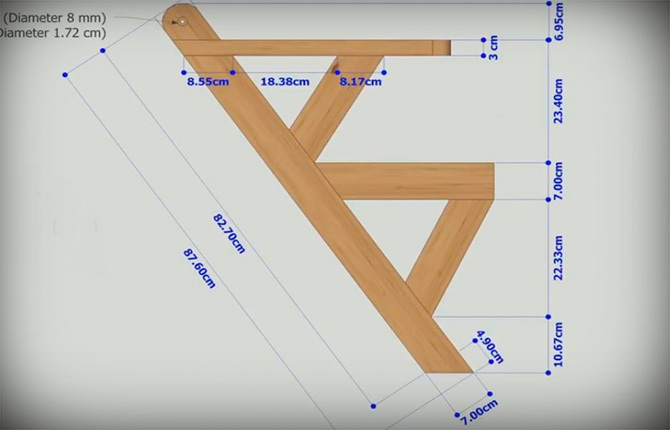

The drawing shows the main dimensions required to assemble the transformer shop.

The height of the structure in the unfolded state is 73 cm, the width is 133 cm. When folded, the backrest height is 57 cm, the seat width is 50 cm.

Material calculation and tools

All nodes of the transformer shop are made from a board 70x30 mm, 70x20 mm, it will need at least 25 m. In addition, for a combined rack (combined with a bench) it is desirable to use a beam of 70x40 mm, it will be required in the amount of 2.5-3 m. The seat of the bench is formed from slats 75x12.5 mm, it will need at least 10 m, the tabletop is made from a wider plank 90x20 mm or 70x12.5, it will also need to be stocked in amount of 10-12 m.

For fastening, wooden spikes are used (corks made of oak - 30 pieces), carpentry screws 45-50 mm. For hinges, you can choose M12 studs with a length of 50 mm.

In the process of building a transformer shop, you will need the following tools:

- electric drill with a set of drills, including centering and cylindrical;

- manual brace with a set of drill bits;

- screwdriver;

- grinder with a cutting wheel for wood with a diameter of 120 mm;

- marking tool.

Studded joints will require precise drilling of holes. Therefore, you will have to use either a desktop drilling machine, or drill with a hand drill with a pen drill, holding the workpiece in a vice.

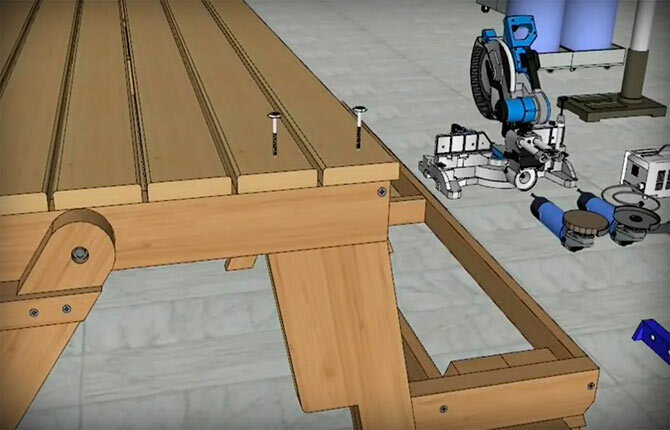

Stages of making a bench-table

First of all, the material must be dried to a level of at least 18% moisture, and then treated with varnish or an alcohol-based varnish composition. This will stabilize the tree, avoid cracking or warping.

For cutting workpieces, a desktop cutting machine is used. It is inconvenient to cut a tree with a hand saw, and in addition, the uneven ends of the rails and timber will spoil the appearance of the transformer shop.

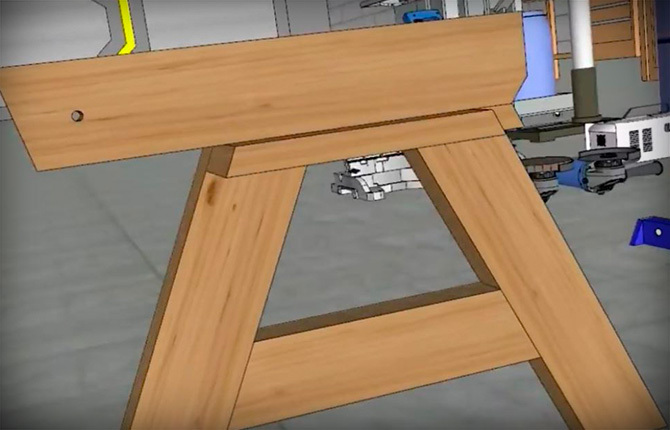

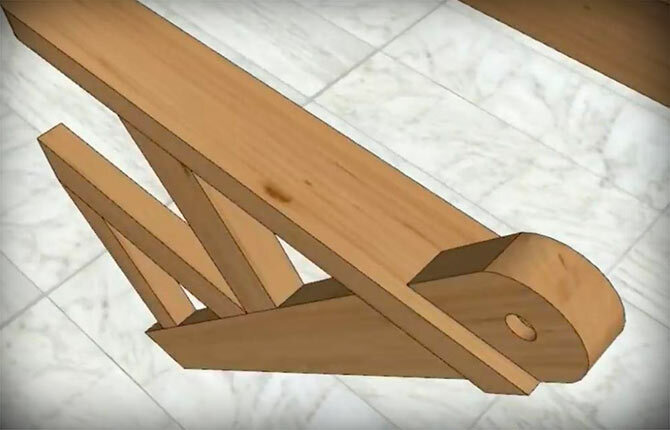

Making side supports for a small bench

The fixed base of the transformer shop will be assembled first. The small bench remains in place during the transformation process, the rest of the parts move relative to it.

This part of the shop is arranged quite simply. Two double supports on each side, seat rails and a pair of hinged horizontal support blocks.

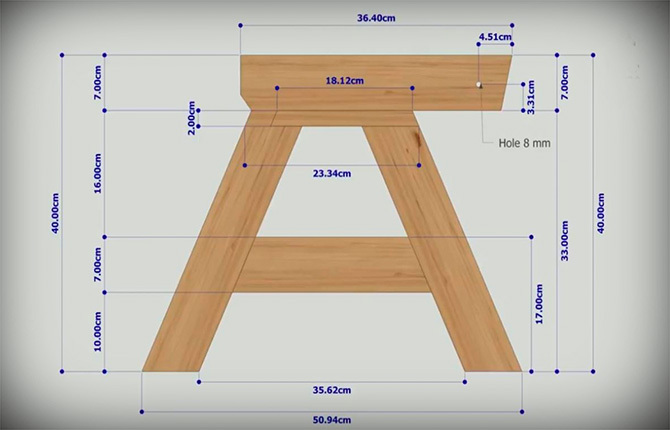

Initially, you will need to cut four legs from a 70x30 mm board, saw the ends at an angle of 15O. The distance at the bottom between the inner edges should be 35.6 cm.

To ensure the horizontal stability of the transformer, a spacer is cut between the two supports at a height of 170 mm. The connection is made with spikes, wood glue and self-tapping screws.

Further, a 25 cm long cross-beam is sewn in the upper part; during assembly, 75x20 mm strips will be stuffed onto it to form the seat. On the outer side of each double support, a wooden block of 70x40 mm timber is sewn. Block length 34 cm.

But before attaching the horizontal block to the supports, it will be necessary to hem the support platform for the handrails to its lower part. It can be made from a piece of board 150 mm wide and at least 25 mm thick. Fasteners are made with five 45 mm self-tapping screws into the body of the timber. You need to fasten it securely, if the platform collapses, then the back of the bench (the transformer in the folded state) will fall back.

The next step is to cut out two movable levers. The shape is quite complicated, you will have to cut it with a grinder from a magpie board 200 mm wide. The ends of the lever are made with an oblique cut of the edge at an angle of 12O.

The upper part of the movable lever will be connected to the box of the table on the dowels, the lower part with the horizontal block - on the hinge.

A cross member, the horizontal part of the table top, is attached to the movable spiked lever.

Assembling a double support for a second bench and table

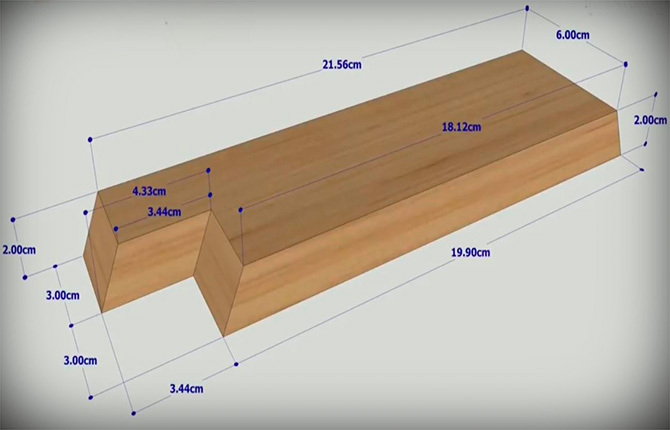

Next, it will be necessary to cut out two sets of parts according to the drawings of the bench, from which a pair of double supports will be assembled.

The kit includes:

- load-bearing timber 70x40 mm, length 100 cm;

- two horizontal blocks, one 40 cm long, section 70x30 mm, with a cutout - a groove, the second - 70x40 mm, 30 cm long, sawn down under 35O leading edge;

- two struts of 26 cm.

First, a pair is attached to the support beam: the lower brace and a horizontal block of 30 cm. For both parts, the edges will need to be sawed down obliquely. The size for drilling dowels is chosen so that after installation on the support block, the distance between the outer edges does not exceed 36 cm.

In a similar way, the top pair: a strut and a horizontal block with a groove. But first you need to drill a 12 mm hole in the head of the support bar for the hinge axis. Drilling is carried out along the midline, stepping back from the edge of 35 mm.

Upon completion of the assembly, all parts at the connection points are additionally reinforced with 25 mm carpentry screws.

Now you need to connect in pairs a small bench with a swing arm and a newly assembled double support. To do this, step back 21 cm from the front end of the side of the table and drill a hole with a diameter of 11 mm.

The result should be two finished side parts of the transformer shop.

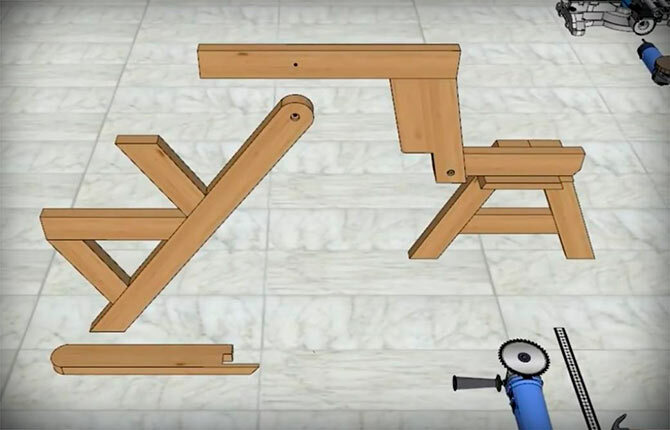

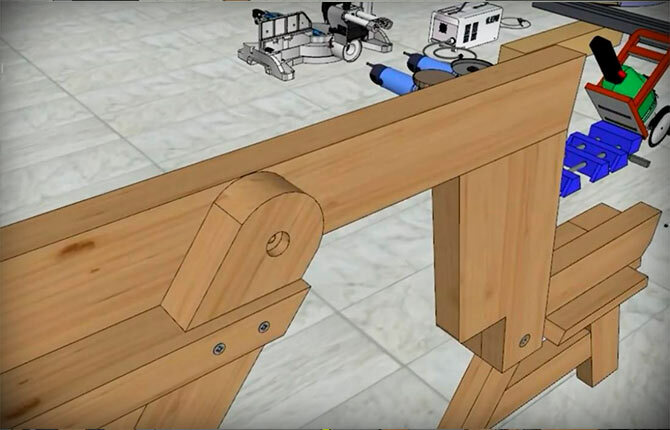

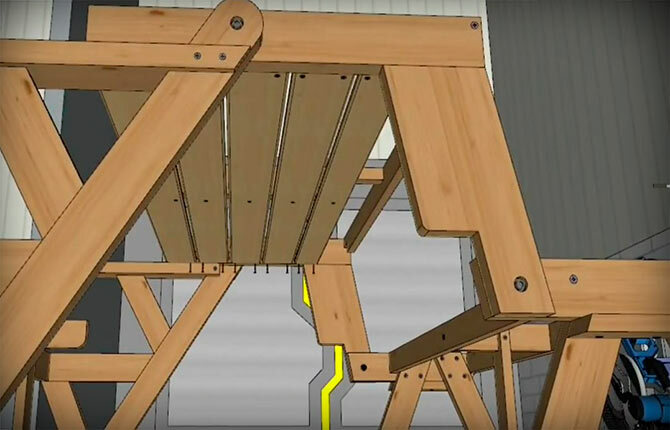

Frame assembly

The most time-consuming part of the work on the manufacture of the transformer shop has been completed. Now you need to install the two sidewalls of the transformer bench in a vertical position and fix them. Before assembling the frame, both parts must be placed on a solid, even base, parallel to each other.

First of all, you need to connect both sidewalls with the help of horizontal rails, two pieces are stuffed under the bench seat on each side.

Stuffed planks will be used to further reinforce the seats. Approximately in the middle, it is necessary to insert an additional L-shaped support of two rails, 220x120 mm in size.

Another reinforcement, now between the paired supports of a small transformer bench. In the lower part, the spacers are connected by an additional cross member cut from a 70x30 mm plank. The part is fastened with ordinary carpentry screws. Such reinforcement will make it possible to insert an additional T-shaped support and sew on the horizontal sidewalls of a large bench.

Before assembling the table top of the transformer bench, you will need to sew on one of the horizontal rails of the table.

Now you can proceed to the final stage of assembling the transformer shop.

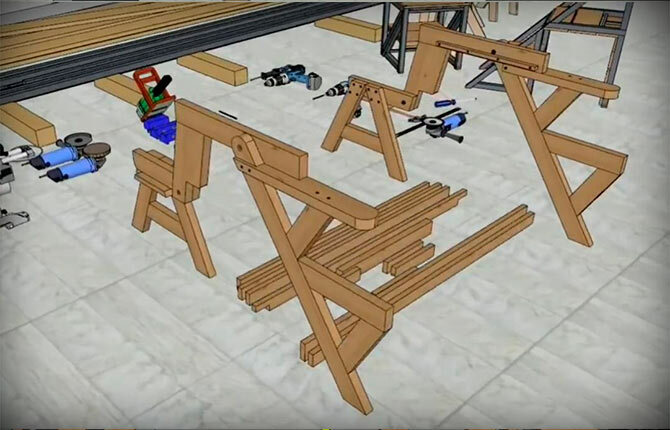

Assembly of a transforming table and benches

The tabletop for the transforming bench is formed by stuffing in a row of slats 12.5 mm thick, 70-75 mm wide. The surface can be sanded or used as a rough base. In this case, the decorative upper part is sewn up with plastic, for example, textolite or furniture board.

The design of the table consists of a box, top and bottom filing of slats. The assembly of the tabletop of the transformer bench begins with the stuffing of the bottom row of rails.

To prevent the planks from bending, an additional cross-section of 70x30 mm is installed in the central part of the table box, connecting the long sides of the box.

Then you can sew the top row of slats. The length of the facing material is selected according to the longitudinal dimension of the transformer. Planks are laid directly on top of the box.

But if the further finishing of the table of the transformer bench suggests, then it is better to cut the top row planks into the box at the same level as the sides.

After finishing the facing work on the table, you need to sew up the seats of the transformer benches. The same strips are used as for the countertop. But in this case, the material is stuffed with a gap of 3-4 mm. This is done to increase the rigidity of the bench structure. In addition, it is believed that sitting on such a bench in the summer heat is more comfortable than if the surface of the transformer seats was completely sewn up.

Important! The fastening of the lining of the benches and the transforming table is carried out with furniture screws. Ordinary carpentry (black or yellow) self-tapping screws are unsuitable for these purposes.

The furniture screw has a wide “head”, which ensures stable pressing of the rail to the base. The main thing is that the thread is cut only on the first 25 mm of the rod, the rest is smooth metal. Therefore, the rail screwed with a furniture screw has a small backlash.

If a person sits on a transforming bench, then the planks bend slightly, without the risk of cracking. If you tighten the self-tapping screw, then after a couple of weeks of using the transformer shop, deep cracks will appear on the edges of the planks.

Fastening with a furniture screw requires accuracy:

- initially, a rough drilling of a hole is made on the rail, it is 0.5 mm larger than the diameter of the screw thread;

- an undercut is made with a pen drill so that the screw head after tightening is completely recessed into the rail material;

- then the bar is laid on horizontal beams and fixed with a clamp;

- with a new drill, with a diameter less than the thread of the screw by 0.7 mm, drill a hole in the support bar;

- the screw is dipped with a thread in a lubricant, for example, in liquid soap or glycerin, and wrapped with a screwdriver until it stops.

How firmly the screw is held depends on the density of the wood. Therefore, for racks, support beams and blocks of a transformer shop, it is better to use hard rocks. Oak or acacia is best. You can use beech or larch, but they are too prone to cracking under impact loading. For example, if you try to fold and unfold a transformer bench with legs hitting the ground.

Upon completion of the assembly of the transformer shop, the tree is treated with sandpaper, with different grain sizes. You need to get a smooth surface. It's not even about the spectacular appearance, but about the safety of using the transformer shop.

In order to expand the transformer, turn it from a bench into a pair of benches with a table, you need to intercept it with your hands several times. On unpolished wood, you can constantly drive splinters. Some types of wood have a high causticity, for example, larch or overdried pine. Therefore, for lining a table or benches, it is better to choose soft rocks, such as linden, birch or ash.

In addition, sitting on a bench assembled from unpolished slats in the summer is not very comfortable.

Finishing Tips

The transformer bench is already ready and can be used. It is only necessary to put a small amount of grease into the hinges and ennoble the appearance of country furniture. Steel axles must be lubricated, otherwise the transformer shop will creak during the unfolding process. Lubrication in the hinges is laid in a small amount, for each axis there will be enough LITOL with a match head. But this must be done.

Painting

The easiest way is to paint the transforming bench with acrylic paint, but for some reason it is considered too expensive for garden furniture. Acrylic is expensive but provides a good look. True, before painting, you need to carefully sand and blow off all the details of the transformer shop. So that the smallest dust does not remain, otherwise, after mixing with paint and drying, it will turn into a kind of sandpaper.

Only old transformer shops with a mass of surface defects are painted with oil paint with drying oil. Before painting, it is recommended to putty the damaged areas of the surface, for example, with a composition of chalk (alabaster) and drying oil. After grinding, the old transformer bench will look like new.

It is better not to use nitro-paints, pentaphthalic enamels for painting benches made of wood.

Vinyl wrapping

A fairly new way of decorating. Traditionally, the table top and bench seats are sealed with vinyl film. Fully wrapping a wood structure will provide good protection for the wood much better than just painting it.

At the same time, it is possible to choose a texture, a pattern for precious woods, you can make a “stone” decor or simply imitate a furniture plate.

Varnishing

A complex type of decorative finish, the main thing is to follow the technology of applying a varnish coating step by step. The surface of the benches and the table, all the details of the frame must be carefully sanded with sandpaper, dusted with shoes, then with a damp cloth.

If the pattern of fibers on the slats of the tabletop is not too expressive (beautiful), then the surface is bleached white, washed and covered with a thin layer of colorless varnish. In this way, it is desirable to process all the details of the transformer shop so that the design turns out to be monophonic.

On the benches, details of the tabletop supports, you can apply (burn out) drawings or inscriptions in the Loft style. Logos in the style of the beginning of the last century, inscriptions in calligraphic handwritten style are very well combined with the light texture of bleached wood. Today it is one of the most popular ways to decorate furniture in the Loft style. After painting, the shop is opened with one or two layers of colorless polyurethane varnish.

A simple transforming garden bench can be simply opened with a pentaphthalic lacquer composition tinted in the color of chestnut or walnut.

Reading: How to make a swing with your own hands from metal

Impregnation treatment

Wood is an excellent material, but for dry and well-ventilated areas. If the transformer shop will stand in an open area, then instead of varnish or paint, it is better to use impregnating waxes or oils used to protect wood in saunas and steam rooms.

The impregnation is applied to the prepared surface, the tree practically does not change color, but if the transformer shop is be exposed to solar ultraviolet, the coating may darken, a reddish-gray tint of artificially aged wood will appear.

Results

Subject to the proposed step-by-step instructions, assembling a transformer shop with your own hands will not be difficult even for beginner furniture makers. You can add your own details, for example, make the handrails more elegant or change the slatted table top to solid plywood.

Tell us about your experience in building transformers. How can wooden furniture be better than a bench made from a professional pipe or a steel corner? Save the article to bookmarks and share it on social networks.