Foam concrete blocks have long been used for low-rise construction. Owners of apartments and houses note only difficulties with the selection of fasteners for walls made of foam blocks. Choosing the right dowel for the foam block is quite difficult, the material is strong, but too fragile. Therefore, hammering a cork into a wall or ceiling in the way that is customary for brick or concrete will obviously not work.

The content of the article:

- Requirements for fasteners to the foam block

-

Varieties

- Plastic dowel

- metal dowel

- Chemical anchors

-

How to install correctly - step by step instructions

- Installing conventional plastic dowels on a foam block wall

- Plastic dowels with screw or "wings"

- Installation of frame dowels and sleeves

- Folk method of fastening for foam block

- Results

Requirements for fasteners to the foam block

We must immediately make a reservation, we are talking about walls made of foamed concrete. It has fairly large pores filled with air. The material is rather soft, brittle, but if necessary, it can be drilled with an ordinary drill bit, even with a large diameter, 15-20 mm. Foam blocks are easy to recognize by their characteristic gray color, since the basis of the material is cement.

The properties of the foam block determine the requirements for the method of fastening. You can screw a self-tapping screw with a large spiral winding directly into the foam block, use a dowel with a plastic stopper, or choose a mount of a special configuration.

What you need to pay attention to when choosing a method:

- The pressure on the walls of the hole should be distributed in depth, so the holes for the cork are made deep. If you try to install a short dowel into the foam concrete, then when you tighten the self-tapping screw or screw, the plastic will destroy the upper layers of the block.

- The plug of the dowel must not be hammered into the hole in the foam block with a strong interference on the surface. Any friction of the outer surface of plastic or metal against the walls of the hole breaks them into grits. Such fasteners will not hold in foam concrete, even if the self-tapping screw is wrapped with a slight interference.

- For fastening in foam concrete, you cannot use screws, self-tapping screws with a helical spiral, in which the tops are rounded or too sharp (fine pitch). They also destroy the material of foam blocks without the formation of adhesion.

All of the above fastener options, as a rule, use dowels with a plastic cork and a long steel self-tapping screw. But foam concrete has a rather fragile structure. A plastic or metal insert can withstand the static load of separation from the wall well. But most often you have to look for a way to fix objects, furniture, door frames, brackets that create a dynamic load with a dowel on a foam block wall.

For example, if you need to hang a wall cabinet on a foam block wall in the kitchen, you can use the classic version of the dowel with a plastic cork, but it will not last long. Due to the swinging of the cabinet body (when the doors are opened), the dowel will “come out” of the foam concrete in a matter of weeks, therefore, for dynamic loading, you have to use metal dowels or fasten the cabinet along the old fashioned way.

Varieties

Dowels are divided into metal “breaking”, wedged with a reverse cone, and plastic - with a bursting plug or a twisting insert. There are also chemical dowels. But this is a completely different type of mount, and it can only be used in limited conditions.

Use cases:

- Lightweight fasteners such as hooks, ties, loops for securing cables, wires, small items weighing up to 200 g, can be fixed using a conventional carpentry (black) self-tapping screw with a large screw winding. The length must be at least 60 mm, then it will hold.

- Heavier objects, up to 2 kg, can be fastened into foam concrete using a classic dowel - a 6x60 mm nylon cork and a joiner's self-tapping screw. For a more complex load, the plastic dowel must be selected individually.

For heavy objects, a chemical or metal frame dowel can be used. Usually these are ceiling mounts or a variant with brackets with a complex bending load installed on the foam block.

Plastic dowel

For fastening in foam concrete, you can use any kind of dowels with a nylon or polypropylene plug. There are many different options on the market with a herringbone notch, a helical, serrated (dotted) surface. All of them adhere quite well to the wall material, so they can withstand a static pull-out load relatively easily.

For fixing furniture on the walls of an apartment or a private house, for example, shelves or cabinets, dowels with a cork with a diameter of at least 8 mm are used. The main condition is that the length of the cork and the self-tapping screw must be at least 60 mm. In practice, for fastening on a foam block, they try to use dowels with a diameter of at least 10 mm.

Another type of dowels for foam concrete is with a twisting plastic plug. There are longitudinal cuts on the surface, therefore, in the process of screwing in the self-tapping screw, the back part is crushed and folded into a thickening.

In theory, pulling out such a dowel is much more difficult than a regular herringbone cork for bricks. But in reality, the strength and reliability of fasteners with a breaking dowel depends on how correctly the diameter is selected and the hole is drilled into foam concrete.

For reinforced fasteners, dowels with additional radial feather shelves are used. If you follow the installation rules, then the strength of the dowel can be up to 20 kg, and when using the adhesive mass - up to 30 kg.

Also, plastic self-tapping dowels are often used for the foam block. In fact, this is a short screw of large diameter with a large helical knurling. The design of fasteners was developed for laying insulation on aerated concrete walls, but the “loving” dowels were also used for foam concrete.

Read this helpful article: How and what to ditch the walls for wiring

metal dowel

For small fasteners on the walls of the foam block, you can use split plugs. In fact, this is a sleeve or a tubular insert with a slight taper and longitudinal cuts. On the surface of the metal plug there is a serrated notch, due to which the dowel enters into a sufficiently strong grip with the material of the hole walls.

Of all the metal dowels, the split dowel is considered to be the easiest to install, in addition, the diameter of the hole for the sleeve is chosen slightly smaller than the size of the cork at the head. Therefore, even if the installation of fasteners fails, there will be no cracks or damage on the surface of the foam block. You can always try a different type of dowel.

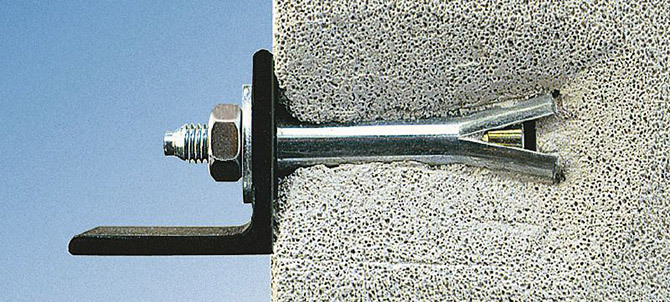

The most reliable is the fastening with a frame dowel. It has a special design. The embedded element is made in the form of a split sleeve with two nuts at the ends. After installing the sleeve, a threaded screw is wrapped. In this case, the far nut begins to move towards the surface, compressing and crushing the sleeve.

Due to the cuts on the sleeve, the material is easily deformed and abuts against the walls of the hole. The pressure force is simply enormous, which allows the frame dowel to easily hold a weight of several tens of kilograms.

The frame dowel withstands static, alternating and bending loads. The mount is held on the foam concrete wall to the end until the bracket is broken or the sleeve petals are deformed.

Chemical anchors

This type of fastener cannot be fully attributed to dowels, although its design also has an embedded part - a capsule and a bearing element - a threaded stud. Unlike other types of fasteners, a chemical anchor is glued rather than screwed into a mounting hole.

The essence of the installation is as follows:

- a cylindrical capsule with an adhesive composition is laid inside the hole in the foam concrete;

- when screwing the stud, the capsule squeezes out the glue, which fills all the free space between the metal and the wall of the hole;

- after hardening, the anchor is firmly fixed inside the hole without any additional upsetting or crimping.

The chemical anchor is applied under big loading. In the description you can find values \u200b\u200bup to 600 kg. But in ideal conditions, in practice, for this type of fastener, the limit is limited to 200 kg. Installing a chemical anchor requires careful preparation of the hole in the foam block and following the sequence of procedures.

This is not a collapsible connection, if it didn’t work out, then the pin will have to be cut off from the surface of the foam block with a grinder. In addition, the chemical anchor "does not like" a vibrating load, therefore it is used to fasten heavy, but statically stationary objects.

But there are cases when a chemical anchor becomes simply indispensable. For example, when building a house from foam blocks, you always need to solve the problem of how to fix the Mauerlat beam on the upper edge of the walls. On brick walls, the Mauerlat is fixed with ordinary studs hammered into the top row of bricks. For a foam block, this method is unsuitable, therefore, chemical anchors are used to fix the timber.

How to install correctly - step by step instructions

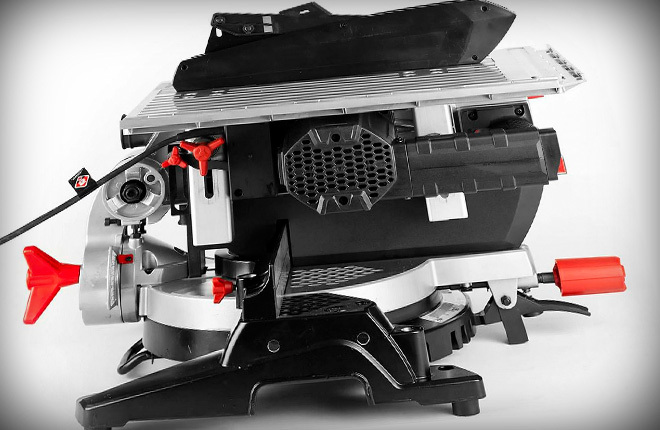

Before installing the dowel in the foam block, you need to choose the right tool. You can screw in the self-tapping screw with a Phillips screwdriver, a screwdriver, or in some cases you will have to hammer it.

The rule is pretty simple:

- To screw the self-tapping screw into the body of the foam block, only a screwdriver is used. This is the only way to wrap the fastener without breaking the helical coil engagement with the wall material.

- In the case of dowels (hole inside the foam block 6-8 mm) with short “breaking” petals (up to 40 mm), a regular screwdriver is used. It is hard to twist by hand, but this is the only way to correctly deform the petals and not turn the fasteners inside the foam block. But with some practice and skill, after a couple of hundred wrapped screws, you can get used to working with a screwdriver.

- All dowels larger than 8 mm are wrapped with a screwdriver, including chemical anchors.

- Corks of large diameter with additional screw shelves on the surface, as well as all the "folk" options for dowels, are hammered into the foam block with a carpenter's wooden hammer. Wooden, because this is the only way not to break a hole inside the foam block. A carpenter's hammer (mallet) forgives a slight inaccuracy when hitting a cork. If you use a conventional hammer for 300-400 g, then one wrong move can lead to pricking the surface of the foam block. It is recommended to hammer steel cases with a conventional metalwork hammer - frame and split sleeve.

Installing conventional plastic dowels on a foam block wall

After marking the attachment point, you need to make a hole for the cork. For all types of plastic plugs, the hole depth is selected 10 mm more than the dowel length. The diameter of the drill is 0.5 mm smaller than the size of the cork at its thinnest point.

Then everything is simple, a cork is inserted into the hole and upset by hand to the level of the cut. It is clear that the draft must occur with effort. This means that the plastic adheres reliably to foam concrete. You can not blow a hole in the foam block, the remaining dust will only improve adhesion. And everything that is superfluous will be squeezed out into the depths. It remains only to wrap the screw with a screwdriver, but without excessive force.

Advice! If the drill size was chosen incorrectly and the hole in the foam block turned out to be 1-1.5 mm larger necessary, then before inserting the dowel, you need to dip it with PVA or stationery glue (liquid glass). Such a dowel will hold inside the foam block even better than a regular one.

Plastic dowels with screw or "wings"

Self-tapping screws with ordinary plastic plugs are normally kept on foam blocks only if the load is directed horizontally or vertically. Any alternating loads knock out ordinary dowel plugs in a couple of days.

Therefore, for fastening heavy objects, plastic bushings with "wings" or "blades" are used. They are called differently, but the bottom line is that additional elements on a plastic cork increase the bearing capacity of fasteners on foam concrete by almost five times. Today it is the best dowel for the foam block.

How to put the model with "blades" correctly:

- On the plastic case there is a marking, for example, "RD10". This means that for fastening it is necessary to drill a hole with a diameter of 10 mm in foam concrete.

- You need to drill with a conventional drill and an electric drill with a collet chuck. A puncher with a quick-clamping chuck and a drill with a carbide insert breaks a hole in foam concrete up to 11-12 mm, and this is already a marriage.

- Now you need to insert the insert into the hole and hammer the cork to the end with gentle blows.

You need to beat carefully so that the dust from the foam block, cut off from the walls by the blades, has time to get enough sleep and does not interfere with the progress of the cork. The blades enter the aerated concrete very easily, you can score in 3-4 strokes. For a foam block, the number of blows doubles or triples.

Advice! If the edge of the hole fell apart from the blows, a piece of foam block fell out, it's okay. It is necessary to expand the size to 20 mm with a pen drill and glue the dowel on the alabaster.

In addition to models with wings on foam blocks, plastic dowel-screws are used. Such a plug looks like a large self-tapping screw with a head and a spiral wound on the body, similar to a thread.

Such a dowel is wrapped in a foam block like a conventional self-tapping screw. But first you need to drill a hole to a depth equal to the length of the cork, plus 10 mm. The diameter is determined by the head of the "screw". To twist inside the foam block, a sufficiently large force is required, therefore, a screwdriver with a nozzle under the screw head is used.

Installation of frame dowels and sleeves

Metal fasteners are traditionally used on a concrete ceiling slab. On walls, steel frame dowels are used as an exception. Firstly, this is a one-time fastener; after installation, it is almost impossible to pull out the deformed frame without destroying the foam block material.

Secondly, after installing the mount, cracks appear. Therefore, frame dowels are used on foam block walls only where very high fastener strength is required.

To install, you need to drill a hole along the diameter of the insert, put a frame inside the foam block, fix it with one key and wrap the head with the second.

The second type of metal dowels - sleeve, are used in large quantities for any finishing and facing work on the surface of the foam block. For example, to assemble the crate.

To install the dowel, you need to drill a hole in the wall, the diameter can be seen on the marking. But most often, craftsmen simply measure the diameter in the middle part of the split sleeve. After drilling, insert the sleeve into the hole by hand (about half will go in), and then hammer it to the level of the wall with an ordinary hammer.

Unlike frame models, sleeve split dowels never break the foam block material.

Folk method of fastening for foam block

Many craftsmen use the old proven methods of fastening on homemade dowel plugs. Despite some archaism, such homemade products perfectly withstand the weight of heavy objects. With their help, it is easy to fix hinged furniture on the foam block. Homemade dowels are often used to fasten door frames and they serve no worse, and sometimes better than plastic ones.

The traditional method of fastening involves the use of homemade plugs cut from a wooden slat. Initially, you need to cut blanks from a square rail 20x20 mm, 80-90 mm long. The back part (the one that will enter the hole) is cut into a length of 3-4 cm and slightly cut with a knife into a cone. The incision is needed for wedging inside the foam block after tightening the self-tapping screw.

Further, at the point of fastening on foam concrete, a hole with a diameter of 19 mm is drilled, to a depth equal to the length of the cork. It remains only to drive the cork into the foam block to the full depth and screw in the screw or hammer in the nail.

Such a wooden insert holds much better than plastic, and if you have to put the door in the opening, then the plugs can be covered with glue so that they do not dry out over time. And although it takes much more time to install fasteners in foam concrete, it is almost impossible to tear such fasteners out of the wall, which cannot be said about plastic or metal plugs.

Results

Choosing which dowel is best to use will not be difficult if you know exactly for what purpose the fasteners will be used. Accordingly, the size and shape of the cork is selected, the method of its installation in the wall. The method has long been worked out, tested in practice, so it is almost impossible to “miss” with the reliability of fastening.

Tell us about your experience in choosing foam concrete fasteners. Which ones do you think are the best? Also, bookmark the article and share it on social networks by reposting.