Relatively simple smoke treatment gives the products a special flavor and at the same time preserves them. Fans of home smoking may have several devices, for example, separately for fish, meat and vegetables. You can make do-it-yourself smokehouse cabinets from anything, the main thing is to comply with sanitary requirements and withstand the smoking technology.

The content of the article:

-

Universal smoking cabinet

- Design requirements

- Universal smokehouse device

- Cabinet for a cold smoked smokehouse made of wood

- Smoking cabinet with smoke generator

- Heated cold smoking cabinet

-

Smoke cabinet for cold smoking electric

- Heating with light bulbs

- Classic variant

- Stainless steel cold smoking cabinet

- Cabinet for smoking sausage

- Cabinet for smoking fish

- Smoking cabinet from the refrigerator

- Results

Universal smoking cabinet

For the category of beginners, it is best to try to make one smoker cabinet for all occasions. This makes it easier to master the technology of smoking, to find the optimal mode for different products.

Design requirements

In order for the smokehouse to be used in two modes, cold and hot, for a variety of, often incompatible products, the design must meet the following requirements:

- disassemble into separate units and parts for washing and removing grease residues (smell);

- use an external source of heat and smoke, as the latter, an ordinary barbecue is best;

- it is desirable to make the volume of products laid down small; for each item, you will have to prepare your own grate and smoke humidifier.

If you plan experiments with a smokehouse, then for the first time it is better to make a small smoking cabinet and preferably collapsible, that is, such that it fits into the trunk of a car. For the first samples, a stationary brazier in the country is best suited. It will be used as a smoke generator.

Universal smokehouse device

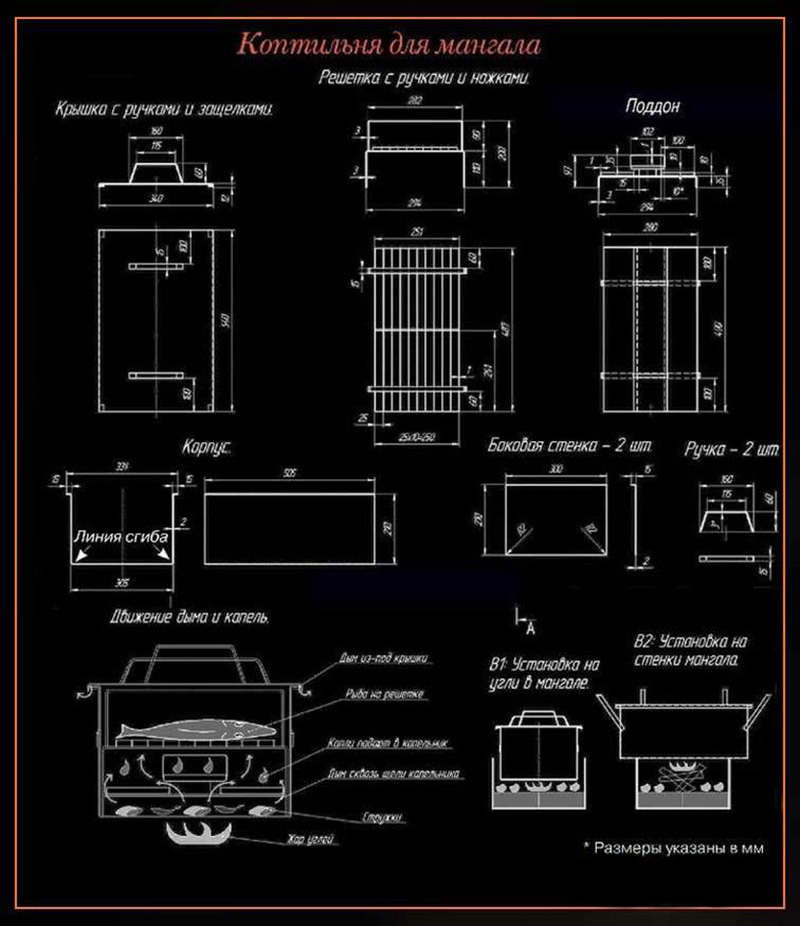

The simplest version of the cabinet is shown in the drawing below.

The design consists of four parts:

- Box-shaped body with bent side edges.

- Tray with dropper for collecting fat.

- Lattice for laying products. Two cross handles allow you to pull products out of the smokehouse without the risk of getting burned.

- Lid also with handles.

The total weight of the cabinet does not exceed 3 kg, with products the smokehouse can pull 5-6 kg. But still, the mass of the cabinet, even when the smoking compartment is fully loaded, turns out to be small, which makes it possible to install it directly on the grill, both on coals and on the side walls.

How the smokehouse cabinet works: shavings of fruit trees are poured into the bottom of the box, a tray is inserted, a bowl for collecting fat. Next, a grid with products is placed on top, the lid is closed. The smokehouse is put on fire. The operating mode of the universal smoking cabinet must be selected experimentally.

Cabinet for a cold smoked smokehouse made of wood

The box does not have to be made of food grade stainless steel, black steel or aluminum. In some modes, the smoke inside the smoker is heated to a relatively low temperature. Therefore, the cabinet can be made of wood or wooden slats.

The easiest option is to make a cabinet out of plywood 6-8 mm thick. Initially, a frame is assembled from a bleached pine lath 20x30 mm, then the walls are sewn on. It turns out a design similar in shape to a mailbox, but larger in size.

Inside there are two pairs of rails for installing the grate. Since the temperature inside the smokehouse does not exceed 60OC, then the heated metal will not affect the durability of the tree.

Now the main thing is to heat the chips and get cold smoke. You can lead the pipe inside the cabinet through one of the walls (usually the side) or install a spiral heating element inside from an electric stove. A stainless steel container with chips is installed on the spiral.

Sometimes the container is covered with a mesh so that the smoke is additionally cooled and the cabinet works in cold smoking mode. If you connect the heater through LATR, then you can smoothly adjust the temperature inside the smokehouse.

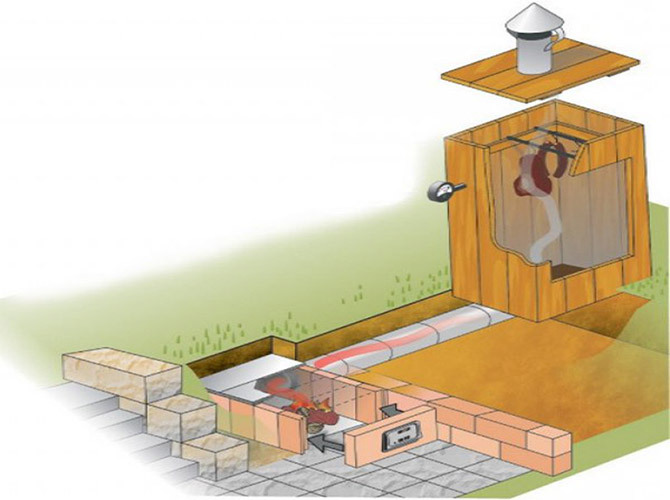

Smoking cabinet with smoke generator

Many amateurs make smokehouses with a remote source of smoke. It is believed that most of the heavy resins that give products a bitter taste remain outside the cabinet: either burn out or settle on the walls of the smoke generator.

For the cabinet itself, you can use any metal container of the required volume, as long as the doors or lid close tightly. Otherwise, the products in the smokehouse will be processed unevenly, part of the smoke will escape through the cracks.

The design of the smoke generator can be in a straight line. That is, sawdust or shavings burn in a separate container and under natural draft (they put a chimney pipe on the smokehouse), get inside the cabinet, where the substances contained in the smoke are absorbed.

If the smokehouse is small, then a small metal can is used for the smoke generator, and air is supplied using a compressor or fan mounted in a plastic bottle.

The air temperature inside the smokehouse can reach 100 ° C, so the cabinet is made of heat-resistant material. The most popular option is a box made of wood (it keeps heat well). The inner surfaces are pasted over or sheathed with aluminum foil for roasting vegetables in the oven.

The quality of smoking is average, as the products are processed with too hot a stream, sometimes fish or meat is simply boiled in smoke and loses a huge amount of fat and moisture. Therefore, cold smoking is more popular.

In this case, the supply of smoke into the cabinet-smokehouse is performed with additional ejection of cold air.

That is, the temperature decreases, and in addition, most of the wood condensate is removed, which is sublimated from the wood in the process of smoldering without air access.

Heated cold smoking cabinet

A full-sized smokehouse for processing products with chilled smoke must be designed separately. The problem is that the smoke stream quickly cools on the products.

If in a classic hot-smoked cabinet the products on the upper shelves were heated the most, then with cold smoke processing, the bottom row is better smoked. The rest of the cooled smoke rises due to draft, and often the products are not completely saturated with substances, flue gases.

Therefore, the cabinet for cold smoking is always made with double walls. Thermal insulation is laid between the walls. You can use penoplex or even polyurethane foam. Inside the smokehouse, it is desirable to line the walls with heat-resistant plastic with a smooth surface.

Many hobbyists refuse to use insulation for environmental reasons, deliberately building wooden cabinets with foam glass tiled insulation on the bottom.

In order to have enough heat during cold smoking, the smoke is supplied through the bottom of the cabinet, and the smoke stream itself is slightly overheated.

In the bottom part of the smokehouse, a washed stone is additionally laid: lumpy silicon or pebbles. Next, they kindle firewood and, before laying the products in the smokehouse, they heat the cabinet like a stove. In this case, firewood from fruit or deciduous trees is used (except for willow, they emit the smell of a swamp).

After a thorough warming up, pebbles and stones are heated to a high temperature. They put a metal container with dry sawdust on them, only fruit firewood is loaded into the smoke generator stove, while the door or damper is covered so that the smoke going through the channel has time to cool. Next, products are hung out in the smokehouse, a container is installed at the bottom to collect the dripping liquid.

In this mode and with good thermal insulation, the smokehouse can work for almost a day. It is only necessary to properly regulate the operation of the smoke generator, avoiding severe overheating.

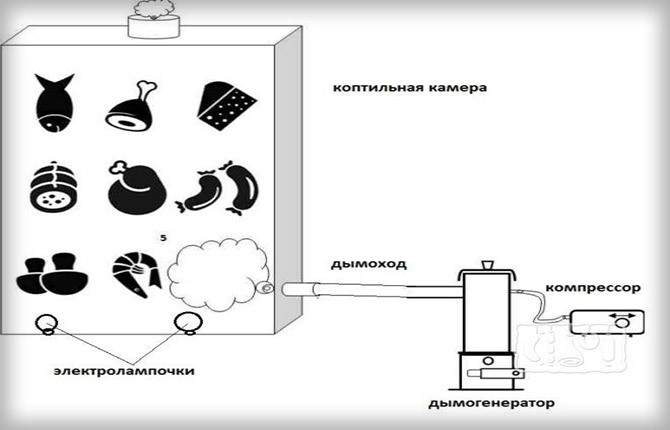

Smoke cabinet for cold smoking electric

It is not always possible to build a full-fledged smokehouse cabinet with an external smoke generator-stove with heating of the bottom of the cabinet. Therefore, lovers of smoked meats came up with another option for arranging a smokehouse.

Heating with light bulbs

In this case, conventional 100 W incandescent lamps are used instead of heating elements or flue gases. The glass bulb of the lamp heats up to 120OC, plus glass does not react in any way with flue gases. Several light sources installed at the bottom or side of the smokehouse warm the flow well.

True, in such a heating system, you need to make sure that fat or juice does not get on the glass, otherwise the bulb will burst.

Classic variant

If the smokehouse is used on an ongoing basis, then instead of paws, they install an ordinary heater-snake from the stove, connect it to the power regulator. In order not to dry out the smoke in the smokehouse, a stainless steel or nickel-plated tray is placed on top of the heaters.

Water is added to it, sometimes with spices. This is easier than rubbing meat or fish with fragrant spices by hand.

Stainless steel cold smoking cabinet

Among those who are just starting to master the smokehouse at home, there is an opinion that it is best to make a stainless steel cabinet. Approximately half of the factory-made smokehouses on the market are made of stainless steel.

In fact, a stainless steel cabinet is not the best solution. The smokehouse does not rust or oxidize, but under hot smoking conditions, the products acquire a characteristic metallic taste. Therefore, if you make a cabinet from stainless steel, then from special food (medical) steel, and only for cold smoking.

Food stainless steel has a matte shade of grayish-yellow. This indicates a high nickel content. Steels with a shiny white surface are stainless steels with a high chromium content. They can only be used for the outer casing of the smokehouse.

The cabinet is made in the form of two boxes 50x70x100 cm - external, and 40x60x90 cm - internal. Thermal insulation is made of mounting foam, it is applied to the inner box and immediately put on the outer one. After a couple of hours, both parts are securely glued together, and it will be possible to hang the door, make an input for the smoke generator.

In this design, the smoke is introduced not at the bottom of the smokehouse, but on the side between two shelves. A warm cloud of smoke, getting into the smokehouse, is sandwiched between two shelves with food, so cools slowly, and most of the heat and volatile compounds get on the smoked meats, and not on the walls closet.

It is better to buy a device for producing cold smoke or, if you do it yourself, then make several options. The operating mode for cold smoking will have to be selected individually.

Sheet thickness is arbitrary, but not less than 2 mm. If possible, it is better to make shelves from nickel-plated brass mesh, and not from stainless steel.

Cabinet for smoking sausage

Meat products can be cooked on hot or cold smoke.

But there are some features, for example, lard, bacon, bacon are pre-salted in marinades or brines. In the smokehouse, such a product is processed with smoke at a temperature not exceeding 60 ° C. That is, fats are not rendered, and the product retains its natural moisture.

In the same way, “quick” raw smoked sausage is often prepared. According to the instructions, the cooking time is reduced from 4 weeks to 8 hours. But the temperature in the cabinet is reduced to 45-50OWITH. That is, theoretically, you can smoke along with pickled brisket or ham. But it’s better not to do this, since the universal cabinet always gives off old fat. Therefore, it is better to make a separate smokehouse for raw smoked sausages.

For the preparation of ordinary smoked sausage, any cabinet with a heater will do. For example, if you need to process a large amount of meat, then a regular barrel will do. In the bottom part, you need to make 15-20 holes with a diameter of 3-4 mm. A clean, wood-burned and evaporated barrel is placed on bricks, cherry and apricot sawdust is loaded inside. Hang sausages and kindle a fire under the bottom.

If you make a special cabinet for smoking sausages, then the best option would be a wood-heated smokehouse model. The body can be welded from mild steel sheet. External surfaces are powder coated. The inner surfaces are simply cleaned and evaporated from the smell of grease.

Such a smokehouse scheme is convenient in that it is possible to regulate the heating temperature using a damper on the pipe. And you can also change the pallet with the smoldering sawdust mass, for example, if the recipe for cooking meat requires sequential processing with two or three types of sawdust.

Cabinet for smoking fish

The smokehouse for fish products must be made separately from the chamber for cooking meat or sausages. Burnt fish oil is almost impossible to remove from the smokehouse. Periodically, the cabinet is evaporated with boiling water, but the smell still remains.

River fish is cooked mainly "hot". She has a lot of fat, and besides, there is always a smell of mud. In addition, this is a good way to rid the product of possible parasites. If you plan to smoke small fish (up to 25 cm long), then the cabinet is made three-tiered with mandatory heating or an additional smoke generator.

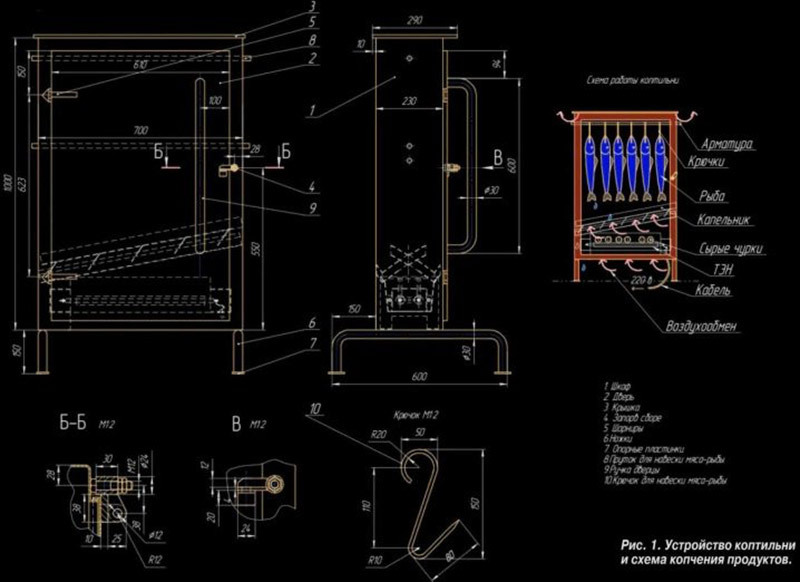

For cooking fish over 30 cm long, a classic smoker cabinet with electric heating and a tray for draining fat is best suited.

The case can be borrowed from an old electrical control cabinet, as in the drawing.

The metal of the walls is quite thick, and they are assembled much better than smokehouses that are sold in stores. You just need to free the cabinet from the contents, remove unnecessary blocks and fixtures. The paint must be burned or removed with a sandblaster.

A heating element and a grid for smoldering raw chocks are installed in the lower part of the body. After loading and turning on the heating element, steam will go first, it warms up the fish well. Further, as the smoke heats up, it becomes more saturated, you can reduce the power and let the smokehouse work for another 3-4 hours.

For smoking fish in the kitchen, you can use the original design of a double-walled metal cabinet. There is no thermal insulation, the space is not filled with anything, in addition, several hundred through holes are made on the inner walls.

The lower part is made in the same way as most hot-smoked chambers. Heating is carried out by an electric stove, the sawdust tray does not have a diffusing sheet. After heating, the smoke rises and enters the smoking chamber through the holes. You can regulate the inflow using a hole closed with a plug.

Such a scheme provides deep, and most importantly, uniform penetration of smoke into the fish, without overheating or scalding. With the help of such a cabinet it is very convenient to smoke small fish, roach, trout, horse mackerel.

Smoking cabinet from the refrigerator

To make a smokehouse, you need an old refrigerator. They do not have a freezer, so it will be easier to disassemble and prepare for work than a regular refrigerator. First of all, you will need to remove the inner plastic lining, including from the doors. Then thermal insulation is removed from the body, it can be made of fiberglass or polystyrene foam. In addition, you will have to remove the paint and clean the surface to white metal.

You will also need to remove the seal, replace it with heat-resistant rubber or felt.

The metal of the walls is thick enough, so the stability of the cabinet will not change in any way. The bottom will need to be replaced: insert a metal sheet with a heating element and make an additional mount for a plate with sawdust. The distance from the bottom of the plate to the tubes of the heating element should be no more than 5 mm.

Inside the chamber, you can install an additional lining made of sheet aluminum, this will simplify the cleaning of the smokehouse and help to keep warm. But often the smoking cabinet works without additional cladding.

In the ceiling of the case, a chimney with a plug or damper is necessarily made, this will help regulate the process of filling the smokehouse chamber with smoke.

Results

It is not difficult to make a smoking cabinet with your own hands if you know the features of the process of smoking products. The most important thing in any chamber is the smooth adjustment of the smoke generation process. This is the only way to set the device to the desired operating mode.

Tell us about your experience building smokehouses. Which of them turned out to be the most successful? Leave your comments below, share the article on social networks and bookmark it.