Insulation of the floor with expanded polystyrene, often from the side of the living quarters or from the side of the basement. The latter option is suitable for houses on a conventional monolithic foundation with underground observations. If there is a spacious basement, and the foundation is piled, you should choose the second option. A detailed description of each technology and useful tips from experienced craftsmen can be found in the presented article.

The content of the article

- Recommendations for choosing a heater

- base insulation technology

- top insulation technology

Recommendations for choosing a heater

Before starting work, it is necessary to select the material and take into account several features. It should be understood that polystyrene foam is not suitable for floor insulation, because it is not strong enough. Therefore, you can choose only expanded polystyrene, which is resistant to shock and stress, as well as other advantages:

- does not absorb income;

- protects well from the cold;

- does not rot and does not grow moldy;

- not attractive to rodents;

- very light;

- easy to install.

You should not choose polystyrene foam for floor insulation in a wooden house, you should immediately go to the choice of polystyrene foam. conditionally use the brand PSB-S-35. A plate of this type is characterized by good thermal insulation (thermal conductivity coefficient 0.4 W / m2) and low moisture absorption (no more than 2%). If the load is large, rationally market-oriented PSB-S-50 (well suited for a garage, utility rooms).

Planning floor insulation along the logs with foam, you must also pay attention to several features:

- it is desirable to level the draft surface first, because in this case the thermal insulation will be uneven due to the uneven distribution of the material;

- be sure to use waterproofing to prevent burning of wooden logs;

- wood always emits a proportion of water vapor, so it is necessary to leave a small gap between the lags and the possibility - then the insulation of the floor with polystyrene foam in a wooden house will work correctly.

base insulation technology

Now you need to figure out how to insulate the floor with polystyrene foam in a wooden house. At home, they prepare the necessary tools and improvised means:

- actual heater;

- knife;

- level;

- roulette;

- vapor barrier;

- stapler for construction work;

- pencil.

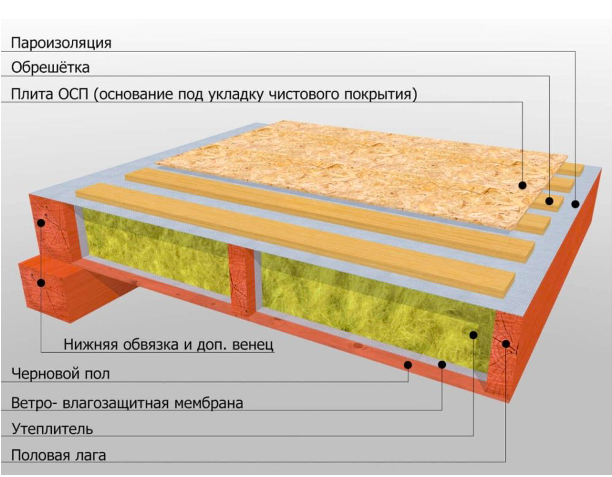

The very insulation of the floor with foam between the lags can be carried out according to different schemes, for example, superficially. This technology is suitable for houses that have a cellar or basement. Failures are also for buildings that have a foundation of a pile or pile-screw type. In this case, the insulation is placed in the space between the frame and the finished floor. Such work leads from the basement. The sequence of actions is as follows:

- Dismantling of the old flooring.

- Inspection of the lag, replacement of rotten parts - in whole or in part. Installing a new beam in their place, adjusting to size and fixing with galvanized corners or channels.

- In order to correctly coordinate the insulation of a wooden house with foam, you need to lay a vapor barrier. The sheets are overlapped by at least 10 cm and fixed with adhesive tape.

- Install the cranial bars with a section of 30 * 30 mm. They are attached to the sides of the log to create a support for the insulation.

- Then lay the material between the lags. It is pre-cut into fragments necessary for collection and collection. The insulation is fixed with mounting foam, for the same purpose you can put wooden slats. Such floor insulation with foam plastic makes it so that it is lower than the lag.

- The waterproofing is also overlapped and fixed with adhesive tape.

- The last stage is a fine finish, for example, from a board or moisture-resistant plywood.

top insulation technology

There are several internal ways to insulate the floor with foam, one of them is laying the material on top. This is a simpler method, because the laying touches the important side of the living space - you do not need to get into the basement. This technology is suitable for typical houses on a monolithic foundation or with a low subfloor.

However, despite all the advantages, the insulation of a wooden floor with polystyrene foam from above also has disadvantages. The main shortage is due to the fact that you have to spend part of the space, and therefore the overall high savings. It is also necessary to outweigh the doors, otherwise they will not be able to open. But in general, there is no doubt whether it is possible to insulate the floor with foam plastic from above. This is a proven technology, which consists of the following manufacturers:

- They dismantle the cleaning floor, inspect the lags and, if necessary, replace the rotten parts, as in the case of detection.

- A cranial beam is installed - the basis for the future black floor.

- Wooden boards or shields with a thickness of 30 mm or more are mounted on it.

- Insulation of floors in a wooden house with foam also involves the treatment of all boards and beams with an antiseptic composition.

- A waterproofing film is laid on the installed rough base with an overlap of at least 10 cm and fixed with adhesive tape.

- On top of it goes the insulation material itself, then the vapor barrier.

- Next, you need to install a counter-lattice to leave a gap for ventilation. This is a mandatory step, regardless of the choice, how to insulate the floor in a wooden house with foam.

Thus, the foam between the floor lags is not the best insulation. A highly reliable polystyrene foam with high chemical strength and resistance to moisture, temperature extremes and decay. You can mount it yourself by choosing the thickness of the surface of the upper or lower surface.