A planer is a tool that is in any carpentry workshop. It is used for planing wooden parts by moving forward and backward in a straight line with the application of a certain force. This results in a polished, smooth surface. The device device and its types are described in this material.

The content of the article

- Tool device

-

Main types and purpose

- For planing

- For planing

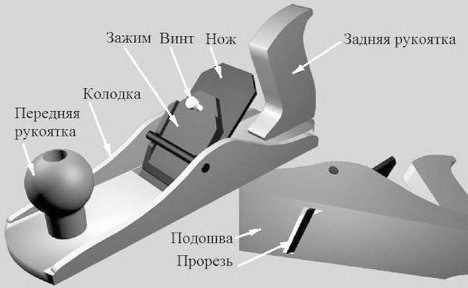

Tool device

It is not difficult to understand what a planer is. This is a tool based on a block made of metal (rarely wooden). The following elements are attached to it:

- Handles (go back and front) - used for comfortable work (the tool is tightly held by hands).

- The sole is the lower part, it is perfectly even, smooth, which allows you to slide on the surface to be treated.

- Slot - a special hole into which a knife blade is installed. The shavings also go through it.

- A knife is the main working element that cuts the surface layer of wood on blanks. It is always made of metal.

- The screw, as well as the clamp - devices for fixing the blade, guide the chip removal element. In new models, the blade is also fixed with a dovetail.

Main types and purpose

About what they do with a planer, you can say this. It is a machine for woodworking and planing. It rolls over the surface and makes it smooth or gives the desired roughness. It is also used to reduce the size of workpieces or form various recesses, such as "quarter" or "tongue".

Today, many models of tools are produced, their classification is diverse. For example, there are mechanical devices and electric planers for floors and other surfaces. The former are driven by hand, the latter by an electric motor.

The main classification is related to the purpose of the tools, that is, for what planing they are used:

- planar (creating a flat, smooth surface);

- figured (with relief, grooves of various shapes).

Within each category, there are several types of mechanisms - all of them are discussed below.

For planing

We can say about the planer that it is a tool for leveling the surface. To make it curly, for example, rounded, the following models help:

-

Zenzubel equipped with a blade that has 3 cutting edges. Used for planing a perpendicular plane, rebate, clearing a quarter. The design is arranged in such a way that it allows you to adjust different angles of inclination of the cutter.

-

Kantenhobel - if we talk about why a planer of this type is needed, then first of all its purpose is connected with the processing of edges and chamfers. This model has a double blade, has the shape of a trapezoid.

-

sheet pile - this type of planer device is characterized by the presence of 2 pads connected together with screws. By loosening or strengthening them, you can adjust the location of the cutter of the wood part to be processed. Thanks to this, even longitudinal grooves can be obtained.

-

Federgubel - with its help they make fine figured processing. The device resembles a tongue and groove - it is also equipped with two pads, and they are connected in a movable way. But the cutting element in this case is represented by 2 parallel blades, with the help of which a longitudinal spike is obtained. That's what this type of planer is used for.

-

Mold - This is a tool with which you can get a multi-level base with steps. Such a tool helps in finishing the cornice, making slopes for doors, plinth or baguette.

-

Falzgebel - used for cleaning this type of part, such as a quarter. Also, the device can be used to make a strip along the edges, and in this case the carpenter does not put a preliminary marking. If we talk about why we need a planer for wood of this type, the main purpose is curly processing in a final version.

-

Shtap - such a tool is used to work with convex and, conversely, concave workpieces. The shape is semicircular, blades of a special type. It has a semi-circular sole and specially shaped blades. Therefore, using the tool, you can also round the ends, pre-setting the desired diameter.

For planing

The main purpose of the planer, for which the tool is used, is associated with planing, that is, obtaining a sufficiently smooth surface of a wood part. This class is represented by the following tools:

-

single planer, the purpose of which is associated with the rough processing of wooden blanks. The result is beautiful chips of the same size, long enough. Moreover, the part needs further processing, since defects in the form of chips remain on it.

-

double planer joiners are also involved in rough work. But in this case, the cutter is straight, the device is equipped with a chipbreaker. Therefore, the surface is relatively smooth.

-

Sherhebel - This type of manual planer device helps to create the desired shape for the workpiece. In appearance it looks like a single planer. Moreover, it is distinguished by the presence of a blade, which has rounded edges. They are directed at 45o to the straight sole. Thanks to this, it is possible to work with such a tool both along the fibers and across.

-

sander - a small planer, the use of which is associated with finishing the part cleanly. Equipped with a cutter and chipbreaker, so the surface is clean and smooth.

-

Jointer - another tool for finishing cleanly. Used at the last stage of work. If you look at the device, it is clear what this type of planer is intended for. It is equipped with an elongated sole and 2 blades. Therefore, the treated surface is almost perfectly smooth.

- Tsinubel - a tool used for cleaning. The device of a wooden planer of this type is as follows: it has a grooved blade, it goes at a large angle to the surface (80 degrees). Therefore, after processing, it turns out rough. This is useful for applying varnish - the area of \u200b\u200bcontact increases.

Now it’s clear what a planer is, the photo of which is presented in the article. This is a common tool that is present in any workshop. It allows you to get a smooth, even or figured surface. At home, manual appliances are usually used, and for professional purposes, electric ones. With their help, you can perform a large amount of work in a short time.