Fokin's flat cutter can be called a unique device: it simultaneously performs the functions of a shovel, a rake, a hoe, and a scythe. They alone can carry out most garden work. Its main advantage and, in fact, its purpose is a blade that plunges to a depth of 2-5 cm, which can cut or pull out weeds.

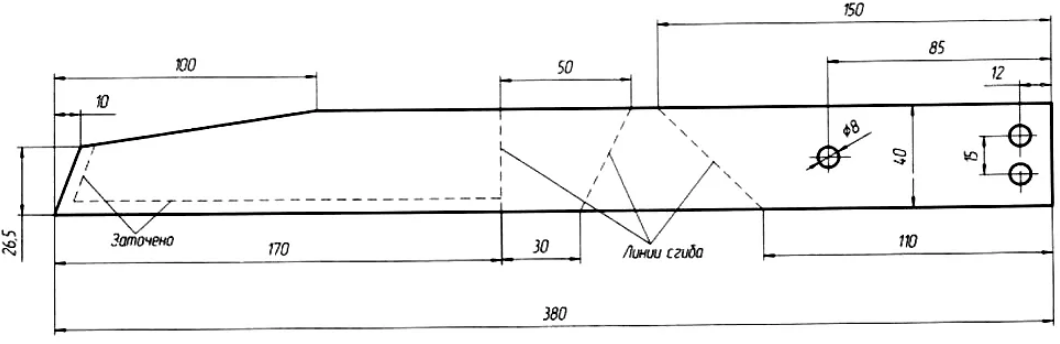

You can make this tool with your own hands. First you need to pick up the material, prepare everything you need for work. Then, based on the drawing, make a homemade product.

The content of the article

- What is a plane cutter made of?

-

Homemade Fokina flat cutter: instruction and drawing

- We make a workpiece

- Making a cutting

What is a plane cutter made of?

The material must be selected for the working part (metal) and the handle (wood):

- You need a strip with a width of 4–4.5 cm and a length of up to 40 cm. The material must have excellent wear resistance. It is better not to take simple iron: it will quickly become dull, it will bend. Either a steel corner that needs to be cut along, or a “passenger car” spring 5–7 mm thick will do. The best choice is high-alloy steel, because this material is the “record holder” in terms of durability, wear and corrosion resistance.

- For the handle, you can take pine. It is the most affordable, differs in budgetary cost, is easy to process, but the minus is short-lived, breaks quickly, becomes covered with cracks. A good choice is birch. Its advantages are durable, affordable. The quality is higher than the previous breed, the wood is easy to work with, but it requires longer sanding. Birch can be called the best choice. Ash is too expensive, although its performance is excellent.

Homemade Fokina flat cutter: instruction and drawing

In the manufacture of a universal tool, it is necessary to adhere to the scheme and sequence of stages as much as possible. This will ensure that the characteristics and ergonomics do not differ from the original.

@istoki-m.com.ua

You should prepare:

- electric drill;

- angle grinder;

- hammer;

- blowtorch;

- vise;

- grinder and bar.

To harden and process a future product in order to protect against corrosion, machine oil is needed. You will also need pliers and two keys - 10 * 12, sandpaper, fasteners. To process the cutting, you will need a planer.

We make a workpiece

High-alloy steel, which is recommended to be used, is characterized by properties such as hardness and brittleness. Before working with it further, it is necessary to “let go” of the material. What is this process?

Should:

- Heat the base with a blowtorch. This is done evenly, along the entire length until a burgundy color appears. It is important to prevent the appearance of an orange tint - this is already overheating.

- Leave the workpiece to cool. It is better that such processing be carried out in the summer or in a warm room - so the cooling will be uniform.

- After complete cooling, you can start manufacturing - cut off the required length with a grinder, place marks, referring to the drawing, where the holes will be drilled, where you will need to bend.

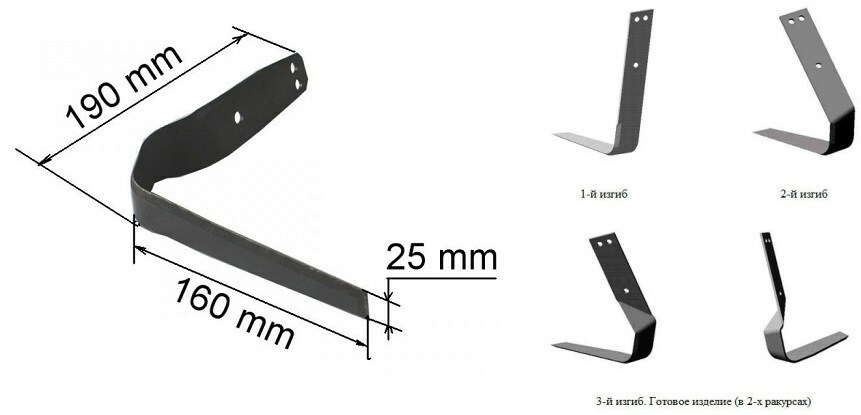

Now it's the turn of the deformation. This stage is very important, because the base must be of the required shape and with the required corner sizes. To carry out such a manipulation, it should be fixed with a vice, then with a hammer and bend the metal according to the marks. To facilitate the process, you can heat the fold lines - this is done with a blowtorch. Bend angles in degrees:

- the first - 95–105;

- the second - 110-130;

- the third should be similar to the previous one;

- the latter is adjusted to the cutting.

@videohandmade.ru

The sequence of the deformation process cannot be violated: then the fourth fold will not work.

At the end it remains:

- Create the final shape in exact accordance with the dimensions indicated on the drawing. For this, a grinding machine and angle grinder are used.

- Sharpen. This is carried out on the machine, and additionally trimmed with a manual grinder. Both edges should be sharp. Proper sharpening affects the further efficiency of use.

@master-azov.ru

- Harden. If you neglect this step, the tool will dull faster.

The hardening process looks like this:

- oil is poured into the container - so much so that the entire base is immersed in it;

- a blowtorch is uniformly heated to a burgundy color;

- then quickly (for 2-3 seconds) the workpiece is immersed in oil, removed and after 5 seconds. plunges again (it is necessary to repeat these manipulations until the liquid stops boiling at the moment of contact);

- the working part is hung up to cool down.

The base should turn black (anti-corrosion protection). After such processing, the metal becomes more durable.

Making a cutting

First of all, you need to choose the type of wood and decide on the blank for the handle - it should look like a rail in the shape of a rectangle - 4.5 cm wide, 2 cm thick.

wooden part Fokine instrument differs from other devices for working on the site - shovels, choppers. Due to its rectangular shape, it does not slip or rotate in the palm of your hand. It is more convenient to work with the device, and there will be no corns.

You need to start by giving it a characteristic shape:

- The planer is adjusted so that a thin layer is removed. After that, they process the edges along the entire length - with the exception of a part of 15–20 cm from the bottom.

- The surface of the cutting is treated with sandpaper.

- At 15 cm from the bottom in the center, two lines are drawn parallel to each other with a step between them of 5 mm.

- The working part is applied to the bottom of the handle. It is necessary to combine the holes made on the working part with the applied markings. Next, mark one of the holes on the last one.

- A hole is drilled - for this, a block of wood is placed under the drill - and a bolt and nut are prepared.

- The working part is attached - it is necessary that some of the holes remaining on it align with the drawn line. For fixing it is better to take large iron washers. When they are located between the bolt and the handle, it will be possible to tighten the fasteners more tightly, to protect the wood from destruction.

- We drill the handle through a hole located in the metal (working) part.

- Insert and tighten another fastener.

All - plane cutter made and can be used.

@master-azov.ru

The handle of the assembled tool, if placed vertically, should be 20 cm below the shoulder. It turns out that the size of the handle is individual.