If the blender does not work, it is quite possible to repair it yourself. For example, the motor may break down, the winding or the fuse may burn out. Therefore, it is necessary to understand how to disassemble the lid from the blender, as well as find and fix the problem. Instructions and useful tips can be found in this article.

The content of the article

- How to remove the cover

- If the speed switch is broken

- If the engine is not running

How to remove the cover

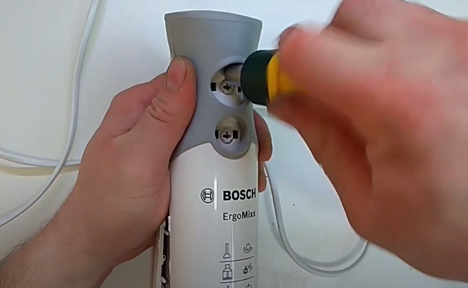

Repairing a Bosch blender begins with removing the cover, since it is under it that all the main parts are located. The step by step instructions are:

- Remove the plastic cap.

- Loosen both screws with a screwdriver.

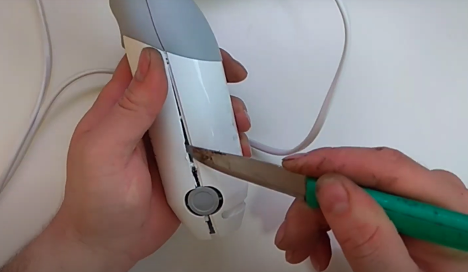

- Insert a knife or screwdriver and gently push both parts of the case apart.

- Push the reverse side in the same way. As a rule, plastic parts hold well, so you need to apply quite a lot of effort.

- Pry off the power button and remove it to disassemble the blender.

- Loosen the screws with a screwdriver.

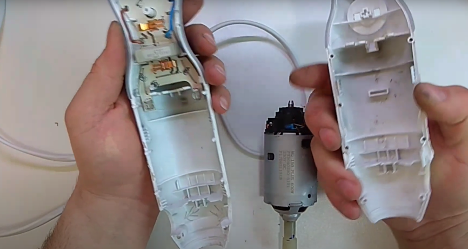

- Disassemble both parts - it should turn out like this.

If the speed switch is broken

Removing the cover will be necessary in some cases, for example, if the speed controller is faulty. Then you must first understand how to disassemble the blender chopper, and then act like this:

- Remove the board - as a rule, it is green.

- Disconnect wires from it.

- Turn on the soldering iron and unsolder the board.

- Then "ring" and make sure that all contacts are intact.

- If individual contacts are not working, you can repair them yourself or contact a service center.

If the engine is not running

Bosch blender repair will also be needed in cases where the engine has broken down. In this case, the tool simply will not work or rotate at a very low speed. To diagnose a problem, you need to not only inspect, but also listen to how the device functions. The instruction is this:

- If, when turned on, the blender buzzes quietly, but the knife does not rotate at all, you need to disassemble the tool, as shown above.

- Next, remove the bowl and take a pencil or other long object. Use it to press the lock button.

- If the knife still does not rotate, the cause of the breakdown is most likely related to the engine. Perhaps the winding burned out. The part needs to be completely changed or a new blender purchased.

- If the engine is working, check the power cord - perhaps the contacts have come off. They disassemble the case and “ring” with a multimeter.

- It is also recommended to make sure that there is a fuse under the case and that it has not burned out. If recently there was a drop in electricity in the network, the reason is probably connected with it.

- Finally, if all the methods did not work, you can simply check the outlet - most likely, it is faulty.

- Then it remains only to understand how to assemble a Bosch blender. In fact, you need to do the same steps, but in reverse order.

Thus, at home it is easy to figure out how to fix an immersion blender. Of the tools you need only flat screwdrivers, a soldering iron, and a knife. The main difficulty can be associated with detaching the two halves of the housing from each other. To do this, you need to make an effort, and also use a knife to insert it into the seam and swing the parts.