The problem of how to degrease the surface may not seem too difficult. Many people periodically use solvents or special liquids to prepare surfaces, often without even thinking about how correctly degreasing is performed at home conditions. But even in this case there are nuances.

The content of the article:

- What is the importance of degreasing surfaces

-

Degreasers you can buy at the store

- Nephras

- White Spirit

- antisilicone

- Antistatic

- Alkaline products

- Ethanol

- Gasoline and acetone

-

What other methods can be used to degrease the surface?

- Sandblasters

- Application of ultrasound

- Electrochemical cleaning

-

Features of degreasing depending on the type of surface

- Hardware

- Wooden crafts

- glass products

- Leather furniture

- Plastic products

-

Features of degreasing depending on the type of future work

- Degreasing before painting

- Degreasing before gluing

- Results

What is the importance of degreasing surfaces

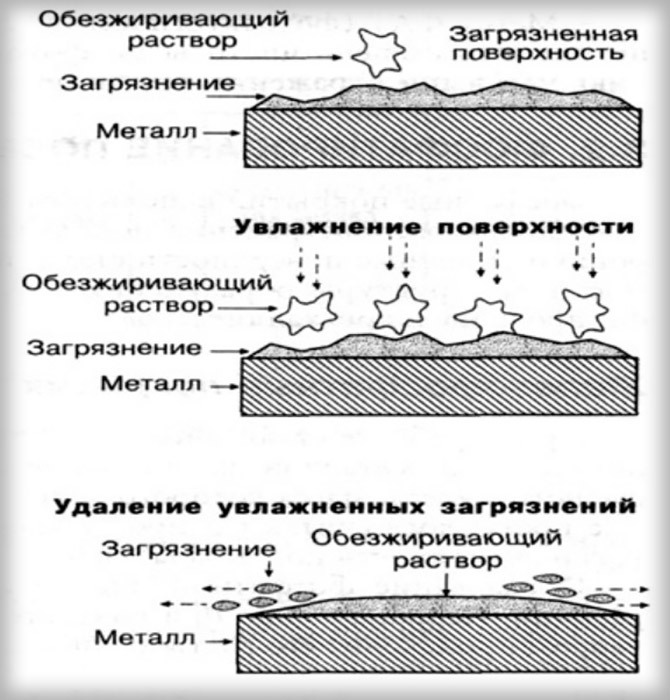

All modern coatings, varnishes, paints, fillers, as well as adhesive compositions were developed for application on a clean, dry, and most importantly, fat-free surface. The problem is that on any surface there is a thin microlayer consisting of:

- dust particles;

- condensed moisture absorbed into the dust;

- organic microfilms;

- microscopic air bubbles that are always present under any films.

All this stuffs and "sits" in microroughnesses (pores) on the surface. And it does not matter what material it is and where it was stored. All this microscopic dirt, especially air and moisture, prevents strong adhesion of varnish, paint, glue to the base. Therefore, the material must first be degreased (remove a film of dirt).

What happens if you properly degrease the surface:

- electrostatic charge is compensated, so dust does not temporarily stick;

- dissolves and mechanically erases most of the organic matter.

Depending on how to degrease the surface and what solvent to use at home, up to 80% of contaminants can be removed. If you use several types of solvents or a special agent for degreasing the surface, you can remove up to 90% of deposits. This is enough for the surface before painting.

The level of degreasing before gluing should be higher than before painting. In addition, before degreasing the surface, the top layer is often subjected to mechanical cleaning. But this requirement applies only to metal and plastic surfaces.

For some materials, the level of removal of contaminants does not exceed 60-70%, these are leather products, wood, highly porous materials. Often the top layer cannot be degreased, as the usual solvent "clogs" (contaminates) the surface. In this case, the composition of the paint (glue) includes a substance that degreases the top layer.

Degreasers you can buy at the store

Most of the substances with which you can degrease the surface at home are volatile and quickly evaporating liquids. Almost all toxic or aggressive, except for ethyl alcohol. Therefore, before degreasing the surface, it is recommended to wear gloves, and to carry out the treatment itself on the street or under the hood.

Nephras

Known as thinner gasoline or Galosha. The safest of all products that can be used to degrease an oily surface. It looks like a white or slightly yellowish oily liquid. It consists of naphthene-paraffin and olefin oil fractions, purified from toxic aromatic compounds. Hazard class "4", this is approximately the level of ethyl alcohol.

It is considered the best tool if you need to degrease any parts of cars, components and mechanisms in contact with oils, greases, resins. You can degrease metal surfaces before applying oil paints.

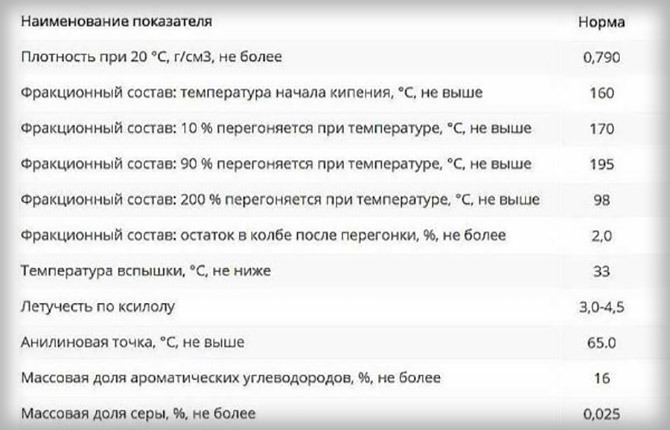

White Spirit

It is made from oil refining products with obligatory clarification or bleaching with bentonite clays. Therefore, in the name there is the word "white", which means "white" in translation. By its properties, it resembles high-quality bleached kerosene - a naphtha mixture.

White spirit is recommended to degrease surfaces for painting with compositions and applying putties on an oil-fat basis. The liquid is used as a thinner for a wide range of paints, melamine, alkyd pentaphthalic enamels. But they are all for outdoor use.

You can degrease on an already painted metal surface, but only in dark shades, and immediately wash off the traces with soapy water. You can remove traces of resin or degrease plastic (except for polystyrene), for example, stains from the adhesive base of adhesive tape.

Disadvantages of white spirit;

- High content of aromatic compounds according to GOST 313178 - up to 16%. This is more than modern unleaded motor gasoline. Therefore, you need to work only with gloves and only in a draft or under a hood.

- High content of sulfur and naphthenic acids. Degreasing metal, such as a cleaned car body, is not recommended to avoid corrosion.

- Unpleasant smell, vapors are deeply eaten into fabrics, insulation, wood. The smell can be removed only by prolonged drying in direct sunlight for 7-8 hours.

It is best to degrease wooden and metal structures, frames, frames with white spirit before painting with pentaphthalic paints.

antisilicone

One of the best universal products for degreasing and surface preparation before painting. The composition of the anti-silicone includes naphthenic hydrocarbons (30-35%), naphtha clarified fraction of oil (up to 35%), isopropyl alcohol. In fact, it is a highly refined gasoline with a low octane rating.

According to the hazard class, antisilicone belongs to level 4. The content of aromatics is 10 times less, and sulfur is 25 times less than in white spirit. This does not mean that you can degrease the surface with your bare hands and work without a hood. Vapors of gasoline can provoke suffocation, and ligroin, if it gets on the skin of the hands, causes irritation.

Anti-silicone is recommended to degrease the body and elements of the chassis of cars, water pipes, steel structures before painting. Professional grade anti-silicons do not use water, so if properly degreased, it will not cause blistering or hidden corrosion under the paintwork.

Antistatic

Available in an aerosol can, recommended for degreasing painted or plastic surfaces to remove dust. Antistatic can effectively degrease the car body to avoid sticking of the smallest microdust particles. Otherwise, the gloss will not work. Especially if the staining is done in a handicraft or semi-handicraft way using nitro paint.

Alkaline products

An aqueous solution of alkali can only degrease metal surfaces. Alkaline compositions etch the surface film, decompose any fats and oils (except silicone ones). After processing, the metal looks like new, clean, without traces of oxides and fatty films.

The process is fast enough, so fat-free areas due to the volatility of alkali should be quickly washed with distilled water.

It is necessary to work with alkaline agents very carefully, since the material is very aggressive, contact with the skin leads to severe chemical burns.

Ethanol

It is used to remove grease and oil films from the surface of metal, glass, plastic, wood and even leather. Due to the very low surface tension, it penetrates deeply into the microrelief of the surface, moistens, washes away dust and traces of water. Evaporates quickly, carrying away moisture and dust.

Alcohol, as a polar solvent, has one disadvantage. It perfectly washes and degreases water-containing dirt and esters. That is, traces of vegetable oil and alcohol will degrease, and machine lubricants (oils) based on hydrocarbons - only partially. Complete degreasing does not occur.

Even alcohol mixed with acetone can effectively process wooden parts. After such treatment, it is possible to carry out treatment with a primer or varnish if bituminous tiles or glass roofing material are glued to the tree.

A mixture of alcohol and hydrogen peroxide degreases and discolors furniture veneer before applying furniture varnish. Wood dust, resin and volatile compounds are well removed from the wood, due to which stains may appear under the varnish.

Gasoline and acetone

If gasoline or any of its "relatives", for example, Galosha or Nefras, are freely sold, then acetone can only be bought in small quantities. For example, as a nail polish remover. This is highly diluted acetone; only a limited list of contaminants can be degreased with such a liquid.

Acetone is a very strong polar solvent, an order of magnitude stronger than ethyl alcohol. Can they degrease metal and wood? Of course, acetone is able to clean almost any surface, except for porous ones. But the solvent consumption for the removal of mineral oils and lubricants increases several times when compared with the same white spirit.

Therefore, it is better to treat heavily contaminated surfaces with a mixture of acetone and gasoline or use a ready-made solvent such as P-10.

What other methods can be used to degrease the surface?

To improve the quality of gluing or staining, additional types of processing are used:

- thermal - roasting;

- mechanical - cleaning or removal of the surface layer;

- chemical - dissolution of durable varnish films.

Heat treatment is used only for metal and wooden surfaces. Usually, the top layer is briefly heated with a gas burner until moisture and fatty films evaporate. At the same time, dust is burned out by a hot flame.

Sandblasters

They are used only for cleaning ceramic and metal parts. Degreasing takes place in a powerful, high-speed stream of air and sand. A jet of abrasive simply erases everything from the surface: from scale and rust to oil, varnish films and old paint.

At the same time, the microroughness of the metal changes, it becomes more uniform. The surface can be painted immediately after removing the dust.

Application of ultrasound

Ultrasonic degreasing or washing is used as an alternative to solvents. Most of them are made on the basis of xylene, toluene, cyclohexanol, butanol, substances are extremely toxic and carcinogenic.

It is easier to degrease a metal part by placing it in water with a small addition of surfactant. Ultrasonic waves cause water to boil on the metal, cleaning it of any organic matter even more effectively than a solvent.

The only limitation is the size and weight of the part; only small items can be effectively degreased.

Electrochemical cleaning

It is used for accurate and effective degreasing, removal of oxide films, removal of fatty layers. As a rule, parts and products made of precious metals are subjected to electrochemical double-sided cleaning.

After immersion in a cleaning solution, a constant voltage is applied to the part, the metal does not dissolve, and oxygen or chlorine released at the anode dissolves all impurities. Atomic oxygen easily oxidizes (burns) even chemically resistant silicones.

Today it is the most highly effective way to safely degrease metal without sacrificing appearance.

Features of degreasing depending on the type of surface

The effectiveness of the preparation largely depends on the surface material. Some of them, such as leather or plastic, allow only limited degreasing, and only with special means.

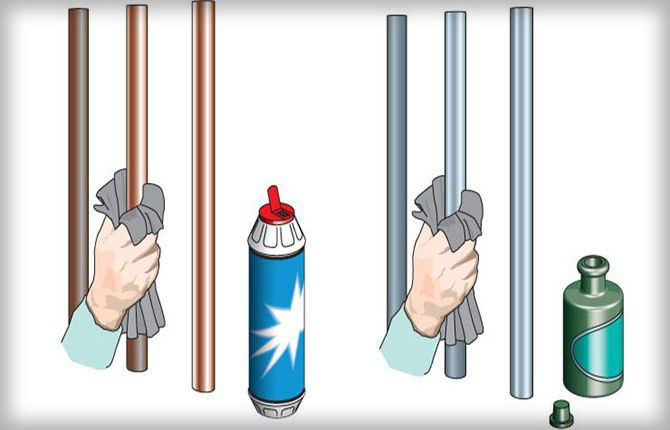

Hardware

For all metals (except noble), before degreasing the top layer, it is recommended to carry out mechanical cleaning with sandpaper or any other type of abrasive. Thus, it is possible to remove the main part - oxides, and also to increase the depth of the microrelief.

After washing with clean water from abrasive dust and treatment with an acetone-gasoline (alcohol) mixture, the adhesion strength to the paint (adhesive layer) increases by 12-20%.

Wooden crafts

Wood is a conservative material, it is difficult to degrease it, as it contains a large amount of organic substances. If preparation is necessary before painting with oil paint, then turpentine, only purified, is considered the best remedy.

If a bleaching effect is required, after turpentine, the tree is treated with pure alcohol, then with the usual "Whiteness".

If there is a supply of alcohol and acetone, then the tree can be degreased quite deeply. To do this, a napkin moistened with an alcohol-acetone mixture is applied to the surface and placed in a bag. After a day, the product is taken out of the package and wiped with pure alcohol. To such a surface, the varnish "clings" without any priming.

For your information! To remove old varnish and oil films from old wood, restorers use a complex set of reagents. For example, you can degrease and clean the surface of old fatty deposits with vinegar, ammonia. Also, the old tree is degreased with dichloroethane.

If a very gentle degreasing is required, for example for wood painting before re-varnishing, then ethyl cellosolve or methyl cellosolve is best.

glass products

Can be degreased with regular isopropyl alcohol. If there are traces of polyurethane foam or adhesive tape on the glass, dimexide or chlorinated hydrocarbons, such as methyl chloride or dichloroethane, can be used.

Glass can be degreased with any polar solvent, alkali, acetic acid, but pure hydrocarbons cannot be used. They always leave stains.

It is possible to degrease glass qualitatively if white spirit is consistently used, then ammonia.

Leather furniture

A thin fatty coating on the skin can be removed with acetic acid, but not with essence, but with ordinary food. After treatment, the surface must be rinsed with distilled water.

If the leather product needs to be degreased quite thoroughly, it is best to use pure isopropanol. Ordinary ethyl alcohol, even when diluted with water, tans the skin, leaches plasticizers and fats from its structure. Therefore, the surface after alcohol treatment may crack.

You can not degrease the skin with powder and detergents. Baking soda and dishwashing detergent act as an abrasive. Even if you rub lightly, the powder removes the top layer of collagen, and the surface brightens. Spots are obtained, which can be removed only by a complete repainting of the leather product.

Plastic products

Each type of polymer has its own type of solvent, it is better to find out in advance that you do not inadvertently dissolve the plastic during degreasing:

- PVC - can be degreased with alcohol, but not with acetone or any chlorinated hydrocarbon.

- ABS plastics can be treated with P646 solvent, isopropyl alcohol. Do not use solvents containing naphthenes, cyclohexanol, benzene, toluene.

- Polyurethane - everyone can degrease the surface, except dimexide, dichloroethane or white spirit.

- Expanded polystyrene, polystyrene - you can degrease with ethyl or isopropyl alcohol.

If it is not known what plastic the part is made of, then it is better to use ready-made products for degreasing, such as Piton, in extreme cases, APP WK900.

Features of degreasing depending on the type of future work

On any surface, in addition to dust, water, fatty films, there are two more layers that can affect the quality of bonding or staining.

- The first is a layer of oxidized or degraded base material.

- The second is chemical pollution. For example, the remains of an old primer, dye, varnish base, or just a chemical that accidentally got on the surface and soaked into it.

Both layers must be removed, preferably during or before the degreasing process.

Degreasing before painting

If the new paint layer is sufficiently transparent, does not hide the base, then before painting it is necessary to etch or neutralize the pollution, and on the entire surface. Organics, as a rule, are decolorized with hydrogen peroxide or "Whiteness", washed and degreased already with isopropanol or acetone.

For opaque paints, the contaminated area of the surface can be etched locally. The main thing is that after processing and degreasing the texture of the top layer does not change, otherwise, after applying the paint, the surface will be spotty, with gloss and a satin sheen. Most often, a change in texture occurs due to the excessive use of white spirit.

Degreasing before gluing

In this case, degreasing is necessary to increase the adhesion of the adhesive film to the base. In preparation for gluing, it is very important to remove the top oxidized layer of the material.

Oxidized plastic, wood, metal, leather have low strength. In addition, for many plastics, the top layer degrades and turns into powder (dust) under the influence of solar ultraviolet radiation. Therefore, degreasing before gluing is mandatory.

Therefore, before degreasing the material, it must be cleaned mechanically or electrochemically. It is enough to remove with a cutter, sandpaper or a file a layer only 0.1 mm thick.

A fresh layer can be degreased to a minimum, just apply a thin layer of glue, wait, let it dry and remove it with a scraper. After 10 minutes, apply the main layer of glue, connect the parts and leave under load.

Results

Choosing how to degrease the surface before painting or gluing is not as easy as it might seem at first glance. The situation is especially difficult with plastics and polymers. It takes a long time to figure out what can be degreased, and which solvent cannot be used.

Tell us about your experience in selecting products for degreasing various surfaces. Which, in your opinion, can be used without the risk of damaging the product? Also share the article on social networks and bookmark it.