Noise insulation of the partition can be performed both with the construction of the frame, and without preparatory work. The second option is simpler, but not as effective, and besides, it is only suitable for flat walls. If the surface has tangible defects, a frame of metal profiles is first installed and only then sound insulation is laid, and at the last stage, finishing is performed. Step by step instructions for each method are provided in this article.

The content of the article

- Frameless technology

- Frame technology

Frameless technology

Noise-insulating partitions can be installed without pre-installation of the frame, which is very convenient both in terms of work and budget. But it is possible to implement such a technology only if the walls are even, for example, after repair or in a new building.

Moreover, the sound insulation of interior partitions without a frame allows you to get rid of only airborne noise. This is the name of sounds that propagate through the air, i.e. crying baby, loud conversation, music. If there are vibrations in the building structures, the soundproofing of partitions requires the installation of a frame, and protection will be required not only for the walls, but also for the floor and ceiling.

For work you will need the following materials:

- panels of soundproofing material;

- damper cloth;

- special sealant (acoustic);

- ordinary building sealant;

- construction tape;

- special dowels (also acoustic).

Noise isolation of partitions without the construction of a frame goes quite quickly, the main stages are as follows:

- A little glue or a composition of ordinary sealant is applied to the surface of the wall.

- The panels are fixed to the wall, fixed to the damper layer and the acoustic dowels are twisted. Holes are pre-drilled under them.

- In order for the soundproofing of interior partitions to be effective, the hats should be drowned and isolated from contact with the lining material (drywall). This can be done using acoustic sealant.

- The soundproof partition is in contact with the adjacent fragment, so a small seam is formed. So that it does not let in noise, it is also necessary to fill it with acoustic sealant using a mounting gun. Moreover, it is desirable to do this at least a day after the end of the installation work. Construction tape is fixed over the joints.

Frame technology

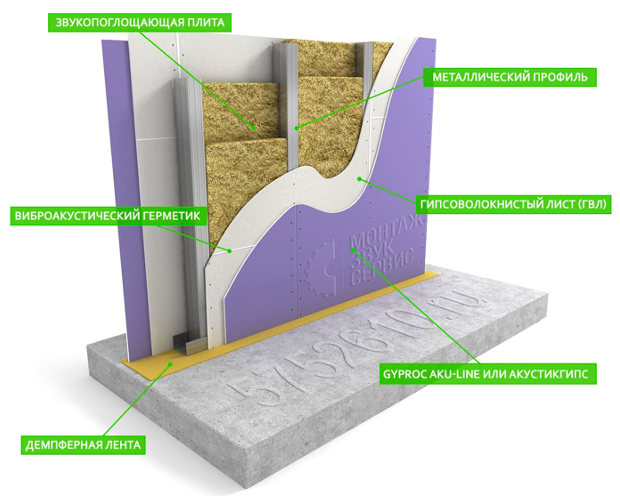

Noise isolation of interior walls is more effective if frame technology is used. It allows you to protect yourself not only from airborne noise, but also from shock. For example, if someone touches the wall, turns on the music, the vibration of which interferes, these sounds can be significantly weakened.

In addition, the frame is placed for other reasons. If the walls are uneven, old, you will have to build a structure, because otherwise the fragments of the canvas will lie unevenly. For work you will need the following materials:

- acoustic sealant;

- damper cloth;

- construction tape;

- acoustic dowels;

- profiles (guides, ceiling);

- soundproof partitions in the apartment (cloth for soundproofing);

- vibration decoupling washers 10*19;

- construction sealant;

- fasteners;

- vibration damping tape.

To install soundproof partitions, proceed as follows:

- Take measurements and stick a damper tape on the metal profile. On the surface of the floor and ceiling along the wall, metal profiles of the guide type are attached.

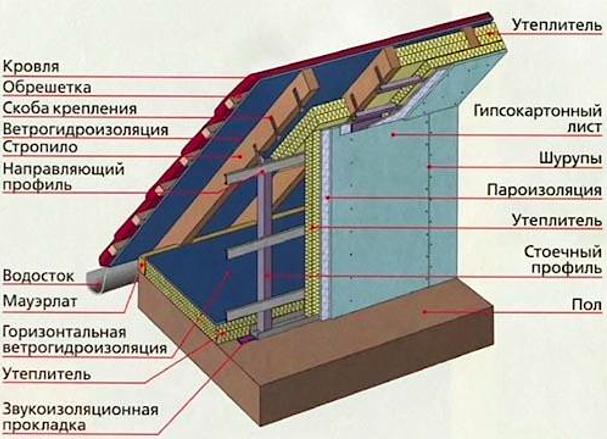

- In order for the soundproof partitions in the apartment to work as efficiently as possible, vibration decoupling washers should also be installed every 6 s. They are mounted at the attachment points of the rails, reinforcing the structure, as shown in the figure. Moreover, holes are drilled in the profile for dowels-nails with a diameter of 10 mm.

- The side walls of the guide profiles and the ends of the ceiling profiles are also glued with a damper tape.

- Profiles are also mounted on the ceiling, installing them at the same interval from 40 to 60 cm. They are fixed to the wall using a wall mount, observing a vertical interval of 60 cm. Further, the soundproofing of the internal walls is laid in the formed cavities of the frame.

- Now you need to take GM 3.5 * 30 self-tapping screws and sheathe the frame with panels for sound insulation, for example, with a quartz filler. Lay them in at least 2 rows. Moreover, the canvas of the second row should overlap the joints of the canvases of the previous row, like brickwork.

- The caps of the self-tapping screws are slightly recessed and isolated from the external environment, treated with an acoustic sealant.

- In order for partitions with sound insulation to reliably protect against extraneous sounds, it is important to process the seams as well. This can be done with both acoustic and conventional sealant. The joints are covered with construction tape.

- Now you can proceed to the finishing cladding, which is performed in 2 layers, and in both cases you can use the same material, for example, drywall. The sheets of the first row are fixed with GM 3.5 * 35 screws directly onto the profile of the metal frame and reinforced with sealant.

- The second row of sheets is fixed using conventional 5 * 45 universal self-tapping screws, and sealant is again used to reinforce. Moreover, it is important that during screwing the fastener does not fall into the frame itself.

The construction of the frame will cost more in price, although the result is better. Thus, you can choose the appropriate method yourself. If the noise is not very large, there is no vibration, and the walls are even, it is easier to implement frameless technology. But for greater efficiency, it is recommended to first make a metal frame, and only then proceed to soundproofing.