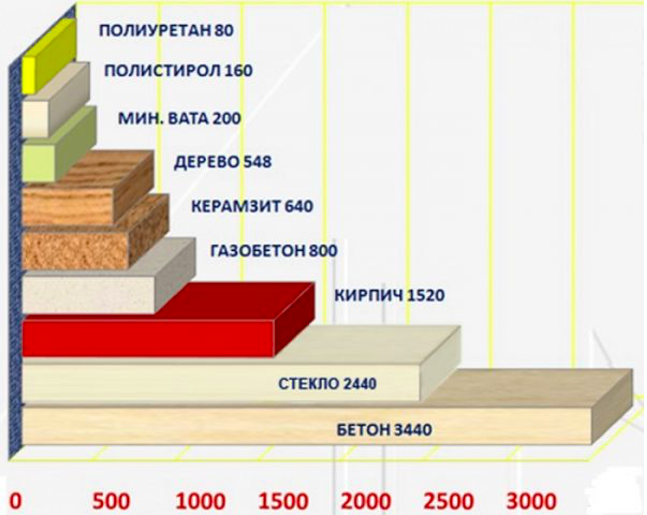

Attic insulation with polyurethane foam (PPU) has great advantages, since it is one of the best materials in terms of protection against cold and noise. Even a small layer of 80 mm replaces 160 mm of polystyrene, 200 mm of mineral wool and more than 500 mm of wood. However, it should be taken into account that the mixture is obtained and poured using special equipment. How to do this at home is described in detail in the presented article.

The content of the article

- Pros and cons of polyurethane foam

- Preparation before warming

- Step-by-step instruction

Pros and cons of polyurethane foam

When planning the insulation of the PPU roof, one should evaluate the advantages, disadvantages and features of the material. This is a polymeric organic plastic that contains small pores with air bubbles that provide protection not only from the cold, but also from noise.

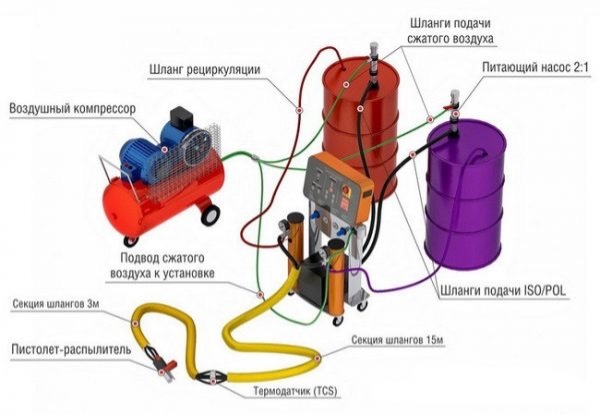

A characteristic feature - polyurethane foam for roof insulation is made directly during installation. To do this, the components are mixed with water in equal amounts and fed to the place of work through a hose using a special compressor. Thus, without the use of equipment, work will not work.

At the same time, attic insulation with foam provides a lot of tangible advantages:

- low thermal conductivity provides maximum thermal insulation, even better than polystyrene, mineral wool and wood;

- the composition does not absorb moisture and, as a result, does not rot, does not become moldy;

- the insulation of the ceiling with polyurethane foam is especially well performed - the material is loose, it is required in small quantities, therefore it creates a minimum load on the structure;

- high class of fire safety - G-2;

- you can create a layer of any thickness with an accuracy of several millimeters;

- insulation of the roof from the inside with polyurethane foam provides protection not only from the cold, but also from noise;

- no need to use hydro or vapor barrier;

- long service life - from 30 years.

However, there are also disadvantages. As already mentioned, it will not work to prepare the mixture on your own, since this requires a compressor station. In addition, it is worth considering that polyurethane foam is not resistant to sunlight. However, this is not a problem since the material is covered with a finish that provides complete blackout.

Preparation before warming

In order to qualitatively perform attic insulation with polyurethane foam, it is necessary to prepare the surface and the room. First, all items are removed, windows are covered with polyethylene film along with window sills and slopes. The fact is that PPU drops adhere very strongly to the surface, and even if you immediately start stripping, it will be quite difficult to remove them.

The previous coating, including old paint, is removed. If the roof is old, the logs should be partially replaced and all elements should be treated with an antiseptic. When the roof insulation with polyurethane is over, and the material hardens, access to them will already be closed. At the last stage, debris and dust are removed to work with a clean surface.

Before installation, prepare equipment and materials:

- hoses;

- containers;

- compressor station;

- hoses;

- mask;

- gloves.

Step-by-step instruction

Insulation of the attic from the inside with polyurethane foam is carried out in several stages:

- After preparing the surface, you will need to install logs (if not). They will not only strengthen the structure, but also perform alignment when filling the mixture.

- PPU attic insulation is carried out using a compressor station, which must be raised and assembled directly on the roof.

- Knead the mixture according to the instructions, observing the ratio of components with water 1: 1.

- The first layer is sprayed, the thickness of which is 15 cm.

- Roof insulation with polyurethane foam spraying is carried out in several stages. Moreover, each subsequent layer is applied only after the previous one has completely dried.

- When the last layer dries, you can install the interior trim. It is laid on the lags or a crate is pre-installed.

It is important to understand that in order to foam the roof with polyurethane foam, you need not only special equipment, but also some experience. It is especially important to observe proportions and control the color - if it darkens, this indicates a violation of the ratio. You can work in the warm season - the minimum temperature should be + 10 ° C.

When it is planned to insulate the attic with polyurethane, it is necessary to calculate the thickness of the layer in advance. For example, for the regions of the middle lane, a minimum of 150 mm is required, while for Siberia - from 250 mm. During operation, you must immediately lay a layer of the required thickness, because it will be too late to return even after a few minutes - the composition dries out rather quickly.