More recently, the chimney was mainly made of bricks, sometimes with asbestos-cement or cast-iron inserts. Chimney channels can be welded from sheet steel. But practical experience shows that a stainless steel chimney is the best solution.

It will cost more than asbestos-cement channels, but it is much easier to assemble an alloy steel pipe than a brick version. At the same time, with the correct installation of stainless steel chimneys, the service life is quite large, it is limited only by the quality, thickness of the metal and the reliability of fastening.

The content of the article:

-

Kinds

- single circuit

- Dimensions and material of single-circuit chimneys

- Sandwich pipes

-

How to make a stainless steel chimney

- Installation rules

- Stainless steel chimney design

- Assembly instructions

-

Features of installing stainless steel chimneys for solid fuel furnaces

- Problems of a stainless steel chimney for a solid fuel boiler

-

Rolled stainless steel chimney

- Chimney pipe for potbelly stove

-

What stainless steel to choose for the chimney

- Option for a garage or country house

- Material for the fireplace and boiler in the house

- fire department requirements

- Results

Kinds

All steel chimneys are made modular or stacked, that is, a chimney of the required length and configuration can be assembled from separate sections (modules) of a standard size. Often stainless steel is installed inside a channel made of heat-resistant ceramics, bricks, blocks made of mineral wool, if the chimney channel is made inside a wooden building.

From the point of view of the working conditions of the chimney, a modular system is not very good, since each an additional joint is the risk of leakage of hot gases or air leakage, which reduces thrust in chimney channel.

For the arrangement of the chimney, two types of stainless steel sections are used:

- single-layer or more often they are called single-circuit;

- sandwich pipes or double-circuit sections.

In addition to straight-line modules, to assemble a stainless steel chimney, you will need a significant number of transition sections, elbows with a flow turn of 30-90O, tees, adapters from a larger diameter to a smaller one, couplers, clamps and, of course, a node for passing a roof or ceiling.

Often, another option is considered single-circuit types - soft corrugation from a thin profiled sheet. But this is more of a kind of transitional sections than an independent chimney channel. It makes no sense to completely assemble the chimney from corrugated stainless steel, the resistance to flow will be so great that all the soot clogs the gap in a couple of months.

In the best case, the corrugation performs the transition on the movable section of the wall, roof frame or ceiling. In those places where a rigidly fixed section of the chimney can be cut off due to shrinkage and movement of the wooden roof structures.

Healthy: Fan in the chimney to improve draft.

single circuit

Due to mass advertising, most users have an incorrect opinion that sandwich pipes are the only possible, universal solution for stainless steel chimneys. But it is not so.

Single-circuit chimney pipes have certain advantages over sandwich structures:

- Light weight and easy assembly that does not require careful fitting of joints between sections.

- A small price, a single-circuit stainless steel pipe costs 2.5 times cheaper than a sandwich. It can be cut with a grinder, scissors, a cutting machine, adjusting the section in length.

Sometimes individual pieces of the pipe have to be welded with a semi-automatic device or argon in order to build up or make a chimney of an individual shape. And this is extremely important for the correct adjustment of the length of individual sections, turns and corner zones.

Important! In order for the draft in the stainless steel chimney to remain consistently high, without dips and reverse falls, it is necessary not to allow more than three sections in the chimney with a turn of the flow (deviation from vertical).

In fact, a single-circuit pipe is just a sheet of stainless steel, rolled up on a mandrel and welded with a longitudinal seam, with knurled grooves (locks) at the ends so that the section can be joined to any other without any additional preparation.

The diameter of one end is made 1-2 mm larger than the size of the second. That is, stainless steel sections can be put on one another, the number of such joints in one chimney is limited only by the height of the chimney and the stability of the structure.

Sometimes individual sections of a stainless steel pipe are made in the form of a continuous section without seams. Several modules are welded into one seamless, 2-3 m long. Usually this is a straight vertical section. This part of the chimney is used as a heat source for the attic or living room on the second floor of the building. Welding is needed in order to avoid opening joints and leakage of products of combustion of firewood or coal gas through the locks.

The distance from the chimney cut to the attic ceiling rarely exceeds 2-2.5 m, so the loss of thrust due to the cooling of the gas flow is relatively small. But on the other hand, the heated walls of the chimney pipe heat no worse than a potbelly stove.

Welded single-circuit structures are also used in the first (lower) sections of the chimneys of steel sauna heaters. Double-circuit sandwiches often do not withstand high heat. The surface of stainless steel is heated from flue gases up to 500-600OWITH.

Basalt thermal insulation is able to withstand more, but at this level of heating, the joints between the sections begin to diverge. Therefore, the owners, in order not to burn out in the steam room, prefer the first, hottest section of the chimney (above the heater) to be joined by welding.

But such a scheme has one major drawback - stainless steel has a large coefficient of thermal expansion. If the chimney section is assembled from separate sections, then the increase in the length of the pipe due to overheating of the stainless steel is compensated by the gaps on the locks.

But if you install one long solid pipe section 2-2.5 m long, then the total elongation can turn out to be large, which can lead to opening the joint somewhere under the ceiling.

It is in this place that the seams on the chimney diverge most often. As a result, hot gases leak under the ceiling and the lining of the ceiling may burn.

Sometimes the chimney is simply taken out of the stove to the street through a hole in the wall. This scheme is popular for installation. But in this case, the stainless steel channel has to be well insulated. Otherwise, the inner surface of the stainless steel chimney will be bombarded with condensed water vapor and soot.

Dimensions and material of single-circuit chimneys

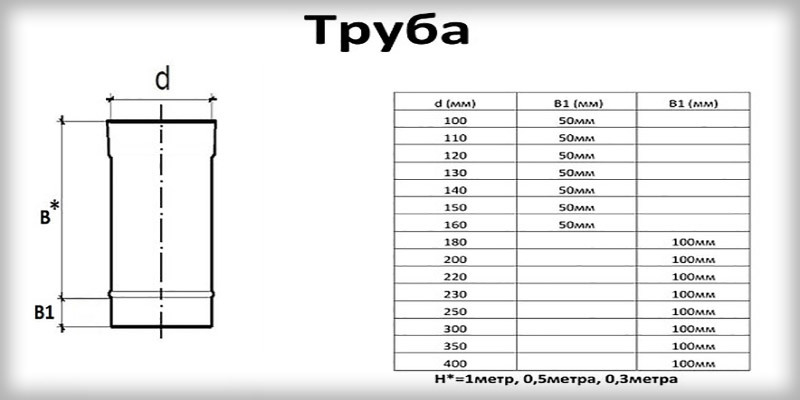

The diameter, height of the section and the width of the landing belt have long been brought to a single standard. For the equipment of chimneys in private houses, baths, summer kitchens, sections with a diameter of 100 mm to 200 mm are used.

Belt width - 50 mm. Wall thickness - 0.8-1.6 mm. The most popular sizes are from 140 mm to 200 mm. Stainless steel chimneys of larger diameter are practically not used in private houses.

In addition to channels of circular cross section, sections of "oval" pipes can be used for the chimney. In advertising, they are often called elliptical or oval, but in fact the cross section of such a module is close in shape to a rectangle with rounded corners.

Why is it so important? Because when calculating the characteristics of a stainless steel chimney, you need to know exactly the area of the flow section of the channel. For round and elliptical shapes, the lumen area can be easily calculated using the formula. In oval chimneys, the cross section is determined with a large error.

Stainless steel chimneys assembled from oval sections are difficult to install along the outer wall of the house. Wind loads must be taken into account. Although if you plan and assemble all the sections correctly, then an oval stainless steel chimney will work no worse than a regular round section.

Standard oval stainless steel chimney sections are designed for sleeving ready-made brick chimneys for apartment fireplaces. In this case, they are safer and work much better than round ones.

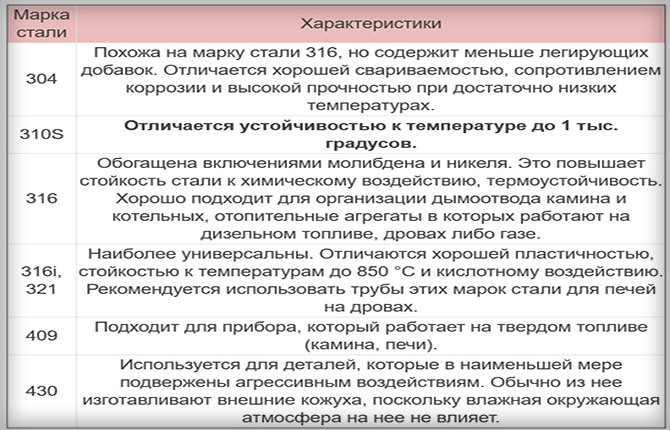

The durability of the chimney pipe directly depends on the brand of stainless steel. The metal can vary greatly in properties depending on the content of alloying additives. This is the biggest problem for stainless steel single-circuit chimneys.

If you need a chimney for a sauna heater, then you need to choose a heat-resistant stainless steel with a high chromium content. For external channels laid along the outer wall of the house, corrosion-resistant grades are usually chosen. It is difficult even for a specialist to distinguish stainless steel in appearance, therefore, when buying sections, the metal brand must be specified according to the documents.

Double-circuit sandwich pipes do not usually have such a problem. External cladding is most often made of black or low-cost low-alloy steel. To give the appearance, it is coated with galvanized chrome and polished to a shine. The inner channel can be made of high-quality corrosion-resistant X18H9T or its equivalent. But you can check the metal only by a cut at the end of the section.

Sandwich pipes

Each section of the sandwich chimney is a double stainless steel pipe, one nested inside the other. Thermal insulation made of basalt fiber is pressed into the wall between them.

The design of the end locks of each sandwich section is designed so that there is no air gap between the thermal insulation of the two sections, in which moisture can accumulate. In addition, some stainless steel sandwich chimneys are additionally equipped with a condensate removal system, which significantly affects the life of the thermal insulation.

If you put the chimney without taking into account the flow of condensate, then the thermal insulation layer picks up moisture and often sags inside the wall. At the same time, the outer and inner walls of the stainless steel chimney remain intact and can still serve for more than a dozen years. You have to disassemble each section and manually change the thermal insulation.

Sandwich pipe is ideal for making a chimney inside the house. It is clear that for the internal chimney it is recommended to use high quality sections.

Important! The first and most important requirement for sandwich pipes is the correct welding of stainless steel. A simple single-circuit chimney for a potbelly stove can be made from a stainless steel sheet literally on the table or “on the knee”. If we are talking about a chimney channel for a solid fuel boiler, then a double-circuit sandwich pipe with a longitudinal welded seam made end-to-end by a laser or an argon burner should be used.

The quality of metal and welding must be confirmed by certificates. It is not recommended to install riveted pipes or models with a rolled seam on high-capacity heating boilers. Otherwise, all the soot and soot will collect inside the thermal insulation, draining condensate along the outer surface of the cladding.

There are two ways to connect sandwich sections:

- For flue gases. This means that the lower edge of the upper section of the pipe has a flare and is put on when docking over the lower part.

- By condensate.In this case, the upper end of the lower section has an extended flare and the upper part is inserted into it as if into a bowl. This is done so that condensation products do not flow through the seam to the outer surface of the chimney.

Docking on "flue gases" is done in order to avoid leakage of combustion products through the joint between two stainless steel sandwich modules. If the connection at the junction turns out to be loose, then the flue gases will suck in air and carry it up the chimney channel.

They will not enter the premises. Typically, this type of docking is used to divert relatively light and volatile combustion products from gas boiler chimneys.

The condensate scheme is used when burning wood, coal or briquettes. Such flue gases contain a lot of tar, soot, phenol-water condensate. They are very hot, the draft in the stainless steel chimney is very strong. But at the same time, the amount of condensate and soot falling on the walls increases by an order of magnitude. Therefore, it is necessary at all costs to avoid leakage of liquid at the locks, to force it to flow down the walls to the condensate collector.

How to make a stainless steel chimney

The specific scheme of the chimney channel, its dimensions, the line of passage through the ceilings and the roof are selected depending on the design of the boiler. If the boiler is gas, usually with an upper outlet flange, then the chimney can be made combined. This means that for one-story buildings, the pipe will be assembled from single-circuit and double-circuit sections.

Installation rules

When planning a chimney for a gas boiler, you must follow a few basic rules:

- the chimney pipe must have its own fastening, in no case should it rest on the ceiling or parts of the roof frame (roofing cake);

- the section of the chimney when passing through the ceiling or roofing must be made of a double-circuit sandwich section;

- a fungus and a deflector are put on the chimney head.

The last item is required only for gas boilers. For stainless steel chimneys installed on solid fuel boilers, the fungus is not installed. Instead, a deflector is mounted.

Stainless steel chimney design

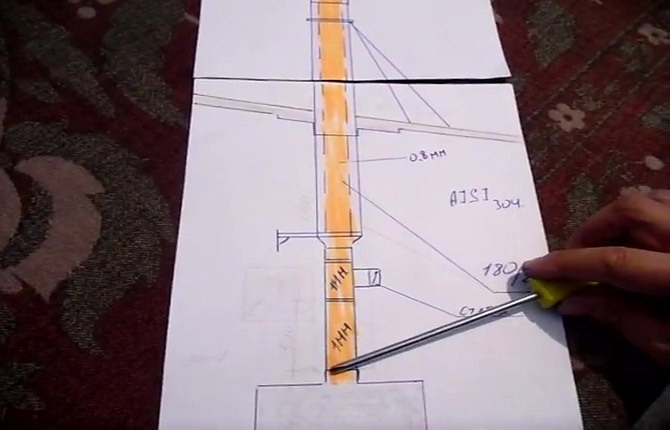

This is a classic version of the chimney for a boiler on network gas-methane. The structure consists of two sections. The first (lower) is made of a single-circuit pipe, goes from the boiler to the mounting bracket, made of stainless steel AISI304 1 mm thick.

Next comes a reinforced type adapter with additional lugs welded on. With their help, the chimney can be securely fixed on a metal frame (wall bracket). The upper part of the chimney is assembled from stainless steel of the same brand, with both pipes: internal and external. Steel thickness - 0.8 mm.

Why was this design chosen?The main part of the combustion products of methane or propane is hot water vapor, carbon dioxide and atmospheric nitrogen. The exhaust is very clean, moderately hot and quite light.

The inner walls of the stainless steel chimney channel are practically not overgrown with soot. Therefore, the lower part of the chimney can be made of single-circuit stainless steel. And everything above will have to be insulated in order to maintain traction in the channel.

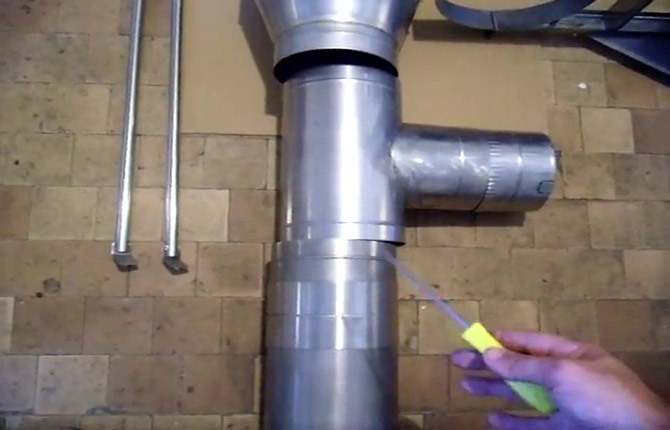

A tee is inserted between the adapter and the single-circuit stainless steel; it will be needed to clean the chimney.

Assembly instructions

The design has 8 joints, each of which can "play" along the width of the mutual overlap by several millimeters. It may turn out that after assembling the lower single-circuit part, installing the transition cone and the sandwich, this whole part simply will not fit in the gap between the boiler and the roof of the house.

Therefore, before assembling the inside of the chimney, all parts are laid out on the floor in the desired sequence and joined without rigid fixation. This is necessary in order to once again check the height of the inside of the chimney and calculate the level of fastening of the bracket with a loop on the wall.

Next, a sandwich pipe is assembled, the hot part of the chimney channel is laid inside the cladding. After that, fixing inserts are installed, they will not allow the insulation to fall out after completion of work.

A cone adapter is put on the bottom edge of the sandwich.

Important! The fitting assembly of the chimney is carried out dry, during the final installation, all joints must be additionally sealed with a heat-resistant sealant.

The next step is to assemble a single-circuit section of the chimney. Now you can put on top of the previously assembled section of the sandwich with a cone and a tee, and then fix the parts with stainless steel clamps.

Only after that it will be possible to apply markings on the wall for attaching the bracket.

A steel frame with a loop is attached to the wall as is, without disassembling the previously assembled part of the chimney.

Now you need to determine the place for drilling a hole on the roof for the passage assembly. For this you need:

- fix the lower part of the chimney with a loop on the bracket;

- unscrew the lock nut on the bracket loop;

- align the lower part vertically using a building level or plumb line.

- after alignment, the nut on the bracket loop is tightened, along the upper edge of the pipe, a contour of the future hole for the passage assembly is traced with a pencil.

Since the boiler is relatively cold, the temperature of the outer lining is quite low, the passage assembly can be made simple from a stainless steel sheet, insulate it with a layer of basalt thermal insulation and stick it on the roof sheathing from the inside premises.

Before installing the pass-through assembly, a clamp must be put on the top of the sandwich. With it, it will be possible to fix the junction of the lower part of the chimney with the upper one, which is displayed on the roof.

Before the flipper and fungus are put on, the entire structure is checked again using the building level. If necessary, the position of the stainless steel chimney is adjusted by turning the lock nut on the bracket loop.

If the height of the chimney above the roof is more than 170 cm, then you will need to put on an additional clamp with "ears" and fix the pipe with braces.

Features of installing stainless steel chimneys for solid fuel furnaces

For solid fuel heating boilers, the requirements for arranging a chimney are much more stringent. Firstly, it is necessary to equip the revision and the condensate collector. Secondly, the entire structure of the chimney must be double-circuit in the lower part (from the boiler to the ceiling) and preferably insulated in the area from the passage node to the upper cut of the pipe.

It is clear that the temperature of the flue gases inside the chimney duct is much higher than that of gas boilers. Therefore, the entire chimney system must be assembled from high-quality heat-resistant stainless steel.

For solid fuel boilers, the outlet is traditionally made from the rear (rear) wall. This is a special solution for a solid fuel firebox, taking into account the installation of a tee and then the entire stainless steel chimney. That is, a tee at the outlet of the boiler will be needed to clean soot, and there will also be a glass at the bottom for collecting condensate. This is the only way to protect the boiler furnace from water and resinous substances condensing on the stainless steel.

For a boiler with a power of 18-25 kW, a chimney with a sufficiently large cross section is required. Usually a sandwich with an inner channel with a diameter of 180 mm and an outer channel with a diameter of 280 mm is chosen. This is for chimneys with a height of at least 8 m. For more modest sizes of 5-6 m, the diameter of the pipe must be increased.

Another thing is that the efficiency and durability of a stainless steel chimney on a solid fuel boiler largely depends on the temperature of the outgoing gases. For example, if on the return line (return pipe of the heating circuit) the water temperature is at least 60OC, then the stainless steel chimney channel will work quite steadily in any weather.

These are the so-called hot heating boilers, in which water is heated to 95-98 ° C for supply to the circuit. Their flue gas temperature reaches 400°C. Approximately at this temperature, the deposits on the stainless steel burn out intensively, and the phenol-water condensate evaporates. Therefore, the draft in the stainless steel chimney is quite stable and powerful.

True, for this you need to select high-quality stainless steel, and not be content with substitutes. Masters recommend choosing sandwiches with an inner tube and outer lining made of heat-resistant steel with a high content of silicon, chromium and nickel.

All budget options with a galvanized, chrome or nickel-plated surface are all temporary. In such pipes, the appearance of corrosion due to scratches after cleaning the soot is a matter of time.

Insulated hot stainless steel chimneys warm up in minutes. This is especially noticeable in severe frost. At the same time, thermal insulation gains and retains heat well.

The problem is that the main deposition of soot and the formation of condensate occurs during the heating period of the chimney. If you do not insulate stainless steel, even if it is of the best brand, all the same, when working on solid fuel, the channel quickly overgrows with soot that accumulates during kindling.

Another nuance is that fungi and “hats” are not placed on the heads of stainless steel chimneys.The flow of flue gases inside the chimney channel with smooth walls accelerates to high speed, strikes fungus, reflects and throws out soot, soot, tar-water condensate on the surface of the roofing roofs. Over time, a huge black spot is formed to wash off and paint over, which is simply unrealistic.

Problems of a stainless steel chimney for a solid fuel boiler

Building a stainless steel chimney for a solid fuel boiler is the right decision. But stainless steel is different. Heating with wood or coal means that the amount of soot on the stainless steel walls will grow much faster.

If brick pipes are cleaned about once every two or three years, on pine wood, maybe a little more often, then on stainless steel, soot growths will have to be knocked down every year. For one heating season, the flow area decreases from 180 mm to 150 mm, if not cleaned, then the solid fuel boiler begins to suffocate. True, this will be noticeable only during the period of the greatest load on the furnace.

A stainless steel chimney can not be cleaned, but burned out. For example, if instead of a Chinese-Belarusian stainless steel pipe, an expensive, but high-quality system like "CRAFT" is installed. Such a chimney will cost about two to three times more than a conventional sandwich with an inner pipe made of 300 or 400 steel and a galvanized outer lining.

The main advantage of such systems is that, thanks to the right metal, the inner pipe can easily withstand heating up to 550-600oWITH.And for a long time. Moreover, the basalt fiber of thermal insulation withstands 800-900OC for 10-12 hours without a significant decrease in the protective characteristics of qualities.

This does not mean that such systems can be burned without restrictions, but craft chimneys can easily withstand the procedure for burning soot and condensate without burning stainless steel. For conventional sandwich chimneys, the thermal insulation is sintered at 600OC for 2-3 hours, after which the pipe can be thrown away.

What does it give? Soot and condensate growths in the channel can simply be burned out and forget about manual cleaning for 10-15 years. It is clear that when installing CRAFT and similar systems, you need to carefully follow the step-by-step instructions installation, fire safety rules, properly equip the floor and roof passage assembly according to the standards SNiP.

Rolled stainless steel chimney

There are many opinions about how to treat stainless steel rolled chimneys, whether they can be used for a domestic boiler or not.

Many experts completely reject the idea of using stainless steel chimney channels with a rolled (chased) longitudinal seam instead of a welded one. It is generally accepted that such a seam does not withstand heat, passes water vapor and even condensate. But, on the other hand, the presence of longitudinal rolling significantly increases the rigidity of the chimney pipe, especially if it is made of relatively thin stainless steel 0.5 mm thick.

Of course, such blanks can be used for the outer cladding of a sandwich section. But they can also be used for chimneys with a small cross section, for example, for an outdoor stove or potbelly stove.

Chimney pipe for potbelly stove

In some cases, an expensive sandwich is not needed due to operating conditions. A simple single-circuit stainless steel pipe will suffice. It is not checked for leaks, in a hot state with increased pressure in case of back thrust.

The height of such a chimney does not exceed 2-3 m, it is not taken out to the roof, but simply put out the window (hole in the wall). In theory, the chimney can be riveted from ordinary sheet steel, but the temperature of the flue gases remains very high, so it is better to make the structure from stainless steel.

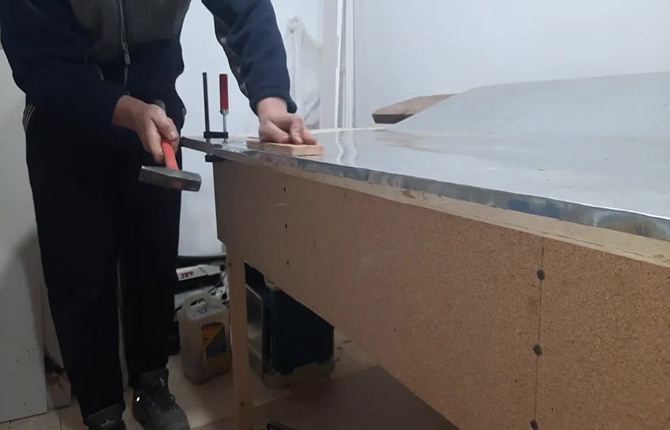

The process of assembling a chimney for a potbelly stove begins with the layout of the sheet. It is necessary to cut off the workpiece with a width equal to the circumference at the end, plus a margin of 40 mm for the rolled seam.

Next, the sheet is laid with an overhang (20 mm) on the edge of the workbench and fixed with a clamp.

Pressing the stainless steel with a plank, with hammer blows, the edge of the sheet is bent at a right angle. Next, the workpiece is turned over and the edge is bent to 120-160O.

A similar bend is made on the opposite side of the sheet.

Next, the blank sheet is turned over “on its back”, with the help of any mandrel blank that is suitable in diameter, the stainless steel is twisted several times by hand until the material turns into a kind of pipe.

Now you need to lay a wooden lath 30x40 mm inside, connect two bends on the edges and temporarily fix it in this position. Next, with a hammer, through a wooden block, roll the seam.

The problem is that you need to upset the seam evenly along the entire length of the stainless steel, otherwise the chimney pipe will turn out with a slight taper.

Important! No sealant or gaskets are placed in the lock.

Now you will need to drill several holes along the seam and install blind rivets, 5-6 pieces will be enough for the entire workpiece.

If the chimney is composite, for example, from two parts, then at the end of one of them it will be necessary to make a gear knurling. You can use round-nose pliers, special pliers or a regular hammer with a screwdriver and a couple of pieces of wood.

To connect two sections of a single-circuit chimney, it is enough to insert one into the other and knock the pipe well on the floor a couple of times.

What stainless steel to choose for the chimney

For chimney channels of a private house, you need to choose sandwich pipes with a metal thickness of at least 0.8 mm; for smoke exhaust systems with a height of more than 5 m, the wall should be from 1 mm or more.

Option for a garage or country house

If you are making a chimney for a small garage potbelly stove, then it is best to take a relatively cheap and plastic grade 400 stainless steel. Exact compliance with some GOSTs is not required. A potbelly stove is not a boiler or a coal furnace, where the exhaust gas temperature at the outlet can reach 900OWITH.

But you need to make sure that the stainless steel is sufficiently plastic. You can refer to the certificate. But since the pipe is often made with one's own hands from any stainless steel that is at hand, it is difficult to document the composition.

You can test the metal for the chimney. To do this, heat and cool the sample several times on a gas burner, and then check for a break with pliers. There should be no cracks.

For any homemade chimneys, stainless steel must be plastic, viscous. During the operation of the potbelly stove, the metal of the chimney channel experiences huge thermal stresses.

Single-circuit pipes and even laser-welded sandwiches, with periodic overheating, the stress in the seam often deforms the walls of the chimney into an accordion, the welding is covered with cracks. And this despite the fact that the welding seam was performed on production equipment. Therefore, if you make a stainless steel chimney with your own hands, then only riveted and rolled.

Material for the fireplace and boiler in the house

If a fireplace or a wood-burning boiler is planned in the house, then the best solution would be a 306 stainless steel pipe with a wall thickness of 1-1.2 mm. In the fireplace chimney, you can put a single-circuit version of the pipe. Still, it will need to be overlaid with a brick. Alternatively, an existing brick channel can be lined with a single-circuit stainless steel chimney.

For a home gas or wood heating system, you can also use 306 steel grade, it will withstand even if the owners, wanting to save money, will heat with pine wood or substandard fuel in the form of home-made briquettes.

If the boiler will be fired with coal or apartment briquette, then for the chimney it will be necessary to choose a stainless steel of grade 316 and higher. This is a truly heat-resistant and at the same time corrosion-resistant steel. In this case, the pipe walls may be non-plastic, but corrosion-resistant.

A coal firebox produces a huge amount of carbon monoxide and volatile sulfur compounds that can burn through any steel, even stainless steel, if the alloying content of the metal was not specially designed taking into account the impact sulfur.

Usually these are steels with a high content of nickel, manganese, chromium.

fire department requirements

It may happen that before starting the heating system it will be necessary to obtain permission from the inspection. There is a fairly extensive list of requirements for the arrangement of chimneys, including stainless steel. There is a common misconception that a stainless steel chimney cannot be a source of ignition. In fact, it can, especially if the chimney is assembled with violations.

Things to consider:

- limit to a minimum the number of horizontal sections, abandon them or reduce the length to a minimum;

- use for installation transitions at an angle of not more than 30O and only one - 90O, it must be installed at the outlet of the boiler;

- the distance from the sandwich to the nearest flammable material must be at least twice the diameter of the chimney (300-400 mm);

- do not use locks with a serrated edge, as well as self-tapping screws. The joint must be fixed only with clamps.

In addition, the diameter of the hot chimney duct must be equal to or greater than the size of the outlet on the boiler. It cannot be reduced.

One of the problems of stainless steel composite chimneys is air leakage at the joints and the deposition of soot in these places. While the boiler is burning, the pipe simply sucks in air. As soon as the power drops, the soot ignites and can burn for hours inside the chimney. Problem areas are clearly visible on the polished stainless steel by dirty spots of soot and condensate drips.

Results

Making a stainless steel chimney with your own hands is quite realistic for any person who knows how to handle metal. You just need to choose the right design of the chimney channel and buy high-quality stainless steel pipes. The rest is a matter of fitting and assembly, as in a children's designer.

Tell us about your experience in building stainless steel chimneys. What are the shortcomings that you need to pay attention to first of all? To what extent is the use of stainless steel justified for boilers in private homes? Also share the article on social networks and bookmark it.