The main lifesaver in the house for things, furniture and household appliances - easy to use and quite effective if you know how to use cold welding. Like any adhesive composition, this type of glue has limitations on the conditions of use, as well as the materials to be glued.

The content of the article:

- What is cold welding

- Features of application

- Compound

-

What is cold welding?

- Liquid cold welding

- Dry

- Where is it used?

- At what temperature can it work?

- What cannot be repaired

- Advantages and disadvantages

-

Instructions for use

- Liquid

- Dry

- How long does it take to dry?

- Security measures

- Storage rules

- Results

What is cold welding

If you try to explain it simply, it is a two-component adhesive based on a certain type of epoxy resin and hardener. Moreover, both components are either in a soft state, like plasticine, or stored in tubes like a cream. It is very convenient to use, there is no need to measure portions, as with epoxy glue.

What is the difference between cold welding and conventional glue:

- viscous, almost solid consistency;

- the components of the epoxy resin and hardener are sealed in microcapsules, which protects them from spreading and reacting with atmospheric oxygen;

- the composition includes filler: fibers or mineral powder, metal or ceramic dust.

Cold welding is produced in different types and types, for a specific purpose. For simple cases, you can use any brand. But for metal or if you are gluing plastic or PVC, it is better to choose specialized heat-resistant ones. This composite has additives and a special filler, but using it is no more difficult than a universal adhesive mass.

Features of application

The adhesive component and hardener are stored either separately or in one bar, similar to a tile of plasticine. In order to activate the adhesive mass, you need to measure the components, knead them with your hands (with gloves moistened with water, this is necessary) or mix them on a ceramic tile.

Once activated, cold welding remains soft, like plasticine, for quite a long time. It is convenient to use, since there is more than enough time for gluing. The composition sets within a quarter of an hour.

A special feature of cold welding is its relatively higher safety than pure epoxy adhesive. Both components (resin and hardener) are included in the starting materials either in jelly or solid form, significantly reducing the volatility of toxic chemicals. Therefore, using welding compound is safer than using pure glue.

There are a huge number of types offered on the market: from cheap universal to expensive specialized ones. Some brands can withstand heating up to high temperatures of 300-350OC, remain hard and do not crack from heat, but do not withstand prolonged contact with a humid environment. Most cold welding compositions are waterproof, plastic, and can be used for gluing, for example, plastic, metal, glass.

Compound

Any cold welding is carried out on the basis of a two-component epoxy composition, a filler and a supporting base-plasticizer. Strength and setting speed depend on the brand of epoxy resin used.

In solid compositions, a plasticizer is not used or is used only if the composition contains metal oxide powders. Despite the high price, using such compositions for sealing pipes is more profitable and convenient than soldering or a clamp. But only if the brand of adhesive mass is selected correctly.

The durability and strength of chemical welding depend on the brand of resin. Most universal cold welds are made on the basis of ED-16, E40, ED-L. For example, compositions based on ED-P and ED-6 are used for linoleum, and ED-20 for metal. Although any composition can be used to seal unloaded polymers.

For the manufacture of high-temperature grades, for example for a muffler, modified resins, including chlorinated ones, are used as a base.

Metal oxides are used as fillers: titanium, zinc, chromium. The cheapest resins often use ordinary cement and metal dust, including copper or aluminum.

Liquid formulations use preservative bases to prevent polymerization of the cold-welded components prior to mixing. The main component is E-40 resin.

What is cold welding?

Based on their form, adhesive compositions are divided into liquid, semi-viscous and solid. The first ones are stored in polymer tubes, the hardener and the main composition are separated. The latter are offered in plastic cans, like regular acrylic glue or epoxy two-component floor varnish. Using a liquid mass is not very convenient, but sometimes such composites are simply irreplaceable (for linoleum).

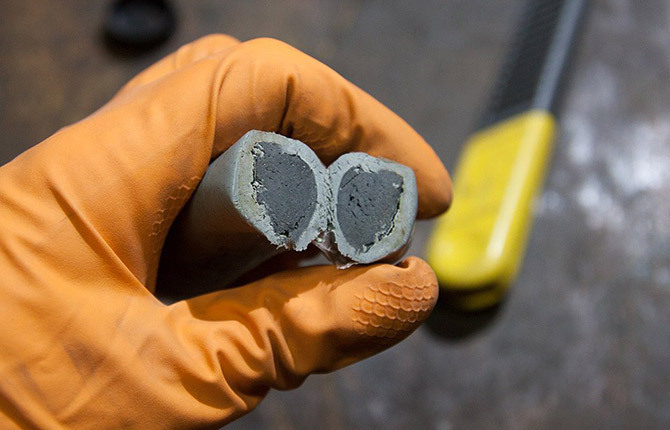

All solid welds are sold either in the form of two pieces of plastic mass of different colors, or in the form of one two-layer “sausage”. The second option is more convenient to use, since by cutting off the required volume of solid glue from the mass with a knife, you get the required amount of hardener and resin.

In the case when the adhesive mass is stored in the form of two separate tiles, it is less convenient to use the product, but, according to reviews, many prefer this option. The glue lasts longer and you can adjust the proportions.

Liquid cold welding

The consistency of both components resembles regular cream or toothpaste. Essentially it is epoxy resin ED-5, ED-6 and hardener, to which filler and plasticizer are added. They are needed to protect the resin and hardener from absorbing moisture from the air.

Even a small amount of water vapor can lead to a sharp deterioration in the mechanical strength of the composition. It is convenient to use a liquid form when the entire batch of glue is consumed once, for example, if you need to cast the entire part into a plaster mold.

Dry

Most compositions are sold in the form of a dense tubular mass, inside of which another layer of white or black is visible.

Universal brands such as Almaz, Titan, ABRO STEEL have a gray outer layer. Specialized heat-resistant brands Mastics or Diamond are painted in dark colors. There are brands with the addition of iron oxides; for example, Diamond has a brown outer layer of mass.

But it is better to choose cold welding for a specific application not by color, but by purpose, and you should definitely read the instructions for use.

Where is it used?

Liquid cold welding is used mainly for sealing thin cracks, restoring chips, and gluing parts of complex configurations without high thermal load. It is easier to press a liquid composition into a joint than a dry one, even if you knead it strongly. It is convenient to use liquid glue if you have to use welding every day.

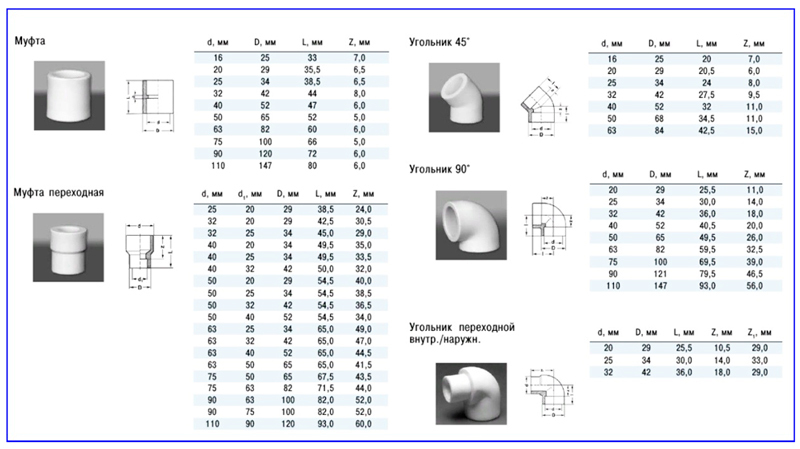

Solid grades are used for external patches:

- in water pipes, heating systems, radiators, sewer and drain pipes;

- for plastic car body cladding as temporary patches on mufflers, decorative trim;

- for gluing parts of wooden and steel furniture;

- for gluing plastic trim to ceramics, gluing tiles and renovating bathtubs.

Hard welding is also used as a base for hand-sculpting all kinds of objects. You can use it to make a lost stopper for a canister, a bracket for attaching a shelf, adapters, handles, and lids. Cold welding, subject to application technology, is characterized by high strength and hardness. It can be drilled, threaded, cut with a hacksaw, or treated with abrasive.

It is very convenient to repair cracks in wooden furniture frames using cold welding: armchairs, kitchen tables, walls. The epoxy composition does not leak out of cracks; it can easily restore lost or damaged pieces of wood. In this sense, cold welding is superior even to specialized repair compounds based on acrylic and epoxy adhesives.

According to reviews, the majority still prefer to use the composition as a means to repair damage in an emergency, somewhere on the road or in the event of a plumbing breakdown.

At what temperature can it work?

The degree of heating depends on the composition of the composition. The most heat-resistant cold welding grades are filled with graphite or metal powder. The operating temperature of such a patch or part usually does not exceed 200OC, provided there is no torsional and vibration mechanical load.

Universal brands can easily withstand heating up to 120OC, so they can be used to repair water heating batteries.

What cannot be repaired

There are certain restrictions when working with cold welding. Firstly, it cannot be used to repair any type of food utensils or any items used in cooking. It is clear that you can glue the fallen handle of your favorite cup. The composition will not come into contact with drinks.

You cannot repair objects and utensils that are touched by hands and used for personal hygiene. Despite the fact that the resin is in a hardened state, some of the cold welding components do not react with each other and may leak onto the joint surface.

Advantages and disadvantages

There is approximately an equal number of reviews regarding cold welding, both positive and negative. This only confirms the fact that cold welding continues to be used for a variety of purposes. True, most of the problems arise due to the inability to properly use the adhesive mass or violation of the instructions for using the composition.

Positive aspects of cold welding:

- It is possible to store it in an unsuitable place, for example, a tool case for a car or on a shelf on the balcony.

- To use, you only need latex medical gloves and a mixing (heating) box. No measuring utensils, jars or syringes.

- Easy to dose, convenient to use, the easiest way is to cut into pieces with a regular knife. Liquid and creamy ones are dosed by squeezing out of a tube onto a board or sheet of metal.

- It sets quickly, cold welding can harden in 10-15 minutes, the strength is sufficient to replace metal soldering.

- High surface hardness.

- High adhesion; minimal surface preparation is required for gluing.

Cold welding also has a lot of disadvantages. The quality of gluing directly depends on the air temperature and how thoroughly both components were kneaded. Not all people have strong enough hands to knead a fairly hard mass into soft plasticine. Therefore, many refuse to use the composition.

If this is not done, the reaction between the components will not go deep enough and cracks may appear. Moreover, this must be done with medical gloves, since the composition contains a rather toxic hardener. Kneading cold welding components with gloves is extremely inconvenient. Many motorists and repairmen prefer to use materials by kneading them with their bare hands, this is much more convenient and faster.

Instructions for use

The main goal of the developers of cold welding was to simplify the use of the adhesive composition in “field conditions”. Therefore, the requirements for preparing the surface and the adhesive material itself are minimal, but they still must be observed so that the strength of the connection does not decrease.

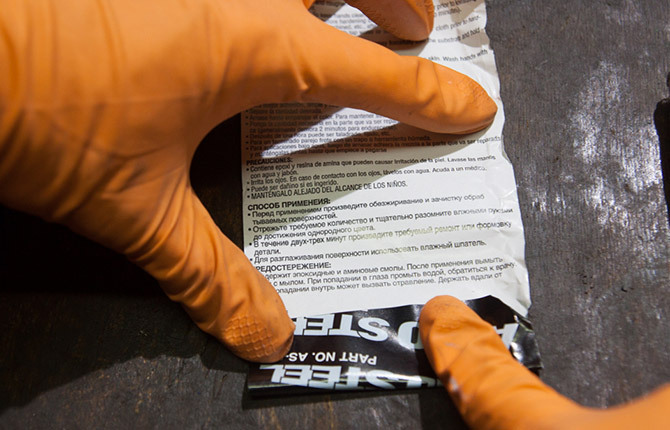

Liquid

Typically this type of cold welding is sold as a pair of tubes sealed inside one package. How to properly use cold welding is described in detail on each tube in the instructions for use. It is less common to find the composition in polystyrene packaging. Cold welding is often confused with repair mixtures for body work.

In cold welding, both components have approximately the same consistency, so they are packaged in two almost identical jars, differing only in color. This is a special technological technique that allows you to accurately measure the required volume of material, and the different colors of the components help control the thoroughness of mixing.

In the repair mixture, epoxy resin contains a huge amount of filler - fiberglass. To activate, you need to heat the jar, squeeze a tube of hardener inside it and only then mix it. It will take a long time to harden.

If the welding package was stored in the cold, then you must first let it warm up in a warm room. Then mix until a uniform color appears and apply to the surface to be repaired. In 10 minutes. you need to remove excess material. After another half hour you can cut it, after an hour or two you can sand it.

Typically, liquid materials are used in conjunction with fiberglass. The reinforcement prevents the cold weld from running off and at the same time increases the mechanical strength of the patch.

Dry

The scheme for using a dry mixture is much simpler. It doesn't even need to be warmed to room temperature. It is enough to cut off the required amount from the main “sausage” and knead it with your hand. A piece of dry welding heats up and changes color, becoming black and brown.

Before applying the patch, the surface to be repaired must be wiped with acetone to remove dirt and water. Acetone is the only type of solvent that can break down epoxy resin.

But if you don’t have a solvent on hand, you can use cold welding as is. Some types of welding, for example Mastic or Diamond, can even join wet surfaces, although in this case adhesion is reduced by 50%.

Can be used as a patch to fix an antifreeze leak or a broken gas tank. It is convenient to use cold welding for repairing cladding and gluing decor. It's better not to put it on the gas line.

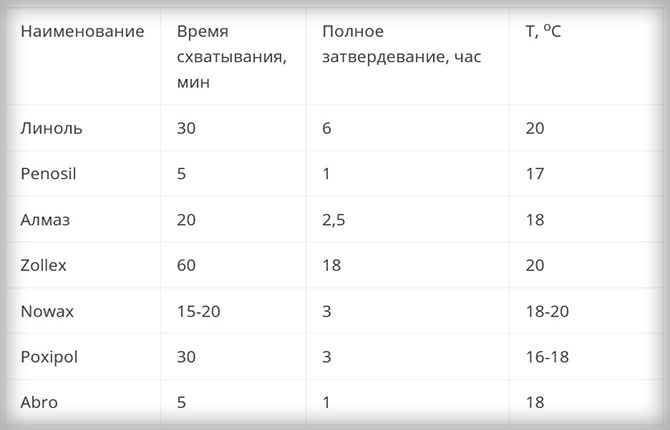

How long does it take to dry?

The rate of resin polymerization depends on the type of cold welding, temperature and air humidity. Most compositions are designed to be used for welding at room temperature and low air humidity. Optimally 18-20OWith and 60% humidity, most brands set in 10-15 minutes. Complete hardening occurs in an hour and a half.

Dry cold welding can be used at lower temperatures, down to 3-4OC, but then you will have to heat the patch with a hairdryer or IR lamp. At 6-7OThe polymerization process becomes uneven; instead of a dense mass, a half-baked cake is obtained, cracking and falling apart at the slightest touch.

Security measures

Both components of cold welding are quite toxic. You can use the composition, knead it and stick it only with latex gloves. The hardener and resin are non-volatile, but when kneading a dry semi-viscous composition, part of the resin and hardener is squeezed out to the surface and sticks to the skin of the hands.

You can use it without restrictions no earlier than polymerization is completely completed. After work, no matter with or without gloves, you must wash your hands with soap, preferably laundry soap.

Cold welding components must not come into contact with drinking water, food or kitchen utensils.

Storage rules

Cold welding should be stored in a sealed, thick plastic bag to prevent water or moisture from entering. You can use a plastic box to store food. The optimal storage temperature is 6-10OWITH. The packaging should be stored in a dry, cool place: in a basement or garage.

You can place the leftover mixed cold brew in an airtight container on the bottom shelf of the refrigerator. This happens if it is not possible to use the composition and the repair needs to be rescheduled to the next day. But the refrigerator cannot be used for long-term storage.

Results

The composition is designed in such a way that using cold welding is very convenient, especially when you need to quickly make a patch or repair damage on the road. All you need to do is read the instructions. This should always be done, as it may contain clarifications and restrictions to help you use the composite adhesive safely.

Tell us about your experience using cold welding. What should people pay attention to when using glue in solid form for the first time? Also save the article to bookmarks and share it on social networks.