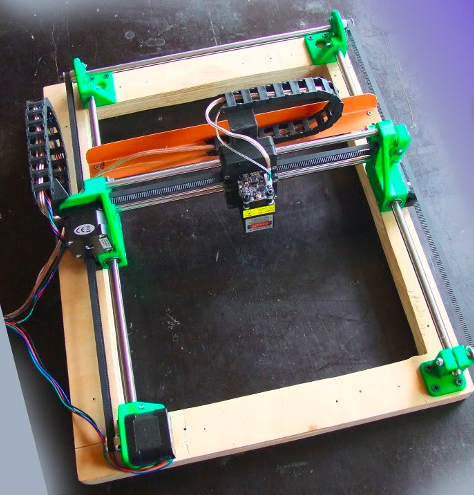

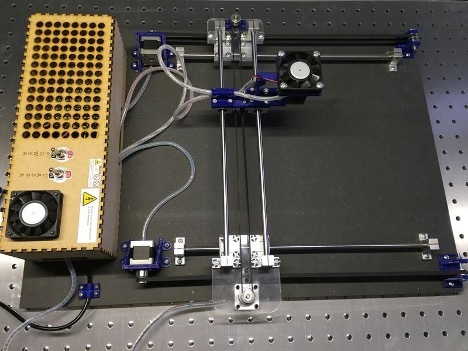

In the modern world, the use of laser engravers is becoming increasingly popular. This tool can be used in a variety of fields: from production to art. Prices for commercial models often go through the roof, but do not forget that it is possible to assemble a laser engraver with your own hands. This article will discuss the key points of this process.

The content of the article

- Planning and preparing resources

- Selecting a Laser Source

- Assembly and calibration

- Testing and Security

- Mistakes when creating a DIY laser engraver

- Conclusion

Planning and preparing resources

Before you start creating a homemade laser engraver, you should carefully plan all stages of the work and prepare the necessary materials and tools. Consider in advance what functions your engraver should perform and what materials it will process. This will allow you to formulate requirements for components and avoid unnecessary costs.

List of required components:

- Laser module.

- Drives and motors.

- Rails and carriages.

- Controller.

- Power unit.

- Ventilation and cooling.

List of tools:

- screwdriver;

- soldering iron;

- multimeter;

- clamps and fasteners;

- wire cutters and pliers.

Selecting a Laser Source

One of the most important steps is choosing a laser source. The quality and functionality of a DIY laser engraver from an inkjet printer or other source is directly dependent on this component. Avoid using unreliable sources or cheap analogues: saving in this case can lead to undesirable consequences and even accidents.

Assembly and calibration

Once all components and tools are prepared, you can begin assembly. One common method is to create a DIY laser engraver from an inkjet printer. The structure of an inkjet printer is great for creating the base of an engraver.

When assembling, it is extremely important to follow the instructions and comply with technical standards. After assembly is completed, calibration must be performed. This process will ensure that your DIY laser engraver works accurately and efficiently.

Testing and Security

Before you start using the engraver yourself, you need to carry out a number of tests. In addition to functionality, it is important to pay attention to security. Make sure that all parts are securely fastened and that the laser module is configured correctly.

Mistakes when creating a DIY laser engraver

When creating a laser engraver yourself, certain mistakes are often made that can not only reduce the efficiency of the device, but also pose safety risks. One of the common mistakes is insufficient elaboration of the power supply circuit. An incorrect circuit or the use of low-quality components can lead to overheating of the device or even a short circuit.

Additionally, underestimating the importance of calibration and tuning can also be a critical mistake. Failure to properly calibrate can result in uneven or poor-quality engraving, and in the worst case, damage to the engraver or the material being processed. To avoid such problems, it is recommended to strictly follow the instructions and use quality components.

Conclusion

Creating a laser engraver with your own hands is a labor-intensive task, but quite feasible. Compliance with all recommendations and technical standards will allow you to obtain a reliable and functional tool that can serve you for a long time. The costs of creating such an engraver will be worth it, especially when you consider the cost of commercial analogues.