Metal gates are intended for registration of entrance to the territory. They will protect and secure a country house, a summer cottage and a garage, a warehouse, retail and industrial areas. An automatic device with a gate will allow you to use it for entry. The rigidity and reliability of the structure depend on the quality of the material and how the gate is welded.

The content of the article:

- Why it is better to make swing gates with your own hands from a profile pipe

- Drawings of swing metal gates made of corrugated sheets and required materials

- Materials for manufacturing

- Manufacturing of gates

- Manufacturing of swing gates

- DIY sliding gates

Why it is better to make swing gates with your own hands from a profile pipe

If doors serve as a room divider, then gates provide access to large areas and serve as a fencing of private property and territory. Metal structures are simple, yet durable and reliable.

There are many types of gates. By opening method: swing, sliding, sliding, hanging, cantilever. They can be opened/closed manually or automatically. For this purpose there is a remote control, push-button stations, photocells, electric drives and signal lamps.

Gate frames are welded from profile pipes, and they are also used as the main material. The swing type is in great demand. They look great on a fence made of 3D mesh or chain-link. They are not inferior in strength to complex and expensive types, and have a number of advantages:

- ease of installation;

- variety of profile materials;

- low price;

- attractive appearance;

- With proper care they will last for several decades.

Their design is quite simple, unlike hanging and sliding gates. It is important to understand how to weld gates from a profile pipe with your own hands so that they meet individual requirements and parameters. For strength, the metal supports and frame are welded from large profile pipes more than 2.5 meters long. In this case, the third part of the support is sunk into the ground and concreted.

All elements are welded on a flat surface. Since metal deforms when heated, the parts are fixed using clamps. Next, the gates are treated with an anti-corrosion compound, especially the seams. The profile holes are closed with plastic plugs. The sashes are attached to the frame on hinges.

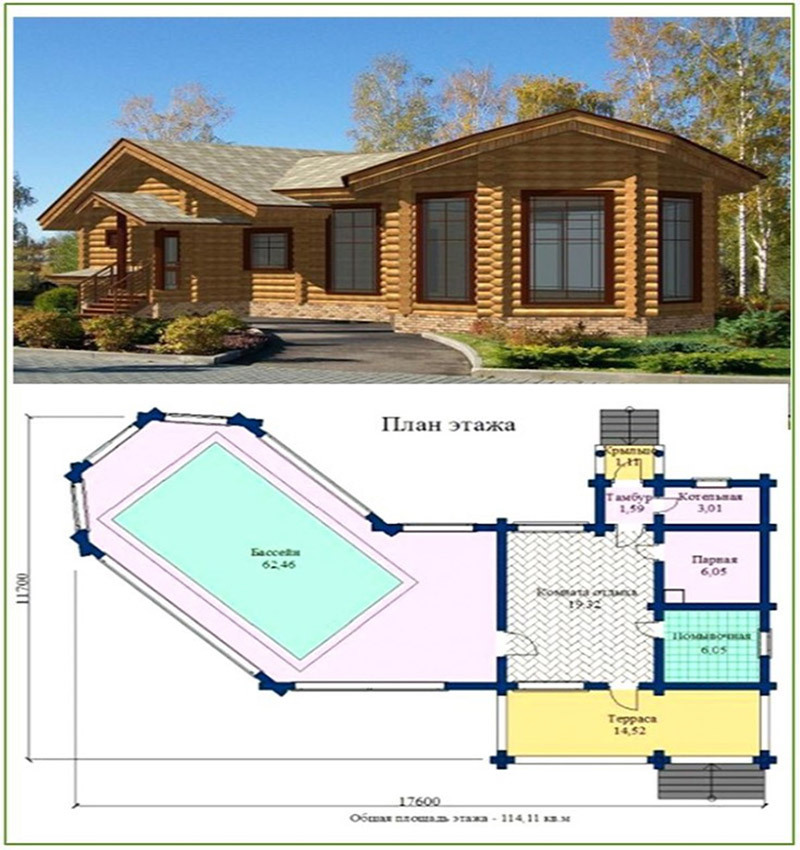

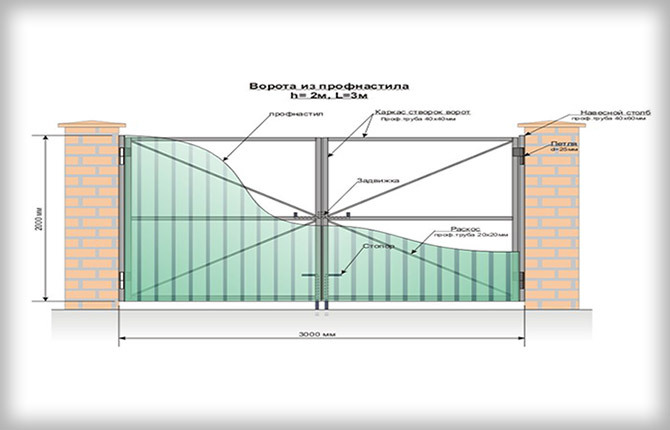

Drawings of swing metal gates made of corrugated sheets and required materials

A metal profile is a galvanized sheet with stiffening ribs, which is produced by cold rolling. The material is resistant to corrosion, with paint or powder coating. Used as filling for frames, as well as individual sections of fences and gates.

Profiled iron is the best option for welding swing gates. They consist of a frame and filling sheets. Usually these are two doors secured by a hinge mechanism on posts. The frame is welded from a professional pipe. Filling - solid profiled or flat sheet. Based on the wide selection of materials and equipment, welding a gate with your own hands is not particularly difficult.

First you need to make a drawing to scale, putting down all the dimensions, indicating the location of the racks and hinges. Then calculate the amount of material required, taking into account the gate, if provided. Determine the weight of the future structure. Under increased loads, the geometry of the gate changes. They may become warped.

Such gates do not require a massive foundation. As a rule, their height is equal to the height of the fence with a difference of no more than 200 mm in one direction or another. The sheathing is welded from profiled pipes. Hinges with support bearings are welded to it and covered with a profiled sheet.

The sewing method is horizontal or vertical, one-sided or two-sided. The sheets are secured with metal screws with the obligatory use of rubber gaskets for roofing work. Another method is to install rivets through drilled holes.

Solid lining is used when it is a square or rectangular frame. If the shape of the frame is arched, the curved sections are covered with decorative elements. These can be gratings, ribs, forged parts. Various shapes are welded from metal pipes. If the region is characterized by strong winds, the filling of swing gates cannot be continuous.

Materials for manufacturing

When producing swing structures, you need to know how to weld the frame correctly. The following sizes of corrugated pipes are suitable for racks and frames: 60 x 40 x 2 mm, 40 x 20 x 2 mm. In addition, you will need the following materials:

- metal profile for filling the sashes;

- bases for supports;

- caps for the top of the racks;

- hinges, locks, door stops;

- hole drill;

- concrete mortar, crushed stone to strengthen supports.

To finalize the gate, you need sandpaper, an anti-corrosion agent, and metal paint.

Profiled sheets are a universal material. The canvas can be of different shapes: paneled, wave. There are plain sheets of different colors, as well as surfaces that imitate stone and brick, or wood. Thanks to a wide selection of colors and textures of materials, the gate will fit into the overall picture of the yard.

The sheets are easily combined with other products and elements. They are laid overlapping, in the same way as a roof is covered, achieving a consistent appearance. This sewing method is also applicable for gates, individual sections of fences, and garage doors.

Some problems arise if the sheets need to be placed under the arched shape of the sheathing. You can cut corrugated sheets with metal scissors. It is important here not to spoil the corrugated structure. When using an angle grinder, the heat may damage the paintwork near the cut.

The disadvantage of the metal profile is its thickness is 0.3–0.4 mm. It is easily subjected to mechanical stress; even a minor impact leaves dents. Paintwork wears out faster than powder coating. Scratches that appear can only be eliminated with the help of a special corrector.

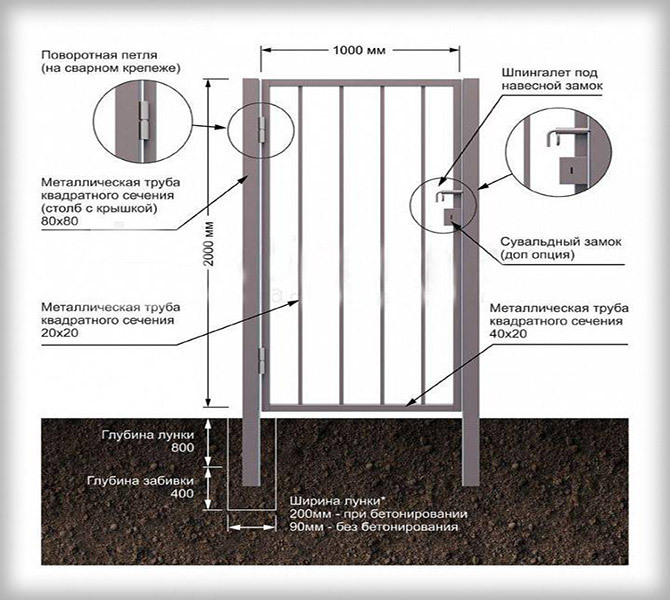

Manufacturing of gates

To get into the yard without using a car entrance, a gate is welded. This can be a free-standing structure or attached to the sash. To maintain the overall appearance, it is welded from the same material as the gate.

For a separately located gate, pillars are installed that will limit the doorway. To do this, you can use brick, stone or a profile metal pipe. Prepare pits up to one meter deep. The pillars are installed and filled with concrete. You can make the mixture yourself using small crushed stone, sand and cement. Concrete supports are maintained in accordance with building codes for up to 28 days.

The next stage is preparing the material for making the gate itself. Profile pipes are cleaned of scale and rust with a metal brush. Degrease with a solvent and treat with an anti-corrosion agent. The outer frame is welded from pipes 60 x 30; 60 x 40; 50 x 50 mm. It should be taken into account that the distance between the finished floor and the gate leaf is at least 50 mm.

The internal one is made from a pipe 40 x 20 or 20 x 20 mm. It is then welded to the outer frame. Such a system is needed to secure the corrugated sheeting, and also gives the structure additional rigidity. Frames are also welded from a universal T-shaped profile.

The elements are welded in a checkerboard pattern. Every 30 cm, “tacks” of 2 cm are made. Otherwise, the frame of the gate may fail due to heating. Weld one part of the hinges, the plate for attaching the lock and the handle. The finished frame is sheathed with corrugated board.

The second part of the loops is welded directly to the support when it is a channel or metal pipe. If the pillars are brick or concrete, a 60 x 30 profile pipe is attached to them using dowels or anchors. The clearance between the canvas and the posts is 5 mm on both sides. Metal strips are welded on the racks, which prevent the blade from moving back and bridge the gaps.

The mortise structure is welded in the same way. The difference is that support pillars are not needed, and the gate is installed on one of the swing gate leaves.

Manufacturing of swing gates

Structures of this type are more often used for agricultural needs, in private households, in summer cottages, and for garages. They meet all the requirements and are suitable both in terms of ease of installation and price.

Swing gates consist of two identical leaves, two of different sizes, or one. The entire structure consists of supports on which the hinges are welded, then the sashes are secured to them. They can swing both inward and outward.

To work, you will need a square metal profile or thick-walled pipes for the frame. Profiled sheets for covering, hinges, lock. Reinforcement is performed using horizontal metal veins. Forged elements can be used as decoration.

The equipment required is a machine for welding metal. Tools: grinder, drill or screwdriver, metal scissors. If the site already has a fence with support posts, then the hinges for the sashes are welded on ready-made supports. If they are not there, the work is carried out in several stages:

- Preparing metal supports, installing them in holes along with fixing reinforcement, pouring concrete. Aging until complete hardening lasts 4 weeks.

- Frame installation. Cutting pipes at an angle of 45°. The parts are laid out on a flat surface and secured by welding. They check the accuracy of the dimensions, the correspondence of the diagonals, make adjustments, and finally weld. For rigidity, corners, ribs, triangles, and cross members are added.

- According to the drawing, canopies, bolts, and limiters are welded.

- The finished frame is treated with an anti-corrosion agent, primed and painted.

- After drying, sheathing is performed. The corrugated sheet is laid on the frame, secured with self-tapping screws, recessing them into the recesses. After this, the gate is hung on its hinges. In the center, at the base, a limiter is installed where the doors will rest when closed. To hold them open, spring clamps or metal pegs are used.

Having the skills to work with a welding machine, you can weld swing gates with your own hands, and, if necessary, build in a gate. They will be reliable and affordable. The negative side of this design is the need for free space to fully open the doors.

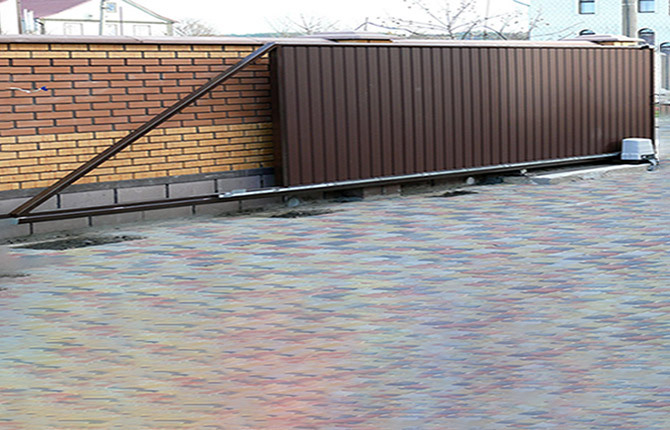

DIY sliding gates

This type is classified as a sliding gate, with the difference that they have two leaves that move apart in different directions and move towards each other. Depending on the opening method, sliding gates can be mechanical or automatic. They do not interfere with traffic. In terms of comfort and operation, it is a step higher than swing doors.

According to the method of fastening, there are suspended, rail, and cantilever. Installing an electric drive allows you to move them apart with the press of a button. This type is a non-standard solution, a necessary measure. In some cases, they are irreplaceable when there is simply not enough space to roll the sash along the fence. If the opening is more than 15 meters, then the sash will be very large and heavy.

Of all the methods for self-assembly, mounting on the lower guide beam is most suitable. This is a durable metal frame fixed to the foundation, a frame with rollers and an electric drive. The design of the doors is no different from swing doors. You need to understand that installing sliding gates will require two sets of automation, which will increase the cost of the project. The work order is as follows:

- calculations and budgeting.

- purchase of materials and selection of necessary equipment and tools.

- filling the foundation and arranging the foundation for the rollers.

- welding the frame for the sashes.

- installation of the structure.

It is difficult to say unequivocally which gate is best to install in a private house, country house or garage. To do this, you will have to take into account many nuances: from functional necessity, area of territory and ending with financial feasibility. For example, to weld metal structures you need not only a welding machine, but also the ability to use it, basic skills and practice.

Have you ever installed a gate yourself? What type of design was chosen? Leave your comment on the article, add it to your bookmarks.