Assembling a grinding machine from a set of old parts is a complex task, requiring a creative approach, and therefore doubly interesting. Such a device will definitely come in handy, especially if the workshop does not have suitable equipment for grinding, because according to statistics, grinding is considered the most common operation in amateur design.

The content of the article:

-

Homemade disc-type sanders

- Disc grinding machine

- Grinding machine from grinder

-

DIY drum sanders

- Drum Sanding Machine for Wood Panels

- Drum sander made from electric motor and plywood

-

Grinding machine made from spare parts from a washing machine

- Grinding machine device

- Machine assembly

- Manufacturing of fixtures and assembly

- Grinding machine from a gearbox from a small angle grinder

- Useful homemade product for the workshop from a broken grinder

- Results

Homemade disc-type sanders

Quite a lot of machine design options have been invented. Most of them are considered universal, but most often a do-it-yourself grinding machine is made to perform specific grinding operations.

Before building a grinding machine, you need to decide:

- with the type of processing: parts of arbitrary configuration will be processed or the machine is needed for highly specialized processing;

- with material for making the machine body;

- with engine: power, speed and drive type.

You also need to come up with a scheme for feeding and positioning the workpiece, otherwise the grinding accuracy will “float” every time.

The last two points are the most important. The quality of grinding depends on how the working tool is configured and the workpiece is fed. It is clear that for grinding a couple of dozen wooden slats or planks, a flat table is enough, plus feeding the workpiece by hand.

But if you need to grind precisely, for example, metal parts, the same key blanks or valves for tuning the engine cylinder head, then additional devices will be required. One of the options for a homemade machine for grinding and tuning valves can be seen in the video:

The quality and accuracy of grinding depend on the speed of the electric motor, the runout of the shaft bearings and the ability to “hold” the load without a strong drop in the spindle speed. The engine is the most valuable and important part of the machine.

Therefore, for home-made grinding machines, mainly high-speed motors with high-precision bearings are chosen. For the first experience, you can use an angle grinder or the engine of any household appliance, but always with a reinforced bearing group.

The most difficult to construct are machines for flat grinding of metal workpieces. You will have to master welding, but the capabilities for grinding work with such machines are much higher.

We read:

- Sanding walls after puttying

- Sanding concrete floor

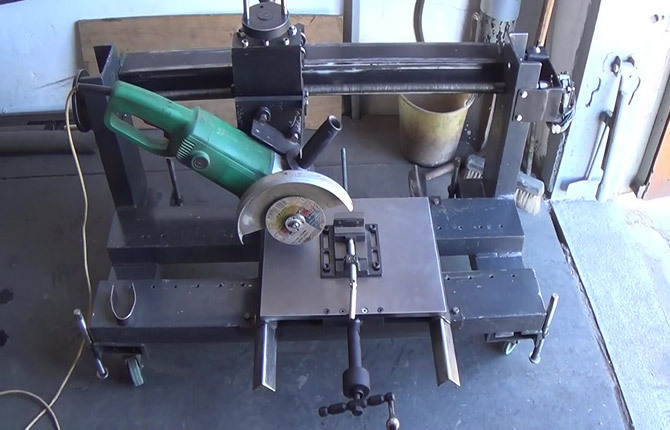

Disc grinding machine

This is a simple grinding machine, assembled practically from spare parts from various devices and mechanisms. For example, two connecting rods from the crankshaft of a car engine are used as consoles. Custom parts are used to a minimum in the design. But at the same time, the grinding machine provides a fairly high precision of flat grinding.

First you need to make a tripod or stand. For the base, a piece of channel No. 15 will be used, in which you will need to drill holes for attaching a vertical stand.

Any cylindrical rod or bracket with two threaded sections at the ends can be used as a rack.

You will also need an adapter flange; it is needed to increase the rigidity of the vertical rack mounting.

The two parts are connected to each other with four bolts and reinforced with an additional nut on the thread of the stand.

The next step is to assemble the rotary console. You will need two connecting rods in a set plus a piece of thick-walled pipe with a diameter of 60-61 mm.

Inside the pipe at the ends you will need to make a groove for installing two thrust bearings.

A piece of pipe with a diameter of 22 mm is inserted into the connecting rod heads. You also need to make a groove inside this part, and then press in a pair of high-speed bearings.

An axle with a flange for attaching the grinding wheel is inserted into the bearings. Since the machine is desktop and low-power, the diameter of the disk should not exceed 80 mm.

For assembly you will need an additional spring; it dampens vibrations and presses the console into the upper position. A coupling with a vernier can be screwed onto the upper section of the thread. These are used in drilling machines. This will make it possible to more accurately regulate the rise of the console and the height of the wheel insertion during grinding.

On the upper part of the axle with a mounted grinding wheel, you need to attach a pulley under the toothed belt. This type of drive does not look very reliable, but for a grinding machine it is an ideal solution, since the belt drive perfectly damps all vibrations. These gears are used in all professional grade benchtop grinding or turning machines.

All that remains is to install the electric motor. In this model, a 24 V DC motor with a power of 600-800 W will be sufficient for grinding. The electric motor is typically bolted to a solid aluminum or steel plate directly to the connecting rods.

Tabletop machines for flat grinding are considered a rarity; everyone involved in modeling willingly buys them. In a home workshop, you can use a machine to grind 50x100 mm workpieces, as well as sharpen knives, scissors, and any cutting tool. The accuracy of the machine is within a tenth of a millimeter.

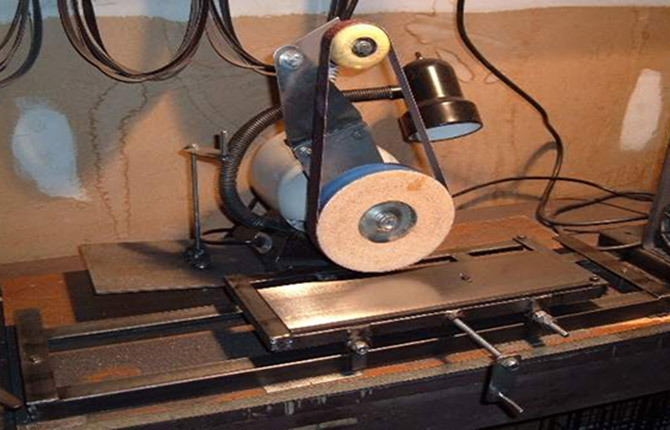

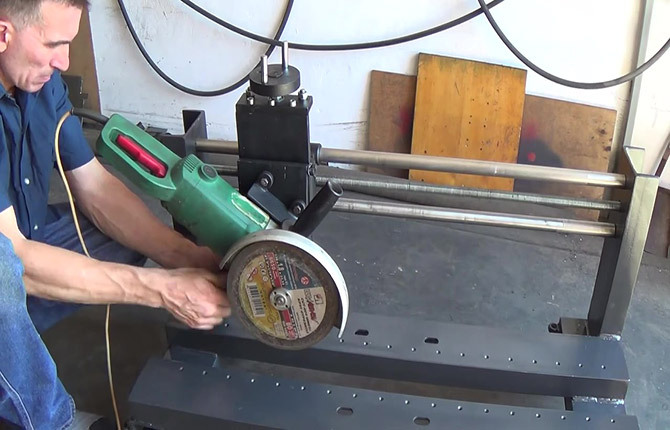

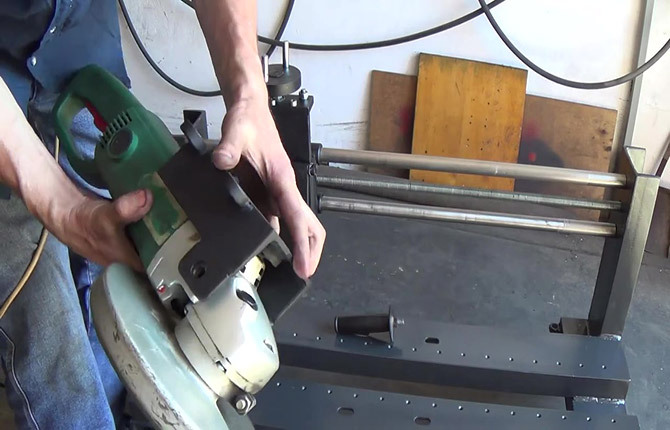

Grinding machine from grinder

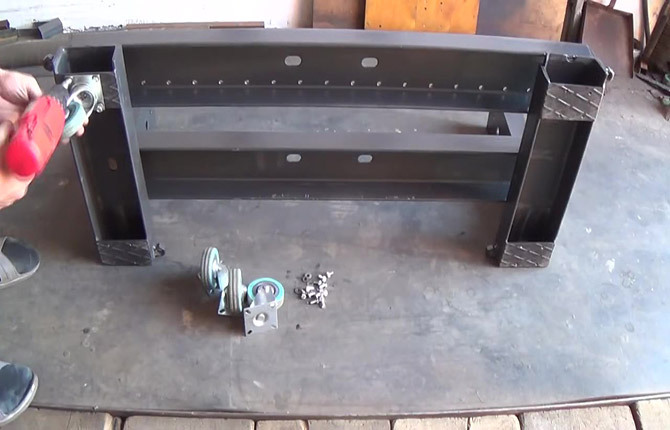

The next model can be classified as a high-end amateur version. The grinding machine turned out to be quite bulky and heavy, since most of the parts, except for the grinder, are made of a profile pipe and channel. The quality of polishing is even higher than that of Chinese models for amateur modeling, by 200-250 thousand. rub.

The grinding machine bed is assembled from two short and two long sections of channel. Connections are made by welding.

Two vertical posts are welded on the back side of the frame; they can be cut from a channel, but it is also possible to use a 50-60 mm square pipe. If you plan to grind fairly long parts on the machine, then it is better to use a channel.

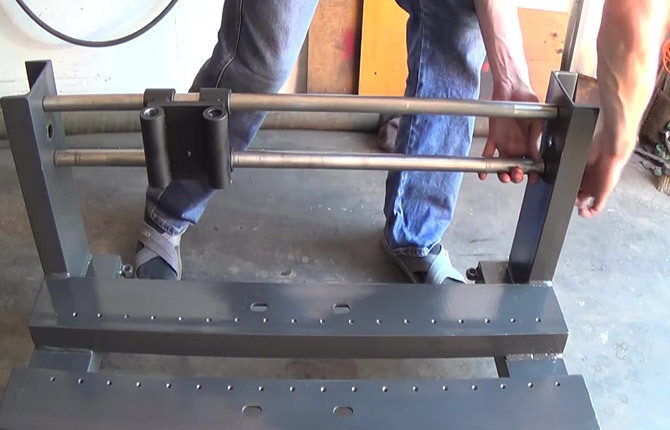

Two longitudinal guides are cut between the vertical posts; they can be made from water or gas pipes. Each must first be turned on a lathe to give the correct geometry. A longitudinal feed sliding support is placed on the guides. It is also assembled by welding from sections of pipe blanks.

To drive the caliper, a screw with a thrust thread is installed.

The most difficult part of the machine is the slide. It is used to fix and hold the grinder. In addition, the height of the tool lift above the grinding plane is adjusted using the slider.

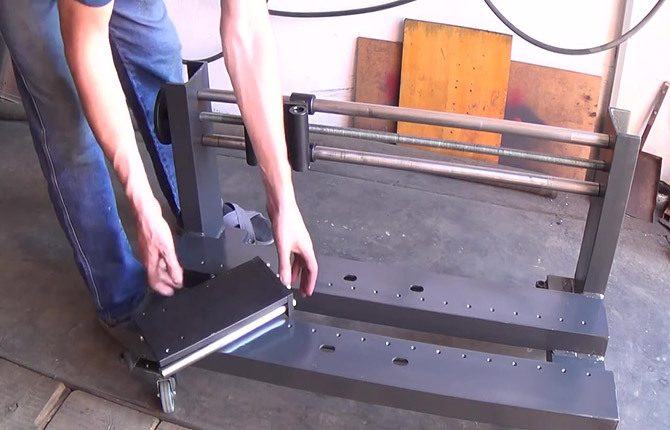

A mount is mounted on the slide to fix the grinder. In this case, grinding will require a powerful 2.5-3 kW tool. The grinder is attached to the caliper without any modifications; the handle is simply removed.

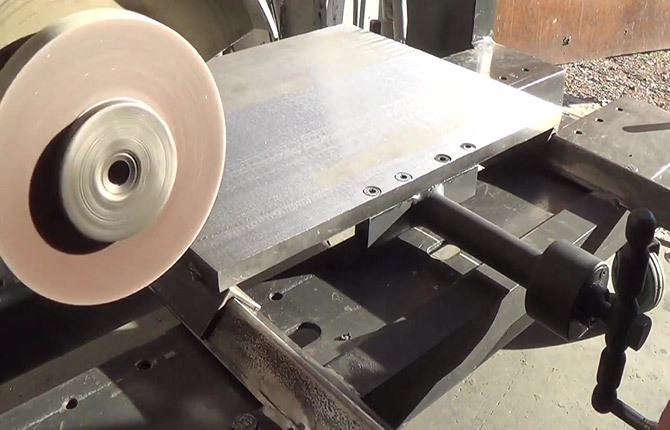

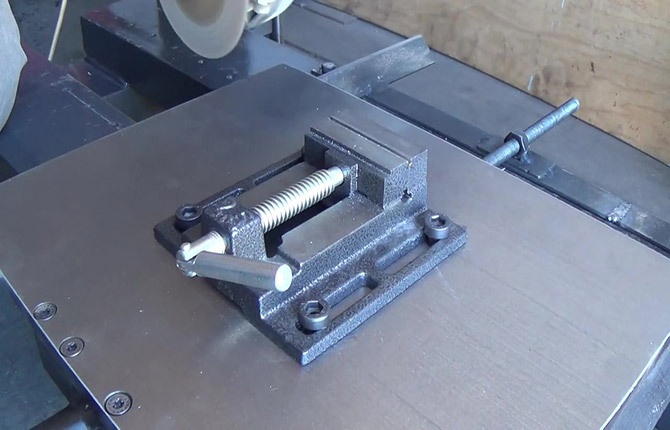

Two corners of 25-30 mm are welded onto the frame. A 600x600 mm steel plate will be installed on them to ensure straight sliding; a couple more corners will be welded to the back side of the plate.

To ensure transverse feed when grinding flat parts, a screw pair with a thrust thread is attached to the table. This will make it possible to move the work table and grind the plane with longitudinal passes.

Before final assembly of the machine, a disc for rough grinding is put on the grinder and the top layer of metal is removed from the plate. This is necessary to level the working surface of the table.

Now you need to install a vice from a drilling machine on the plate, and you can grind steel workpieces measuring 50x50 mm or single parts up to 800 mm long.

DIY drum sanders

For grinding wooden panels, boards, planks, two types of machines are used: disc and drum. For a disc machine, special large-diameter circles with sandpaper glued on are used.

With such equipment, it makes sense to grind only if it is necessary to ensure a certain angle of inclination between the flat base and the surface being processed. For example, if you need to grind to adjust the geometry of a wooden box made from sheets of plywood or boards.

In other cases, drum grinders are mainly used for home workshops. Processing is carried out using a drum, onto the cylindrical surface of which large-grain sandpaper is glued.

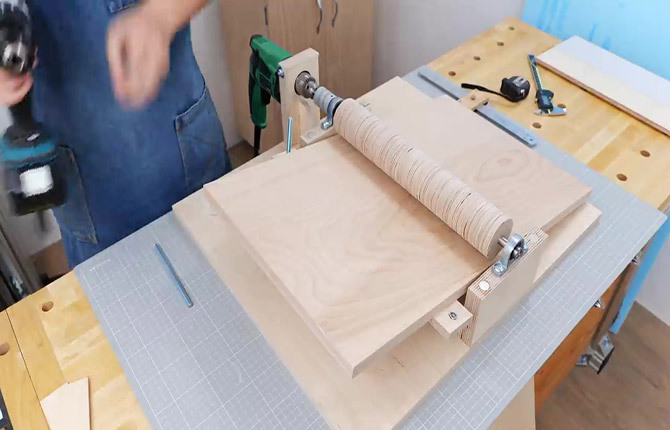

Drum Sanding Machine for Wood Panels

The simplest version of a woodworking machine is easiest to make from pine plywood 12-18 mm thick. The capabilities of such a machine allow you to grind prefabricated panels and trim the ends of planks and slats.

A special feature of this design is the use of a double table. The bottom sheet is used as the machine bed; it is cut from 18 mm plywood, size 65x65 cm. The second - the top sheet, also 18 mm thick, is made in size 50x65 cm, it is attached to the first with the help of window awnings.

This design makes it possible to change the installation height of the top sheet. This is important for adjusting the vertical sanding size of the wood.

The drum itself will be installed on two vertical supports 35-36 mm thick, each glued together from two pieces of plywood. At the end, holes are drilled for fastening with self-tapping screws to the frame. In addition, a couple more holes will be needed to fix the bearings.

The tool for grinding - the drum - is assembled from individual discs cut out of plywood with a ring drill. The discs are glued with PVA and assembled on a shaft.

After turning the drum, bearings are put on the axle and installed on the vertical supports of the machine. Since the main load during grinding is directed vertically, it will be enough to fix the bearings with clamps made of steel strips or use a steady rest.

A compensation coupling is placed on one end of the drum axis, through which the electric motor shaft will be connected. In this case, a screwdriver is used, since when grinding it is important to be able to regulate the rotation speed.

You will also need to make a support for mounting the electric motor itself or the screwdriver.

Now you will need to make a device to adjust the feed height when grinding. To do this, a strip is glued to the back of the top sheet, and threaded rods are screwed into the ends of the strip. This is enough to adjust the grinding height on the machine within 50-80 mm.

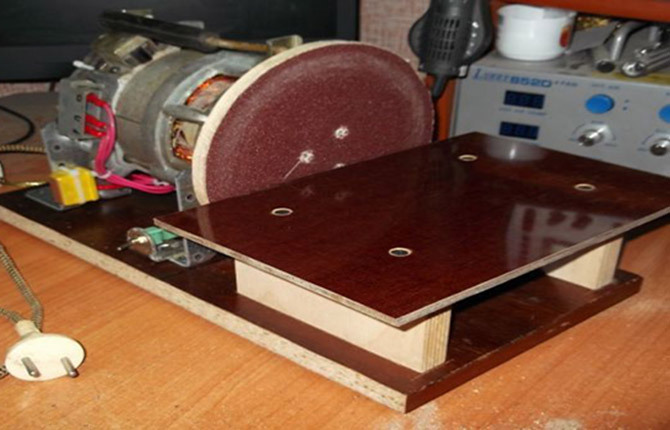

Drum sander made from electric motor and plywood

In many cases, sanding wooden parts is much more convenient when the drum is positioned vertically. A machine with a vertical drum combines the advantages of drum and disk grinding methods.

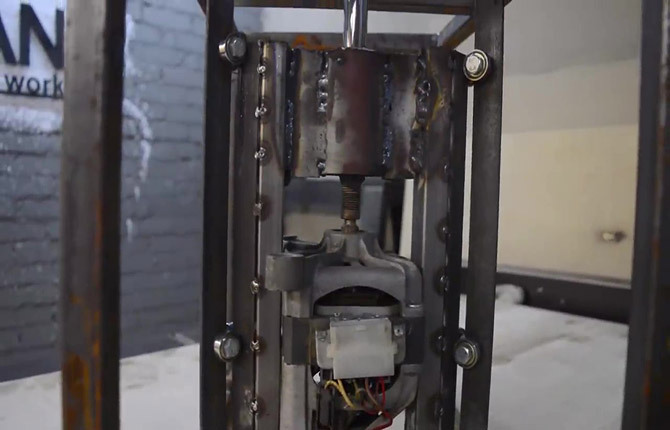

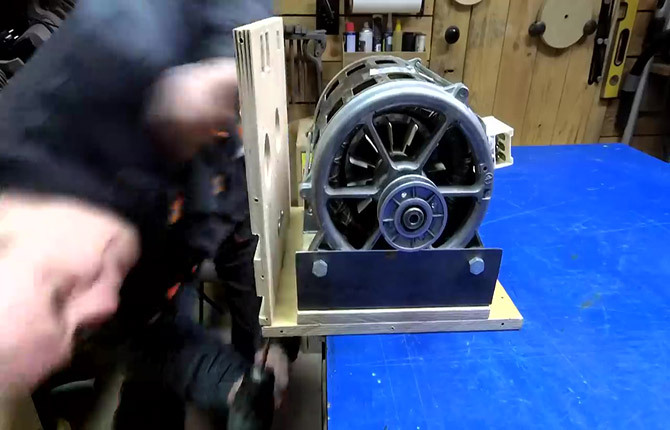

The drive for the machine is the motor from the washing machine. It will need to be installed vertically, inside a steel frame welded from a square pipe.

An additional axis is mounted on the electric motor shaft, which will rotate the drum during grinding. In order not to break the motor shaft, an intermediate bearing assembly has to be made for the axle.

The frame of the machine is covered with sheets of thick pine plywood.

The upper part - the desktop - will need to be made with a replaceable insert. This will allow you to change the drum to a tool with a larger diameter if necessary.

For your information! Some hobbyists make a rocker drive for the axis, thanks to which the drum can make vertical movements during grinding.

It is believed that this method reduces the wear of sandpaper, but at the same time the quality of processing on the machine decreases significantly.

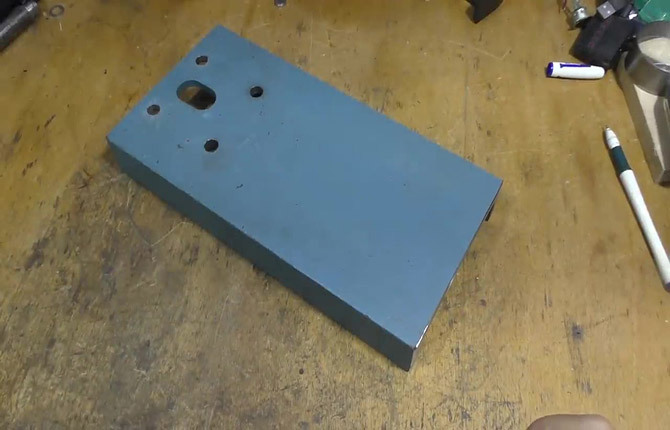

Grinding machine made from spare parts from a washing machine

In some cases, a device with additional functionality is required to perform grinding at a precisely selected angle or inclination of the surface being processed relative to the plane of the working tool. This is one of the most successful machines for grinding anything that can be found in a home workshop.

Grinding machine device

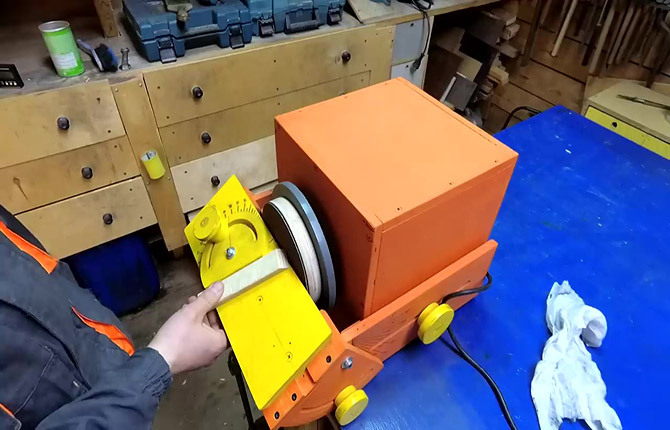

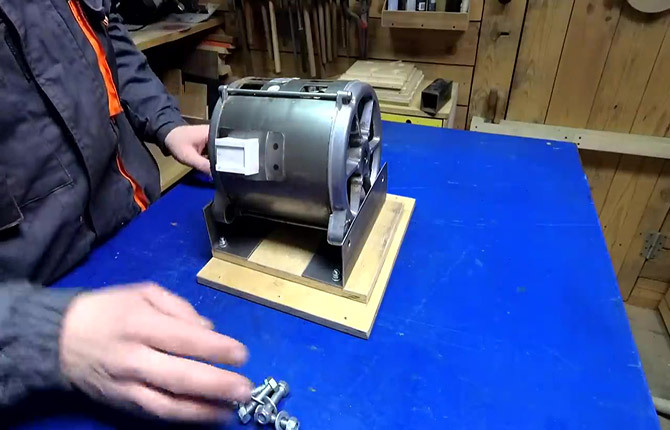

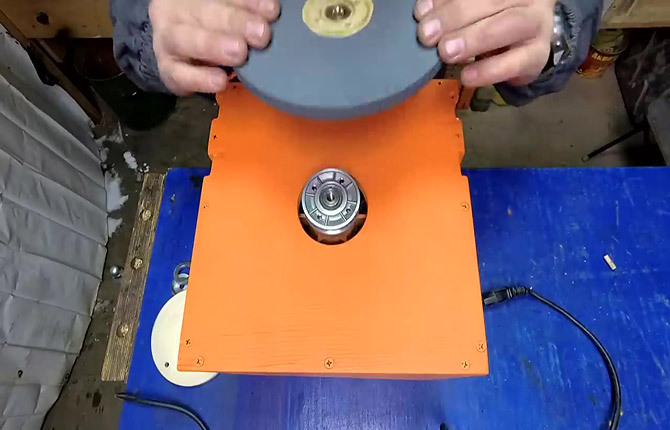

The design of the device is based on an electric motor from a washing machine with a flange. This unit was taken entirely from the washing machine along with the controls.

The engine is installed in a plywood box for several reasons:

- the box serves as a supporting frame or machine bed;

- engine noise is reduced;

- protects the electric motor from abrasive dust generated during grinding.

Another box is the basis for installing a hanging table. Many users claim that a rectangular box is more convenient to store and carry than if the machine were assembled on a metal welded frame.

Machine assembly

First of all, you need to cut blanks from plywood for all six walls of the box, and make ventilation holes in the side walls. In addition, on the sidewalls you will need to cut two horizontal grooves on each side.

A wooden lining is placed on the bottom part, then a pair of steel corners are sewn on, to which the electric motor itself is directly attached.

A 250 mm adapter washer with a 25 mm adapter flange is screwed onto the electric motor shaft, this makes it possible to install all grinding wheels intended for use in Bulgarians

Manufacturing of fixtures and assembly

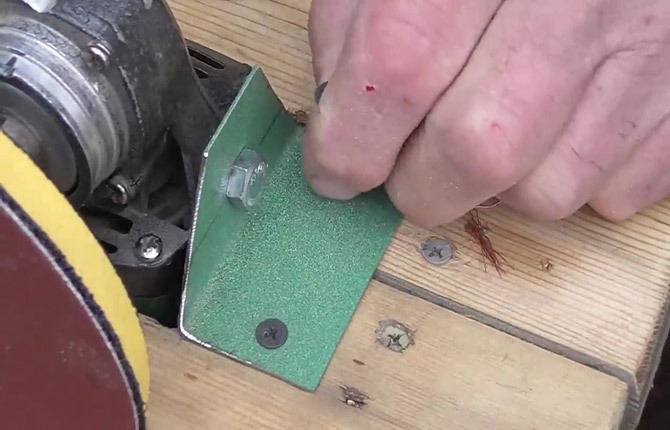

Separately for the machine, you will need to make a U-shaped retractable table. The table is inserted into grooves on the walls of the machine body, extended to the desired size and secured with a screw.

What does it give: When grinding on a wheel, the part has to be held suspended by hand, which greatly reduces the accuracy and quality of the work. The conditions are not the best. Grinding slats in weight is not difficult, and if you need to sharpen a drill, you can’t do without a table.

Another device with an angular scale can be mounted directly on the table. In this case, in addition to regular grinding, you can sharpen various cutting tools. You will have to make a set of grinding wheels yourself and periodically update them as the sandpaper wears out.

Grinding machine from a gearbox from a small angle grinder

Sometimes during the renovation process, for example, at a dacha, it is not possible to bring a full-fledged grinding machine. Although the need to polish or sharpen a workpiece arises periodically. In this case, you can make a small device-machine for grinding small parts.

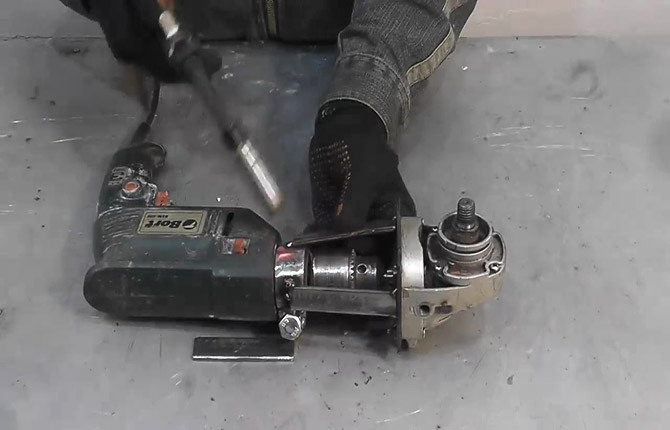

All you need is an old 500-700 W angle grinder, self-tapping screws, a jigsaw and a couple of corners. Many old angle grinders have a gearbox life that is much longer than the electric motor, so an angle grinder, even in the form of a device, can last for a very long time.

First you need to choose a location for the machine. Typically, the grinding fixture is made on a work table or the nearest suitable tabletop.

First of all, you will need to cut out two corners with which the machine will be attached to the tabletop.

Then, using a jigsaw, you need to cut a hole for the working part with a flange. On the gearbox of any angle grinder there are two threaded holes for screwing the side handle. The holes are located on opposite sides, so they can be used for attaching to corners.

All that remains is to install the machine on the tabletop and secure it to the boards.

Instead of a cutting wheel, an abrasive wheel is mounted on the shaft. Now you can sand small pieces of wood, such as the handle of a shovel.

Useful homemade product for the workshop from a broken grinder

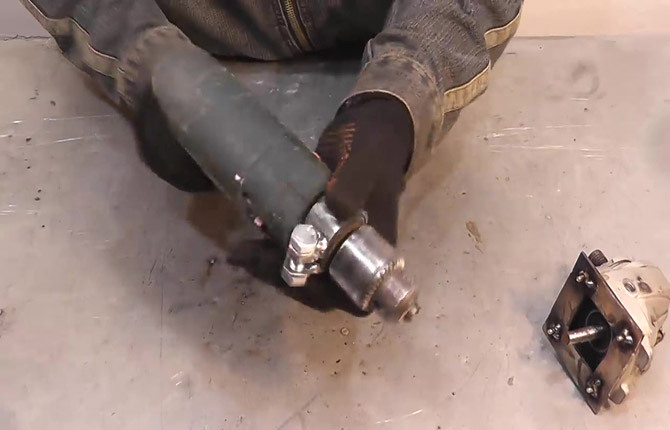

Often, after several years of operation of an angle grinder, only the bevel gear remains operational. If the workshop has a welding machine and several strips of stainless steel, then you can easily build a useful device for an electric drill from a useless grinder.

First you need to remove the USHV housing, leaving only the gearbox. Since all grinders have a gearbox cast from aluminum alloy, you need to make an adapter from stainless steel. Secure it with bolts to the body and secure it with welding.

The future device somehow needs to be mounted on an electric drill, so you will need to make a loop-clamp for an M18 bolt. Next, the gearbox shaft is inserted into the chuck and fixed motionless on the table. Now you need to connect the flange on the gearbox to the clamp. The easiest way is to weld four strips using electric welding.

The next step is to attach an additional plate with a welded M12 nut to the device. The side handle from the grinder will be screwed into it.

After assembly, the device can be painted, a cutting disc from a circular saw can be installed and tested in operation. An electric drill with a gear attachment cuts much faster than a jigsaw or hand saw.

Results

It’s not difficult to make a grinding machine with your own hands, but the work will require careful and precise cutting of the material. In addition, you will need to choose the right stone for grinding, since not all grinding wheels can withstand high speeds.

Tell us about your experience building grinding machines. What model would you recommend for a home workshop? Also save the article to bookmarks and share it on social networks.