The optimal solution of all the options for heating devices at home, in terms of energy costs and ease of maintenance, you can call the gas equipment.

If you want to not only heat the room, but also provide the house with hot water, then the best choice would be double-floor gas boiler, capable of serving as a compact home and spacious apartments.

The purchaser is not an easy task. Agree to orient heating units is difficult enough in a variety of proposals producers.

We will help you to understand the device and the specifics of the different models, we denote the basic parameters of the competent purchase and give practical advice on choosing a gas boiler.

The content of the article:

- Convection or condensing boiler

- Power Type: non-volatile or not

- heating principle: flow or storage

-

Materials for the heat exchanger: which one is better

- Steel embodiment exchanger

- Copper heat exchanger type

- Boilers with cast iron heat exchanger

-

Choosing the type of equipment for smoke removal

- Boilers with flue type smoke

- Parapet boiler: design features

- Turbocharged boilers

- Methods ignition bypass boiler

- The use of heat transfer fluids in boilers

-

How to choose the power of the boiler bypass

- power calculation formula

- automatic modeling function

- What else you need to pay attention

- Conclusions and useful videos on the topic

Convection or condensing boiler

What you need to know about the characteristics of such equipment, its design and operating characteristics, try to understand.

Conventional gas outdoor heat boilers used for heating the heating medium obtained by the energy which is released in time of gas combustion. A large amount of heat with steam and flue gases out into the atmosphere.

The efficiency of the convection gas boilers is expressed in terms of efficiency and frequently does not exceed 85-90%

Though convection heaters and are not considered the most effective in terms of cost, their existence in the market of heating equipment justifies a number of advantages. These include simple design, reasonable cost, compact size, easy installation and maintenance.

Condensing boilers are considered the most efficient and productive - they are 20% more efficient than convection heating devices. A higher efficiency is obtained due to the additional heat exchanger, which uses more energy and steam (+)

One disadvantage of condensing boilers can be considered as relatively high cost. The last factor, however, quickly pays for itself, because there is an appreciable reduction in gas consumption. The second is the difficulty of disposing of the condensate, which can not easily be drained into the septic tank, not to destroy bacteria wastewater processing.

The operating principle of a bypass condensing boiler to reduce gas flow rate, receive more energy at the equal fuel consumption (+)

Power Type: non-volatile or not

The principle of operation of the boiler volatile following: Automatic fixes installed using activation of sensors or equipment DHW temperature drop in the heating circuit and comprises heating.

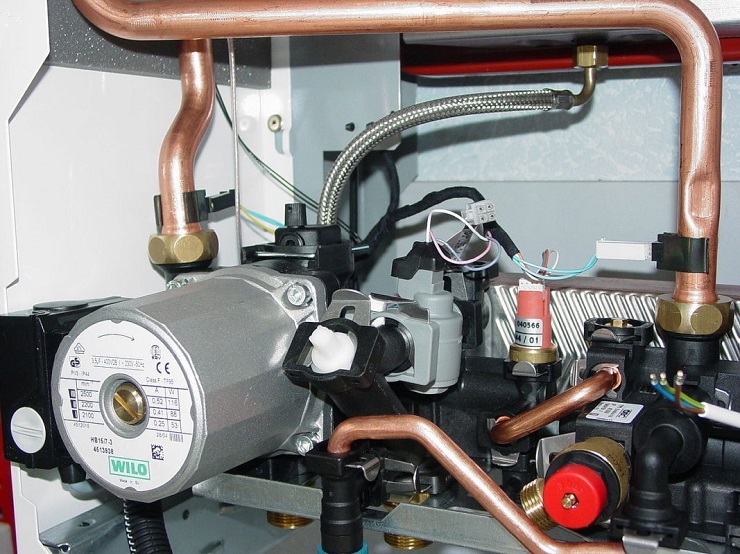

The heat medium passing through the heat exchanger is heated to the desired temperature and fed to the heating system or hot water circuit via circulating pump.

It is clear that the volatile device will consume energy. To reduce its consumption, it is best to choose a model with the class A ++ energy. But, apart from energy consumption, it is necessary to take into account the cost of repairs, replacement parts, automation.

For example, failure of electronic circuit board - a fairly common phenomenon, the repair is expensive, and replacement parts to the new cost about half the cost of the boiler itself.

Volatile boilers more manufacturable, they maintain a certain temperature mode saves more gas

But nonvolatile model can be called the most adapted to the conditions, when the electricity is turned off, and power fluctuations cause to worry about the integrity of automation.

heating principle: flow or storage

Flow principle of heating may be two types of heat exchangers:

- split;

- Bithermal.

Both of them have both advantages and disadvantages, so the choice may depend only on the buyer's equipment and its preferences.

Boiler with a separate heat exchanger It has a primary (for heating) and secondary (used for water heating) heat exchanger. The secondary heat exchanger has an integrated circuit which serves for heating water, which is heated, taking heat from the heating circuit a coolant.

This type of boiler can not simultaneously operate in the heating mode and the water heating as soon as the work is included in one system, the second job is suspended.

The disadvantage of double-flow boilers floor is overrun cold water, which would drain before the valve begins to flow in the warm. Also, when using water from two or more points simultaneously - the pressure in the hot water system to be uneven, as the temperature of water in the taps (+)

The bithermic heat exchangers water heats the burner, located in a tube which extends inside the main heat exchanger. In such equipment, the water heats up much faster. Such boilers are compact and cheaper.

Significant disadvantage bithermic boilers is a temperature drop in the hot water. This leads to the fact that immediately after the opening of the crane can go very hot water.

For those homes where consumption is not so high, the work of combi boilers is fully capable to provide the minimum requirements in the warm water. But if the consumption planned in large quantities, it is better to provide a more powerful version - Boiler connecting the boiler, which will accumulate a certain reserve of hot water (+)

Combi floor gas boilers with built-in tank, in contrast to the flow models can provide water to the full. Displacement tanks varies from 25 to 60 liters. To heat large volumes of used devices with high power. Even greater performance possible with the help of boilers incorporated in the cascade.

Materials for the heat exchanger: which one is better

Exchanger plays a major role in the design of gas heating devices - circulating coolant therethrough. The most common materials used in the manufacture of heat exchangers for gas-fired boilers, - copper, iron, steel.

Steel embodiment exchanger

The cheapest, and as a result, demand for the heat exchanger material is steel. Therefore, it is actively using domestic manufacturers in order to reduce the cost of the final product. In contrast to the iron it is alien to the fragility.

Compared with the iron steel it is much easier, but when compared with copper, is considerably greater than its heavier weight and structure of the boiler.

Steel coil rapidly heats and cools. Apart from convenience, this leads to negative consequences - "fatigue" of the metal causes damage. The downside of the steel is also susceptibility to corrosion.

During operation, corrosion is exposed and the inner and outer side of the steel heat exchanger. Over time, this leads to its destruction

Copper heat exchanger type

The material has many beneficial properties - resistance to corrosion, small volume, low inertia. Because of the compactness and light weight of copper is actively used for the production of light wall-hung boilers.

Corrosion - one of the main qualities for heating equipment, which is designed to heat process water

Opinion about the fragility of the copper heat exchangers have long refuted the manufacturers of modern heating equipment - They burner power is reduced by 30%, which reduces the thermal influence on the metal and is good for the duration work.

Boilers with cast iron heat exchanger

Superior quality cast iron, it should be noted that - inertia. The material is heated for a long time and a long cools than increases the efficiency of heat transfer.

This inertia can be considered as a positive quality, and negative - in the case of sharp warming on the street, the boiler will be a long time to maintain a high temperature in the heating system.

Cast iron boiler weighs twice as much steel, so the boiler design makes sectional, it was convenient to deliver, install and repair

Cast iron undergoes dry and wet corrosion. The latter contributes to the appearance of rust, but, due to the thick walls, the corrosion process stretched for a long time.

The disadvantages of cast iron boilers can be attributed to the fragility of the material, which is evident due to improper operation - in temperature, mechanical damage during transportation and installation.

Choosing the type of equipment for smoke removal

The method of flue gas output - one of the most important factors when choosing a gas equipment. It directly influences the choice of the model, and the possibility of its installation in a particular area. It is therefore important to explore options and choose the best smoke.

Boilers with flue type smoke

The combustion process in the boiler chimney type is provided by natural draft which utilizes air from the room. The required amount of air enters the combustion chamber through the open.

Cons chimney floor boilers bypass type:

- Efficiency of a few percent belowThan the turbocharged gas equipment - some of the heat emitted into the pipe with the smoke.

- Additional costs chimney construction. If everything is done correctly, according to government regulations, the need to obtain further permission, install the sensor that measures the level of carbon dioxide each year invite a specialist for survey.

- Active formation of condensation - modern equipment has a higher efficiency and gives little on the outlet exhaust gas temperature. As a result, especially if not insulated chimney, condensation, which leads to rapid destruction of the chimney walls.

- The need for sufficient ventilation. As a result, the combustion warm air from the room is drawn into the chimney. In the presence of the boiler chimney must always ensure forced ventilation.

Due to the nature and operation of the mechanism requires a separate abduction boiler rooms.

Advantages of the equipment:

- relatively low cost devices;

- a simple design, which is easier and less expensive to maintain;

- the ability to output the products of combustion at a greater distance from home.

Due to its cost, durability and easy operation, floor flue boilers are quite popular.

In cases when the house already have a chimney that is properly installed and running, experts advise not to spend money on more expensive models, and establish a normal fixed equipment with a connection to the chimney, open chamber combustion.

The chimney can be output through the wall or roof. When mounting is necessary to ensure proper and safe assembly (+)

Parapet boiler: design features

Parapet boilers can be identified as a separate category for their placement equipment, but there are also a feature associated with the withdrawal of the products of combustion. They differ from stationary gas boilers necessity coaxial connecting pipes for output of smoke.

Coaxial pipe system looks like, which is arranged in the pipe. Output flue gases takes place through the interior of and through the outer air is drawn from outside

Parapet boilers can be installed in the premises for any purpose, even in a multi-storey apartment house (if it has permission), anywhere - on a windowsill or under it, instead of the battery. The only limitation in this case - horizontal portion of the pipe length should not exceed 3 m.

In their characteristics and structural features reminiscent of coupling devices, but, unlike them, quite unpretentious in operation (+)

Turbocharged boilers

Sometimes, due to the absence of the chimney or the architectural features of the building, chimney equipment can not be installed. Then use a turbocharged boiler as a heating device.

This device, wherein the combustion process is carried out in a closed chamber, and the flue gases occurs forced through a built turbine, which can be adjusted by rotation speed - installed on the optimal pressure.

With proper adjustment achieve maximum turbo boiler fuel and increase processing efficiency. This leads to considerable savings of gas (+)

Disadvantages turbo combi boiler Floor Type:

- Another item of expenditure in case of breakage of the turbine;

- slight but additional noise, which produces fan;

- an increase in power consumption.

Compared to the chimney boilers, turbines consume about 50 watts more.

Advantages of the equipment are as follows:

- Versatility - the boiler can be installed in virtually any room (a private house, apartment).

- No access to open sources of fireIt decreases the likelihood of carbon monoxide in the home penetration.

- No need to install a chimney. Turbine boiler has a higher cost, but because of the fact that it does not require installation of a chimney, its installation is much cheaper. Saving on the cost of the purchase of pipes and installation services covers much more expensive equipment costs.

- The boiler does not draws air from the roomAnd therefore, the heat losses are reduced. It takes air for combustion from the outside. Therefore does not require the equipment in the room ventilation (although, in some cases, the replacement of chimney boilers, turbo, no additional ventilation leads to a deterioration of air and increasing humidity house).

The differences between the various types of boilers exist, but in general they are all designed to operate safely and fairly high efficiency. Model selection is more dependent on the financial capacity and the specific operating conditions.

Methods ignition bypass boiler

No automatic ignition system is few comfortable use of gas heating equipment. There are two completely different principle, which can be used both for elektrozavisimyh and fully self-contained boilers - electrical and pezorozzhigom.

Automation unit for pezorozzhigom bypass gas boiler has a simple structure and the device resembles gas lighter (+)

pezorozzhigom method operates on the same principle as in the lighter ignition - pressing gives rise to a spark which triggers the process of combustion. Subsequently, the control so that the flame is not extinguished, made using thermocouples.

Burner element is heated, generating a current which holds the solenoid valve from collapsing. During the temporary suspension of the boiler still remains burning wick.

Pezorozzhigom often used in non-volatile boiler and is, in fact, a semi-automatic system. If the gas is turned off, the burner is extinguished, and the valve closes, stopping the further flow of gas. Restart the boiler by pressing the button.

Electrical ignition provides full automation - heating device starts with the appearance of a spark and the flame control is carried out via control of the ionization unit. When power failure is triggered automation, it overlaps the gas, and when the operation of the boiler starts.

In such devices, there is no need to constantly burning ignition filter, and it is a significant gas savings. Eliminate the dependence of the boiler with electronic ignition power by using batteries.

The use of heat transfer fluids in boilers

If the country or in a private home is planned irregular residence or frequent and prolonged departures and plums and purging fluid from the system is not regarded as a viable option, it is necessary to prevent its freezing.

This can be done by adding antifreeze to the coolant - substances that do not freeze to some negative temperature, and in the case of still lower temperatures does not harden and turn into gel substance without increasing in volume.

Use double-circuit floor boilers running on gas, antifreeze, in most cases, is not recommended (for single-circuit boiler, these rules are less strict). The instructions clearly stated that coolant in the heating system It should be water.

If a user is at your own risk of flooding in the heating system is not prepared water, and any other solution, the problems that have arisen because of this, do not belong to the warranty case

Some manufacturers specify a particular brand of antifreeze, which can be used for filling in the heating system. As an example, a manufacturer of equipment Viessmann It recommends the use of coolant brand Antifrogen.

Others point out that, as an exception, you can use anti-freeze, if the manufacturer guarantees that the device does not harm the components and materials of the boiler, in particular a heat exchanger. It should be borne in mind that for a particular model can go a coolant and did not approach the other.

Therefore, if it is important that the heating system as a heat transfer medium used antifreeze is necessary in advance to purchase determine whether, and if so, what brand of coolant is allowed to use for a particular make and model boiler.

How to choose the power of the boiler bypass

One of the most important indicators that you should consider when buying gas heating equipment - power.

It should be borne in mind that the boiler is too powerful would lead to cost overruns fuel gas, and the lack of capacity of the device is not be able to provide a comfortable temperature, or the equipment will operate at maximum capacity, and quickly out of system.

power calculation formula

Achieve accuracy in calculations is hardly the strength to the ordinary user, but approximate figures can try to get. For a basis it is necessary to take the specific power of the heating device, designed for a specific region, multiplied by the heated floor area and divide by 10.

Specific boiler output is calculated for each region separately. To find out the record for a particular premises, it is necessary to use (+)

The obtained result - a required power boiler in ideal conditions.

Depending on the features of the room to be amended:

- Improvement to a height greater than 2.8 m per 10 cm of the above initial value to be increased by 3%;

- two walls facing the street, means that you need to hold the power increase of 15%;

- unheated rooms requires an increase in the top index by 12%, from the bottom - 7%;

- if all of the floor space glazing takes more than 8%, then for each excess of 1%, 1% power;

- the outer door, which opens systematically increases heat loss by 15%.

When buying outdoor bypass gas boiler, whether outdoor or pendant, You need to add another 20%. After all the calculations it is also recommended to add a small power supply - so the load on the device will be smaller and it will last longer.

automatic modeling function

It is better that the boiler was selected not only on the level of power, but also has a function of its adjustment. There are devices with single-stage, two-stage and simulated power. Models of the last two types are more efficient to operate, as they have the ability to adjust.

Since the need to work at maximum output is no more than a third of the winter season, the possibility of adjustment can significantly save on heating and extend boiler life time

If the boiler has an automatic power control, it is not simply switched on and off the time when it reaches the preset temperature, it reduces power independently to minimum.

If the work turns out to be redundant, only then the unit enters on-off mode in the minimum temperatures.

Automatic modeling of power increases the energy savings, effectively affects the durability of the equipment and increases user comfort.

What else you need to pay attention

Also power boilers weight Performance affect the operation of the gas heating system.

The following parameters require particular attention:

- The amount of gas consumed floor two-planimetric gas boiler. Select economical model is possible by comparing the product with the same capacity.

- efficiency. One of the most important factors affecting the economical use of energy resources. Increase over its work quite successfully leading manufacturers of gas appliances - in modern devices it reaches about 100%.

- Performance hot water circuit. The indicator may be from 2.5 to 30 l / min.

- electricity consumption in volatile equipment. On average boilers can consume about 2 kW per day. A month would be about 60 kW

- The maximum temperature readings. The hot water system is about 55 ° C; a heating circuit - to 90 ° C.

- water pressure. The values in the heating circuit reaches 10 bar.

Determine quality equipment manufacturer among the many brands on the market, will only careful study and comparison of performance, user reviews, sellers, representatives, installation and repair and maintenance services, which work with gas boilers.

Keep in mind that the savings on the cost of the boiler can result in energy and repair costs, and the high price does not always meet the objective value, and includes a premium for the brand

Additional recommendations selection, evaluation of technical and operational characteristics of different models, as well as an overview of the best gas boilers are given in the articles:

- Floor gas heating boilers: types, how to choose, review of best brands

- How to Choose the good gas boiler: the criteria for selecting the best option

- Combi boilers: Types, operating principle, the selection criteria + review of the best brands

Conclusions and useful videos on the topic

The principle of operation of a bypass gas boiler:

How to choose a gas boiler:

Select Device for heating private house - a responsible and serious task. It is that trusting implementers gas equipment, have to pay for someone else's mistakes or "bail out" sellers obsolete technology.

The result is not at all or not quite what you expect to receive. Often, too late comes the understanding that deal in a variety of double-circuit characteristics floor gas boilers in their structural characteristics and parameters of the system work it would be necessary first himself.

We have experience in operating a bypass floor boilers on gas? Tell us which model you use to heat your home, what are the characteristics of her work. Share your experiences about the operation of equipment with our readers. Ask questions and leave comments on the article can be in the form below.