Quick and simple method of increasing the temperature in the room are various kinds of large heating units, which include a heat gun for waste oil.

Such devices allow for even a short time to heat large areas, most often used for heating workshops, garages, auto centers, other service and manufacturing facilities, which accumulates a large number of mining.

In this article we consider in detail the principle of the heat guns, their varieties. Also give some popular manufacturers of equipment and explain how to make the heat gun with their hands.

The content of the article:

- The general principle of guns

- Main characteristics of the device

- The required power rating

- Features heat guns on working out

- Types of aggregates waste oil

- Advantages and disadvantages of working out on guns

-

Gun on working off their own hands

- Heater apparatus homemade

- The necessary parts and materials

- Mounting devices for working out

- Tips for using heat guns

-

Manufacturers of heat guns on working out

- Kroll - true German quality

- Master - a company with fifty years of experience

- EnergyLogic - heaters Waste oil

- Hiton - budgetary instruments

- Conclusions and useful videos on the topic

The general principle of guns

The designation "heat gun" means mobile heat generators that can quickly carry more heat out.

Such devices have the name as per the specific elongated shape and a powerful jet of hot air coming out of the specially designed holes.

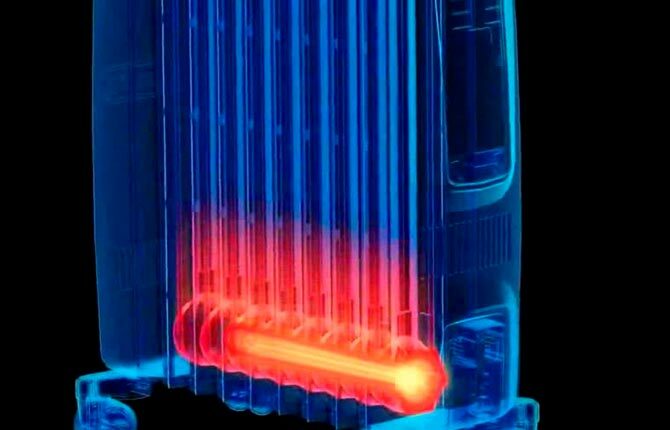

Schematic representation of heat gun design. The models run on electricity, the fuel tank is replaced by a powerful TAN - Tubular heaters

The principle of operation of various types of such devices is as follows:

- The main component of such devices is a heating member (heater burner). It is housed in a metal case. The device begins to generate heat only after it starts, or ignition.

- Powerful built fan drives air through the interior of a flow whose temperature is raised by contact with the heating component.

- The hot air mass is pushed through with force out the gun nozzle, allowing a few minutes to warm up even the large room.

As fuel for the guns can be used various fuel: electricity, hot water, diesel fuel, liquefied petroleum gas, waste mineral and biological oils. Depending on the used fuel design models may be slightly different from each other.

Main characteristics of the device

For quality production models of heat guns are characterized by the following features:

- strength and reliability in the operation;

- resistance to mechanical damage, thermal jumps, occurrence of corrosion;

- water resistance, whereby such heaters may be used for heating spaces with high humidity;

- durability - with proper operation of the device may be for 5-10 years or even more, without requiring special maintenance and repairs;

- great lineup; manufacturers produce both small mobile fan heaters used for domestic purposes, and large stationary devices that are useful for heating large spaces, such as manufacturing plants or warehouses.

It should be remembered that the use of a heat gun is necessary in ventilated areas with the air supply system or with a regular airing.

The required power rating

The main index of the device is its capacity, because that depends on it the effective functioning of the device.

To determine the required heat transfer device at the same time it is important to take into account a number of factors:

- The volume of the heated space, which is sufficient for computing to multiply its parameters (height, width, length).

- The difference between the temperatures inside and outside the premises.

- Heat loss coefficient, which depends on the thermal insulation of the room. The average value of this index is equal to 1-2, while the non-insulated building has a coefficient of 3-4, and a well insulated house - 0.6.

The minimum value of the required power, denoted in kilocalories per hour, can be obtained by multiplying the values described above.

In order to transfer a certain number in kilowatts is sufficient to multiply the number by a factor of 0.001163. This value and the need to keep in mind when choosing a ready instrument in the store.

Features heat guns on working out

Construction units functioning in used oils, are very similar to other types of guns. Their feature is equipped with a burner of the combustion bowl, which is a fuel supply (or other engine oil) using a rotary pump.

The circuit operation of the heat gun at the working off supercharged and blowing, the external oil pump, two-pass and the control unit

Under the influence of heating combustible substances burn, this generates heat and combustion products, which are output outside the room through specially provided for this purpose chimney.

Different models may have their own design features. In some two fans provided, of which one heats the combustion chamber, another delivers fresh air to the chamber. In other uses external oil pump by which the fuel enters the combustion chamber.

As fuel for working out heating furnaces can also be used become unusable biological oils, in particular frying hopelessly rancid

Oil guns are considered safe for people and pets. They can be used for heating garages, warehouses, greenhouses and other buildings. Permission for their use is not required, but in their application need to comply with fire safety regulations.

Types of aggregates waste oil

Similarly, the gas and diesel guns, devices operating on working out, can be of two basic types: direct and indirect action.

In the models of the first type (direct heating) Within-the housing is a circular cylinder gas burner, which on all sides is blown by the air stream flows from the fan. The heated air mass in conjunction with the products of combustion discharged through the pipe disposed on the opposite side of the gun.

Cannon with direct heating has a higher heat, but when it works in the room fall into harmful substances. This shortcoming deprived model of the indirect action

Since the waste gases contain harmful to human health and animal substances, guns are recommended only in well-ventilated spaces. direct heating apparatus can be used to maintain a comfortable temperature in deserted areas: buildings, garages, workshops.

Constructions heat guns second type (indirect heating) Are provided with integrated system allowing to separate flue gases released during the combustion of oil. At the same time, the heat is transferred from them is blown air blower that accumulates in provided for this purpose the heat exchanger, thus avoiding direct contact between the gas and air masses.

After the last heat out of the heat exchange chamber through a special opening fitted in the housing, while combustion products leave the gun through a side branch pipe which is connected to a chimney pipe.

indirect heating ecological models differ in their use in a room does not get harmful gases, and the lack of odor, making these devices suitable for space heating in the presence of people.

All the heat gun on working out can also be divided into the following categories:

- stationary - high power devices, which are mounted on one place and is connected to a chimney.

- Mobile - compact devices that can be moved around the room. Typically, they are direct heating and low power, as heat transfer devices with a large scale is isolated many combustion products.

Apparatuses that operate on waste oils differ in size, shape, design, availability of extra features.

Advantages and disadvantages of working out on guns

Oil heaters have their positive and negative sides. At the guns of this type has many advantages.

They universal: Thermal units can work not only on mineral oils (heat, motor), but also in other types of fuel, such as a biological oil or mixtures of combustible substances. Not only allowed the use of the transformer and other oils with a density greater than 90 on the SAE scale.

Heating devices, the functioning of which various waste oils used, can dispose of waste transport of fuel, polluting

They cheap: Waste mineral or biological oil, which is used as fuel for thermal heaters such models, it can not be restored, and is a waste of production. It can be purchased at a minimal cost.

devices have high efficiency. The efficiency of modern models thermal devices can reach 100%.

Heat guns of various kinds are widely used in everyday life and in the economy. They are used for extra heating of housing, maintaining a comfortable temperature in the public and industrial buildings, greenhouses

the device does not emit odors, soot, so the air in the room is always clean when using the indirect heating models.

However, when burning fuel in appliances release carbon dioxide, the amount of which depends on the power of the device. Due to the high content of CO2 a gun with a large exhaust heat dissipation it is desirable to "bind" to the flue through which combustion products are displayed, so high-power models working off almost always stationary.

Gun on working off their own hands

The design of the heat gun is simple enough, so having some work skills, you can try to collect such a machine by yourself.

Heater apparatus homemade

To perform the self device can use the simplified diagram of the heat gun. The fuel tank is located lower part of the structure over which there is a fan and the working chamber. In the last fuel is supplied, while the fan brings in a hot air room.

Self-made thermal device for working out much cheaper than purchased in a store, but its technical characteristics somewhat lower

In addition, the device provides a pump, the filter and the connecting tube through which It passes the fuel injector for the combustion products exit for the heated air pipe and a number of other elements.

The necessary parts and materials

Before starting work, should stock materials or finished components of the device.

In the manufacture of the heater heat waste oil in the housing may be used as the cut-off portion of an old gas cylinder

Casing heat gunFor which a thick walled metal must be used. As this part, for example, fit the appropriate size of pipe section or another suitable article. It is also possible to make a casing of stainless steel sheet thicker (3-4 mm), heat sealing seam.

The combustion chamber. Under this item suitable metal cylinder whose diameter is twice less than that of the housing.

Fuel tank. This element is a cup made of a material having low thermal conductivity. Suitable and conventional metallic container, carefully closed insulator.

The fan, which is required for the device on the tool working off the heat, can be purchased in a store, or use the existing device provided it is a good condition

Fan. For simplicity and reliability of construction and reliable use preferably cost-vane fan at 220 volts, which is characterized by simple use and durability.

On our website there are a few articles that we reviewed in detail how to build a heat gun with their hands. Recommended read and:

- Heat gun on different kinds of fuel.

- Heat gun for waste oil.

- Diesel heat gun.

- Thermal gas gun.

Mounting devices for working out

First of all, it should take the pipe, the balloon or other device external shell.

- Located at the bottom heater and the fuel tank to be separated from the top of the device at a distance of 15 cm. To this part of the unit looked neater, you can hide in a metal box.

- In the center space is set combustion chamber, which can be used for a galvanized tube. On both sides of the compartment is sealed, after which it makes a hole for the injector and the chimney. The combustion chamber is firmly fixed to the walls of the housing. Work is desirable to equip pezorozzhigom compartment and connected thereto fan.

- Further it is necessary to install the fuel pump to the nozzle by adding a filter between these parts. It is also important to arrange outlet tube from the tank, through which will fall on the testing of the fuel filter and the nozzle.

- It is also necessary to solve the question of the fan power source. If there is within the reach of the grid, this element can be connected to a power outlet. If there is no need to use battery.

In the end it is necessary to cover the grids located at the top of the hole.

Tips for using heat guns

Experts recommend to pay attention to the following points in the production of heating devices:

- Security rules should be followed in operating the instrument: remember that at 1 meter from the device temperature of the heated air stream may reach 300 °FROM.

- To warm the room of 600 square meters, it takes only 10 liters of fuel.

- Clean evaporation bowl, removing slag from mining, it is necessary once after 20-50 hours of operation of the device.

- should not be allowed to get along with spent oil or another kind of fuel to the fuel cell fell into the water. If the tank gets a large amount of the liquid, the burner can go out.

It should also not forget about fire safety rules: homemade thermal device is best not to leave unattended and be within reach of a fire extinguisher or other device for fire fire.

Manufacturers of heat guns on working out

On sale you can find ready-made models of devices which work is carried out on waste oil. From improvised devices are different aesthetic appearance, high efficiency, power consumption as well as high performance.

Current models are equipped with electronic ignition and automatic, through which you can adjust the supply of fuel, extra turn off the device during emergency situations, set different thermal conditions, to adapt the machine to work on different types of fuel.

Phones running on waste oil produced by the company, which are deployed in Europe, US and Asia. To name just a few reputable manufacturers and their top models.

Kroll - true German quality

The well-known company, founded over 30 years ago, is considered one of the world leaders in the field of heating appliances (burners, dryers, heat guns, generators).

Kroll models an affordable cost and small size. Due to the minimal amount of automation, for their service does not require sophisticated equipment and professional help

Products of this brand, with all the required Russian and European quality certificates, are safe, economical, reliable in operation, and also have an attractive design.

Master - a company with fifty years of experience

Well-known American manufacturer, which is one of the leaders in sales of heating equipment, especially the heat generators. Tehparametry proposed instruments show record figures in the industry, at the same time almost all the variants differ compactness and mobility.

Regular heater MASTER WA 33B, issuing up to 30 kilowatts of heat, can work on any kind of mining. The device design provides for manual ignition, resistant to wear and completely safe housing

Ruler MASTER WA combines a series of cost-effective devices that can run on almost any variety of spent fuel: engine and biological oils, hydraulic fluids. Power models within the series varies from 19 to 59 kW, so you can easily pick up the device for space heating a certain area.

EnergyLogic - heaters Waste oil

The US company, which has 30 years of experience and dozens of patented innovations, emphasizes attention to the production of boilers, burners, heaters and other equipment running on waste oil.

The model EnergyLogic EL-200H provides a fuel pump, which gives the ability to accurately dispense various types of fuel. In it, there are also shutters to release hot air, which may have a different arrangement

The products are mainly made of stainless steel, is resistant to corrosion and a great ability to withstand high temperatures. At the same time, standard parts, are widely present in the market, making it easier to operate, easier installation and maintenance.

Hiton - budgetary instruments

The Polish company, the date of which the base is 2002.

The company specializes in the production ekotoplivnyh heaters, including heat generators and heat gun running on used motor oil.

Heaters Hiton, the effectiveness of which can reach 91%, the fuel tank and equipped with a burner, characterized by simplicity of design, do not require complicated installation to function reliably for a long time

Heaters of this type of drop marks HP-115, HP-125, HP-145, HP-145R can operate on waste mineral oils, diesel oil or a mixture of these two types of fuel, as well as on plant oils.

Conclusions and useful videos on the topic

The figure below the video you can see the detailed instructions on how to create their own fan heaters, working on working out.

Made their own hands or store-bought heat gun on working out will greatly save money on energy source while using essentially worthless product - waste engine oil.

When operating the machine, be aware that it may cause a fire, so it is advisable to comply with all fire safety regulations and not leave the appliance unattended.

You can not be defined with a choice of a heat gun, or have questions about the construction of the device with your hands? Please leave your comments, share your experiences, ask questions in the box located below.