Considering the issue of cooling or heating your own private house, it makes sense to find out what a chiller is. This alternative to air conditioning is practically not used for individual small rooms, but for a spacious cottage it can be a very profitable solution.

In the article presented by us, the principle of operation of this type of climatic equipment is described in detail. The rules of assembly and construction of the system that forms the indoor microclimate are given. Taking into account our recommendations, you can easily select the optimal model.

The content of the article:

- Chiller principle of operation

- How to choose the right chiller?

- Features of mounting such devices

- Conclusions and useful video on the topic

Chiller principle of operation

Chillers are a kind of refrigeration machines that are used to cool a variety of liquids. Most often, these units are used in industry, but they are also suitable for air conditioning in large residential buildings, shopping malls, offices, etc.

In combination with fan-coil fan coil units, chillers perfectly play the role of a central air conditioner. If in traditional air conditioners freon cools the air directly, then with chillers everything is a little different.

Here, heat energy is transported using ordinary water. To prevent it from freezing, a mixture with antifreeze, such as antifreeze, can be used. Chiller works thanks to the evaporator, compressor and condenser, which are part of it.

Water and refrigerant flows through the evaporator. The latter absorbs the thermal energy of water and boils. The refrigerant turns into gas and the water cools. After that, the vaporous refrigerant enters the compressor, where under the influence of compression forces it is heated and mixed with oil.

Image Gallery

A photo of

Chiller - air conditioning system capable of processing several independent premises simultaneously

The principle of operation of the chiller is based on cooling or heating of the coolant transported through the pipeline. Environmentally friendly freon is not involved in its work.

Easy-to-operate equipment does not require special training from the operator; an ordinary person with secondary education can master the refrigeration machine.

In the climate system with a chiller, a powerful pumping station moves coolant through pipes to fan coils - devices that deliver treated air to the premises

Installing the chiller on the roof of a high-rise building

Constructive components of the chiller

Control unit chiller and fan coil units

Device for supplying treated air to the room

Then this composition is transferred to the condenser, here it gives a significant part of the thermal energy and turns into a liquid. After that, the refrigerant enters the filter dryer to get rid of excess moisture.

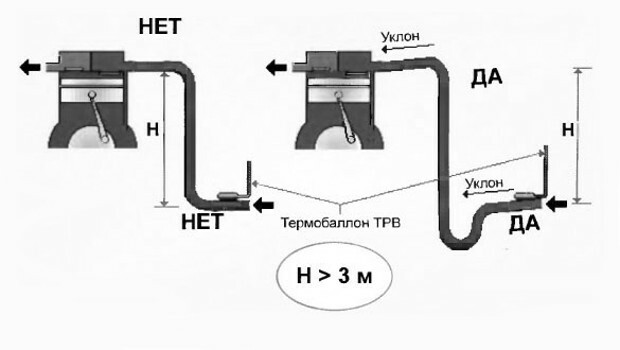

The pressure of the liquid refrigerant decreases as it moves through the thermal expansion valve. Here he again goes into the vapor state and is fed to the evaporator to repeat the cycle.

Chiller consists of a compressor, a condenser and an evaporator. Moving between these devices, the refrigerant takes thermal energy of water and cools it (+)

Thus, the compressor is designed to compress and move the refrigerant, which is consistently moves through the air condenser and the evaporator, then heating up and simultaneously cooling the water, then cooling down

The condenser in this system plays the role of a heat exchanger, through which the heat energy absorbed by the refrigerant is transferred to the environment.

Modern models of chillers are equipped with a control panel with a liquid crystal screen, which reflects the current state of the device and reports of possible breakdowns

Excessive pressure on the refrigerant circuit can damage the system. To monitor this indicator, a high pressure switch is used, as well as a pressure gauge, which allows you to visually monitor the state of the system. The liquid receiver is intended for storage of the refrigerant.

The filter drier removes from the refrigerant not only water vapor, but also foreign contaminants. A solenoid valve is designed to control the flow of the refrigerant, which automatically shuts off the system when the compressor stops working.

This protects the system from falling into the refrigerant vaporizer in the liquid state. As soon as the compressor turns on, the valve opens. The system has a sight glass that allows you to visually monitor the state of the refrigerant.

If air bubbles are seen in the fluid flow, then it is necessary to increase the amount of freon. Sensors with color indication are intended to control the humidity of the refrigerant. And regulation of the amount of refrigerant entering the evaporator is carried out using a thermostatic valve.

To increase system capacity, it is sometimes recommended to use a hot gas bypass valve. This item is not always included in the package.

To ensure that the amount of water in the system remains sufficient for its operation, a system of automatic water refilling is installed in industrial models of chillers. Circulation of water inside the circuit provides a coolant pump.

Monoblock models of chillers are already prepared for installation, so they are easier and more convenient to install than a unit with a remote condenser.

Previously mentioned fan coils They are devices with the help of which cooled air enters separate rooms. Install fan coils indoors. They are mounted on the wall, ceiling and even on the floor. Several fan coil units can be connected to one chiller.

Their specific number is determined by the number of rooms that need air conditioning. But at the same time, the performance of the chiller should provide a certain amount of fan coil units.

For chiller and fan coil connections in a common system using ordinary water pipes. This favorably distinguishes them from traditional split-systems, for which only expensive copper communications are suitable.

Remote condenser chillers are not as productive as monoblock models, but they allow you to use less space for mounting the device inside the house

An important part of such a device is a pump that circulates the coolant. The higher the performance of this pump, the greater the distance between the chiller and fan coil units. This is convenient because it increases the number of options when choosing the right place for the chiller.

Often the unit is placed on the roof of a building, but if you wish, it can be placed in a special utility room. This allows you to fully preserve the appearance of the existing facade of the building. Split system almost never provide such an opportunity.

Chillers are classified according to various characteristics:

- according to the type of refrigeration cycle, such as absorption and vapor compression;

- by construction as a monoblock or a system with a remote condenser;

- according to the type of cooling of the condenser, which can be air or water;

- connection scheme;

- by the presence or absence of a heat pump.

Chillers that have a heat pump in their construction are suitable not only for air conditioning in the room, but also for heating it. They are designed for use throughout the year.

How to choose the right chiller?

For the needs of a large cottage, experts recommend using a water cooled chiller condenser. Such devices have a simpler design than analogs with air cooling, respectively, and they are cheaper.

The air cooled chiller design includes a fan (axial or centrifugal) to take in air from the room in which the device is installed.

Some models of chillers can be used not only for air conditioning, but also for heating residential premises in winter

Local water resources can be used to cool the condenser with water: rivers, lakes, wells, etc. If a for some reason, there is no access to such sources; an alternative is used: ethylene or propylene glycol.

Chillers of this type are ideal for use in the cold season, when ordinary water just freezes.

The choice between a monoblock chiller, when both the compressor, and the evaporator, and the condenser are enclosed in a common case, and the option when the condenser is installed separately is not so straightforward. Monoblock is easier to install, in addition, the performance of units of this type can be quite high.

Choosing a suitable chiller model, you should evaluate its performance and relate it to the number of fan coil units that the device will service.

Remote systems are mounted in different places: the actual chiller is in the utility room inside the building (even in the basement), and the condenser is outside. To connect these two blocks usually use pipes through which freon circulates. This explains the increased complexity of installation of the system, as well as additional material costs for installation.

But less space is used to install a chiller with a remote condenser, and such savings may be necessary. When choosing a suitable device, you should also consider the additional functions with which the device is equipped.

Among the popular and useful additions can be noted:

- control and adjustment of water balance in the system;

- water purification from undesirable impurities;

- automated filling of containers;

- control and correction of internal pressure in the system, etc.

Finally, be sure to evaluate the cooling capacity of the chiller, i.e. its ability to extract heat energy from the working fluid. Specific quantitative indicators are usually listed in the product data sheet. The cooling capacity of each specific chiller-fan coil system is calculated separately.

This takes into account the maximum and minimum temperature readings, chiller power, pump performance, pipe length, etc. These are general guidelines for choosing chillers. In each case, you should consult with an experienced specialist, who will be able to take into account the various nuances and help you make the right choice.

Features of mounting such devices

Only an experienced specialist will be able to save on the installation of the chiller. All other owners of this device will have to pay for the services of professional installers, since in this matter any mistake can be fatal. Begin the installation with a thorough study of all technical documentation and manufacturer's recommendations.

Chiller consists of many structural elements. Industrial model is best to install and run with the help of experienced professionals (+)

After that, proceed directly to the installation. For the chiller, you should choose a support platform capable of supporting the weight of this device.

On the platform mount the frame, the position of which is carefully checked using a level. If there is no site with the required characteristics, it is necessary to concrete the area suitable for the installation, and install a frame on it.

This should take into account the vibration effect that occurs during operation of the chiller. The site and frame must be installed in such a way that vibration is not transmitted to other building structures. Other elements of the system can also have an impact: pipes, air ducts, hydraulic module, etc.

Installation of the chiller is performed on a special frame, while it is necessary to take measures to protect the objects surrounding the device from vibration exposure

If the installation of the chiller is planned in the utility room inside the building, it is necessary to build a foundation for it that will rise above the floor level. This will reduce the overall inertia of the system, reduce the vibration effect, improve the mass distribution of the unit.

The chiller itself is mounted on special spring or rubber supports in order to quench the vibration effect. Under these supports put another layer of rubber, then fix the structure with anchor bolts. When determining where to install the chiller, it should be remembered that there should be free space around the unit.

For mounting the chiller on the street or on the roof of a building, use a special casing to protect the device from the weather.

It will provide access to mechanisms for performing maintenance. In addition, air must circulate freely around the unit to improve the cooling of the condensers. If the chiller is installed outside the building, it must be protected from contamination, for example, by fallen leaves.

If debris enters the heat exchanger, it will lead to incorrect operation of the system and serious damage to the equipment. It is unacceptable for the chiller bodies to touch foreign objects or communications, since they can be transmitted vibratory impact. Another important point when installing the chiller outside is wind direction.

When installing indoors, the noise effect that occurs during unit operation should be taken into account. It makes sense to take care of additional noise insulation and consider how excess noise will affect the neighboring rooms. It is not recommended to install the chiller next to living rooms.

If you plan to install some more units near the chiller, you need to take care that the mechanism does not subjected to excessive heat exposure, as well as to avoid obstacles to the free movement of streams of air.

When the chiller is mounted externally, a special casing is used, which protects the device from the effects of weather factors. An evaporator is placed inside the casing, a place is provided on the side for mounting the compressors, and the condenser is installed on top.

Similarly, the unit is installed on the roof of a building. When installing inside, the casing, of course, is not needed, but if in this case a model with a remote condenser is used, then part of the installation work is performed outside.

For installation of the chiller on the roof of the building, you may need special construction equipment, since the device has a large physical weight

In the study of technical documentation should pay attention to the installation of the frame under the chiller. For some high-performance models, special vibration dampers are used, which do not need to be additionally fastened with anchor bolts.

For individual units it is not required to fill in a separate foundation, it is enough to properly install the frame and fasten the device with bolts.

Couplings are usually used for connecting pipes to chiller nozzles, since the diameter of these utilities is small. The chiller is connected to the pipelines only after the unit has been installed on the foundation and vibration dampers. You should not perform this stage in advance so as not to damage the communication.

Conclusions and useful video on the topic

Video with the presentation of the industrial model chiller CHA-14 can be viewed here:

An industrial chiller is a rather complicated device, but with proper installation and maintenance it can work flawlessly for many years. In order not to be mistaken in the process of installing the equipment, it is better to contact a specialized company.

Please write comments in the block below. Tell us how you installed a similar climate system in your home or office, share useful information on the topic of the article. Ask questions, report about the defects found in the text, publish photos on the topic.