Selecting a reliable, inexpensive, maintainable pump for domestic use? The best option would be a modification that can cope with various tasks on the plot, right?

Have you looked at the Springnik water pump, but you are not sure if it will be able to supply water from wells and wells for irrigation, to supply water to the house or to pump out flooded premises?

We will help you to deal with this vibration technician - the article describes in detail its structure, technical characteristics, significant advantages and disadvantages, and operating features. What will allow to use the equipment to destination, and it is guarantee of long work without problems and breakdowns.

Also in this article, we paid special attention to proper connection and commissioning, providing the material with visual photographic materials and a video clip with an overview of this pump.

The content of the article:

- Model range and manufacturers

-

Analysis of technical characteristics

- №1 - the performance of the unit

- No. 2 - device and principle of operation

- No. 3 - water intake option

-

Connection and commissioning

- Stage # 1 - perform equipment connection

- Stage # 2 - Proper Pump Use

- Stage # 3 - equipment maintenance

- Advantages and disadvantages of pumps

- Conclusions and useful video on the topic

Model range and manufacturers

Initially, "Spring" was developed for industrial purposes. But given that powerful pumps of this type need a lot of electricity, the developers decided to focus on the private consumer.

As a result, they created a compact model of a vibratory submersible type, which is still being successfully used in everyday life.

To date, the official manufacturer of the classic pump “Spring” is Uzbi - Ural Plant of Household Products, producing two modifications of the pump:

- “Spring” BV-0.12-63-U - option with the upper water intake;

- “Spring "BV-0.12-63-U - option with the lower water intake.

Both models can be completed with a power cord 10m, 16m, 20m or 25m.

Also, the production of pumps "Spring" is engaged in the Moscow plant CJSC “Zubr-OVK”, which produces a model called the “Spring ZNVP-300”, which is not much different from the classic electric pumps produced by UZBI.

Vibration submersible pumps for domestic use, produced under the brand "Rodnichok" correspond to GOST and are reliable, safe and durable equipment

Considering that “Spring” is not so well-known and popularly loved pump, as the same "Kid", it is extremely rare to find his fakes.

The affordable price of an electric pump is explained by the simplicity of its design and the use of only Russian parts for its production.

Image Gallery

A photo of

Inexpensive, but extremely durable vibration pumps are ideal for drawing water from country wells. In the organization of permanent autonomous water pipes they are used much less frequently.

The installation of the pump unit is extremely simple: a pressure pipe is connected to the pump nozzle (1) through a non-return valve, a fixing nylon cord is passed through the lugs (2)

In order to fix the position of the cable with an adhesive tape attached to the pressure pipe. The first hitch (3) is 20-30 cm from the nozzle, following every 1.0-1.2 m

To ensure that between the bottom of the well and the bottom of the pump, as well as the top of the unit and the water mirror the distance indicated by the manufacturer is left on the pressure pipe before immersion in water bright label

In order for the vibratory pump to not beat against the walls of the well during water transfer, it is better to place it in the center of generation

For normal operation of a vibratorion in a well, it is necessary that the inner diameter of its casing is 10 cm larger than the maximum diameter of the pump.

In order to prevent the vibrating unit from beating the well casing during operation, it is equipped with protective rings from a hose or rubber rolled into a tube

Rubber rings that work as shock absorbers should be changed periodically. they wear off the borehole walls

Vibration pumps in the dacha economy

Vibration pump connection

Power Pipe Couplings

Mark the depth of installation of the pump

Device for installation of vibrator

Well to install the vibration pump

Device to protect the pump and well

Replacement of protective rings on the vibrator

Analysis of technical characteristics

Vibration springwell pumping devices are designed for pumping clean and non-substantially polluted water. The allowable size of solids in the pumped liquid should not exceed 2 mm.

№1 - the performance of the unit

The pump is perfect for water supply of 2-storey houses, because maximum head delivered equipment is 55 - 60 m. "Spring" works from the usual household electrical network with voltage 220 V.

Before starting the pump, you should carefully inspect the case to identify mechanical damage. Particularly meticulous should be to examine the state of the power cable and network connector

Use of the pump for transfer of soap water, it in the chlorinated state from artificial reservoirs is allowed.

The unit can pump out water from flooded private river vessels and basements. Allowed to use in draining tanks.

It is forbidden to pump all types of liquids except water., especially aggressive, explosive, toxic, oil-contaminated and similar varieties. If you need a pump for pumping contaminated liquid, we recommend that you familiarize yourself with the following material.

The performance of the Rodnik pump is approximately 432 l / h, which allows uninterrupted water supply to several water points at once.

The performance of the electric pump is directly dependent on the height of the water supply. The maximum immersion depth specified by the manufacturer is 5 m, however, thanks to the robust housing, the pump can be successfully used at a depth of 10 m and even more.

The spring is designed for intake and transportation of water with a slight degree of pollution. The pump can deliver water to a height of 55 - 60 m

“Spring” is intended for use at ambient temperatures from +3 ° C to + 40 ° C. The mass of the unit is only 4 kg, making it mobile and easy to install.

Overall dimensions of the pump do not exceed 250 x 110 x 300 mm, which makes it possible to operate it in narrow wells and boreholes of Ø more than 12 cm.

Before you buy the springwell spring pump, you need to ask if a kapron cable is included in the kit to lower the unit into the well or well.

If such a cable is not included in the kit, then it must be purchased separately. It is strictly forbidden to lower the electric pump using the power cord!

The dependence of performance on the height of the water supply: the greater the supply height, the lower the performance of the electric pump when using standard pipes

No. 2 - device and principle of operation

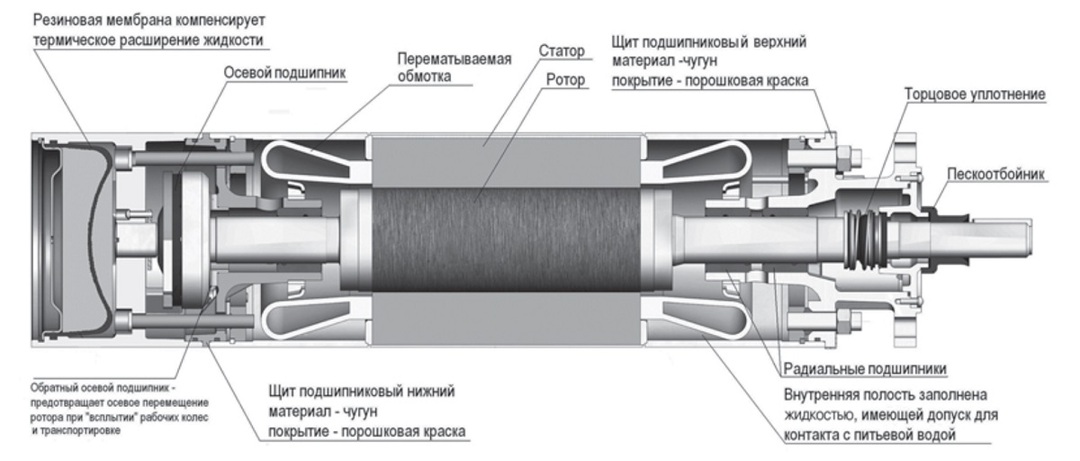

The “Rodnichka” design is simple, it is no different from other submersible-type vibrating electric pumps. The main working elements due to which the pumping of water is carried out - a vibrator and an electromagnet.

The vibrator is an anchor with an elastic spring shock absorber. The anchor is fixed on the shaft, and its movement is limited by a special sleeve.

At a certain distance from the armature and the rubber damper, there is a diaphragm that guides the rod, supporting it during the operation of the pump. The diaphragm is made of rubber and hermetically closes the electrical part of the pump.

The electromagnet consists of a core with a winding in the shape of the letter “P”. The latter is composed of two coils.

It removes excess heat from the coils and fixes the specified parts in the desired position relative to each other and the pump casing.

When the Springwell pump is connected to the power supply network, the core begins to reciprocate. Performs them with a speed of about 100 vibrations per second, while attracting to itself the anchor located on the shaft.

A rubber shock absorber pushes the anchor away, transmitting the vibration to the piston, which is located on the rod with the anchor.

During retracting, a hydraulic chamber is formed, the volume of which is limited on one side by the piston, on the other - by a valve on the body.

Getting into the pump through the suction inlet (water intake), the water is in the hydraulic chamber and with the movement of the piston with the force pushed through the discharge port.

So that the water, getting inside the pump, does not flow out of it back, there is a valve on the body that prevents its return leakage. Cooling of the pump casing is carried out by pumping water.

The springwell pump casing is made of metal, which allows it to be used at a depth that is two times higher than that specified by the manufacturer.

No. 3 - water intake option

Pumps "Spring" are available in two variations: with the upper and lower water intake. In the first case, the suction nozzle is located at the top of the housing, in the second - at the bottom. Each model has its advantages and disadvantages.

Advantages of the pumping device with the top fence:

- continuous cooling of the pump casing means a longer period of operation;

- bottom sediments are not sucked in, which means that the optimal quality of the water supplied is ensured;

- the pump does not suck up the sludge, therefore, needs more rare cleaning.

The disadvantages of modifications with the upper fence include the inability to pump water to the end, but only to the point of location of the inlet. This is inconvenient if the unit is used for pumping water from flooded visits, pools, boats.

The electric pump “Rodnichok” with a lower water intake, on the contrary, is capable of pumping liquid to a minimum level.

Some experts argue that units with a lower fence are able to create greater pressure due to the fact that water lingers a little longer inside the pump, where it is given greater acceleration.

The negative side of the pump with the lower fence can be considered the probability of seizing bottom sediments, which means that such a pump will quickly become clogged, which will lead to its failure.

Choosing the electric pump “Spring” you need to decide in advance the conditions in which he will work. If the pump is purchased to supply water from the water intake structures, well or well, then preference should be given to equipment with the upper fence.

If the electric pump is necessary for pumping flood water from flooded rooms, draining tanks, eliminating the consequences of utility accidents, then the bottom intake model is the best choice.

In case you find it difficult to make a choice, we recommend reading our article with tips on choosing pumps for wells.

The pump with the lower fence can be operated in the well and the well, but it must be suspended so that the suction inlet is located at some distance from the bottom

Connection and commissioning

Installation of the pump “Spring” is carried out in a well or well with a minimum diameter of 12 cm. Immersion depth - 5 m, but if necessary can reach 20 m.

Note that the deeper the pump is located, the less its performance and pressure.

Stage # 1 - perform equipment connection

The sequence of connecting the pump "Spring" is as follows:

- Before installation, inspect the equipment for mechanical damage, and also inspect the power cord and cable.

- The rubber ring is tightly worn on the body of the electric pump, which protects the unit from impacts against the walls during operation.

- With the help of a cable inserted into special holes on the body, the pump is lowered into the water so that it is suspended at a distance of at least 30 cm from the bottom.

- The installation of the hose should be carried out in accordance with the recommendations of the manufacturer, namely, the height of the water supply (the distance from the pump to the final water user) should not exceed 60 m.

- The hose is securely fastened with clamps and fittings, so that it does not kink. The hose must be located away from heating appliances and sharp objects. In most cases, a pump with a diameter of 15 mm or ½ inch is suitable for pumps of this brand.

- The “Spring” pump is started when the plug, located on the power supply cord, is plugged into a 220V outlet.

After immersion and switching on the power supply, the Springnik pump starts working immediately, so it is necessary to check the water level before switching on. The work of the submersible electric pump "dry" is not allowed!

When using the Rodnik pump for pumping out pools, tanks and rooms, as well as when working in low-income wells and wells, it is necessary to monitor the water level almost non-stop in order to timely turn off water pump.

Disconnection is carried out by disconnecting the plug from the outlet. Step-by-step instructions for installing the pump in the well, read Further.

The “Spring” pump is not designed for long-term continuous operation; using the unit for pumping out tanks or premises, periodically disconnect the equipment from the power supply network.

Stage # 2 - Proper Pump Use

The electric vibration pump "Spring" is very easy to use, it is enough to follow the basic rules, and the unit will last more than a dozen years.

Using “Spring” for the water supply or pumping out water system, first of all make sure that the power supply voltage corresponds to the rated voltage of the product 220V plus / minus 5V.

The power supply cable must be positioned so as to completely exclude the possibility of its damage and short circuit. Plug-in connectors should be located in dry places, well protected from moisture.

After completing the work, for example, when the accumulator tank is completely filled, disconnect the pump from the mains. The pump is turned on only after it is completely immersed in water and installed in a vertical position.

Image Gallery

A photo of

In the photo on the left, the vibratorion nozzle to which the pressure pipe is connected, on the left a water intake channel, which is desirable to protect when pumping highly polluted water

If the vibrating pump is to be used in an open pond, then it is possible that the algae that can damage the unit

The simplest filter can be made from a plastic bottle by cutting holes for connecting the nozzle to the pipe in addition to perforation.

A self-made filter is rigidly attached to the pump body with tape. It should be remembered that the power cable can not be pinched. It is also better to pass it through the bottom of the perforated bottle.

The device of the pump with the top intake of water

Self-made algae protection device

Elementary homemade filter from the bottle

Fastening a homemade pump with scotch tape

If during operation you have heard extraneous sounds (shocks, friction) or an atypical sound of a running motor, then you must immediately disconnect the “Spring” from the mains.

And also to make his rise to the surface to identify and eliminate the reasons for the emergence of extraneous sounds.

When using the Rodnik vibration pump for pumping out flooded rooms or pools, do not leave it after work is finished in the open air.

The pump should be stored in a dry place, where it will not be affected by negative temperature, high humidity and other climatic factors.

The springwell pump casing is made of metal, so its strength depends on proper storage and operation, if you store the pump correctly, then corrosion will not appear for a long time

Safety precautions for connecting and operating the Springwell pump are no different from safety rules when working with other household submersible pumps.

Recall the basic rules:

- heating equipment - It is prohibited to use the electric pump in the immediate vicinity of heating boilers, generators, flammable liquids and gas cylinders.

- Direct sunlight - Do not expose the pump to direct sunlight, prolonged exposure to aggressive media.

- Increased head - do not use the pump to create a head larger than specified in the instructions, for example, by pinching the hose or using a hose of smaller diameter.

- Work without breaks - prevent continuous operation of the pump for more than 12 hours.

The most common malfunctions of the Springnik pump are related to its clogging in the process of pumping contaminated liquid or due to a malfunction of the power cord.

In the first case, it is necessary to disassemble the unit and clean it, and in the second case, replace or repair the electrical cable.

Stage # 3 - equipment maintenance

Submersible pump units “Rodnichok” are very easy to operate and do not require costly and time-consuming maintenance.

The equipment does not need regular lubrication. The use of lubricants is prohibited!

Maintenance of the pump is reduced to periodic lifting to the surface, visual inspection of the hull and cleaning its sludge and sediment.

After using an electropump to pump out slightly polluted, chlorinated or sea water, it is necessary to clean the pump by pumping clean water for 1-1.5 hours.

Before operation, carefully study the manufacturer's instructions and strictly follow its recommendations, this will help ensure the smooth operation of the equipment for many years.

Advantages and disadvantages of pumps

About the merits and demerits of submersible vibration pumps “Spring” they say and write a lot.

The feedback from its owners is just the opposite: some note the high quality and ease of use, others consider this equipment obsolete, and its use uncomfortable and troublesome. We note only some of the advantages and disadvantages of these pumps.

Virtues:

- low price;

- the possibility of pumping slightly polluted water;

- simple design, robust housing;

- the ability to select the required length of the cable;

- possibility of choosing equipment with upper or lower water intake;

- economical power consumption;

- ease of connection and operation;

- high performance and head.

“Spring” perfectly functions at depth, withstands impressive hydrodynamic pressure. For normal operation between the upper point of the body and the water mirror should be no more than 5 m.

disadvantages:

- requires monitoring during pumping pools and flooded premises;

- low degree of protection against mains voltage;

- the inability to use at temperatures below +5 and above +40 ° C;

- cannot be used in wells and wells with unstable walls, because vibration causes their destruction.

Of course, today you can find on sale more modern and high-performance pumps equipped with electronic protection systems, however “Spring” is almost an ideal combination of price and quality, proven by time.

We recommend that you familiarize yourself with rated submersible pumpswhich is presented in our other material.

Manufacturers include Repairkomplekt pump kit for replacing rubber sealing parts that are prone to abrasion after intensive use.

Conclusions and useful video on the topic

Video review of the Rodnik pump manufactured by CJSC Zubr OVK:

The Rodnik pump is an economical and high-performance equipment in its class, which is widely used for various purposes: water supply and pumping.

The main advantages of the pump are low cost, the possibility of pumping water with particles up to 2 mm and robust housing that allows the unit to be used at a depth of two times the specified by the manufacturer. The simple design and unpretentiousness in service do this pump popular among summer residents and owners of private households.

If you have experience using the Springwell submersible pump and you can share valuable advice, please leave your comments in the block below. Here you can ask your questions on the topic of the article.