One of the cheapest fuels from those that are used for heating boilers, is the waste oil. It can be anything: a synthetic or natural. Suitable oil fused with culinary units, cars or locomotives.

In any case, when burned, it gives a lot of heat. Therefore collect waste oil boiler with his hands very profitable. Especially if you want to heat the utility room or garage.

We'll show you what's inside and running the heater, what are the structural nuances homemade unit, as well as describe the step by step process of the boiler assembly and features of its operation.

The content of the article:

- Heating with working out: beneficial or not?

- Solid working out: what they are

- How does the heater

- The structural intricacies of self-made equipment

- How to make their own pot

- A little bit about the safe operation of

- Conclusions and useful videos on the topic

Heating with working out: beneficial or not?

System heating waste oil It is in high demand. It is not surprising, because it has many advantages. First of all, it's affordable cost of equipment and operation.

Given that the price of fuel for this boiler is very low, it will pay for itself in the first heating season. In addition, if you do not buy equipment, and build it with his own hands, it will cost even less.

A properly configured boiler completely burn waste oil. Toxic combustion products are formed, so this device is safe for the environment. The device design is very simple, for it uses a minimum of parts. Thus, the device outputs a risk of failure is reduced and its reliability increases.

The boiler heats up quickly and raises the temperature in the room, aided by forced convection.

Have devices and disadvantages:

- Rapid oxygen burnout in the room where the appliance is installed, a hundred arrangement requires an efficient ventilation system.

- The need for regular cleaning. Boilers on the return pipe to quickly get dirty, and therefore their maintenance is required more often.

Any waste oil or mixtures of several oils can be used for the equipment.

Boiler for working out can be used as a fuel, natural and synthetic oils, as well as mixtures in any proportions

The heterogeneity of the raw materials used and the high probability of presence of most different impurities requires a special filter. He is placed on the oil supply to the boiler area. In operation, the filter becomes dirty quickly, so it will have to change often.

Solid working out: what they are

Manufacturers produce heating oil boilers three species. Heaters raise the temperature of indoor air by direct heating. Such devices offer high performance for a long time and can keep the temperature even in areas of substantial area.

The tank with fuel in these devices are usually located on the floor, and the heater may be mounted on the ceiling or on the wall.

The heater may heat the air in the room or working off the warm water circuit, and sometimes two immediately

The boilers are designed to heat the heat transfer medium, usually water.

There are two types of equipment:

- combi - are able to heat water for domestic use and to warm up the coolant;

- single-circuit - "responsible" only for heating.

Automatic heat generators are the boiler. They are equipped with automatic control system, which controls the operation of the device.

Automation for boilers working out can perform different functions. This may be the temperature control of the air in the heated room, control of coolant heating and others.

Boilers for working out with or without automatic performed only in the outdoor embodiment. Their cost varies greatly depending on the functionality. However, in any case, it is large enough, so the domestic craftsmen gather such devices with their own hands.

How does the heater

This boiler is extremely simple. It includes two-compartment chamber: vaporization and combustion. In the first preparation process of the oil it occurs to combustion, in the second it is burned.

Everything happens as follows. From a reservoir with working pump delivers waste oil in an evaporation chamber which is located at the bottom of the device. There is maintained a temperature sufficient to start working off warmed and evaporate.

Since working oil boiler with evaporation and forced air supply (+)

Oil vapor rises to the top of the housing where the combustion chamber is located. It is equipped with a duct, which is a tube with holes. By means of the air supplied by the fan duct and mixed with the oil vapor.

Oil-air mixture is combusted almost completely - the resulting heat heats up the heat exchanger the combustion products are directed to the chimney.

Preheating the oil - a mandatory part of the process. It should be understood that extraction contains a large amount of impurities and toxic substances. All this is decomposed into simple carbohydrates, which are then burned.

After that the water vapor formed, carbon dioxide and nitrogen is completely harmless elements. However, this result is only possible subject to certain temperature conditions.

Complete oxidation or combustion of the hydrocarbons takes place only at + 600 ° C. If it is lower or higher by 150-200 ° C, then a large number of different toxic substances in the combustion process. They are safe for humans, so the combustion temperature must be precisely observed.

The structural intricacies of self-made equipment

The major component of the combustion technology is considered to preheat the oil. This makes it possible to expand the "heavy" oil into lighter components. Well-chosen parameters pozvolyayutpoluchit almost smokeless and complete combustion of waste oil.

Domestic yourselfers find that the easiest way to achieve this result by using a thick-walled bowl of red-hot metal, which drops served detention.

One of the possible schemes of heating equipment with oil mist (+)

When the oil is heated metal regard, it is immediately converted into pairs that are directed to the combustor. For a better burning them to be mixed with air. For this purpose, the duct is used.

At its mouth the impeller is set to create a swirling flow required for a sufficiently long stay oil-air mixture in the combustion chamber. Only in this case filed in the bowl fuel burns completely.

Certain complexity during the self-assembly of the heating device is heating the evaporator bowl.

The easiest way to implement it - to put into the tank soaked wick any combustible structure. Then pour in the bottom of the cup a little gasoline or diesel fuel and set on fire. After the metal is glowing up to the desired temperature, the feed of oil. It is as simple as possible, but rather dangerous way.

Another difficult moment in the implementation - the supply of oil. The Internet and other open sources you can find many examples of functioning for waste oil boilers, where the supply of mining carried out jet.

Yes, the system is efficient, but it is extremely dangerous for the user. The oil is fed jet, does not have time to burn. A large amount of toxic substances that could get into the room. And this is very dangerous.

So it is possible to arrange the dropping flow of waste oil into the evaporation cup. Used nipple, tees and a fragment of the medicine dropper

To effectively smokeless combustion mining is required to arrange the oil supply dropping. It is difficult, but it is solved. Optimal, according to domestic artists a way to drip feed the next.

We must take the hose, which will operate as an oil line. At one end it is required to clean the filter is fixed mining takes from impurities and contaminants.

It should be a filter car oil filter full. The latter is very important. Not partial, namely full. Be prepared for the fact that it will have to be changed frequently. On average, once every 30 days, and even more often. All will depend on the quality of the fuel used.

Some difficulties may arise in the course of the attachment. It is equipped with thread by means of which is fixed in the car.

You can proceed as follows. It is to find small fragment oil resistant hose, the diameter of which coincides with the cross section of the thread, and put it on the filter. From the resulting oil pipe assembly joined by fitting.

It is very important that the oil supply hose does not accumulate its surplus, or drip feeding is not possible.

Solid working out of the pyrolysis type. Due to the presence afterburner combustion chamber during one portion of the fuel is significantly increased

Alternatively, one can choose a pump power to output only the required amount of mining. But it is so hard. A simpler version of the assembly is used in industrial boilers. This simple construction of tees, fittings and nipples.

With it can easily adjust the flow of the desired amount of oil. Surplus will be returned to the tank with fuel.

The last element of the drip feed system - a fragment of the medicine dropper. We must take the land with wheel regulator. Element allows to control the speed and fuel flow rate into the bowl. Fragment emitter securely on the nozzle.

Optimally, working out is not chadila and burned steadily. This is only possible if the oil has a normal flow. For this purpose, its temperature should be in the range 10-20 ° C.

You should know that every time you change the composition or working off its temperature will have to re-select the frequency and dropping oil feed speed. Deliver fuel directly from the emitter to the combustion chamber does not succeed. Its fed into a funnel connected with a pipe feeding fuel into the bowl.

In this simple way can be to arrange a uniform supply of oil into the chamber and thus extend the burning fuel audio planted portions (+)

This boiler can be different. It can be connected to the pipes of the heating system. Mandatory requirement in this case - pump installation to ensure effective circulation of the coolant.

If around the device to arrange so-called water jacket, it will heat the water. If the water circuit, only one - the boiler will serve only heating. If two circuits - would be provided even hot water.

Another option - a heat exchanger embedded in the form of letter U. It is placed in the upper part of the furnace portion and is connected to the external tank, which will be hot water. Alternative - accommodation exchanger at flue.

Solid working out can be pyrolysis. Its main feature - the possibility of continuous operation on a single fuel tab. Structurally, this model will differ by the presence of afterburner chamber.

Here is the final combustion of all the chemical elements that make up the used oil. Due to the presence of afterburning time of the camera pyrolysis boilers one portion of the oil is significantly increased.

How to make their own pot

For the manufacture of the heater we need the following materials and tools. Cooking steel sheet with a minimum thickness of 4 mm, the valve section 10 or 8 mm, the pipe duct, tees, sleeves and half-inch angles to the burner, steel adapter, a compressor, an expansion tank, and pump.

In addition, the need welding equipment, heat-resistant sealant, asbestos cloth and Bulgarian.

One of the simplest designs to the boiler working out. Such a device is very easy to make yourself, at the same time it will work effectively

Consider the process of making the most simple homemade boiler working out. Actually the device can take many forms. Therefore, to facilitate the work can not take the steel sheet, and a large section of a tube with thick walls.

For example, a workable device, a heating easy standard size garage, is obtained from two fragments of the pipe. One section of 0.5 m, the second - 0.2 m.

Furthermore they need another two metal plates of thickness of at least 3 mm cut in the shape of circle. If you need a more powerful heater, then picked up or is made of sheet steel parts required size.

Now you can proceed to the assembly. We start with the preparation of the case. It will be made of a larger cross-section of the pipe. Grinder to cut it so as to obtain a fragment of about a meter in height.

Pipe of smaller section is also cut off. So as to obtain fragment 20 cm height. Now we are preparing a plate that will function as the bottom and the cover of the housing.

In one of them performs an opening corresponding to the size of the chimney. It will cover the body. In another cut hole for connection with the fragment of the small tube. This will be the bottom of the structure.

A detailed scheme for the manufacture of the boiler to working out with all necessary dimensions (+)

Welded thereto a cylinder cut from a tube of smaller diameter. Its bottom closing another circular plate. Collect body, covering his plates on both sides. PARTS, scald them in a circle.

To fasten the housing bottom legs made of reinforcing bars. Drill pipe in the ventilation openings. We produce cylindrical boiler, in the lower part of the body which is a small reservoir.

Now we need to equip the door. Cut it at the bottom of the cylinder using grinders. On the upper part of the housing and anchoring set chimney. The simplest embodiment of the boiler is ready.

To ignite it, you will need to pour a little working out in the bottom container and set fire to the wick of her burning paper.

This is the easiest of all known variants. You can collect more complex, and therefore more efficient design.

Actually any fuel circuit diagram of the device for working off comprises two boxes of durable metal, connected by a duct in the form of a perforated pipe.

Lower box equipped with a hole through which oil is poured into the vaporization chamber, it is typically located opposite the flap. The top box is equipped with an opening into which the chimney pipe.

Such a scheme is easy to complement a variety of nodes: oil feed pump, a dropping mining supply, air compressor or connected to the boiler feed tank with fuel.

One can also connect the water circuit. But in this case it needs an effective burner arrangement which can realize the maximum uniform heating fluid.

burner option for boiler working out, which is powered by a diesel engine glow plug. This burner can be used for devices, heated water loop

Consider the process of manufacturing such a burner. Actually, its shape can be arbitrary, but it must be remembered that the mixing zone should always be just above the combustion zone.

Only in this case, the unused working out will return to the reservoir. For the manufacture of the burner body take half inch corners and connect them by means of tees and ebbs.

For the oil line, the feed testing of further need for the adapter fitting. All threaded connections before twisting coat with good heat-resistant sealant. To use the burner cap steel sheet. The thickness of the sheet at least 3 mm.

Cut out of her piece corresponding to the size of the socket on the boiler. Once we have collected the torch left to install it correctly.

For this prepare two steel plates, one should be slightly smaller than the other, nuts, bolts, and asbestos cloth. Half-inch tube and the inner surface of the adapter should be closed by asbestos. Cloth necessarily fixed.

Silicate sealant paste it in two layers on tubes of asbestos fix steel wire. Now we take the burner and insert it into the housing, to customize the installation in the socket if required.

After the burner is "stood" in place, the smaller the size of the plate set in the socket and cover with several layers of asbestos cloth. Optimally, if there will be four or five.

Large plate use anchoring as an overlay. Drill some holes in it by fasteners, and then laid on top of the asbestos and the twist screws two plates.

All work on the production of boiler working out should be in strict accordance with the rules and requirements of instructions, bad assembly could cause an accident with serious consequences

It should be appreciated that the resulting compound should be as dense if it is not, the burner elements can budge during operation. For this ignition burner uses a standard glow plug, which is applied to diesel engines.

Interesting options improvised heaters working on working out, are described in these articles:

- Working out of the oven on the tube: making effective waste oil stove from scrap materials

- How do burzhujku waste oil with their own hands: Options and stove manufacturing examples

- Heat gun for waste oil with their own hands: Step by step instructions on making

A little bit about the safe operation of

Heaters operating on working out, quite dangerous in operation. This should be remembered always.

Whatever happens troubles, a few simple rules should be strictly abide by:

- The room where the heater is installed, should be equipped with an efficient ventilation.

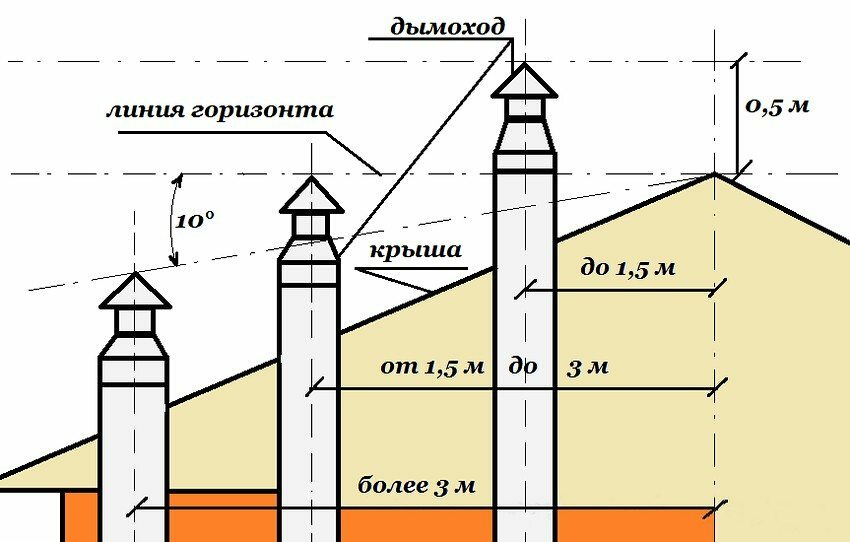

- The boiler should be equipped with a correctly designed and executed chimney removes the combustion products without residue. It must necessarily be a damper.

- Plot flue passage through the roof installation is performed by a special casing.

- The boiler must be installed in accordance with the requirements of fire safety.

- Storage of combustible and flammable materials near the heater is strictly prohibited.

The boiler to working out, as well as any other heater, should be treated with care. Time to carry out all the necessary maintenance work, then problems with the operation and its safety will not arise.

Conclusions and useful videos on the topic

How to self-assemble boiler for working out:

Solid working out with a connected water circuit:

Another design variant of the boiler:

Heating Equipment for working out - a practical solution for household heating or garage facilities. More complex models equipped with automatic, servo burning process and security and can be installed as a heater for a home.

The main advantage of such devices - the use of cheap, sometimes gratuitous fuel, which makes their use is most beneficial for the owner.

If you have a boiler manufacturing experience to waste oil, please share the information with our readers. Leave your comments on the article, and add photos of their homemade in the form below.